1. Introduction

The stellarator has many unique features that makes it attractive as a fusion energy system. Stellarators are intrinsically steady state, can operate at high plasma density to achieve high gain while potentially relaxing plasma exhaust constraints, have relatively benign responses to magnetohydrodynamic (MHD) instabilities, avoid current-driven disruptions and have low recirculating power requirements. These benefits all provide an opportunity to develop a net electric pilot plant at reduced risk and low capital cost (Gates et al. Reference Gates2018; Baalrud et al. Reference Baalrud, Ferraro, Garrison, Howard, Kuranz, Sarff and Solomon2020). The key tradeoff for these benefits is a highly non-uniform three-dimensional plasma shape and coil configuration, which adds challenges with regards to modeling, design integration, fabrication and maintenance of integrated stellarator systems (Gates et al. Reference Gates2018). In the near term, this requires the development of new tools and approaches to be able to adequately assess and modify blanket designs for stellarators (Häußler et al. Reference Häußler, Warmer and Fischer2018; Palermo et al. Reference Palermo, Warmer and Häußler2021; Lyytinen et al. Reference Lyytinen, Snicker, Virtanen, Palermo, Alguacil, Bogaarts and Warmer2024; Palermo et al. Reference Palermo2024). Regardless of confinement concept, all deuterium-tritium (DT) fusion-based fusion pilot plants (FPPs) require meaningful technological development beyond the burning plasma itself. Critical enabling technologies such as plasma facing components, structural and functional materials and breeding blanket and tritium handling systems need to be further advanced in order to realize reduced-risk commercial systems (US Department of Energy 2021). The breeding blanket and tritium fuel cycle (TFC) related aspects of DT fusion systems in particular embody some of the most fundamental and challenging feasibility and attractiveness issues in the development of commercial fusion energy. Three primary, system driving functions must be satisfied by these components and have strong implications on overall design performance.

The first and most important function relates to the breeding of tritium, which is not naturally occurring in significant quantities and is impossible to stockpile long term due to its short half-life of 12.32 years. The current world-wide tritium inventory is projected to be 30 kg to 40 kg over the next decade, and tritium production in existing CANada Deuterium Uranium (CANDU) fission reactors is less than 0.13 kg per year per reactor (Ni et al. Reference Ni, Wang, Yuan, Jiang and Wu2013; Kovari et al. Reference Kovari, Coleman, Cristescu and Smith2018). In contrast, tritium consumption in high availability fusion power systems will be larger than current production, of the order of 5.6 kg per 100

![]() $\mathrm{MW}_{\mathrm{th}}$

fusion plasma power per full-power year. This drives the requirement that tritium must be bred, extracted and carefully controlled during operation to ensure fuel self-sufficiency and ultimately closure of the DT fuel cycle. Further complicating the matter is the relatively low utilization of tritium in a magnetic fusion energy (MFE) plasma core (order of a fraction to a few percent) which leads to the requirement for effectively and efficiently processing significant amounts of tritium in a continuous fashion (Whyte et al. Reference Whyte, Delaporte-Mathurin, Ferry and Meschini2023). The amount and throughput of tritium that will need to be managed in a fusion power plant will likely be several orders of magnitude larger than the quantities of tritium that have been handled in existing or planned fusion experiments to date, and although relevant technologies exist, they will need to be scaled up in order to handle the expected throughput of commercial systems. These operational inventories drive key engineering considerations such as the tritium start-up inventory, tritium breeding ratio (TBR), safety and waste, and must be minimized to the extent possible.

$\mathrm{MW}_{\mathrm{th}}$

fusion plasma power per full-power year. This drives the requirement that tritium must be bred, extracted and carefully controlled during operation to ensure fuel self-sufficiency and ultimately closure of the DT fuel cycle. Further complicating the matter is the relatively low utilization of tritium in a magnetic fusion energy (MFE) plasma core (order of a fraction to a few percent) which leads to the requirement for effectively and efficiently processing significant amounts of tritium in a continuous fashion (Whyte et al. Reference Whyte, Delaporte-Mathurin, Ferry and Meschini2023). The amount and throughput of tritium that will need to be managed in a fusion power plant will likely be several orders of magnitude larger than the quantities of tritium that have been handled in existing or planned fusion experiments to date, and although relevant technologies exist, they will need to be scaled up in order to handle the expected throughput of commercial systems. These operational inventories drive key engineering considerations such as the tritium start-up inventory, tritium breeding ratio (TBR), safety and waste, and must be minimized to the extent possible.

In addition to fuel self-sufficiency, the breeder blanket will also play a pivotal role in the overall thermal efficiency of DT fusion energy systems. It must extract heat originating both from volumetric heat generation caused by neutrons, subsequent prompt photon energy deposition and nuclear reactions inside the blanket as well as plasma radiation towards the first wall, which is typically integrated on the surface of the blanket for neutron economy reasons (Hesch et al. Reference Hesch, Boccaccini and Stieglitz2018). Since the blanket is anticipated to account for 80 %–90 % of the plasma facing surface, the majority of the energy of the DT fusion reaction is imparted into high energy neutrons (approximately 80 %), and MFE systems typically run with a strong radiative fraction (90 %–95 %), it is conservatively estimated that at least 75 % of the overall system heat loads will reside in the blanket. This heat must be effectively removed both for effective thermal conversion but also to keep materials and components within operating temperature limits. This is done through the forced flow of one or more coolants, depending on design. The characteristics of this coolant flow, including pumping power requirements, and its coupling to a thermal conversion system will dictate both power production and overall power conversion efficiency of an energy producing system.

Finally, the breeder blanket will be responsible for providing a significant amount of nuclear shielding for device lifetime components. For MFE devices this typically includes the plasma confining magnetic field coils, which are relatively sensitive to radiation, but can also include other large components such as the vacuum vessel, which may be too costly or difficult to easily replace over the life of the device. A key consideration of any fusion blanket design is its efficacy in both slowing and absorbing neutrons (El-Guebaly Reference El-Guebaly2018; Pereslavtsev et al. Reference Pereslavtsev, Hernández, Zhou, Lu, Wegmann and Fischer2019), given the relatively large penetration length scales of the energetic DT fusion neutrons (order of meters) as well as the requirement to reduce the neutron flux by approximately four orders of magnitude from the first wall to the coil structures. In addition to the minimum blanket volume required for breeding, the optimized shielding performance of the blanket, including any integrated dedicated shield material, will play a factor in determining the minimum allowable plasma-to-magnet spacing and ultimately drive the size of MFE devices such as stellarators. This shielding will also play a vital role in safety and activated material management considerations of a DT energy system.

In addition to serving these core functions, in-vessel components such as the blanket will be subjected to, and must survive, immensely harsh conditions, including a combination of extreme radiation, high heat, mechanical stress and volatile chemical environments. This represents one of the ultimate challenges in materials science and engineering, and it is expected that the performance of these components will ultimately dictate the economic, safety and environmental attractiveness of any given fusion system (Aubert et al. Reference Aubert2018). At present, the behavior and reliability of materials subjected to this environment have relatively high uncertainty, and this uncertainty affects design choices as well as research and development (R&D) needs.

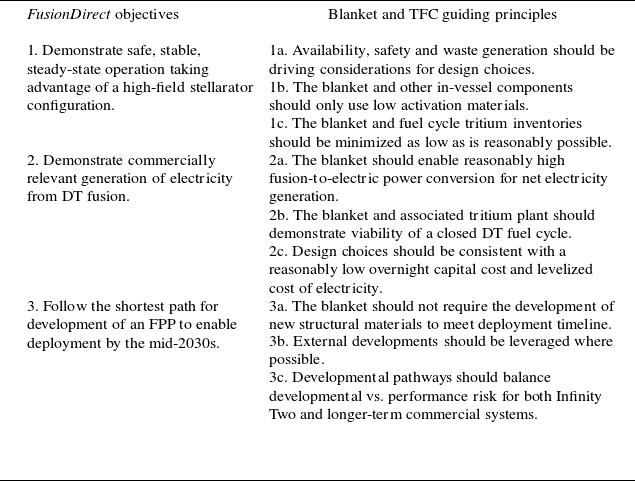

For these reasons, the selection, design and optimization of a suitable blanket configuration for an advanced high-field stellarator concept is seen as a key feasibility issue and has been incorporated as a vital and necessary part of the Infinity Two physics basis from the onset. The purpose of this paper is to document at a high level the selection process, including identification of objectives, analyses and findings. As outlined in the overview (Hegna et al. Reference Hegna2025), Type One Energy Group Inc. (T1E) is pursuing an ambitious and uniquely direct path to fusion known as the FusionDirect program, the cornerstone of which is the disciplined adherence to a technology development path with the lowest possible risk and shortest possible schedule to realize a high-field stellarator FPP. The overarching objective of the FusionDirect program’s mission is to demonstrate safe, stable, steady-state operation of a high-field stellarator capable of reliably generating clean, sustainable electricity for commercial applications by the mid-2030s. Cascading from this objective, several high-level guidelines were imposed on the T1E blanket and TFC program at an early stage to ensure the technology choices and subsequent technology development program remain compatible with the overarching missions embodied by FusionDirect. These guidelines are summarized in table 1.

Table 1. FusionDirect objectives and subsequent blanket and TFC guiding principles.

2. Technical background

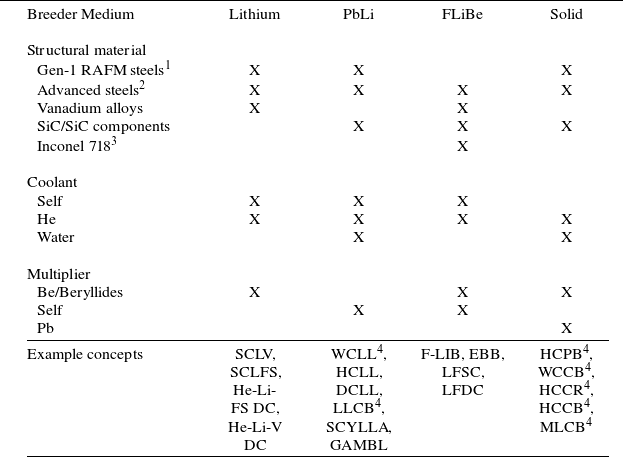

Over the past decades countless studies have examined various breeder blanket concepts for both MFE and inertial fusion energy applications. Until a few years ago, the primary drivers of this research were public research organizations involved in government sponsored research world-wide. One of the main focal points of this research is on the development of breeder blanket mock-ups to be tested on the ITER tokamak currently under construction in Cadarache, France, known as the test blanket modules (Giancarli et al. Reference Giancarli2020). The basic concept of all breeder blankets envisaged for DT fusion focuses on achieving tritium self-sufficiency via conversion of lithium to tritium by means of nuclear reactions. Lithium may be present as a liquid metal, liquid eutectic alloy, molten salt or in solid form such as a lithium-bearing ceramic. At the most fundamental level, a blanket consists of this breeding medium in an assembly fabricated of fusion relevant structural materials, a flowing coolant used to extract heat and a neutron multiplier for increased neutron economy as needed. Families of existing low activation structural materials under consideration include reduced activation ferritic martensitic (RAFM) steels, advanced steels (castable nanostructured alloys (CNAs) and oxide dispersion strengthened (ODS) steels), vanadium alloys or silicon carbide (SiC) based ceramic matrix composites. Coolants under consideration include water, helium (He), carbon dioxide (CO

![]() $_{2}$

) or self-cooling through the flow of liquid breeding media. Neutron multipliers include beryllium and lead-based materials. A non-exhaustive, general summary of popular combinations considered in the literature can be seen in table 2.

$_{2}$

) or self-cooling through the flow of liquid breeding media. Neutron multipliers include beryllium and lead-based materials. A non-exhaustive, general summary of popular combinations considered in the literature can be seen in table 2.

Table 2. Primary blanket combinations under consideration in literature.

1 F82H, EUROFER97.

2 CNA, ODS.

3 Inconel is not considered to be a low activation material.

4 Blanket concepts currently proposed for the ITER Test Blanket Modules program.

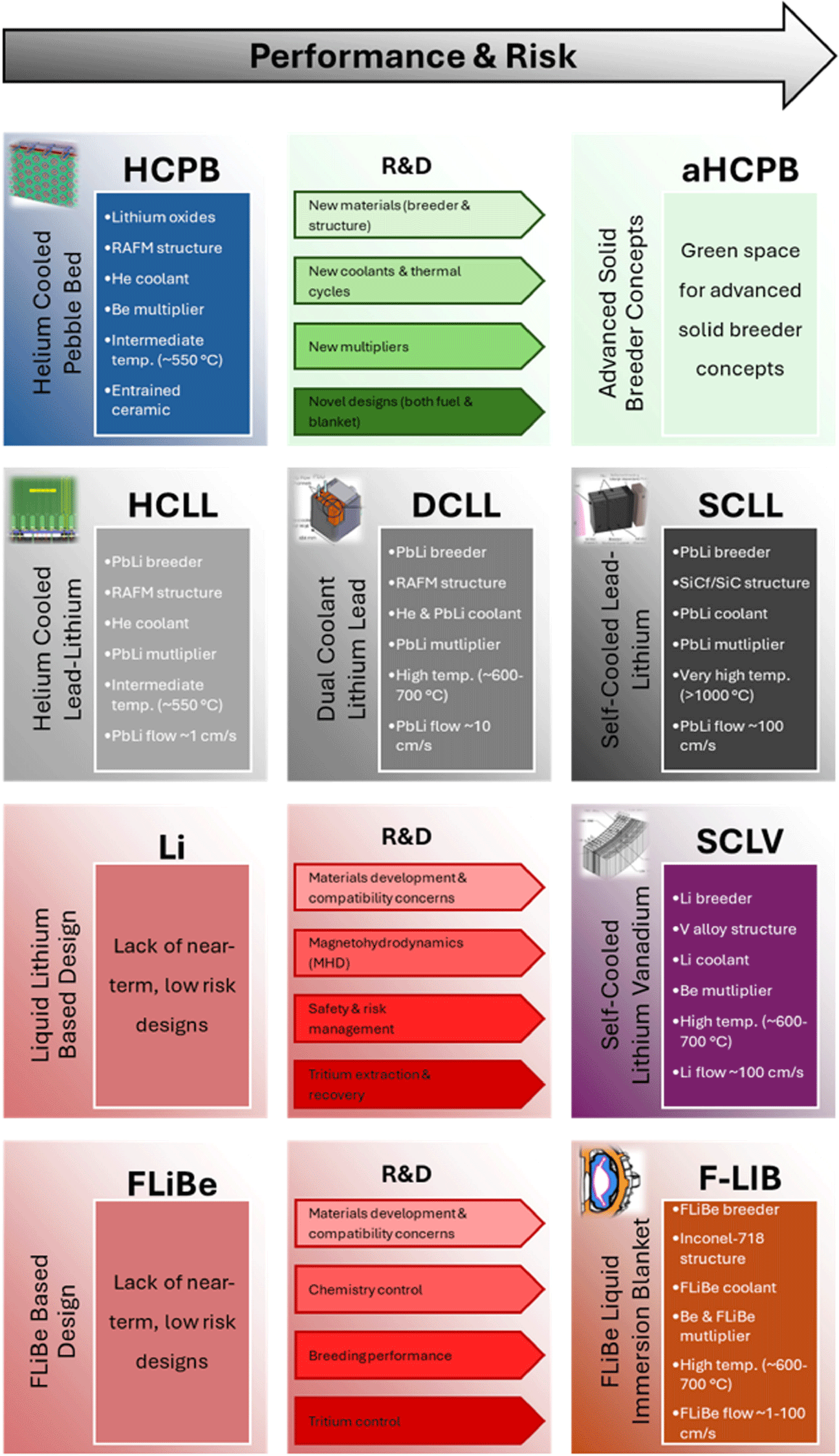

In order to help narrow down the field of extremely diverse concepts, six reference concepts were identified from design studies in the literature. These reference concepts are meant to be indicative of the broad ‘family’ of designs defined by the selection of primary components, namely, breeding medium, structure, coolant and neutron multiplier, as well as the relevant regimes in which they are employed. A brief description of each reference concept is included below, and readers are directed to the referenced publications for further details. The first three reference concepts represent some of the most commonly explored designs to date, mainly owing to their inclusion in both the ITER test blanket modules and international fusion energy programs. The focus of these designs tends to be on near-term technical feasibility.

