Article contents

Preparation and characterization of monosized Cu–Sn spherical alloy particles by pulsated orifice ejection method

Published online by Cambridge University Press: 21 June 2018

Abstract

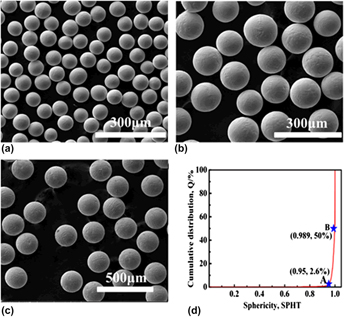

Monosized spherical Cu–20% Sn (wt%) alloy particles with diameter ranging from 70.6 to 334.0 μm were prepared by the pulsated orifice ejection method (termed “POEM”). Fully dense without pores and bulk inclusions, the cross-sectional micrographs of the spherical alloy particles indicate an even distribution of Cu and Sn. These spherical Cu–Sn alloy particles exhibit a good spherical shape and a narrow size distribution, suggesting that the liquid Cu–Sn alloy can completely break the balance between the surface tension and the liquid static pressure in the crucible micropores and accurately control the volume of the droplets. Furthermore, the cooling rate of spherical Cu–20% Sn alloy particles is estimated by a Newton’s cooling model. The cooling rate of the Cu–20% Sn alloy particle decreases gradually with the particle diameter increasing. Smaller particles have higher cooling rates and when the particle diameter is less than 70 μm, the cooling rate of particles can reach more than 3.3 × 104 K/s. The secondary dendrite arm spacing has strong dependence on particle diameter which increases gradually with the increase of particle diameter. The results demonstrate that POEM is an effective route for fabrication of high-quality monosized Cu–20% Sn alloy particles.

Keywords

Information

- Type

- Article

- Information

- Copyright

- Copyright © Materials Research Society 2018

References

REFERENCES

- 10

- Cited by