Article contents

The hot deformation behavior and processing map of powder metallurgy NiAl-based alloy

Published online by Cambridge University Press: 09 September 2016

Abstract

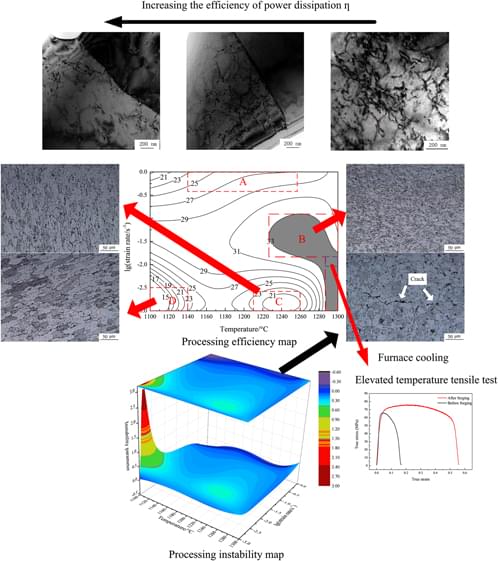

Hot deformation is an effective way to tackle major problems in powder metallurgy, i.e., inferior mechanical properties and low relative density. To characterize the hot deformation behavior of NiAl-based alloy manufactured by hot pressing sintering, the isothermal compression tests were performed in the deformation temperature range of 1100–1300 °C with strain rate of 0.001–1 s−1. The result indicates that calculated hot activation energy Q is 326.31 kJ/mol. The processing efficiency maps and instability maps of NiAl-based alloy were established to optimize deformation parameters on the basis of dynamic material model. They were validated through microstructure evolution. The microstructure observation revealed that fine grains, dislocation pile-up, cracks appear in high efficiency, low efficiency, and instability domains, respectively. According to effective processing window revealed by processing maps, hot forging of sintered billets was performed. The elevated temperature elongation increases from 17.86% to 74.87% after forging. The stripping feature is found on fracture surface after forging.

Information

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2016

References

REFERENCES

- 5

- Cited by