The helium-cooled pebble bed (HCPB) concept is one of two blanket concepts selected for the EU Demonstration Power Plant (EU DEMO) (Hernández et al. 2023). The current reference HCPB design is the so-called ‘pin’ design, which is based on a radial arrangement of ceramic fuel-breeder pins using RAFM structure (EUROFER97) for optimized neutronics performance. Each pin consists of two concentric tubes that form the inner and outer cladding which are filled with the tritium breeding material (Karlsruhe lithium orthosilicate advanced ceramic breeder pebbles). The volume between pins is filled by hexagonal prismatic blocks of neutron multiplier material (Be

![]() $_{12}$

Ti). Each pin is cooled with high pressure He. A separate stream of He purge gas doped with hydrogen is flowed through the breeder pins and multiplier prismatic blocks for tritium removal (Hernández et al. Reference Hernández2019, Reference Hernández2020; Zhou et al. Reference Zhou, Hernández, Pereslavtsev, Kiss, Retheesh, Maqueda and Park2023a

).

$_{12}$

Ti). Each pin is cooled with high pressure He. A separate stream of He purge gas doped with hydrogen is flowed through the breeder pins and multiplier prismatic blocks for tritium removal (Hernández et al. Reference Hernández2019, Reference Hernández2020; Zhou et al. Reference Zhou, Hernández, Pereslavtsev, Kiss, Retheesh, Maqueda and Park2023a

).

The helium-cooled lithium lead (HCLL) concept was one of the four candidate blankets selected for the EU DEMO prior to down-selection at the preconceptual design phase (Aubert et al. Reference Aubert2018). The general concept of the HCLL breeding blanket consists of several boxes stiffened by actively He-cooled plates, between which the PbLi neutron multiplier, tritium breeder and carrier medium slowly flow. The structural material of choice is RAFM steel (EUROFER97). The current reference design is known as the ‘advanced-plus’ HCLL, which is aimed at providing optimized breeding, shielding and thermo-mechanical performance through the implementation of only thin horizontal stiffening plates (Aubert et al. Reference Aubert2018; Boullon et al. Reference Boullon, Aubert, Aiello, Jaboulay and Morin2019; Jaboulay et al. Reference Jaboulay, Aiello, Aubert and Boullon2019).

The dual coolant lithium lead (DCLL) concept has been considered by a number of public programs including both the EU (Rapisarda et al. Reference Rapisarda, Fernández-Berceruelo, García, García, Garcinuño, González, Moreno, Palermo, Urgorri and Ibarra2021) and US (Kessel et al. Reference Kessel2018) due both to its readiness for deployment as well as to its high degree of design flexibility and potential for extrapolated performance. This blanket concept uses RAFM steels (F82H or EUROFER97) or higher temperature and/or radiation resistant variants (such as the CNA or ODS steels) as structural material. The primary coolant is He and the PbLi liquid metal acts as a breeder, multiplier, tritium carrier medium and secondary coolant. SiC-composite flow channel inserts are typically employed as electrical and thermal insulators between the PbLi and the RAFM steel in the blanket to minimize MHD pressure drops for the liquid metal. The details of the individual DCLL designs can vary widely depending on materials selection, PbLi flow speed and operating temperature (Smolentsev et al. Reference Smolentsev, Morley, Abdou and Malang2015). The reference DCLL design used in this analysis was the same as that employed on the US Fusion Nuclear Science Facility (FNSF) study (Kessel et al. Reference Kessel2018), which was chosen due to the availability of design details, although higher performing concepts are also under development (Rapisarda et al. Reference Rapisarda, Fernández-Berceruelo, García, García, Garcinuño, González, Moreno, Palermo, Urgorri and Ibarra2021).

In addition to these more traditional designs, a number of higher-risk, higher-reward concepts have also appeared in the literature. These predominantly focus on self-cooled blankets, which were first conceived in the 1980s as an optimal solution which allows for design simplification and increased performance compared with the separately cooled concepts highlighted in the previous section. The initial design space for these concepts was mostly explored through the US blanket (Smith et al. Reference Smith, Baker, Sze, Morgan, Abdou, Piet, Schultz, Moir and Gordon1985; Raffray et al. Reference Raffray, Akiba, Chuyanov, Giancarli and Malang2002) and Advanced Research Innovation and Evaluation Study (ARIES) programs (University of Wisconsin-Madison 2024a) due to their potential attractiveness for commercial systems. Currently, no self-cooled blanket has been developed beyond the concept exploration phase primarily due to the limited need to develop advanced blanket technology for fusion experiments such as ITER (Giancarli et al. Reference Giancarli2020), but also due to the perceived maturity of suitable materials required for implementing such blanket designs (Raffray et al. Reference Raffray, Akiba, Chuyanov, Giancarli and Malang2002). The emergence of the fusion private industry has renewed interest in these concepts, with three MFE-relevant designs identified in this study.

The first is the self-cooled lithium lead (SCLL) concept which is being championed by Kyoto Fusioneering (Pearson et al. Reference Pearson, Baus, Konishi, Mukai, D’Angio and Takeda2022). This design builds on the ARIES-Advanced and Conservative Tokamak (ACT1) blanket concept, which is embodied by the choice of SiC composite structural material and PbLi eutectic, which serves as the breeder, coolant, multiplier and tritium carrier (Kessel et al. Reference Kessel2015). An optional additional Be neutron multiplier known as a ‘booster’ or reflector are also variations on the design, which can be included or adjusted based on performance requirements.

The second is the self-cooled lithium vanadium (SCLV) concept which builds on the ARIES-reversed-shear tokamak blanket concept (Tillack et al. Reference Tillack, Malang, Waganer, Wang, Sze, El-Guebaly, Wong, Crowell, Mau and Bromberg1997; Sze et al. Reference Sze1998) and historic R&D activities at the Argonne National Laboratory Blanket program (Mattas et al. Reference Mattas, Smith, Reed, Park, Kirillov, Strebkov, Rusanov and Votinov1998; Gohar et al. Reference Gohar, Majumdar and Smith2000). The SCLV is embodied by the choice of a vanadium alloy (typically V-4Cr4Ti although advanced V alloys are also under development (Aaron Li Reference Li2024)) as structural material and pure lithium metal which serves as the breeder, coolant, multiplier and tritium carrier. An external multiplier and/or reflector may or may not be required depending on the design. Historically, lithium vanadium concepts have not been strongly considered for separate or dual-cooled designs because of concerns with oxidation and embrittlement by the uptake of interstitial atoms including oxygen, carbon, nitrogen or hydrogen (Muroga et al. Reference Muroga, Chen, Chernov, Kurtz and Le Flem2014). However, both helium-cooled lithium vanadium (Lord et al. Reference Lord, Bennett, Harrington, Cooper, Lee-Lane, Cureton, Olde, Thompson, Jayasundara and Meatyard2024) and dual coolant lithium vanadium (Li Reference Li2024) have been proposed recently, although these designs were not incorporated into this analysis due to time constraints and lack of sufficient technical detail.

The third is a self-cooled molten salt concept which is being developed by the Massachusetts Institute of Technology in collaboration with Commonwealth Fusion Systems (Sorbom et al. Reference Sorbom2015; Ferry et al. Reference Ferry, Woller, Peterson, Sorensen and Whyte2023). This design builds on US blanket (Sze et al. Reference Sze, Jung, Cheng, Piet and Klein1986; Wong et al. Reference Wong2005) and ITER program designs (Abdou et al. Reference Abdou, Sze, Wong, Sawan, Ying, Morley and Malang2005), but with the major modification of removing flow channels and replacing them with a continuous pool of quasi-stagnant salt. This allows for the removal of a significant fraction of structural material for enhanced breeding performance, which historically was a challenge for molten salt concepts. The salt typically chosen for this application is FLiBe (2:1 molar mixture of LiF-BeF

![]() $_{2}$

salt eutectic) due to its lithium content and historical usage in the molten salt reactor experiment experiment at ORNL, which provides for a relatively robust operational baseline (Wong et al. Reference Wong2005). This concept, known as the FLiBe liquid immersion blanket (F-LIB), initially proposes to utilize Inconel-718 as the structural material and Be as a neutron multiplier. It is important to note that Inconel-718 is not considered a low activation material due to its high nickel content, and so is not viable in the long term. However, it may be an acceptable choice for a low volume, one-of-a-kind plant assuming that suitable materials are identified and matured prior to full commercialization, which is an area of ongoing development (Commonwealth Fusion Systems 2024).

$_{2}$

salt eutectic) due to its lithium content and historical usage in the molten salt reactor experiment experiment at ORNL, which provides for a relatively robust operational baseline (Wong et al. Reference Wong2005). This concept, known as the FLiBe liquid immersion blanket (F-LIB), initially proposes to utilize Inconel-718 as the structural material and Be as a neutron multiplier. It is important to note that Inconel-718 is not considered a low activation material due to its high nickel content, and so is not viable in the long term. However, it may be an acceptable choice for a low volume, one-of-a-kind plant assuming that suitable materials are identified and matured prior to full commercialization, which is an area of ongoing development (Commonwealth Fusion Systems 2024).

It should also be noted that several water-cooled designs were identified, but ultimately not explored. Although water cooling enjoys a relatively robust technology basis, including application as a coolant in fossil and nuclear fission power plants, it was recognized that water-cooled systems have some significant challenges which limit their potential attractiveness for commercial DT fusion devices and ultimately were not an attractive pathway for the FusionDirect program. For a detailed discussion of these challenges, as well a perspective on why the US fusion program has not historically favored water as a coolant, readers are referred to Tillack et al. (Reference Tillack, Humrickhouse, Malang and Rowcliffe2015).

The following sections of this paper detail the process by which each of the six blanket concepts were analyzed parametrically to better understand differences in performance. Section 3 details the neutronics analysis via Monte Carlo techniques, § 4 details the thermal analysis evaluating system-level integration and performance with a Rankine cycle and § 5 details a TFC analysis using the residence time method (RTM). In each of these sections, the associated tools were also used to evaluate the Infinity Two FPP baseline plasma physics configuration. Section 6 combines the outcomes of these quantitative analyses with a qualitative analysis of technical maturity and other performance risks and discusses implications of various blanket choices on the overall FusionDirect program. Section 7 details the conclusions of this study.

3. Neutronics analysis

3.1. Introduction

One of the most significant challenges in designing a stellarator-based fusion energy system is the selection of a blanket concept optimized for its complex geometry. From a large phase space of blanket concepts, a design and associated radial build must be chosen which is able to satisfy both tritium self-sufficiency and shielding requirements, constrained to as reasonably small build depth as possible in order to satisfy space limitations between the plasma and the magnets. For tritium self-sufficiency, the TBR must be greater than unity depending on the specifics of the TFC and objectives for doubling time. In the neutronics portion of this study, a TBR of 1.35 was set as the viability target, understanding that detailed system-level requirements have not yet been set, but also that significant margins may be necessary to accommodate additional fidelity in design details (El-Guebaly Reference El-Guebaly2018). This includes detailed component geometries as well as the inclusion of the divertor, penetrations and gaps which will remove volume from the breeder layer. For shielding, conservative lifetime limits included: (i) restrictions on the fast neutron fluence at the magnets to below 5

![]() ${\times}$

10

${\times}$

10

![]() $^{18}$

n cm

$^{18}$

n cm

![]() $^{-2}$

for super conductor degradation concerns (El-Guebaly Reference El-Guebaly2018), (ii) He production/damage in the vacuum vessel below 1 atomic parts per million (appm) to ensure reweldability (El-Guebaly Reference El-Guebaly2018) and (iii) 5 displacements per atom (dpa) as a conservative limit of radiation induced embrittlement of austenitic stainless steels (such as 304 and 316) used for the vacuum vessel (Zinkle & Was Reference Zinkle and Was2013). The target lifetime used in this study was five full-power years based on preliminary requirements and objectives of Infinity Two.

$^{-2}$

for super conductor degradation concerns (El-Guebaly Reference El-Guebaly2018), (ii) He production/damage in the vacuum vessel below 1 atomic parts per million (appm) to ensure reweldability (El-Guebaly Reference El-Guebaly2018) and (iii) 5 displacements per atom (dpa) as a conservative limit of radiation induced embrittlement of austenitic stainless steels (such as 304 and 316) used for the vacuum vessel (Zinkle & Was Reference Zinkle and Was2013). The target lifetime used in this study was five full-power years based on preliminary requirements and objectives of Infinity Two.

The body of this section details the approach for determining optimal radial builds for each family of breeder concepts using computational neutronic simulations, comparing the blanket concepts based on their optimal radial builds and arriving at the recommendation of the leading concept from a neutronics perspective. The radial build used for this analysis was based on the FNSF study (Kessel et al. Reference Kessel2018), excluding the blanket and magnets portions, which were drawn from the literature and T1E internal design activities, respectively. A key differentiator of this study with respect to other design activities was the decision to not allow water within the vacuum boundary for engineering and safety considerations. This resulted in the creation of a water-cooled low-temperature shield as a layer external to the helium-cooled vacuum vessel which contains both the blanket and the high-temperature shield.

All neutronics simulations were performed using OpenMC (Romano et al. Reference Romano, Horelik, Herman, Nelson, Forget and Smith2015) with FENDL 3.2c neutron cross-section data library, ENDF/B-VIII.0 supplement for Nd neutron and all element photon reaction cross-sections. The focus of the subsequent analysis sections is to outline the implication of blanket choices on radiation transport and subsequent effects, including neutron flux/shielding attenuation, tritium breeding, nuclear heating, material damage to blanket structures and He production by nuclear transmutation.

