Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Liu, Juan

Wu, Yuze

Wang, Lin

Wang, Hui

Kong, Charlie

Pesin, Alexander

Zhilyaev, Alexander P.

and

Yu, Hailiang

2020.

Fabrication and Characterization of High-Bonding-Strength Al/Ti/Al-Laminated Composites via Cryorolling.

Acta Metallurgica Sinica (English Letters),

Vol. 33,

Issue. 6,

p.

871.

Cao, Miao

Wang, Cui-ju

Deng, Kun-kun

Nie, Kai-bo

Liang, Wei

and

Wu, Yu-cheng

2020.

Effect of Interface on Mechanical Properties of Ti/Al/Mg/Al/Ti Laminated Composites.

Materials Research,

Vol. 23,

Issue. 1,

Tang, Wei

Shao, Bin

Shan, Debin

Guo, Bin

and

Zong, Yingying

2021.

Material Flow Behavior and Microstructure Evolution During Direct Hot‐Press Bonding of Ti/Mg Laminates with Interlocking Structure.

Advanced Engineering Materials,

Vol. 23,

Issue. 10,

Zong, Zhifang

Chen, Depeng

Zhao, Chunxiao

Tang, Gang

Ji, Yilong

Zhang, Hao

and

Lv, Zhong

2021.

Application of Ce–Eu/TiO2 phase change material as the wall material to improve the indoor environment.

Journal of Materials Research,

Vol. 36,

Issue. 3,

p.

615.

WANG, Pengju

CHEN, Zejun

HUANG, Hongtao

LIN, Jianshu

LI, Boxin

and

LIU, Qing

2021.

Fabrication of Ti/Al/Mg laminated composites by hot roll bonding and their microstructures and mechanical properties.

Chinese Journal of Aeronautics,

Vol. 34,

Issue. 8,

p.

192.

Wang, Pengju

Huang, Hongtao

Liu, Jiangjiang

Liu, Qing

and

Chen, Zejun

2021.

Microstructure and mechanical properties of Ti6Al4V/AA6061/AZ31 laminated metal composites (LMCs) fabricated by hot roll bonding.

Journal of Alloys and Compounds,

Vol. 861,

Issue. ,

p.

157943.

Zhao, Tianli

Zhang, Bing

Zhang, Zhijuan

Chen, Le

Xu, Yi

Cai, Jun

and

Wang, Kuaishe

2022.

Deformation behavior and microstructural evolution of pure Ti produced by hot compressing.

Journal of Materials Research and Technology,

Vol. 21,

Issue. ,

p.

2383.

Luo, Wenbo

Feng, Yunzhe

Xue, Zhiyong

Kong, Qinke

and

Han, Xiuzhu

2022.

Effect of Al Layer Thickness on the Bonding and Mechanical Behavior of a Mg-(Al-)Ti Laminated Sheet Prepared by Hot-Rolling after Differential Preheating Treatment.

Materials,

Vol. 15,

Issue. 8,

p.

2805.

Da Huo, Peng

Li, Feng

Wang, Ye

and

Xiao, Xing Mao

2022.

Formability and interface structure of Al/Mg/Al composite sheet rolled by hard-plate rolling (HPR).

The International Journal of Advanced Manufacturing Technology,

Vol. 118,

Issue. 1-2,

p.

55.

Gao, Rong He

Li, Feng

Da Huo, Peng

and

Niu, Wen Tao

2022.

Evolution mechanism of interfacial morphological characteristics for Al/Mg/Al composite plate rolled by the hard plate.

Materials Today Communications,

Vol. 33,

Issue. ,

p.

104257.

Sarvi, Zohreh

Sadeghi, Alireza

and

Mosavi Mashhadi, Mahmoud

2023.

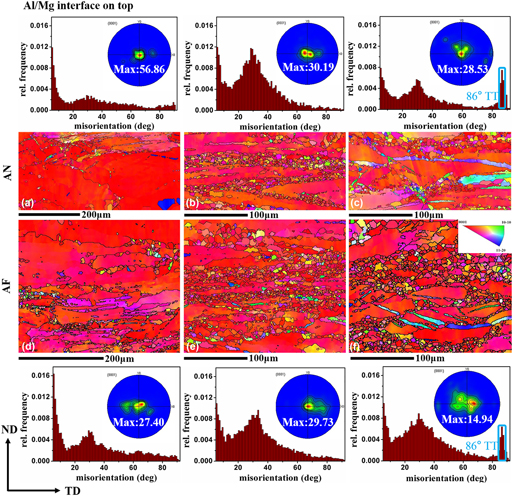

Stoichiometry and Texture Evolution of Individual Layers during Accumulative Roll Bonding of Al-Mg Laminated Composites.

Journal of Materials Engineering and Performance,

Vol. 32,

Issue. 18,

p.

8358.

Tian, Yuhe

Luo, Nianchun

He, Weijun

Jiang, Bin

and

Pan, Fusheng

2024.

Effect of Zn and Ti transition foil on the microstructure and mechanical properties of hot rolling bonded Al/Mg composite plates.

Materials Science and Engineering: A,

Vol. 891,

Issue. ,

p.

145978.

Li, Xin

Liu, Chunguo

and

Zhang, Mingzhe

2024.

Forming Limits Prediction of Laminated SUS430/Al1050/SUS430 Composites and the Effect of Component Properties on Mechanical Performance.

Advanced Engineering Materials,

Vol. 26,

Issue. 16,

Yang, Xia

Zheng, Rui

Zhou, Cunlong

and

Cui, Huitong

2024.

Effect of Rolling Process on the Microstructure and Mechanical Properties of TC4/6061/AZ31B/6061/TC4 Symmetrical Clad Sheets.

Journal of Materials Engineering and Performance,

Vol. 33,

Issue. 9,

p.

4435.

Semenchenko, L. V.

Mier, R. M.

Muyanja, N. S.

and

Demkowicz, M. J.

2024.

Near-Surface Layer Perforations as Precursors to Fracture in Accumulative Roll Bonding of a Multilayered Metal Composite.

Metallurgical and Materials Transactions A,

Vol. 55,

Issue. 1,

p.

63.

Duan, Xingwang

Xin, Xiangqian

Cao, Miao

Tan, Yunyun

and

Zheng, Xiaohua

2025.

Study on the Effect of Annealing Temperature on the Forming and Mechanical Properties of Hot‐Pressed Ti/Al/Mg/Al/Ti‐Laminated Composites.

Advanced Engineering Materials,

Vol. 27,

Issue. 12,