Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by Crossref.

Behera, P

Sriraman, K R

Chromik, R R

and

Yue, S

2017.

Combiningin situtribometry and triboscopy to understand third body behavior of a Cd coating.

Surface Topography: Metrology and Properties,

Vol. 5,

Issue. 1,

p.

014001.

Shockley, J. Michael

Horton, Derek J.

and

Wahl, Kathryn J.

2017.

Effect of aging of 2507 super duplex stainless steel on sliding tribocorrosion in chloride solution.

Wear,

Vol. 380-381,

Issue. ,

p.

251.

Stoyanov, Pantcho

and

Chromik, Richard

2017.

Scaling Effects on Materials Tribology: From Macro to Micro Scale.

Materials,

Vol. 10,

Issue. 5,

p.

550.

Chromik, Richard R.

and

Zhang, Yinyin

2018.

Nanomechanical testing of third bodies.

Current Opinion in Solid State and Materials Science,

Vol. 22,

Issue. 4,

p.

142.

Dienwiebel, Martin

and

Stoyanov, Pantcho

2018.

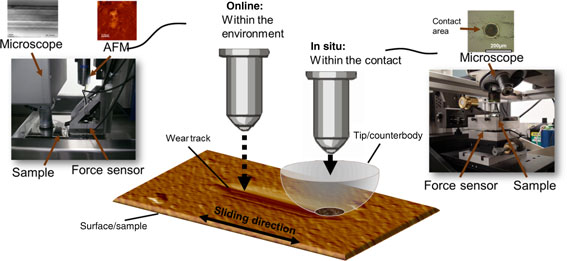

Advanced Analytical Methods in Tribology.

p.

289.

Zhang, Yinyin

and

Chromik, Richard R.

2018.

Self-Lubricating Composites.

p.

33.

Zhang, Yinyin

Mollon, Guilhem

and

Descartes, Sylvie

2020.

Significance of third body rheology in friction at a dry sliding interface observed by a multibody meshfree model: Influence of cohesion between particles.

Tribology International,

Vol. 145,

Issue. ,

p.

106188.

Zhang, Yinyin

and

Chromik, Richard R.

2022.

Self-Lubricating Composites.

p.

31.

Aghababaei, Ramin

Brodsky, Emily E.

Molinari, Jean-François

and

Chandrasekar, Srinivasan

2022.

How roughness emerges on natural and engineered surfaces.

MRS Bulletin,

Vol. 47,

Issue. 12,

p.

1229.

Harfouche, Maya M.

Alidokht, Sima A.

and

Chromik, Richard R.

2025.

In Situ and Ex Situ Analysis of the Reciprocating Sliding Wear Behavior of Cold Sprayed CrMnCoFeNi Cantor HEA Coatings in Dry Air and Ambient Air Conditions.

Tribology Letters,

Vol. 73,

Issue. 4,

Huang, Peng

Chen, Xinchun

Deng, Wenli

and

Luo, Jianbin

2025.

Superlubricity based on tribolayer.

Materials Today,