Article contents

Three-dimensional study of twin boundaries in conventional and grain boundary-engineered 316L stainless steels

Published online by Cambridge University Press: 15 May 2018

Abstract

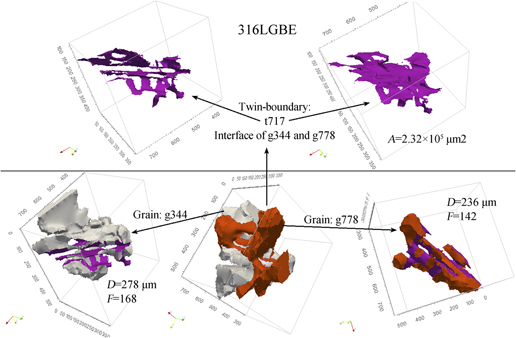

The three-dimensional microstructures of two conventional 316L stainless steels and a grain boundary (GB)-engineered version of the same steel have been characterized by using serial sectioning and electron backscatter diffraction mapping. The morphologies, area fractions, and number fractions of twin boundaries (TBs) were measured and compared, and the random boundary connectivity was evaluated. Although two-dimensional observations suggest that TBs are planar, occluded twin-grains and tunnel-shaped TBs were also observed. In addition, some large and morphologically complex TBs were observed in the GB-engineered sample, and these TBs were responsible for the increase in the twin area fraction that has been reported in past studies. While GB engineering increased the boundary area fraction, the TB number fraction was almost unchanged. Because the GB engineering process changed only the area fraction and not the number fraction, the connectivity of random boundaries was not disrupted.

Information

- Type

- Article

- Information

- Copyright

- Copyright © Materials Research Society 2018

References

REFERENCES

- 8

- Cited by