Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Xu, Jianing

Huang, Tianlin

Dong, Hongliang

Tan, Dayong

Feng, Zongqiang

Wei, Tingcha

Susilo, Resta A.

Wang, Yanju

Wang, Hailun

Yuan, Mingzhi

Zhang, Lingkong

Wan, Shun

Huang, Yuanjie

Lu, Tiecheng

Chen, Yan

Chen, Zhiqiang

and

Chen, Bin

2020.

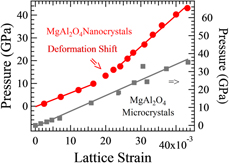

Structural and mechanical properties of magnesium aluminate nanoceramics under high pressure.

Applied Physics Letters,

Vol. 117,

Issue. 4,

Ratzker, Barak

Wagner, Avital

Sokol, Maxim

Meshi, Louisa

Kalabukhov, Sergey

and

Frage, Nachum

2020.

Deformation in nanocrystalline ceramics: A microstructural study of MgAl2O4.

Acta Materialia,

Vol. 183,

Issue. ,

p.

137.

Chen, Bin

2020.

Exploring nanomechanics with high-pressure techniques.

Matter and Radiation at Extremes,

Vol. 5,

Issue. 6,

Shi, Zhuoqi

Zhao, Qingliang

Guo, Bing

Ji, Tianyu

and

Wang, Hao

2020.

A review on processing polycrystalline magnesium aluminate spinel (MgAl2O4): Sintering techniques, material properties and machinability.

Materials & Design,

Vol. 193,

Issue. ,

p.

108858.

Li, Rui

Ma, Yimo

Liu, Xingshuo

Lu, Ye

Zhang, Yifei

Yu, Pengfei

and

Li, Gong

2022.

Effect of defects on the phase transition of Al0.1CoCrFeNi high-entropy alloy under high pressure.

Intermetallics,

Vol. 140,

Issue. ,

p.

107388.

Meng, Lingyao

Vu, Tuan V.

Criscenti, Louise J.

Ho, Tuan A.

Qin, Yang

and

Fan, Hongyou

2023.

Theoretical and Experimental Advances in High-Pressure Behaviors of Nanoparticles.

Chemical Reviews,

Vol. 123,

Issue. 16,

p.

10206.

Zhou, Jie

Peng, Fang

Hong, Fang

and

Yue, Binbin

2024.

Dislocation-mediated ultrahigh mechanical properties in nano-TiN.

Physical Review Materials,

Vol. 8,

Issue. 3,

Teoman, Atanur

Göde, Engin

Çetin, Barış

Tonbul, Kürşat

Çalışkan, Umut

and

Öğünç, Gökhan İbrahim

2024.

Design of an add-on ceramic composite armour against 14.5 × 114 mm API/B32 projectile for the armoured vehicles and investigation of the ballistic performance of the armour.

Materials Research Express,

Vol. 11,

Issue. 4,

p.

045202.

Singaravel, Dhipan Aravind

Ashokan, Anbuchezian

Rajendran, Silambarasan

and

Dhairiyasamy, Ratchagaraja

2024.

Influence of nanoceramic addition on the performance of cement-based materials.

Matéria (Rio de Janeiro),

Vol. 29,

Issue. 3,

Wang, Yan

Ni, Peiyuan

Liu, Yuling

and

Deng, Tengfei

2025.

Study on the ion behavior of solid-phase reaction synthesis of iron chromite at 1473 K.

International Journal of Minerals, Metallurgy and Materials,

Vol. 32,

Issue. 5,

p.

1103.