Article contents

Impact of rolling temperature on microstructure, ordered phases, and ductility in Fe–6.5 wt% Si magnetic material

Published online by Cambridge University Press: 27 September 2016

Abstract

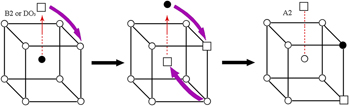

Ordered phases and ductility of Fe–6.5 wt% Si magnetic material were investigated under different rolling temperatures, and the constitutive equation of the warm deformation was established. The results show that at high rolling temperature, accompanying with the appearance of some shallow dimples, the intergranular fracture can be transformed into the quasicleavage fracture, which makes the ductility of warm-rolled sheets greatly improved. In the 450–650 °C rolling temperature range, the antiphase domains (APDs) of warm-rolled sheets are cut, the superdislocation density increases greatly with decreasing warm rolling temperatures, resulting in a decrease in APD sizes during warm deformation. Meanwhile, more B2 and DO3 ordered phases occurring in the matrix improve the long range order parameters, thereby significantly reducing ductility of the alloy. The work softening of Fe–6.5 wt% Si alloy is attributed to a contribution combining the sizes of APDs with ordered phases.

Information

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2016

References

REFERENCES

- 7

- Cited by