No CrossRef data available.

Published online by Cambridge University Press: 17 October 2017

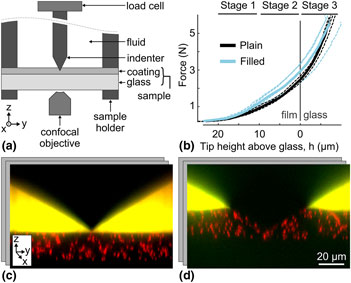

We present an indentation-scope that interfaces with confocal microscopy, enabling direct observation of the three-dimensional (3D) microstructural response of coatings on substrates. Using this method, we compared microns-thick polymer coatings on glass with and without silica nanoparticle filler. Bulk force data confirmed the >30% modulus difference, while microstructural data further revealed slip at the glass-coating interface. Filled coatings slipped more and about two times faster, as reflected in 3D displacement and von Mises strain fields. Overall, these data indicate that silica-doping of coatings can dramatically alter adhesion. Moreover, this method compliments existing theoretical and modeling approaches for studying indentation in layered systems.