Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Sahoo, Sudhir K.

Kormath Madam Raghupathy, Ramya

Kühne, Thomas D.

and

Mirhosseini, Hossein

2018.

Theoretical Investigation of the Interaction of the CuInSe2 Absorber Material with Oxygen, Hydrogen, and Water.

The Journal of Physical Chemistry C,

Vol. 122,

Issue. 37,

p.

21202.

Hariskos, Dimitrios

and

Powalla, Michael

2018.

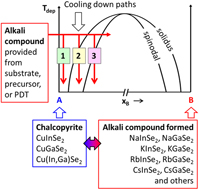

Thermodynamic limitations for alkali metals in Cu(In,Ga)Se2 – CORRIGENDUM.

Journal of Materials Research,

Vol. 33,

Issue. 2,

p.

239.

Colombara, Diego

2019.

Frank-Turnbull dopant migration may enhance heteroatom diffusivity: Evidence from alkali-doped

Cu(In,Ga)Se2.

Physical Review Materials,

Vol. 3,

Issue. 5,

Stoliaroff, Adrien

Jobic, Stéphane

and

Latouche, Camille

2019.

New insights into the determination of maximum chemical potentials to account for alkali doping in β-In2S3 by ab initio calculations.

Computational Materials Science,

Vol. 168,

Issue. ,

p.

221.

Siebentritt, Susanne

Avancini, Enrico

Bär, Marcus

Bombsch, Jakob

Bourgeois, Emilie

Buecheler, Stephan

Carron, Romain

Castro, Celia

Duguay, Sebastien

Félix, Roberto

Handick, Evelyn

Hariskos, Dimitrios

Havu, Ville

Jackson, Philip

Komsa, Hannu‐Pekka

Kunze, Thomas

Malitckaya, Maria

Menozzi, Roberto

Nesladek, Milos

Nicoara, Nicoleta

Puska, Martti

Raghuwanshi, Mohit

Pareige, Philippe

Sadewasser, Sascha

Sozzi, Giovanna

Tiwari, Ayodhya Nath

Ueda, Shigenori

Vilalta‐Clemente, Arantxa

Weiss, Thomas Paul

Werner, Florian

Wilks, Regan G.

Witte, Wolfram

and

Wolter, Max Hilaire

2020.

Heavy Alkali Treatment of Cu(In,Ga)Se2 Solar Cells: Surface versus Bulk Effects.

Advanced Energy Materials,

Vol. 10,

Issue. 8,

Nwakanma, Onyekachi

Morales-Acevedo, Arturo

and

Subramaniam, Velumani

2020.

Study Of The Effects Of Non-Vacuum Deposited Alkali-Metals On Copper-Indium-Gallium-Selenide Absorber Layers For Solar Cells.

p.

2392.

Colombara, Diego

Elanzeery, Hossam

Nicoara, Nicoleta

Sharma, Deepanjan

Claro, Marcel

Schwarz, Torsten

Koprek, Anna

Wolter, Max Hilaire

Melchiorre, Michele

Sood, Mohit

Valle, Nathalie

Bondarchuk, Oleksandr

Babbe, Finn

Spindler, Conrad

Cojocaru-Miredin, Oana

Raabe, Dierk

Dale, Phillip J.

Sadewasser, Sascha

and

Siebentritt, Susanne

2020.

Chemical instability at chalcogenide surfaces impacts chalcopyrite devices well beyond the surface.

Nature Communications,

Vol. 11,

Issue. 1,

He, Mingrui

Yan, Chang

Li, Jianjun

Suryawanshi, Mahesh P.

Kim, Jinhyeok

Green, Martin A.

and

Hao, Xiaojing

2021.

Kesterite Solar Cells: Insights into Current Strategies and Challenges.

Advanced Science,

Vol. 8,

Issue. 9,

Nwakanma, O.

Velumani, S.

and

Morales-Acevedo, A.

2021.

Review on the effects due to alkali metals on copper–indium–gallium–selenide solar cells.

Materials Today Energy,

Vol. 20,

Issue. ,

p.

100617.

Aboulfadl, Hisham

Sopiha, Kostiantyn V.

Keller, Jan

Larsen, Jes K.

Scragg, Jonathan J.S.

Persson, Clas

Thuvander, Mattias

and

Edoff, Marika

2021.

Alkali Dispersion in (Ag,Cu)(In,Ga)Se2 Thin Film Solar Cells—Insight from Theory and Experiment.

ACS Applied Materials & Interfaces,

Vol. 13,

Issue. 6,

p.

7188.

Nwakanma, Onyekachi

Morales-Acevedo, Arturo

Subramaniam, Velumani

Ezema, Fabian

and

Sugiyama, Mutsumi

2025.

Effects of heavy alkali metals (Rb, Cs) post-deposition treatments on CuInGaSe2 using a spin-coating technique.

Journal of Physics D: Applied Physics,

Vol. 58,

Issue. 3,

p.

035101.