3.2. Parametric analysis of breeder blanket concepts

A simplified one-dimensional neutronics analysis was used to perform a comparative evaluation of six blanket concepts based on their breeding efficiency with breeder thickness, as well as the shielding efficiency with thickness of breeder and shield layers. These one-dimensional simulations were performed using a plasma ring source (Shimwell, Reference Shimwell2021) and material-homogenized toroidal shell representations of the layers of interest (first wall, breeder, vacuum vessel, shielding, magnet coil winding pack, etc.). Although not fully representative of complex three-dimensional stellarator geometries, this type of simplified quantitative comparison is helpful to inform the down-selection of blanket concepts at early design stages (El-Guebaly et al. Reference El-Guebaly, Raffray, Malang, Lyon and Ku2005, Reference El-Guebaly2008). Models comprising concentric toroidal shells of homogenized blanket layers were generated based on the following references:

-

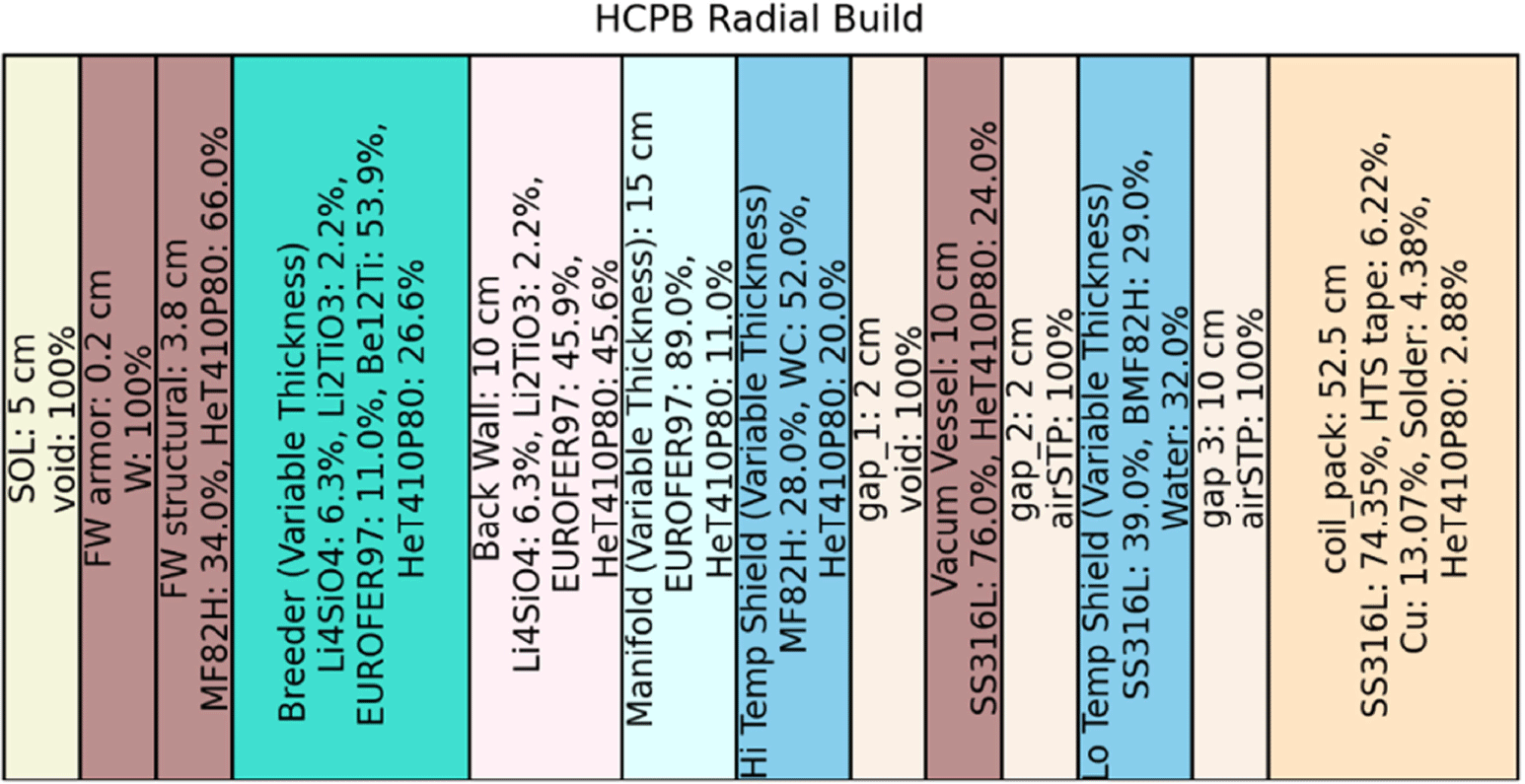

a. HCPB (Zhou et al. Reference Zhou, Hernández, Pereslavtsev, Kiss, Retheesh, Maqueda and Park2023a ), shown in figure 10 in Appendix A.

-

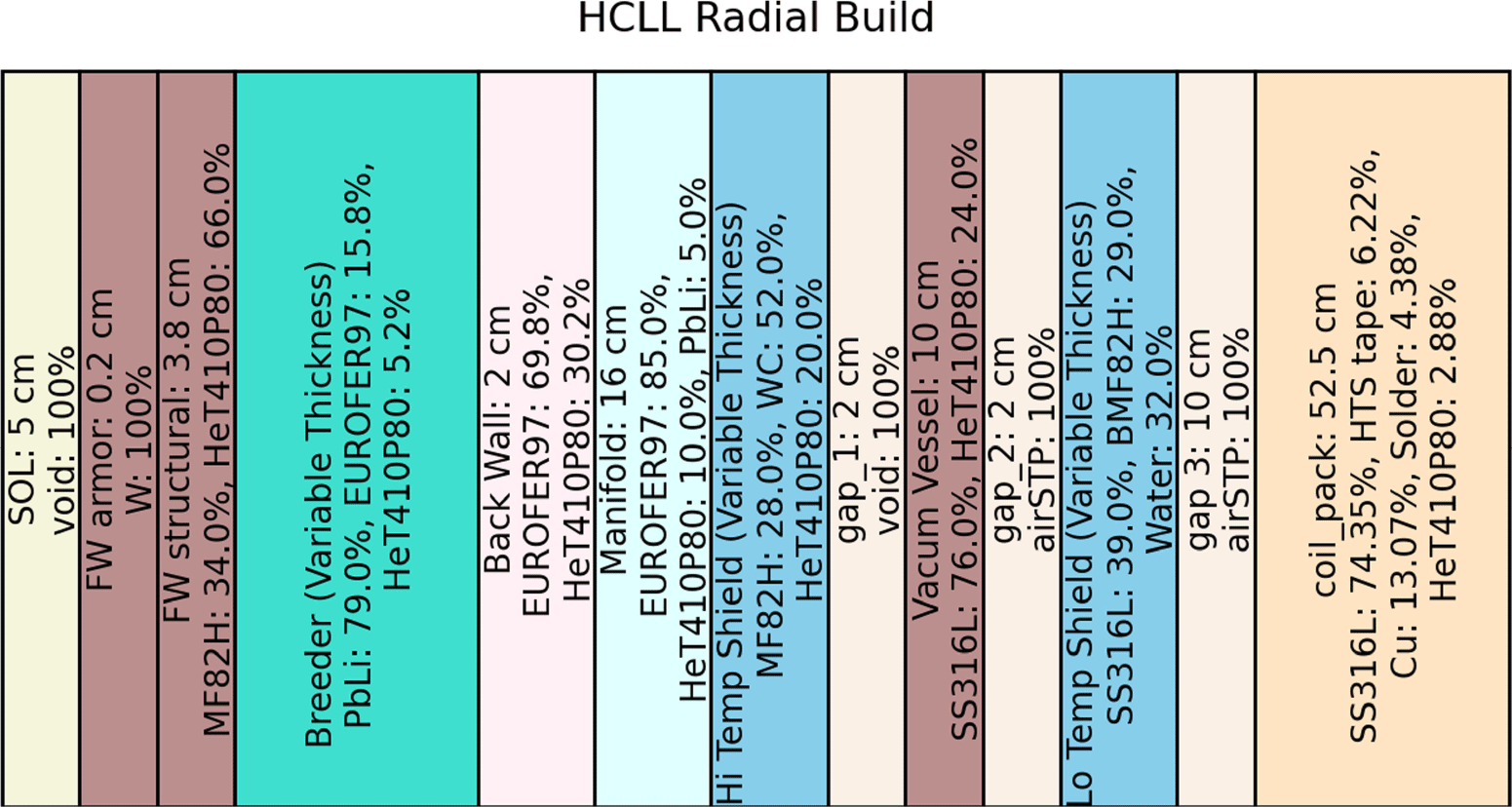

b. HCLL (Aubert et al. Reference Aubert2018), shown in figure 11 in Appendix A.

-

c. DCLL (Davis et al. Reference Davis, Harb, El-Guebaly, Wilson and Marriott2018), shown in figure 12 in Appendix A.

-

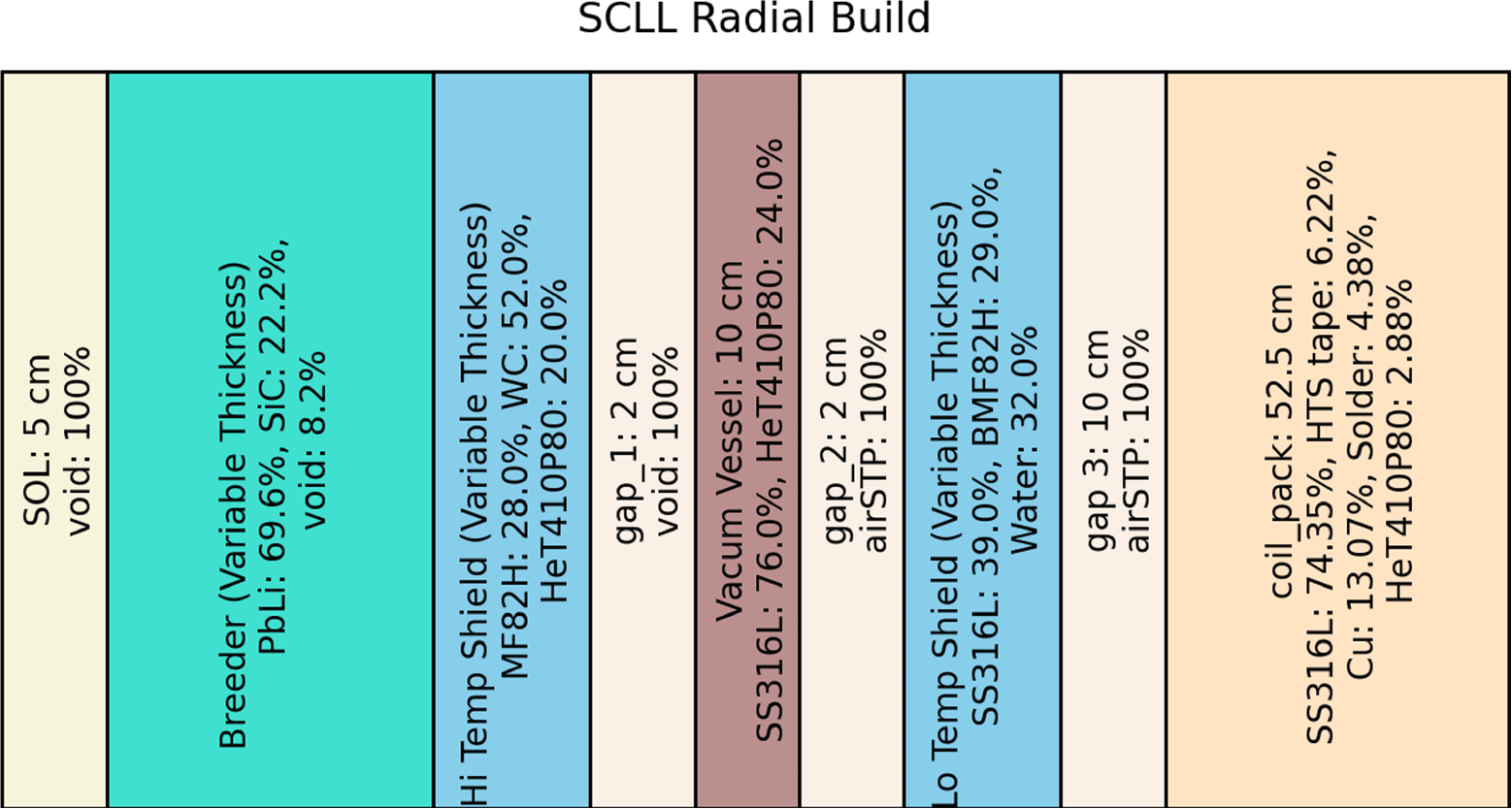

d. SCLL (Kessel et al. Reference Kessel2015), shown in figure 13 in Appendix A.

-

e. SCLV (Gohar et al. Reference Gohar, Majumdar and Smith2000; Kirillov et al. Reference Kirillov, Danilov, Sidorenkov, Strebkov, Mattas, Gohar, Hua and Smith1998), shown in figure 14 in Appendix A.

-

f. F-LIB (Segantin et al. Reference Segantin, Testoni, Hartwig, Whyte and Zucchetti2020, Reference Segantin, Meschini, Testoni and Zucchetti2022; Bae et al. Reference Bae, Peterson and Shimwell2022), shown in figure 15 in Appendix A.

The layers whose thickness were varied are denoted in the diagrams with turquoise for breeder layer and blue for shields. All other layers without ‘variable thickness’ designation in the diagrams were fixed in the parametric models. Toroidal shell models were parametrically generated for each blanket concept to cover the domain where the breeder thickness varies from 10 to 100 cm and the two shielding thicknesses vary from 10 to 60 cm.

