Published online by Cambridge University Press: 03 July 2017

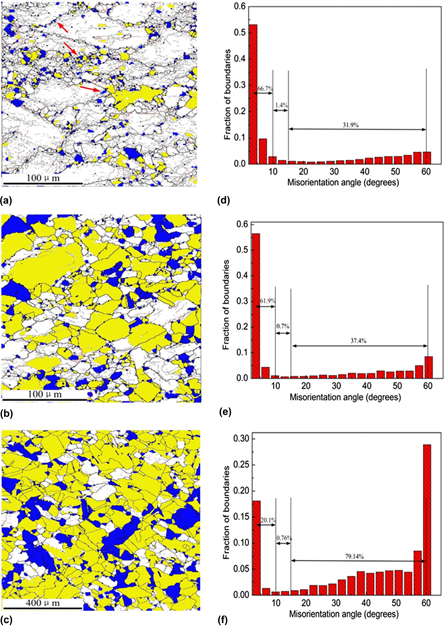

The predictability of modified constitutive model, based on Arrhenius type equation, for illustrating the flow behavior of Fe–36%Ni Invar alloy was investigated via isothermal hot compression tests. The hot deformation tests were carried out in a temperature range of 850–1100 °C and strain rates from 0.01 to 10 s−1. True stress-true strain curves exhibited the dependence of the flow stress on deformation temperatures and strain rates, which then described in Arrhenius-type equation by Zener–Holloman parameter. Moreover, the related material constants and hot deformation activation energy (Q) in the constitutive model were calculated by considering the effect of strain as independent function on them and employing sixth polynomial fitting. Subsequently, the performance of the modified constitutive equation was verified by correlation coefficient and average absolute relative error which were estimated in accordance with experimental and predicted data. The results showed that the modified constitutive equation possess reliable and stable ability to predict the hot flow behavior of studied material under different deformation conditions. Meanwhile, Zener–Holloman parameter map was established according to the modified constitutive equation and used to estimate the extent of dynamic recrystallization.

Contributing Editor: Michael E. McHenry