Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Guo, Qiang

Fu, Xidan

Guo, Xiaolei

Liu, Zhiying

Shi, Yan

and

Zhang, Di

2018.

Indentation-Enabled In Situ Mechanical Characterization of Micro/Nanopillars in Electron Microscopes.

JOM,

Vol. 70,

Issue. 4,

p.

487.

Wang, Yaqiang

Kiener, Daniel

Liang, Xiaoqing

Bian, Jianjun

Wu, Kai

Zhang, Jinyu

Liu, Gang

and

Sun, Jun

2018.

Constituent constraining effects on the microstructural evolution, ductility, and fracture mode of crystalline/amorphous nanolaminates.

Journal of Alloys and Compounds,

Vol. 768,

Issue. ,

p.

88.

Ding, Jie

Li, Q.

Li, Jin

Xue, S.

Fan, Z.

Wang, H.

and

Zhang, X.

2018.

Mechanical behavior of structurally gradient nickel alloy.

Acta Materialia,

Vol. 149,

Issue. ,

p.

57.

Fan, Cuncai

Li, Qiang

Ding, Jie

Liang, Yanxiang

Shang, Zhongxia

Li, Jin

Su, Ruizhe

Cho, Jaehun

Chen, Di

Wang, Yongqiang

Wang, Jian

Wang, Haiyan

and

Zhang, Xinghang

2019.

Helium irradiation induced ultra-high strength nanotwinned Cu with nanovoids.

Acta Materialia,

Vol. 177,

Issue. ,

p.

107.

Li, Qiang

Cho, Jaehun

Xue, Sichuang

Sun, Xing

Zhang, Yifan

Shang, Zhongxia

Wang, Haiyan

and

Zhang, Xinghang

2019.

High temperature thermal and mechanical stability of high-strength nanotwinned Al alloys.

Acta Materialia,

Vol. 165,

Issue. ,

p.

142.

Fan, Zhe

Li, Qiang

Fan, Cuncai

Wang, Haiyan

and

Zhang, Xinghang

2019.

Strategies to tailor serrated flows in metallic glasses.

Journal of Materials Research,

Vol. 34,

Issue. 9,

p.

1595.

Li, Kai

Gao, Fangliang

Chou, Yu-Jen

Shen, Kaixiang

and

Li, Guoqiang

2019.

Microdomain atomic structure of Zr50Pd40Al10 metallic glasses and its formation mechanism.

Journal of Materials Science & Technology,

Vol. 35,

Issue. 3,

p.

248.

Xiong, Fan

Li, Ming-Fei

Malomo, Babafemi

and

Yang, Liang

2020.

Microstructural evolution in amorphous-nanocrystalline ZrCu alloy under neutron irradiation.

Acta Materialia,

Vol. 182,

Issue. ,

p.

18.

Su, Ruizhe

Neffati, Dajla

Li, Qiang

Xue, Sichuang

Cho, Jaehun

Li, Jin

Ding, Jie

Zhang, Yifan

Fan, Cuncai

Wang, Haiyan

Kulkarni, Yashashree

and

Zhang, Xinghang

2020.

Ultra-high strength and plasticity mediated by partial dislocations and defect networks: Part I: Texture effect.

Acta Materialia,

Vol. 185,

Issue. ,

p.

181.

Jing, Hai-yan

Li, Ming-fei

Wang, Peng-wei

Malomo, Babafemi

and

Yang, Liang

2021.

Self-healing mechanisms of ZrCu nanocrystalline/amorphous laminated alloy under irradiation.

Materialia,

Vol. 20,

Issue. ,

p.

101227.

Su, Ruizhe

Neffati, Dajla

Li, Qiang

Xue, Sichuang

Fan, Cuncai

Cho, Jaehun

Zhang, Yifan

Li, Jin

Wang, Haiyan

Kulkarni, Yashashree

and

Zhang, Xinghang

2021.

Ultra-high strength and plasticity mediated by partial dislocations and defect networks: Part II: Layer thickness effect.

Acta Materialia,

Vol. 204,

Issue. ,

p.

116494.

Ni, Jinyang

Li, Jin

Jian, Jie

He, Jianchao

Chen, Hongsheng

Leng, Xuesong

and

Liu, Xiangli

2021.

Recent Studies on the Fabrication of Multilayer Films by Magnetron Sputtering and Their Irradiation Behaviors.

Coatings,

Vol. 11,

Issue. 12,

p.

1468.

Sahu, Bibhu Prasad

Wu, Wenqian

Wang, Jian

and

Misra, Amit

2022.

Deformation behavior of crystalline/amorphous Al-Si nanocomposites with nanolaminate or nanofibrous microstructures.

Physical Review Materials,

Vol. 6,

Issue. 9,

Wang, Peng-wei

Jing, Hai-yan

Li, Ming-fei

Malomo, Babafemi

and

Yang, Liang

2022.

Effective self-healing behavior of nanocrystalline-amorphous laminated alloy under irradiation.

Journal of Applied Physics,

Vol. 132,

Issue. 22,

Song, Zixian

Luo, Wei

and

Zhu, Yiying

2023.

The surface effect on the mechanical behavior of MG nanowires: A molecular dynamic simulation.

Journal of Non-Crystalline Solids,

Vol. 606,

Issue. ,

p.

122224.

Lv, Hang

Gao, Xinxin

Zhang, Kan

Wen, Mao

He, Xingjia

Wu, Zhongzhen

Liu, Chang

Chen, Changfeng

and

Zheng, Weitao

2023.

Bamboo-like dual-phase nanostructured copper composite strengthened by amorphous boron framework.

Nature Communications,

Vol. 14,

Issue. 1,

White, Danielle E.

Appleget, Chelsea D.

Rossi, Edoardo

Sebastiani, Marco

and

Hodge, Andrea M.

2023.

The mechanical performance of optically tuned ceramic nanomultilayers.

Materials & Design,

Vol. 231,

Issue. ,

p.

112014.

Ni, Jinyang

Li, Jin

Bai, Heda

Meng, Fanqiang

Huang, Yuji

Li, Qiulin

Leng, Xuesong

Wang, Xiaoya

Huang, Yifan

and

Liu, Xiangli

2025.

Study of CrAl coatings fabricated by HiPIMS with enhanced resistance to LBE corrosion.

Surface and Coatings Technology,

Vol. 513,

Issue. ,

p.

132476.

White, Danielle E.

Jagadish, Koushik

Shao, Yu-Tsun

and

Hodge, Andrea M.

2025.

Synthesis and characterization of aperiodic multifunctional AlN/Al2O3 nanomultilayers.

Thin Solid Films,

Vol. 815,

Issue. ,

p.

140638.

Qin, Feng

Wang, Yaodong

Chen, Jie

Chen, Shaohua

and

Li, Jianjun

2025.

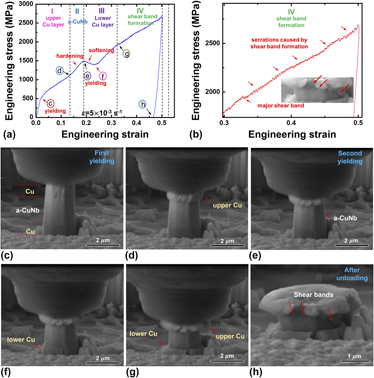

The quantitative evaluation of the plasticity of Nb/amorphous CuNb nanolayered thin films by micro-pillar compressions and micro-indentations as well as their correlation.

International Journal of Plasticity,

Vol. 188,

Issue. ,

p.

104294.