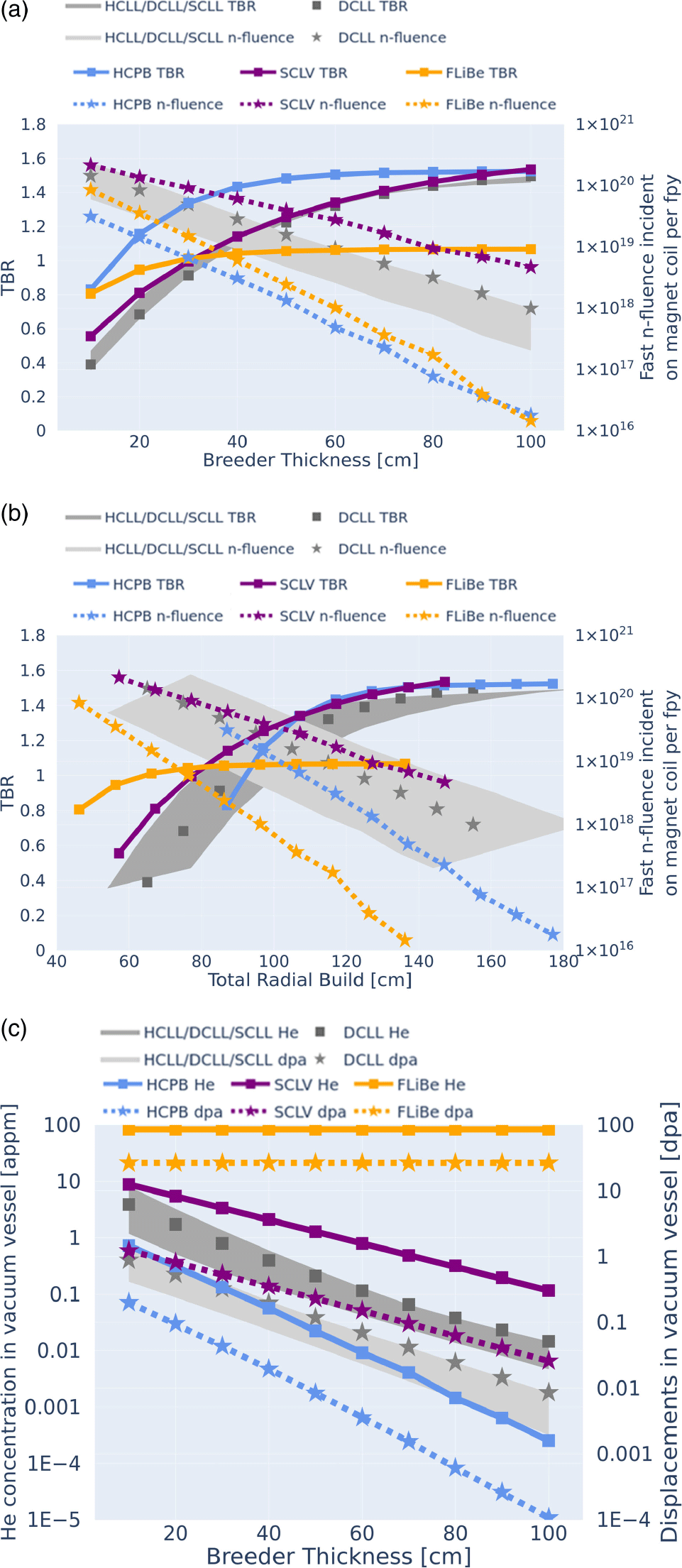

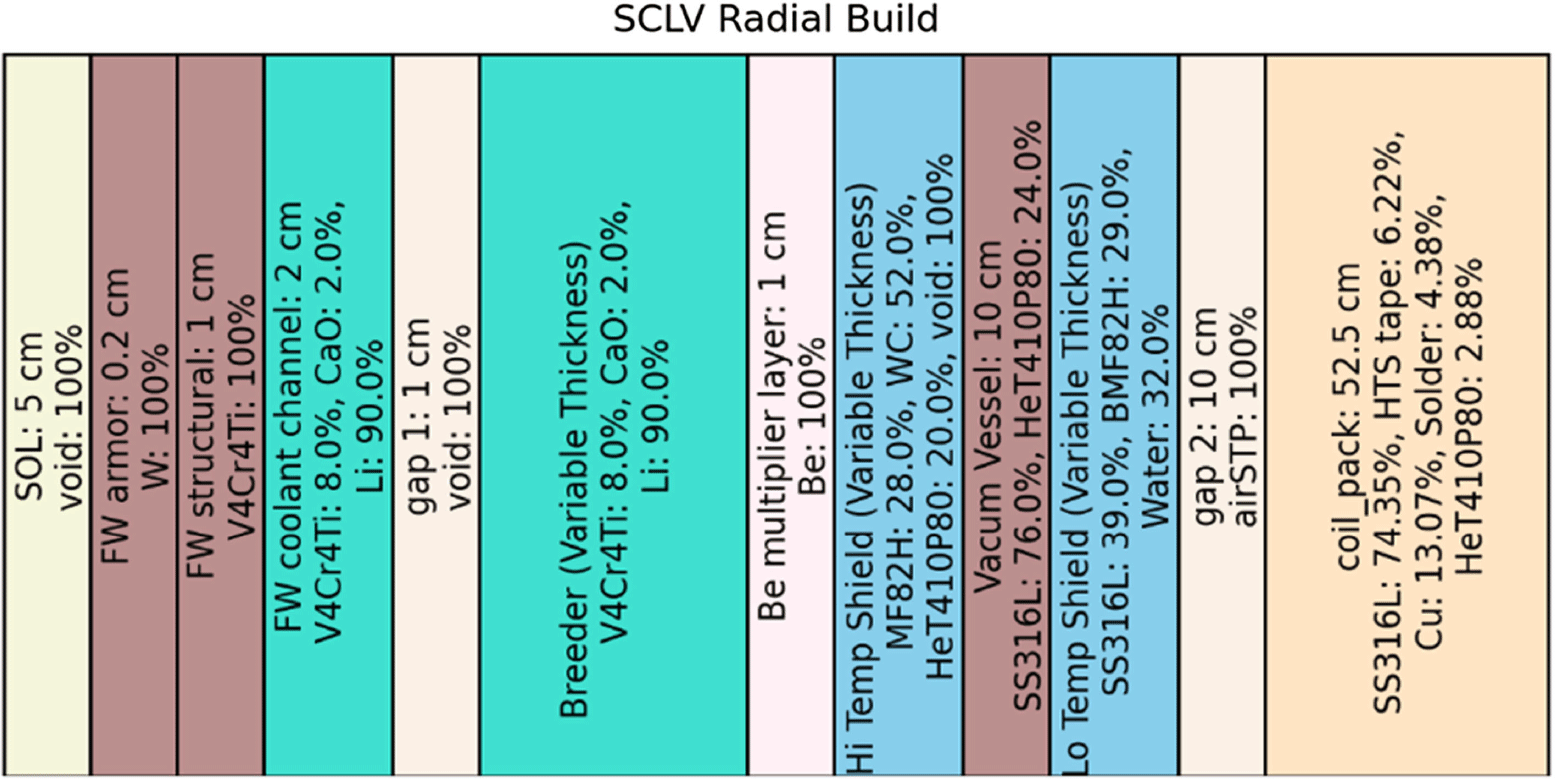

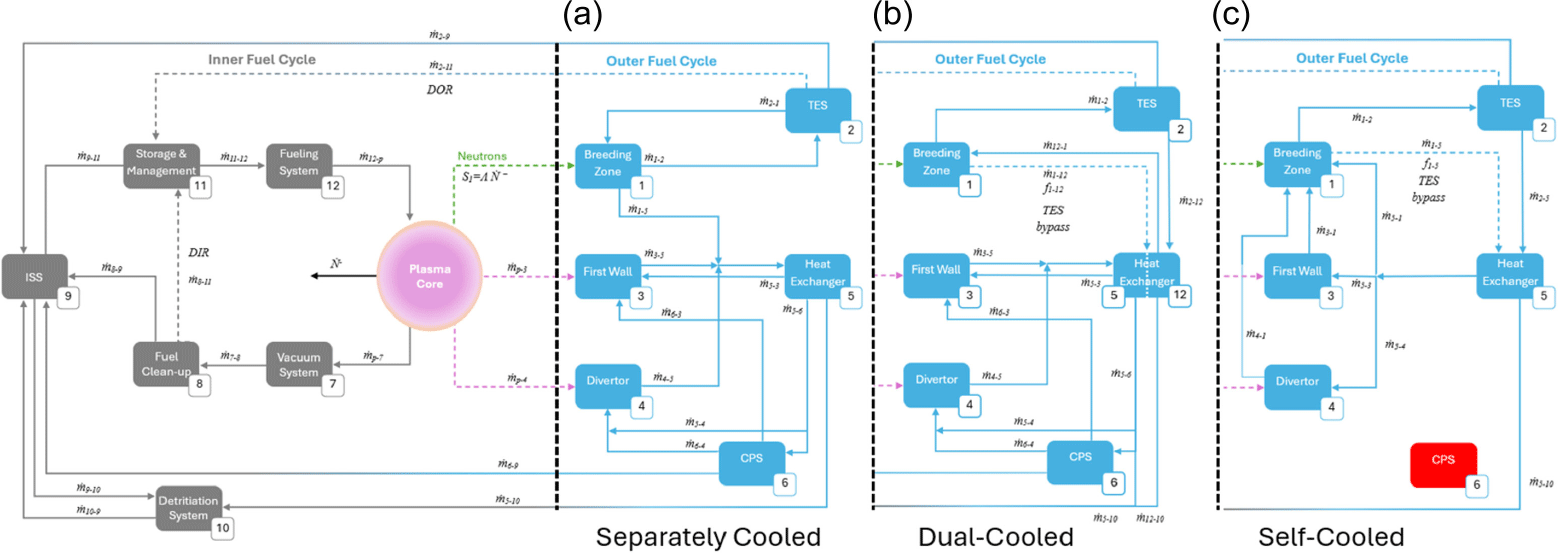

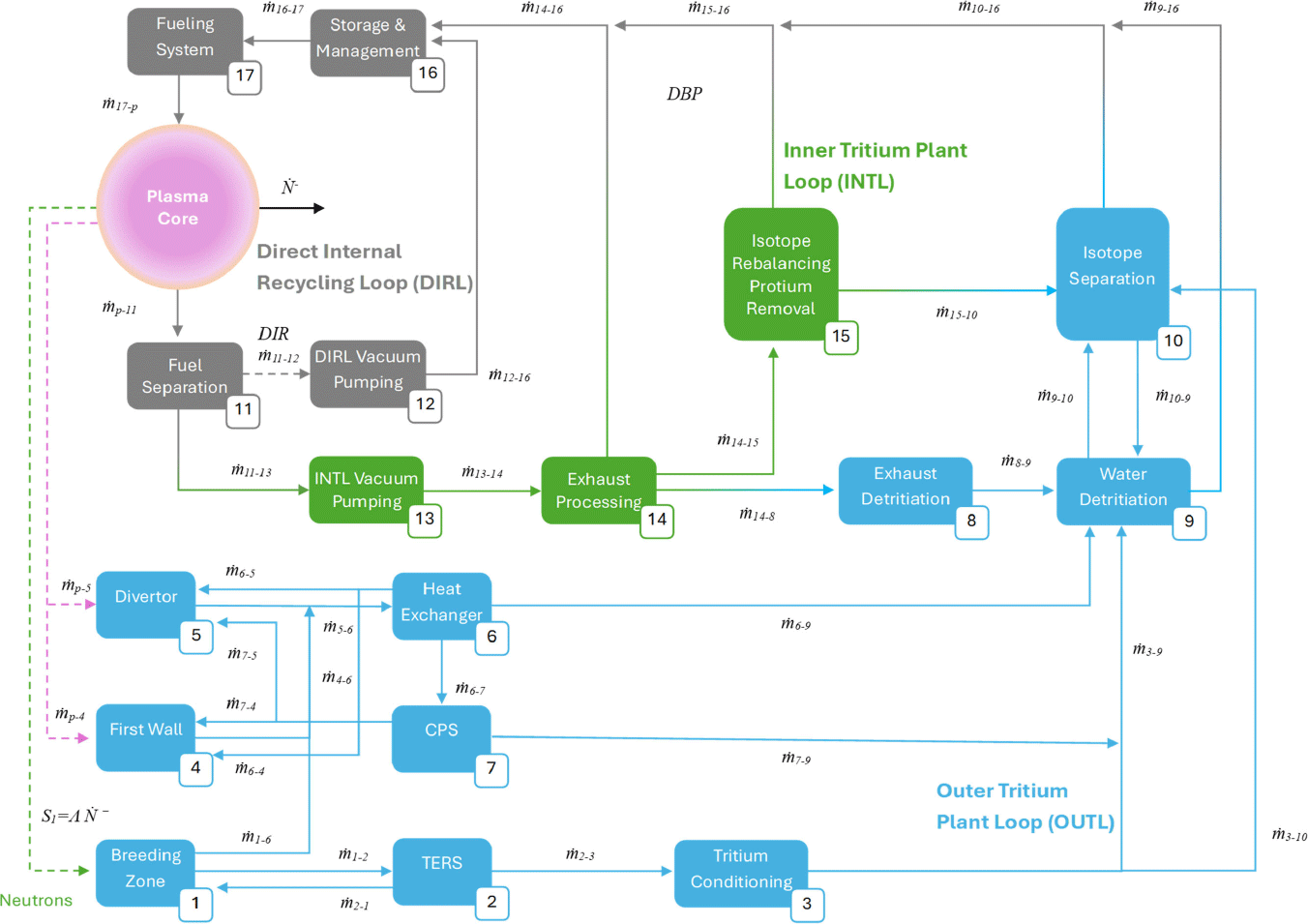

Figure 1. (a) The TBR and fast neutron fluence on the magnets vs homogenized breeder layer thickness. (b) The He concentration produced by transmutation in vacuum vessel per full-power year and dpa in vacuum vessel per full-power year vs breeder thickness. (c) The TBR and fast neutron fluence on the magnets vs radial build thickness reflecting that the blanket concepts differ in associated manifold sizes.

