Article contents

Optimizing fatigue performance of nacre-mimetic PE/TiO2 nanolayered composites by tailoring thickness ratio

Published online by Cambridge University Press: 12 June 2018

Abstract

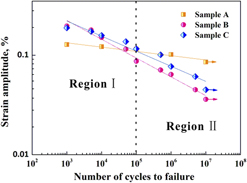

Nacre-mimetic (PE/TiO2)4 nanolayered composites (NLCs) with the nanocrystalline TiO2 layer thickness less than 30 nm and different thickness ratios of inorganic/organic layers were successfully prepared by using layer-by-layer self-assembly and chemical bath deposition method. Mechanical properties, especially fatigue properties of the NLCs with different thickness ratios were evaluated. The elastic modulus, hardness and fracture toughness, strain amplitude to fatigue limits of the NLCs reached 27.78 ± 5.69 GPa, 1.33 ± 0.31 GPa, and 4.16 ± 0.20 MPa m1/2, respectively. Fatigue performance of the NLCs in the high and low cycle fatigue regimes was optimized by tailoring the thickness ratio of the TiO2/PE layers. The PE/TiO2 NLCs with the larger thickness ratio of ∼3 has the high fatigue limit (the critical strain amplitude of 0.0853%) in the high-cycle fatigue regime, while that with the smaller thickness ratio of ∼1 and ∼0.5 are of the good fatigue strength in the low-cycle fatigue regime. The basic mechanism for the enhanced fatigue performance is elucidated.

Information

- Type

- Article

- Information

- Copyright

- Copyright © Materials Research Society 2018

References

REFERENCES

- 5

- Cited by