Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Deng, H.W.

Xie, Z.M.

Wang, M.M.

Chen, Y.

Liu, R.

Yang, J.F.

Zhang, T.

Wang, X.P.

Fang, Q.F.

Liu, C.S.

and

Xiong, Y.

2020.

A nanocrystalline AlCoCuNi medium-entropy alloy with high thermal stability via entropy and boundary engineering.

Materials Science and Engineering: A,

Vol. 774,

Issue. ,

p.

138925.

Alijani, Fatemeh

Reihanian, Mohsen

Gheisari, Khalil

Yuasa, Motohiro

and

Miyamoto, Hiroyuki

2020.

Microstructural Characterization of Mechanically Alloyed FeCoNiMnV High Entropy Alloy Consolidated by Spark Plasma Sintering.

Advanced Engineering Materials,

Vol. 22,

Issue. 4,

Dewangan, Sheetal Kumar

Samal, Sumanta

and

Kumar, Vinod

2021.

Development of an ANN-based generalized model for hardness prediction of SPSed AlCoCrCuFeMnNiW containing high entropy alloys.

Materials Today Communications,

Vol. 27,

Issue. ,

p.

102356.

Jeong, H.T.

Park, H.K.

and

Kim, W.J.

2021.

Dynamic recrystallization and hot deformation mechanisms of a eutectic Al0.7CoCrFeMnNi high-entropy alloy.

Journal of Alloys and Compounds,

Vol. 871,

Issue. ,

p.

159488.

Fan, Xiaojuan

Qu, Ruitao

and

Zhang, Zhefeng

2021.

Relation Between Strength and Hardness of High-Entropy Alloys.

Acta Metallurgica Sinica (English Letters),

Vol. 34,

Issue. 11,

p.

1461.

Wang, Xin

Huang, He

Shi, Jie

Xu, Hai-Yan

and

Meng, Da-Qiao

2021.

Recent progress of tungsten-based high-entropy alloys in nuclear fusion.

Tungsten,

Vol. 3,

Issue. 2,

p.

143.

Dewangan, Sheetal Kumar

Kumar, Devesh

Sharma, Ashutosh

Ahn, Byungmin

and

Kumar, Vinod

2022.

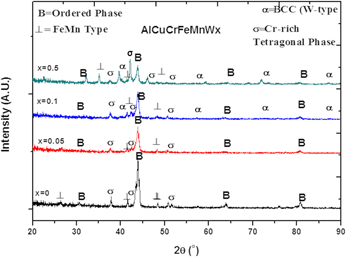

Enhancing the oxidation resistance of nanocrystalline high-entropy AlCuCrFeMn alloys by the addition of tungsten.

Journal of Materials Research and Technology,

Vol. 21,

Issue. ,

p.

4960.

Dewangan, Sheetal Kumar

and

Kumar, Vinod

2022.

Application of artificial neural network for prediction of high temperature oxidation behavior of AlCrFeMnNiWx (X = 0, 0.05, 0.1, 0.5) high entropy alloys.

International Journal of Refractory Metals and Hard Materials,

Vol. 103,

Issue. ,

p.

105777.

Dewangan, Sheetal Kumar

Maulik, Ornov

Kumar, Devesh

Kumar, Saurav

Kumar, Vinod

and

Ahn, Byungmin

2023.

Impact of heat treatment on spark plasma sintered magnesium-containing lightweight AlFeCuCrMg high entropy alloy.

Journal of Materials Research and Technology,

Vol. 26,

Issue. ,

p.

383.

Xiao, Na

Guan, Xu

Wang, Dong

Yan, Haile

Cai, Minghui

Jia, Nan

Zhang, Yudong

Esling, Claude

Zhao, Xiang

and

Zuo, Liang

2023.

Impact of W alloying on microstructure, mechanical property and corrosion resistance of face-centered cubic high entropy alloys: A review.

International Journal of Minerals, Metallurgy and Materials,

Vol. 30,

Issue. 9,

p.

1667.

Wang, Lei

Jiao, Yichao

Liu, Ruifan

Wang, Deyu

Yu, Zhigang

Xi, Yuntao

Zhang, Keren

Xu, Shanna

Liu, Haitao

Wen, Lei

Xiao, Xinke

Zhang, Wei

and

Ji, Jiangtao

2024.

A Review of Mechanical Properties and Improvement Methods of Medium Entropy Alloys at High Temperature.

JOM,

Vol. 76,

Issue. 1,

p.

353.

He, Jianye

Li, Zezhou

Lin, Jingchen

Zhao, Pingluo

Zhang, Hongmei

Zhang, Fan

Wang, Lin

and

Cheng, Xingwang

2024.

Machine learning-assisted design of refractory high-entropy alloys with targeted yield strength and fracture strain.

Materials & Design,

Vol. 246,

Issue. ,

p.

113326.

Wan, Haiyu

Xie, Baobin

Feng, Hui

and

Li, Jia

2025.

Machine Learning-Enabled Prediction and Mechanistic Analysis of Compressive Yield Strength–Hardness Correlation in High-Entropy Alloys.

Metals,

Vol. 15,

Issue. 5,

p.

487.