For each breeder blanket concept, in addition to variation in breeder and shielding thickness, parametric studies were also performed to determine the variation in neutronic response for various relevant parameters including

![]() $^{6}$

Li enrichment, multiplier material and composition, composition of structural material and composition of coolant material. The reference cases listed in the previous section were used as a basis for comparison. In addition, for the HCPB concept the neutronic performance of several novel breeder materials of interest was also studied. Figure 1(a) shows the change in TBR and full-power year fast neutron fluence incident on the magnets with increasing breeder layer thickness and a shielding thickness of 10 cm for the high-temperature shield and low-temperature shield, which is the minimum shielding in the cases studied. Figure 1(b) shows the same TBR and fast neutron fluence incident on magnets with increasing breeder thickness as in figure 1(a), but with respect to total radial build to reflect the fact that different breeder concepts differ in associated manifold sizes and support structures. Figure 1(c) shows He production and damage in the vacuum vessel with increasing breeder layer thickness. In figure 1(c) the concentration of He in the vacuum vessel material in appm was calculated from the He production tally in the vacuum vessel normalized to the atomic number density of material in the cell volume. The expected dpa in the vacuum vessel material was calculated from the mean damage energy tally in Fe for cases where the vacuum vessel material is steel (for the blanket concepts HCPB, DCLL, HCLL, SCLL); in vanadium, titanium and chromium for cases where the vacuum vessel material is V-4Ti-4Cr (SCLV); in nickel, iron and chromium, for cases where the vacuum vessel material is Inconel 718 (F-LIB). Data reduction was performed according to the following heuristic: the minimum breeder thickness was determined for each blanket concept for 10 cm each of high-temperature and low-temperature shielding which meets the magnet shielding constraints of less than 1

$^{6}$

Li enrichment, multiplier material and composition, composition of structural material and composition of coolant material. The reference cases listed in the previous section were used as a basis for comparison. In addition, for the HCPB concept the neutronic performance of several novel breeder materials of interest was also studied. Figure 1(a) shows the change in TBR and full-power year fast neutron fluence incident on the magnets with increasing breeder layer thickness and a shielding thickness of 10 cm for the high-temperature shield and low-temperature shield, which is the minimum shielding in the cases studied. Figure 1(b) shows the same TBR and fast neutron fluence incident on magnets with increasing breeder thickness as in figure 1(a), but with respect to total radial build to reflect the fact that different breeder concepts differ in associated manifold sizes and support structures. Figure 1(c) shows He production and damage in the vacuum vessel with increasing breeder layer thickness. In figure 1(c) the concentration of He in the vacuum vessel material in appm was calculated from the He production tally in the vacuum vessel normalized to the atomic number density of material in the cell volume. The expected dpa in the vacuum vessel material was calculated from the mean damage energy tally in Fe for cases where the vacuum vessel material is steel (for the blanket concepts HCPB, DCLL, HCLL, SCLL); in vanadium, titanium and chromium for cases where the vacuum vessel material is V-4Ti-4Cr (SCLV); in nickel, iron and chromium, for cases where the vacuum vessel material is Inconel 718 (F-LIB). Data reduction was performed according to the following heuristic: the minimum breeder thickness was determined for each blanket concept for 10 cm each of high-temperature and low-temperature shielding which meets the magnet shielding constraints of less than 1

![]() ${\times}$

10

${\times}$

10

![]() $^{18}$

n cm

$^{18}$

n cm

![]() $^{-2}$

per full-power year. The associated TBR was noted as well as whether this radial build satisfies vacuum vessel damage constraints. The results of this data reduction are listed in table 3. In this way the blanket concepts can be compared simultaneously on 3 axes: compactness of radial build, TBR and shielding.

$^{-2}$

per full-power year. The associated TBR was noted as well as whether this radial build satisfies vacuum vessel damage constraints. The results of this data reduction are listed in table 3. In this way the blanket concepts can be compared simultaneously on 3 axes: compactness of radial build, TBR and shielding.

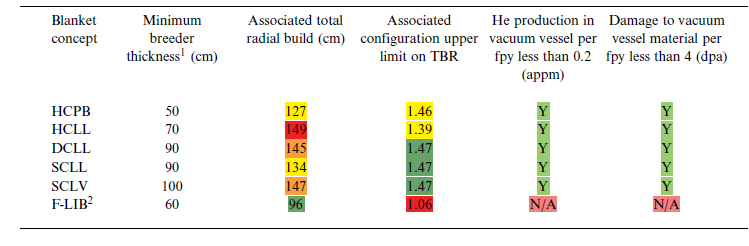

Table 3. Upper bound of tritium breeding performance for the blanket concepts of interest under standardized geometry and the minimum shielding needed to meet magnet and vacuum vessel lifetime requirements.

1 Minimum breeder thickness that meets n-fluence limit on magnets approximately 1E18 n/fpy.

2 No shielding between first wall and vacuum vessel incorporated into design; this design concept is incompatible with vacuum vessel as lifetime component.

These results indicate that the HCPB concept promises a very high upper bound TBR of 1.46 for a relatively mid-sized radial build, presenting a compromise between high tritium breeding performance and compact radial build. In addition, it is evident that the HCPB concept saturates at almost the highest TBR with the lowest breeder material loading. Finally, it is clear that solid ceramic breeder materials afford the greatest supplemental shielding effect to both the vacuum vessel and magnets for the most compact radial build, which benefits the economics of the T1E design in both minimizing the size and maximizing the lifetime of the device by minimizing the damage on lifetime components. This performance can be attributed to the higher atomic number density of the solid breeder materials even in the case of a pebble-based design, as well as the utilization of Be-based materials for highly effective neutron multiplication.

The breeding and shielding with material thickness of the DCLL was found to be intermediate between the SCLL and HCLL. This is expected because the DCLL supplements He cooling with PbLi cooling to offset some of the He manifold thickness resulting in a more compact radial build than the HCLL but not quite as compact as the SCLL. On the other hand, the DCLL exhibits a higher TBR than the HCLL as expected due to the higher PbLi mass loading in the device. Of all liquid PbLi concepts, the SCLL is by far the most compact and tritium breeding-efficient. From figure 1 and table 3, it can be seen that the PbLi designs and SCLV promise the highest saturated TBR (approximately 1.47), but also have the highest associated total radial build requirements, with their performance being comparable. The key difference between these concepts is the requirement for

![]() $^{6}$

Li enrichment, where the pure lithium holds a clear advantage by utilizing natural enrichment versus the 90 % enrichment utilized by the PbLi concepts. The large radial builds required for the liquid metal concepts can be attributed to the lower moderation and multiplication efficacy of liquid metals, which negatively impacts both breeding and shielding performance.

$^{6}$

Li enrichment, where the pure lithium holds a clear advantage by utilizing natural enrichment versus the 90 % enrichment utilized by the PbLi concepts. The large radial builds required for the liquid metal concepts can be attributed to the lower moderation and multiplication efficacy of liquid metals, which negatively impacts both breeding and shielding performance.

Figure 1 and table 3 show that the F-LIB concept achieves a TBR greater than unity at the smallest radial builds, but it also saturates at lower values (1.09) and ultimately is the only concept which fails to meet the target TBR of 1.35. Regarding shielding, it is evident that the F-LIB concept provides the greatest shielding to the magnets thanks to the high neutron moderating and absorbing properties of FLiBe constituent nuclides, although it is this shielding capability that ultimately limits the saturated TBR due to self-shielding effects. These findings are consistent with prior neutronics studies of the F-LIB (Segantin et al. Reference Segantin, Testoni, Hartwig, Whyte and Zucchetti2020), and although opportunities exist for refinement and potential improvement of the TBR in FLiBe-based blankets through the careful tailoring of

![]() $^{6}$

Li enrichment, multiplier content and detailed layout (Segantin et al. Reference Segantin, Testoni, Hartwig, Whyte and Zucchetti2020; Boullon et al. Reference Boullon, Jaboulay and Aubert2021), such optimizations were outside the scope of this study. In addition, the F-LIB concept is not conceived with the intention of the vacuum vessel being a lifetime component, which explains why its design precludes any substantial shielding of the vacuum vessel and neutron fluence is permitted to exceed material damage limits. Finally, it should be noted that this particular reference design assumed zero structure in the blanket, which is not currently envisioned as being applicable to the T1E high-field stellarator approach. This is due to specific design decisions which require structural elements for supporting the vacuum vessel, tank sector separators for modularity and penetrations for plasma access. In addition to the lowest saturated TBR, the F-LIB concept was also found to be sensitive to this additional structure requirement which negatively impacts the TBR.

$^{6}$

Li enrichment, multiplier content and detailed layout (Segantin et al. Reference Segantin, Testoni, Hartwig, Whyte and Zucchetti2020; Boullon et al. Reference Boullon, Jaboulay and Aubert2021), such optimizations were outside the scope of this study. In addition, the F-LIB concept is not conceived with the intention of the vacuum vessel being a lifetime component, which explains why its design precludes any substantial shielding of the vacuum vessel and neutron fluence is permitted to exceed material damage limits. Finally, it should be noted that this particular reference design assumed zero structure in the blanket, which is not currently envisioned as being applicable to the T1E high-field stellarator approach. This is due to specific design decisions which require structural elements for supporting the vacuum vessel, tank sector separators for modularity and penetrations for plasma access. In addition to the lowest saturated TBR, the F-LIB concept was also found to be sensitive to this additional structure requirement which negatively impacts the TBR.

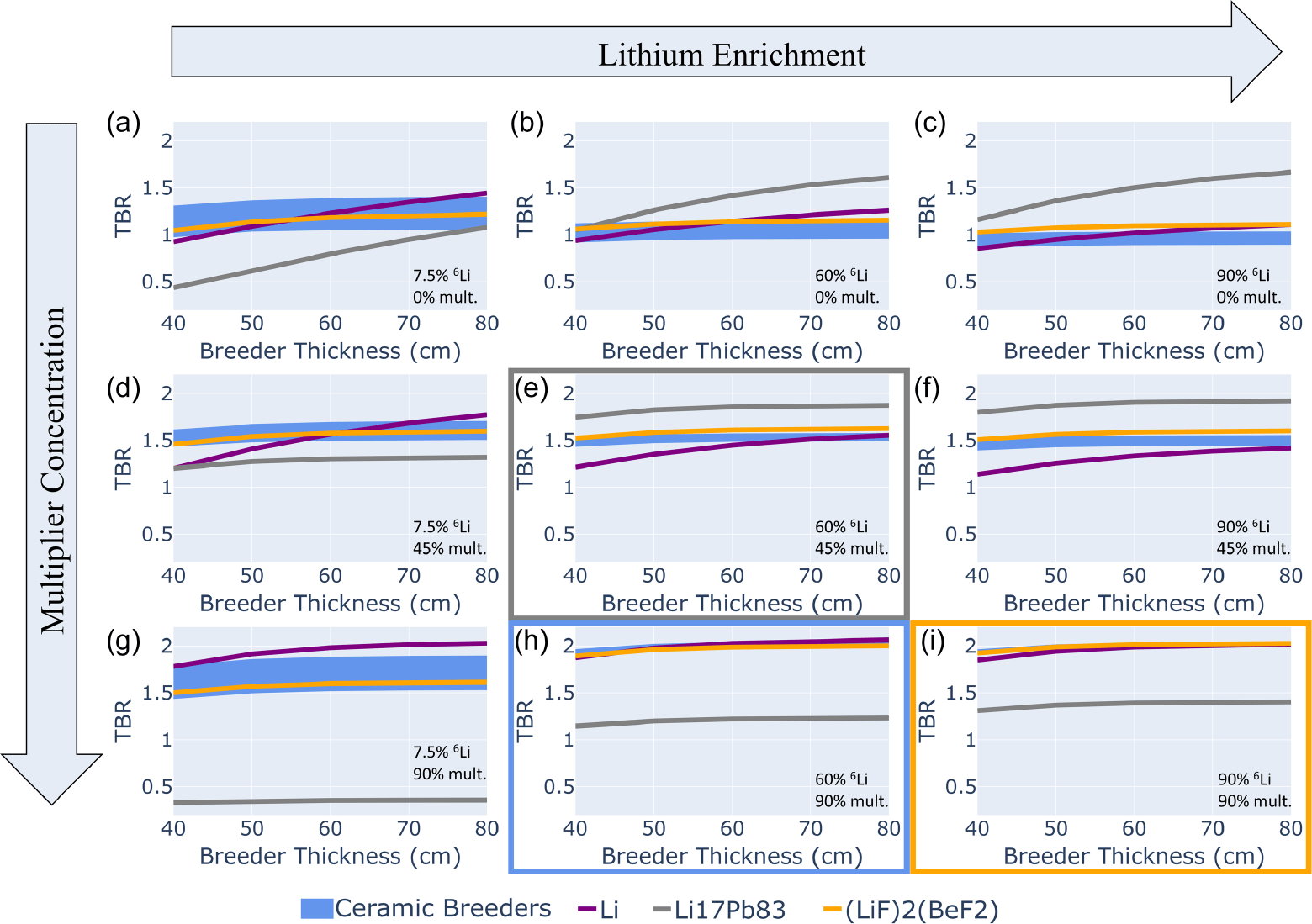

As a supplement to the reference configurations above, a wide variety of neutronics calculations in simplified geometric approximations were performed to better probe and understand the overall design space for breeder concepts consistent with prior studies (Zheng & Wu Reference Zheng and Wu2003), but using modern tools and more representative geometries. One such example is shown in figure 2, where the TBR was calculated for various breeder materials mixed homogeneously with concentrations of multiplier (Be

![]() $_{12}$

Ti) increasing in the y-direction. The relationship between breeder thickness and TBR was then calculated at enrichments increasing in the x-direction and with varying multiplier material content in the breeder region. This analysis enables a comparison of breeder materials from the point of view of resource utilization, where designs utilizing low

$_{12}$

Ti) increasing in the y-direction. The relationship between breeder thickness and TBR was then calculated at enrichments increasing in the x-direction and with varying multiplier material content in the breeder region. This analysis enables a comparison of breeder materials from the point of view of resource utilization, where designs utilizing low

![]() $^{6}$

Li enrichment and low Be multiplier loading are most desirable, although the detailed optimization of engineering, safety and cost trade-off between these two aspects is still an open question requiring resolution. The compactness of the radial build is reflected by the breeder thickness as a proxy.

$^{6}$

Li enrichment and low Be multiplier loading are most desirable, although the detailed optimization of engineering, safety and cost trade-off between these two aspects is still an open question requiring resolution. The compactness of the radial build is reflected by the breeder thickness as a proxy.

Figure 2. Relationships of breeder thickness and TBR using (a) natural lithium without multiplying material, (b) 60 wt %

![]() $^{6}$

Li enrichment without multiplying material, (c) 90 wt %

$^{6}$

Li enrichment without multiplying material, (c) 90 wt %

![]() $^{6}$

Li enrichment without multiplying material, (d) natural lithium with 45 wt % multiplying material, (e) 60 wt %

$^{6}$

Li enrichment without multiplying material, (d) natural lithium with 45 wt % multiplying material, (e) 60 wt %

![]() $^{6}$

Li enrichment with 45 wt % multiplying material, (f) 90 wt %

$^{6}$

Li enrichment with 45 wt % multiplying material, (f) 90 wt %

![]() $^{6}$

Li enrichment with 45 wt % multiplying material, (g) natural lithium with 90 wt % multiplying material, (h) 60 wt %

$^{6}$

Li enrichment with 45 wt % multiplying material, (g) natural lithium with 90 wt % multiplying material, (h) 60 wt %

![]() $^{6}$

Li enrichment with 90 wt % multiplying material and (i) 90 wt %

$^{6}$

Li enrichment with 90 wt % multiplying material and (i) 90 wt %

![]() $^{6}$

Li enrichment with 90 wt % multiplying material. For the three ceramic breeder materials of interest, the blue shaded regions show the maximum TBR for the lowest resource utilization.

$^{6}$

Li enrichment with 90 wt % multiplying material. For the three ceramic breeder materials of interest, the blue shaded regions show the maximum TBR for the lowest resource utilization.

