Article contents

Evolution of Nb oxide nanoprecipitates in Cu during reactive mechanical alloying

Published online by Cambridge University Press: 03 January 2020

Abstract

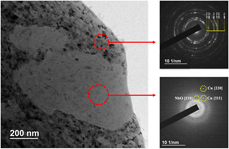

Microstructural evolution of Cu–Nb oxide nanocomposite alloys during ball milling is investigated using a two-step ball-milling approach. In the first step, Cu and Nb powders are milled to create a two-phase alloy comprising a Cu-rich matrix containing a high density of 20- to 30-nm Nb precipitates. In the second step, this nanocomposite is co-milled with CuO, resulting in the reduction of CuO and the oxidation of the Nb nanoprecipitates. Transmission electron microscopy characterization shows that three distinct types of Nb oxide precipitates evolve at different levels of strain. First, nanocrystalline NbO particles (∼10 nm) are formed by dissolved Nb in Cu reacting with oxygen evolved from the CuO. Next, the Nb nanoprecipitates in Cu further reduce CuO to form Nb/Nb oxide and NbO/Nb oxide core–shell inclusions (20–30 nm). These inclusions coalesce during additional milling to form amorphous Nb oxide agglomerates (>700 nm after 50 h). The growth of Nb precipitates during step-one milling, the initial growth of NbO nanoparticles, and the formation of core–shell Nb oxide precipitates during step-two milling are attributed to the convective transport of atoms and clusters combined with shear-induced agglomeration.

Information

- Type

- Article

- Information

- Journal of Materials Research , Volume 35 , Issue 1: Focus Section: Advances in Battery Technology: Material Innovations in Design and Fabrication , 14 January 2020 , pp. 98 - 111

- Copyright

- Copyright © Materials Research Society 2020

References

- 3

- Cited by