Published online by Cambridge University Press: 15 May 2018

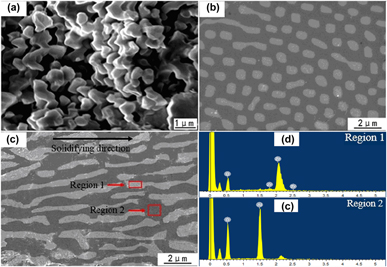

To prepare high quality large solidified Al2O3/ZrO2 eutectic ceramic, the preparation processing of the presintered ceramic as a feed rod was investigated via experiments; some parameters of the induction heating zone process were optimized via numerical modeling; an Al2O3/ZrO2 eutectic ceramic rod with a diameter 10 mm was prepared. The results show that increasing the sintering temperature could increase the presintered ceramic’s bulk density, while increasing sintering time had little effect. And the bulk density increased first and then decreased with the molding pressure increase. And the saucer coil obtained a higher temperature gradient than the tubbiness coil for a fixed crucible wall maximum temperature, and the coil turn’s increase could increase the melting zone height in the induction zone melting process. In the directionally solidified Al2O3/ZrO2 eutectic ceramics, Al2O3 phase is the matrix phase, and the ZrO2 phase embedded in the Al2O3 phase mostly with the rod shape, and little with lamellar. The hardness of directionally solidified eutectic ceramics reaches 16.17 GPa and the fracture toughness reaches 4.76 MPa m1/2, which are 1.7 times and 1.5 times of the presintered eutectic ceramic, respectively.