The superiority of solid breeder materials Li

![]() $_{2}$

O, Li

$_{2}$

O, Li

![]() $_{4}$

SiO

$_{4}$

SiO

![]() $_{4}$

and Li

$_{4}$

and Li

![]() $_{2}$

TiO

$_{2}$

TiO

![]() $_{3}$

is highlighted by figure 2(d) where compact radial builds with breeder thicknesses as low as 50 cm, multiplier concentration as low as 45 weight percent (wt %) and

$_{3}$

is highlighted by figure 2(d) where compact radial builds with breeder thicknesses as low as 50 cm, multiplier concentration as low as 45 weight percent (wt %) and

![]() $^{6}$

Li enrichment as low as natural

$^{6}$

Li enrichment as low as natural

![]() $^{6}$

Li abundance can achieve TBR approximately 1.6, the highest of all materials. Using natural lithium and less than 45 wt % of multiplying material mixed with the breeder material, Li

$^{6}$

Li abundance can achieve TBR approximately 1.6, the highest of all materials. Using natural lithium and less than 45 wt % of multiplying material mixed with the breeder material, Li

![]() $_{2}$

O generally outperformed the other breeding materials up to thicknesses of 70 cm. The TBR calculated using natural liquid lithium was slightly higher than Li

$_{2}$

O generally outperformed the other breeding materials up to thicknesses of 70 cm. The TBR calculated using natural liquid lithium was slightly higher than Li

![]() $_{2}$

O when using a 90 wt % composition of multiplying material. At low lithium enrichments and low multiplying material content, Li

$_{2}$

O when using a 90 wt % composition of multiplying material. At low lithium enrichments and low multiplying material content, Li

![]() $_{2}$

O has the highest TBR at depths relevant to T1E designs and implies a potential pathway for a natural lithium blanket beyond pure lithium metal.

$_{2}$

O has the highest TBR at depths relevant to T1E designs and implies a potential pathway for a natural lithium blanket beyond pure lithium metal.

The color-coded boxes show the maximum TBR for the lowest resource utilization for three breeder materials of interest: figure 2(e) was identified as the case showing the best TBR for liquid lead-lithium (gray), figure 2(i) was identified as the case showing the best TBR for FLiBe (yellow) and figure 2(h) was identified as the case showing the best TBR for Li

![]() $_{2}$

O, Li

$_{2}$

O, Li

![]() $_{4}$

SiO

$_{4}$

SiO

![]() $_{4}$

and Li

$_{4}$

and Li

![]() $_{2}$

TiO

$_{2}$

TiO

![]() $_{3}$

(blue). In this representation it becomes clear that liquid PbLi offers the highest TBR for the lowest absolute resource utilization of all cases of interest which highlights the attractiveness of the breeder material. It is also the breeder that performs the best in scenarios where only

$_{3}$

(blue). In this representation it becomes clear that liquid PbLi offers the highest TBR for the lowest absolute resource utilization of all cases of interest which highlights the attractiveness of the breeder material. It is also the breeder that performs the best in scenarios where only

![]() $^{6}$

Li enrichment is employed (figures 2

b and 2

c). FLiBe only offers superior TBR with maximum resource utilization; however, it is possible for FLiBe to achieve a TBR greater than unity with only natural

$^{6}$

Li enrichment is employed (figures 2

b and 2

c). FLiBe only offers superior TBR with maximum resource utilization; however, it is possible for FLiBe to achieve a TBR greater than unity with only natural

![]() $^{6}$

Li if the ‘compact radial build’ constraint was relaxed. In these circumstances, the TBR can benefit from elevated

$^{6}$

Li if the ‘compact radial build’ constraint was relaxed. In these circumstances, the TBR can benefit from elevated

![]() $^{7}$

Li reactions with increased moderation deeper into the FLiBe breeder material for increased

$^{7}$

Li reactions with increased moderation deeper into the FLiBe breeder material for increased

![]() $^{6}$

Li reactions.

$^{6}$

Li reactions.

The results of these studies using simplified approximations illustrate the parameter space for different breeding media and understand opportunities in nuclear design for breeder blankets. In general, it was found that solid breeders have the best, most well-rounded performance in regions of interest. PbLi was found to be the best breeder for scenarios where Be multiplier is undesirable. Similarly, pure lithium is the most apparent candidate for scenarios where

![]() $^{6}$

Li enrichment is undesirable, although opportunities exist for other breeders with proper optimization. Finally, FLiBe is the leading candidate for circumstances where shielding efficiency is a primary consideration.

$^{6}$

Li enrichment is undesirable, although opportunities exist for other breeders with proper optimization. Finally, FLiBe is the leading candidate for circumstances where shielding efficiency is a primary consideration.

3.3. Detailed three-dimensional analysis of paraStell models

This section discusses the application of the T1E automated space-claim algorithm to virtually build out non-uniform stellarator blanket structures for a given plasma configuration. This tool is being developed for the optimization of TBR constrained by shielding to meet lifetime needs. Additionally, it enables analysis of spatially resolved neutronics responses in various blanket structures for a given plasma configuration, including identification of regions most vulnerable to neutron damage. Given resource limitations, only the HCPB and DCLL blanket concepts were examined using these higher fidelity tools.

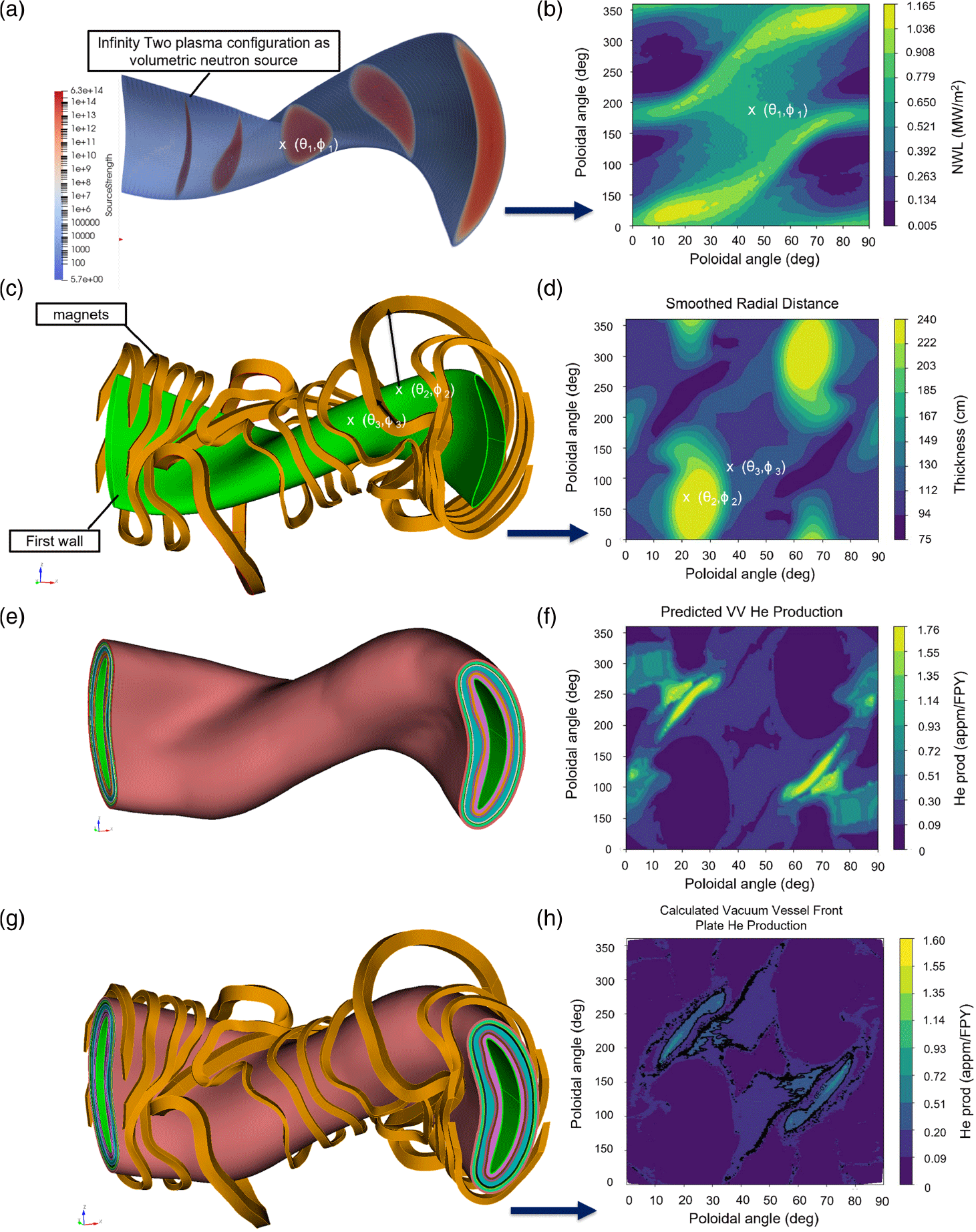

Figure 3. (a) Three-dimensional representation of neutron density of the Infinity Two plasma modeled as a volumetric neutron source. (b) Two-dimensional projection of the loading of neutron flux on the first wall due to neutron production from the plasma as a DT neutron source in units of MW/m

![]() $^{2}$

. (c) Three-dimensional CAD of the first wall based on Infinity Two geometry and its relevant magnets. (d) Output from radial distance finder algorithm: two-dimensional projection of radial space for building structures. (e) Three-dimensional CAD of the blanket structures automatically built out given the radial build space shown in figure 1(d). (f) An example of the He production in the vacuum vessel in this stellarator build predicted by the index. (g) Three-dimensional CAD of geometry definitions of blanket structures with magnets imported into OpenMC for neutronic simulations. (h) He production in the vacuum vessel in this stellarator buildout determined by neutronic simulations of the geometry in (g).

$^{2}$

. (c) Three-dimensional CAD of the first wall based on Infinity Two geometry and its relevant magnets. (d) Output from radial distance finder algorithm: two-dimensional projection of radial space for building structures. (e) Three-dimensional CAD of the blanket structures automatically built out given the radial build space shown in figure 1(d). (f) An example of the He production in the vacuum vessel in this stellarator build predicted by the index. (g) Three-dimensional CAD of geometry definitions of blanket structures with magnets imported into OpenMC for neutronic simulations. (h) He production in the vacuum vessel in this stellarator buildout determined by neutronic simulations of the geometry in (g).

This three-dimensional neutronics analysis made use of ParaStell, which is an open-source python code developed by Moreno et al. (Reference Moreno, Bader and Wilson2024) to automate the parametric computer-aided design (CAD) geometry generation of stellarator blanket structures with uniform thickness given the geometrical definition of the plasma, in this case, the Infinity Two configuration. As part of the workflow for the three-dimensional neutron transport simulations, the first step is to simulate the plasma as a volumetric neutron source with full fidelity of the distribution of DT reaction density in space (figure 3 a). This three-dimensional neutron source is used to derive the two-dimensional spatial distribution of 14.1 MeV neutron flux on the first wall, i.e. neutron wall loading (NWL) (figure 3 b).

It is evident that the radial distance normal from the stellarator first wall to the nearest bounding magnet is not uniform over the field period (figure 3 c). This means that blanket structure thickness can be optimized according to the neutron flux and available space in every radial direction. An optimized blanket build potentially has non-uniform breeder and shield thicknesses. The second step therefore is to obtain a matrix representing the radial distances between the last closed flux surface of the plasma and the magnets (figure 3 d). A proprietary tool was developed for this purpose.

The third step is to optimally allocate the available build space in each radial direction between breeder and shielding material and generate the geometry for every associated layer, as shown in figure 3(e). Figure 3(f) shows the first-order expected neutronic performance on one metric of interest based on this optimization, in this case for example He production by neutron-induced transmutation in the vacuum vessel. This first-order prediction is based on the index of neutronics responses in the relevant blanket build collated from the one-dimensional parametric neutronics study. The one-dimensional radial build configurations for each blanket concept collated are provided in Appendix A.

The blanket layer geometries are then combined with the magnet coil geometries as a full field period of the stellarator geometry (figure 3 g) for full neutronics simulations with OpenMC. Figure 3(h) shows the actual neutronics performance of this geometric model according to the simulation for the same metric – He production in vacuum vessel. The spatial distribution of He-production hotspots predicted in figure 3(f) accurately reflects the distribution obtained in the full simulation.

The radial build space available for the Infinity Two configuration and coil set is shown in figure 3(d), with brighter regions indicating where in toroidal, poloidal space the magnets afford a wider berth for the potential insertion of more breeder or shielding material. The available radial build distance map is dictated only by plasma configuration and coil set, and is therefore independent of the blanket concept. The NWL response matrix (figure 3 b) dictates the net shielding on the magnets required, thereby informing the assignment of breeder, high-temperature shield and low-temperature shield thicknesses constrained by radial build space (figure 3 d). The radial build layers for HCPB are shown in Appendix A, figure 10 and the radial build layers for DCLL are shown in Appendix A, figure 12. The primary difference between the HCPB layers and DCLL layers outside of breeder layer compositions (including breeder material, multiplier and structural materials) and its back wall (abbreviated ‘bw’ in the diagram) are the size of the manifold: the HCPB reference concept was designed for the manifold layer to scale with the breeder layer; the DCLL reference concept was designed for a uniform manifold layer, with radial thickness of 6 cm.

