Article contents

Nanoindentation and nanoscratch behavior of ZnO:Pr thin films deposited by DC sputtering

Published online by Cambridge University Press: 07 August 2018

Abstract

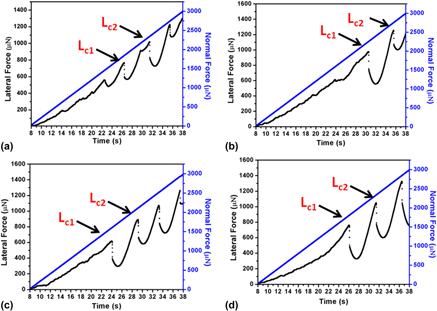

Mechanical properties of Pr (praseodymium)-doped ZnO thin films, deposited on a corning glass substrate and fused quartz at different deposition pressures using DC sputtering were investigated. Crystalline growth in Pr-doped ZnO thin films is more pronounced and improves at 10 mtorr deposition pressure. However, lower sputtering deposition pressure evoked deposition rates to the formation of polycrystalline films emerged in several crystal planes. Pr ions incorporated in the ZnO host lattice was examined by X-ray photoelectron spectroscopy (XPS), AFM, and FESEM. XPS spectroscopy revealed the presence of Pr3+ and Pr4+ at the ZnO surface layer and it was in tandem with EDS mapping. Nanoindentation prior to scratch testing is used for analyzing deformation characteristics. Pr-doped ZnO thin films exhibit better hardness (9.89 ± 0.14 GPa) and Young’s modulus (112.12 ± 3.45 GPa) on the glass substrate. The crack propagation resistance parameter of the films was evaluated using initial critical load, Lc1 ∼ 2250.5 µN for the crack initiation and upper critical load Lc2 ∼ 2754.5 µN for film failure. Better crack propagation resistance was observed for films deposited at 10 mtorr sputtering pressure on both substrates, attributed to better crystalline nature of the films.

Information

- Type

- Article

- Information

- Copyright

- Copyright © Materials Research Society 2018

References

REFERENCES

- 6

- Cited by