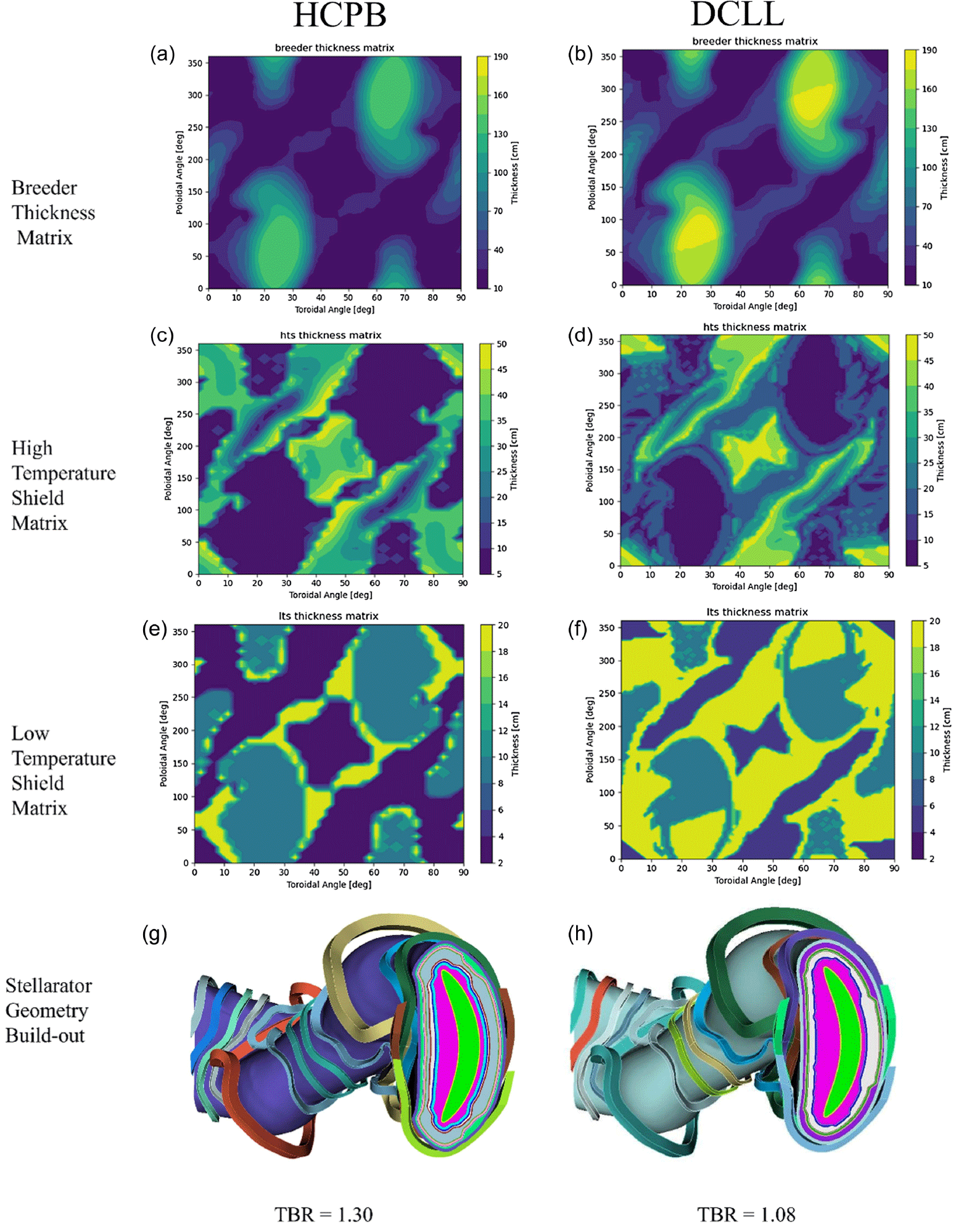

Figure 4. (a) Breeder thickness matrix in (

![]() $\theta$

,

$\theta$

,

![]() $\phi$

), HCPB; (b) breeder thickness matrix in (

$\phi$

), HCPB; (b) breeder thickness matrix in (

![]() $\theta$

,

$\theta$

,

![]() $\phi$

), DCLL; (c) high-temperature shield thickness matrix in (

$\phi$

), DCLL; (c) high-temperature shield thickness matrix in (

![]() $\theta$

,

$\theta$

,

![]() $\phi$

), HCPB; (d) high-temperature shield thickness matrix in (

$\phi$

), HCPB; (d) high-temperature shield thickness matrix in (

![]() $\theta$

,

$\theta$

,

![]() $\phi$

), DCLL; (e) low-temperature shield thickness matrix in (

$\phi$

), DCLL; (e) low-temperature shield thickness matrix in (

![]() $\theta$

,

$\theta$

,

![]() $\phi$

), HCPB; (f) low-temperature shield thickness matrix in (

$\phi$

), HCPB; (f) low-temperature shield thickness matrix in (

![]() $\theta$

,

$\theta$

,

![]() $\phi$

), DCLL; (g) ParaStell geometry generated for HCPB layers; (h) ParaStell geometry generated for DCLL layers.

$\phi$

), DCLL; (g) ParaStell geometry generated for HCPB layers; (h) ParaStell geometry generated for DCLL layers.

The automated radial build algorithm resulted in the HCPB requiring a much thinner maximum radial build, reflected in the predominance of cooler hues in the color scale plot in the HCPB compared with DCLL, in figures 4(a) and 4(b). The algorithm assigned the HCPB a maximum breeder thickness of 143 cm (figure 4 a) to achieve TBR greater than 1 (unity) compared with the DCLL, which was assigned a maximum breeder thickness of 184 cm (figure 4 b) for similar results, both with comparable shielding. This represents the first major advantage of the HCPB concept over the DCLL concept in that a lower volume of breeder medium is required to achieve a superior TBR. However, it should be noted that the excess balance in the HCPB radial build was not assigned to breeder, high-temperature shield or low-temperature shield and instead was assigned as a manifold layer, which highlights a potential weakness of the HCPB concept which will be further investigated during detailed design activities. The second major advantage of the HCPB concept reflected in the models is that the resulting algorithmic build-out shows a shield design with far fewer contours for the HCPB – which is very desirable for ease of manufacturability – compared with the more DCLL shield design which shows widespread ripple-like contours. This effect is most evident in the high-temperature shields (figures 4 c and 4 d). The required low-temperature shield thickness is lower on average for the HCPB with predominance of cooler colors in the low-temperature shield thickness matrix (figure 4 e) as compared with the one for DCLL (figure 4 f).

The result of this automated buildout is represented by figure 4(g) for HCPB and figure 4(h) for DCLL. The difference in breeder material (pink layer in figures 4 g and 4 h) thickness required for each build for HCPB and DCLL is readily apparent: the DCLL requires a greater breeder material thickness than the HCPB. OpenMC neutronic simulations run with 300 M particles found the TBR for the HCPB case to be 1.30 and the DCLL case to be 1.08. These TBR results are deemed satisfactory at this stage given the level of fidelity as well as the results of § 5 and the various opportunities for continued improvement with subsequent iterations.

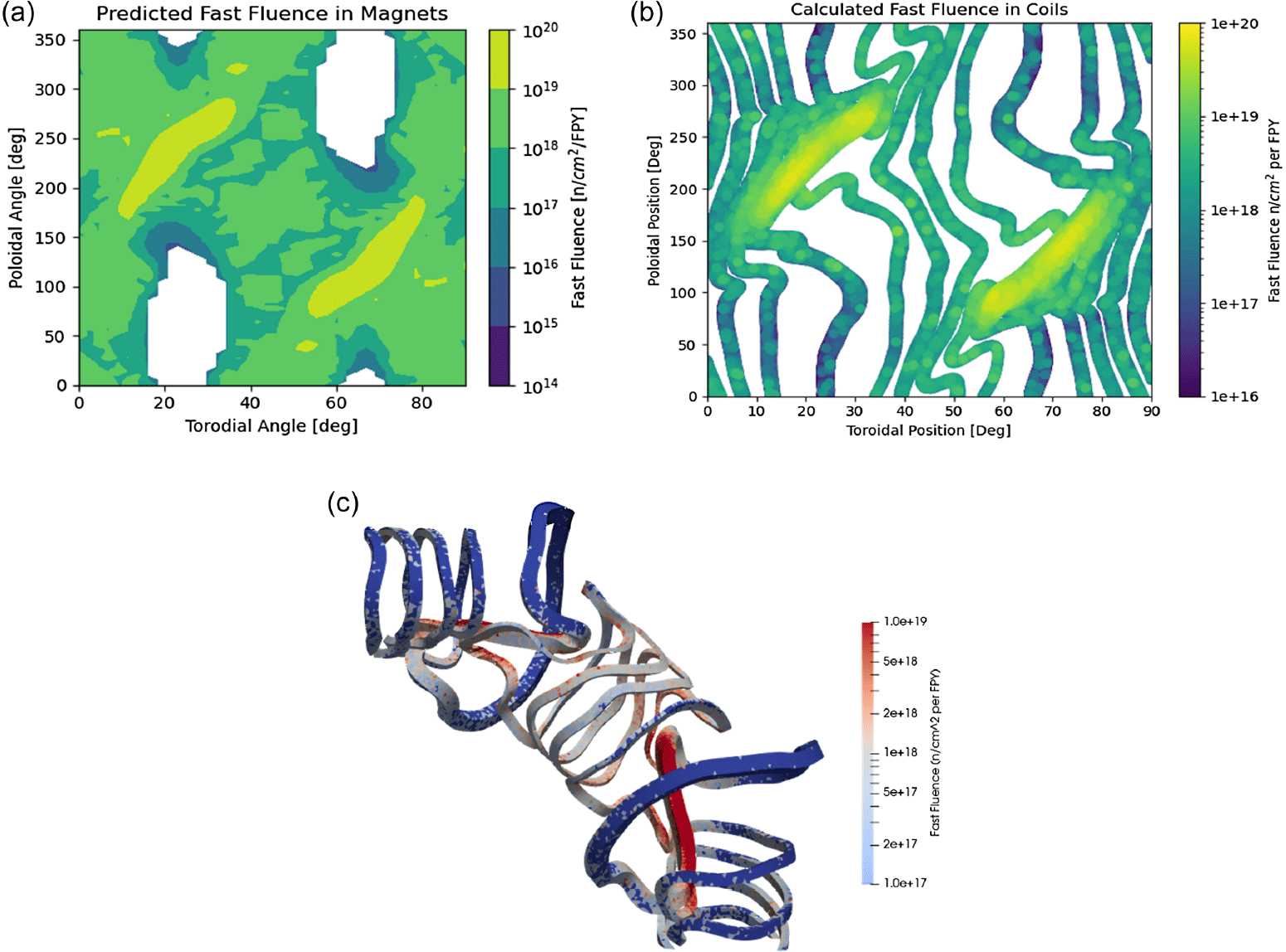

The combination of varying NWL and radial build thickness of the breeder/ shielding layers leads to the expectation that damage primarily occurs in highly localized regions of the various components of interest. The T1E high-throughput workflow enables rapid identification of the presence and location of these high-damage regions for any given plasma–magnet configuration which feeds back into the overall stellarator optimization workflow. To illustrate this point, figure 5(a) shows the mapping of the neutron fluence on the magnet regions in toroidal, poloidal coordinates, which can be rapidly produced without the need for time and computationally intensive three-dimensional neutronics. The blank zones in figure 5(a) reflect regions where predicted neutron fluence is so low that they fall outside the bounds of the developed neutronics response index. Compared with the full stellarator geometry simulation run over seven days on a high-performance computing cluster shown in figure 5(b), the rapid mapping has correctly identified the regions in which the neutron fluence limits are violated at greater than 1

![]() ${\times}$

10

${\times}$

10

![]() $^{18}$

n cm

$^{18}$

n cm

![]() $^{-2}$

per full-power year (green and warmer colors) to a first-order level of accuracy. A three-dimensional representation of the spatial distribution of fast neutron fluence on the magnets is shown in figure 5(c). White and blue regions indicate where the fluence on the magnets meet design constraints of less than or equal to

$^{-2}$

per full-power year (green and warmer colors) to a first-order level of accuracy. A three-dimensional representation of the spatial distribution of fast neutron fluence on the magnets is shown in figure 5(c). White and blue regions indicate where the fluence on the magnets meet design constraints of less than or equal to

![]() $1 \times 10^{18}$

n cm

$1 \times 10^{18}$

n cm

![]() $^{-2}$

per full-power year and red regions indicate where this constraint is violated with greater than 1

$^{-2}$

per full-power year and red regions indicate where this constraint is violated with greater than 1

![]() ${\times}$

10

${\times}$

10

![]() $^{18}$

n cm

$^{18}$

n cm

![]() $^{-2}$

per full-power year. Figure 5(c) generally reflects that hotspots are predicted mostly on the inboard side.

$^{-2}$

per full-power year. Figure 5(c) generally reflects that hotspots are predicted mostly on the inboard side.

Figure 5. (a) Two-dimensional spatial distribution of neutron fluence per full-power year at magnet locations in (

![]() $\theta$

,

$\theta$

,

![]() $\phi$

) predicted based on neutronics response index generated from the rapid optimization workflow step 2 for HCPB radial build configuration. (b) Two-dimensional spatial distribution of neutron fluence per full-power year at magnet locations in (

$\phi$

) predicted based on neutronics response index generated from the rapid optimization workflow step 2 for HCPB radial build configuration. (b) Two-dimensional spatial distribution of neutron fluence per full-power year at magnet locations in (

![]() $\theta$

,

$\theta$

,

![]() $\phi$

) based on full stellarator geometry simulation of HCPB radial build configuration. (c) Three-dimensional representation of space-resolved neutron fluence per full-power year on stellarator magnets based on full stellarator geometry simulation of HCPB radial build configuration.

$\phi$

) based on full stellarator geometry simulation of HCPB radial build configuration. (c) Three-dimensional representation of space-resolved neutron fluence per full-power year on stellarator magnets based on full stellarator geometry simulation of HCPB radial build configuration.

At this juncture, it must be emphasized that the results presented here are for a simplified neutronics model of an early design iteration and do not constitute a final, optimized radial build at full engineering fidelity. The current radial build model is a high-level placeholder for use in an initial scoping analysis, and it will be refined to incorporate opportunities for reduced component volumes and increased shielding performance moving forward. In addition, the radiation limits on lifetime components are dependent on design and in some cases are not based on quantities which are well understood, such as the radiation limits on high-temperature superconducting magnets (Unterrainer et al. Reference Unterrainer, Fischer, Lorenz and Eisterer2022). As such, they are subject to modification as both fundamental understanding and design fidelity improves. Given these points, the current findings show that the Infinity Two configuration has sufficient performance and no fundamental roadblocks exist towards the continued optimization of radial builds which will satisfy detailed performance and engineering requirements.

4. Thermal analysis

4.1. Introduction

This section presents a sensitivity analysis of the various blanket concepts and their possible integration with a Rankine thermodynamic cycle, which was selected as the baseline due in large part to its robust industrial base and existing supply chain. The primary focus of this study was to understand the potential of each concept for producing at least 100 MW

![]() $_{e}$

as a nominal minimum target for Infinity Two. To ensure flexibility in design space and allow operation over a range of fusion plasma power, a fusion plasma power of 400 MW

$_{e}$

as a nominal minimum target for Infinity Two. To ensure flexibility in design space and allow operation over a range of fusion plasma power, a fusion plasma power of 400 MW

![]() $_{\mathrm{th}}$

was used as the low-end baseline for evaluating this performance. The scalability of these results was also explored for designs up to 1000 MW

$_{\mathrm{th}}$

was used as the low-end baseline for evaluating this performance. The scalability of these results was also explored for designs up to 1000 MW

![]() $_{\mathrm{th}}$

of fusion plasma power. The blanket concepts and baseline design parameters evaluated in this study are listed in table 4.

$_{\mathrm{th}}$

of fusion plasma power. The blanket concepts and baseline design parameters evaluated in this study are listed in table 4.

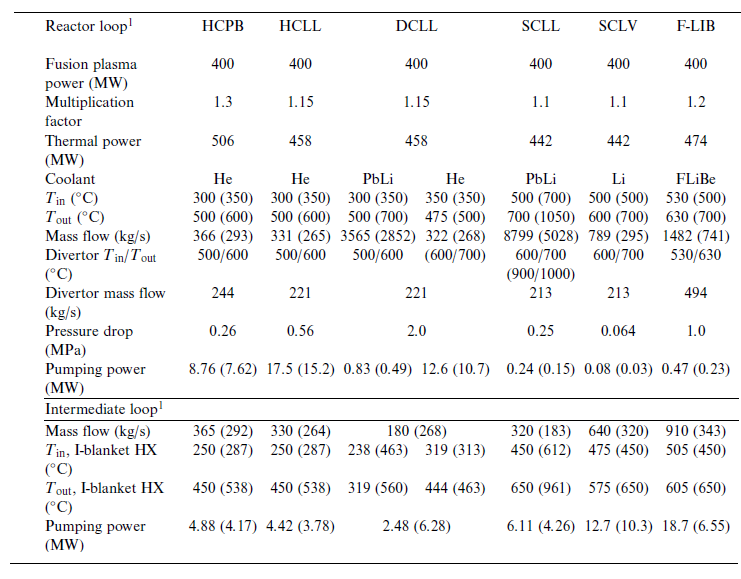

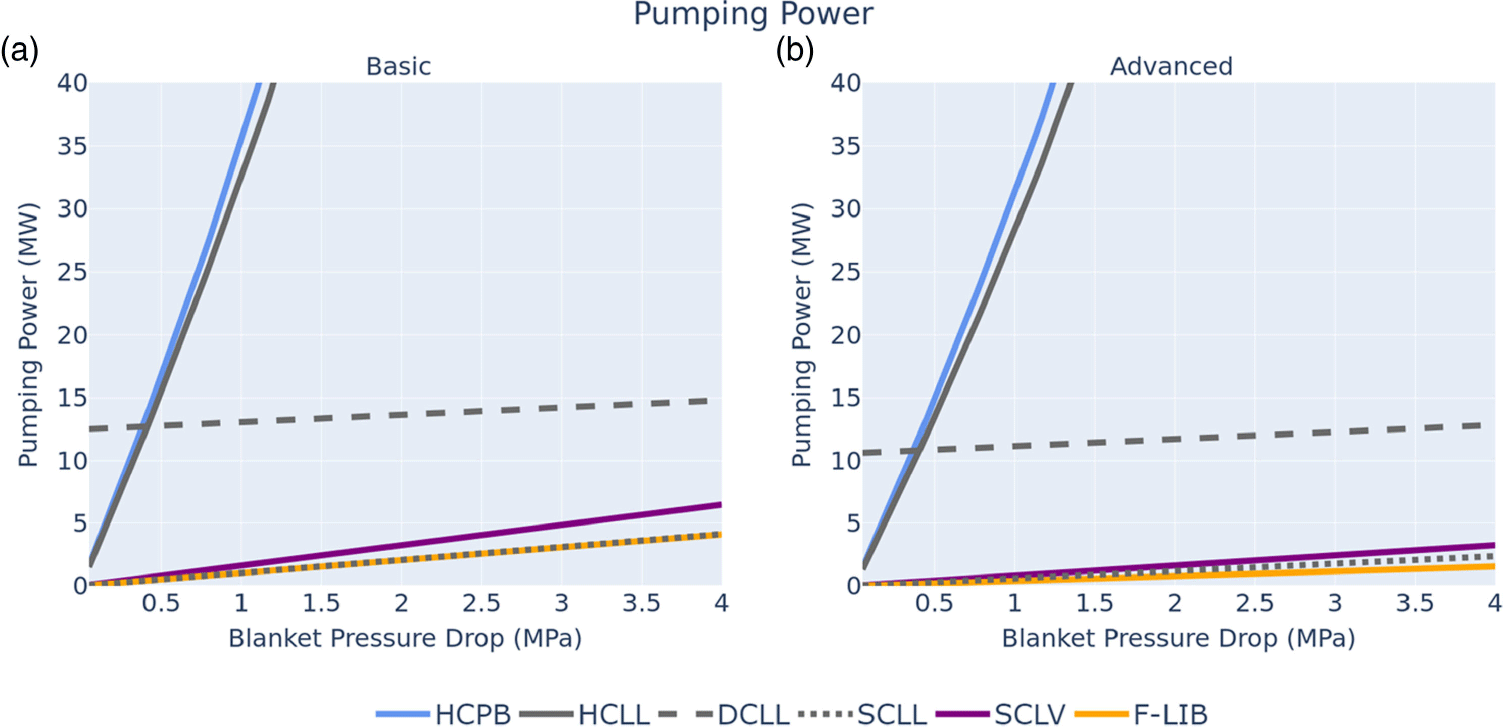

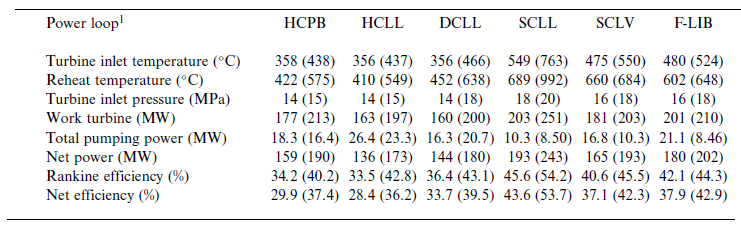

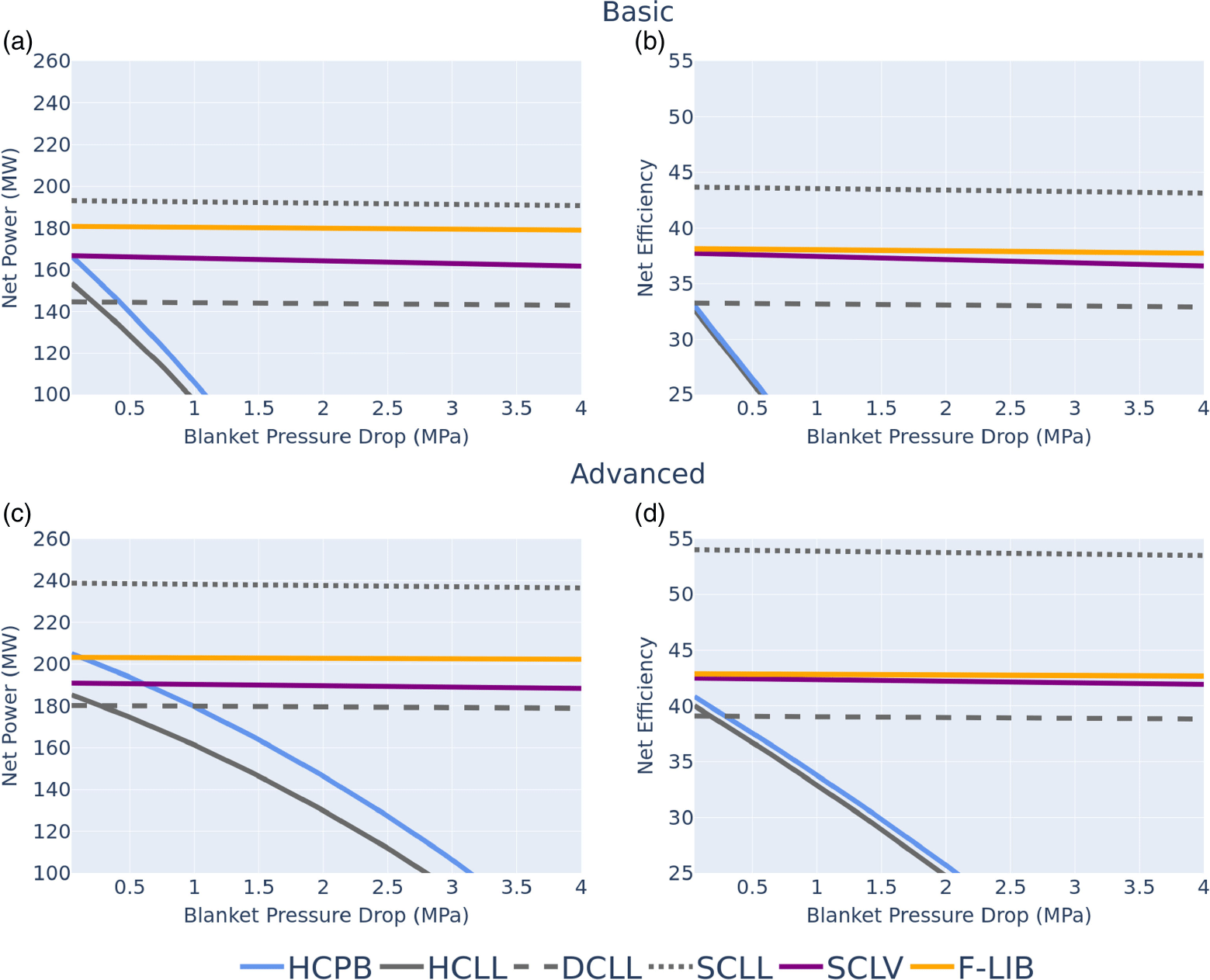

Table 4. Summarized thermal parameters for blanket concepts under consideration.

1 Values in each cell are for the basic concepts. Values in parentheses are for the advanced concepts.

In an MFE energy system, heat is distributed throughout the power core and high-grade heat sources typically include the blanket, the divertor and potentially the vacuum vessel, depending on design. For this analysis, only the blanket and divertor were considered as heat sources, with the assumption that all heat not directed at the divertor (conservatively assumed to be 25 %) is instead deposited in the blanket. In the case of the F-LIB concept, the internal vacuum vessel is cooled with molten salt which is discharged directly into the blanket and keeps in convention with this same assumption. In addition to the heat being deposited in the blanket, each concept has an additional neutron energy multiplication factor, which for the purposes of this study were assumed to be the same as those developed by El-Guebaly et al. (Reference El-Guebaly, Raffray, Malang, Lyon and Ku2005). This energy multiplication factor results in a different total thermal power for each blanket concept, assuming a standard fusion plasma power.

The pressure drops shown in table 4 are based on values found in the literature for each reference design (Sagara et al. Reference Sagara1997; Gohar et al. Reference Gohar, Majumdar and Smith2000; Giancarli et al. Reference Giancarli, Golfier, Nishio, Raffray, Wong and Yamada2002; Hernández et al. Reference Hernández, Pereslavtsev, Kang, Norajitra, Kiss, Nádasi and Bitz2017; Aubert et al. Reference Aubert2018; Smolentsev et al. Reference Smolentsev, Rhodes, Pulugundla, Courtessole, Abdou, Malang, Tillack and Kessel2018). The pumping power of each blanket concept was then calculated using the mass flow rate of the blanket and divertor using the assumed pressure drop from the literature. An isentropic efficiency of 100 % was assumed for all pumps/compressors used in the blanket loop given the variety of coolants used. Since the pressure drop is highly dependent on design specifics, it was varied parametrically to calculate the required pumping power and thus efficiency of each concept in this analysis across a range of potential values. Similarly, the operating temperatures, both high end and low end, are primarily dictated by the structural material of choice and compatibility with applicable coolants (Zinkle & Ghoniem Reference Zinkle and Ghoniem2000). In the case of the DCLL, the helium temperature range is not consistent throughout literature. For this reason, the helium temperature range in the DCLL was based on a similar temperature change but within the temperature range used in the references. The initial temperature ranges, as well as associated parameters like mass flow and pumping power, are shown in table 4 and are based on the baseline assumption for structural materials. If advanced materials become available, it is possible to broaden the temperature window of all the blankets concepts to improve overall performance (Zinkle & Ghoniem Reference Zinkle and Ghoniem2000). The second value in columns with multiple values in table 4 shows the parameters associated with designs which use these advanced materials. One point of note is that the SCLL only has an advanced design utilizing SiC composites, but in order to provide an additional comparison point between concepts a lower-temperature SCLL was run consistent with the SCLV advanced parameters, which are the values shown for the SCLL baseline configuration in table 4.

For this analysis, an intermediate heat transfer system using He was implemented between the primary loop and the Rankine cycle loop for all blanket concepts. The parameters for these intermediate loops are shown in the intermediate loop section of table 4. The intermediate loop serves as a barrier separating the water in the Rankine loop from the breeder in the blanket loop, which may contain tritium and liquid lithium-based coolants, depending on the concept. These liquid lithium-based coolants can have strong reactions to water at elevated temperatures, which could potentially lead to exothermic reactions and/or explosivity, and the intermediate loop helps to prevent such interactions. It also helps to avoid the creation of tritiated water. Both phenomena have safety and economic implications and for these reasons, gaseous, relatively inert coolants like He or CO

![]() $_{2}$

are considered for the intermediate loop. Other types of coolants such as molten salts have been considered for the same reasons above, with the benefit of serving in a thermal storage capacity which is important for pulsed concepts such as the tokamak (Barucca et al. Reference Barucca2021). Some concepts like the HCPB do not necessarily require an intermediate loop, but an intermediate loop was assumed as a baseline for all concepts to better compare performance under equitable conditions. An analysis without an intermediate loop was also performed for the relevant concepts and is discussed further in § 4.3.

$_{2}$

are considered for the intermediate loop. Other types of coolants such as molten salts have been considered for the same reasons above, with the benefit of serving in a thermal storage capacity which is important for pulsed concepts such as the tokamak (Barucca et al. Reference Barucca2021). Some concepts like the HCPB do not necessarily require an intermediate loop, but an intermediate loop was assumed as a baseline for all concepts to better compare performance under equitable conditions. An analysis without an intermediate loop was also performed for the relevant concepts and is discussed further in § 4.3.

For the power loop, a Rankine cycle with reheat was analyzed. The temperature-entropy (T-S) diagram and the cycle configuration are shown in figure 17 in Appendix A. In this configuration, the blanket heat is deposited in the intermediate loop and used to create superheated steam in the Rankine cycle loop. The divertor heat is used to reheat the steam in the Rankine side. A temperature difference of 100

![]() $^\circ$

C between the maximum intermediate loop temperature and the inlet turbine temperature was assumed. Other assumptions include an isentropic efficiency of 0.85 for both the pump and the turbine. The steam quality at the turbine outlet was set to 0.90 for the lower-temperature end pressure cycles and to 0.99 for the higher-temperature end pressure cycles. A pressure drop of 0.5 MPa was used for every heat exchanger. Recirculating power for auxiliary systems, plasma heating and other sources of pressure drop apart from the pressure drop in the blanket loop were not considered in the analysis.

$^\circ$

C between the maximum intermediate loop temperature and the inlet turbine temperature was assumed. Other assumptions include an isentropic efficiency of 0.85 for both the pump and the turbine. The steam quality at the turbine outlet was set to 0.90 for the lower-temperature end pressure cycles and to 0.99 for the higher-temperature end pressure cycles. A pressure drop of 0.5 MPa was used for every heat exchanger. Recirculating power for auxiliary systems, plasma heating and other sources of pressure drop apart from the pressure drop in the blanket loop were not considered in the analysis.

A python script was developed to perform the parametric analysis capable of calculating how the mass flow rate, net power and efficiency changed with varying conditions like blanket pressure drop, fusion power, steam quality, etc. using the energy balance equation. The IAPWS R 7–97(2012) python module was used to calculate all the thermodynamic states of steam in the Rankine cycle loop. The module requires two initial parameters (pressure, temperature, entropy, enthalpy or steam quality) to return the remaining thermodynamic parameters needed.

4.2. Intermediate loop and blanket pressure drop analysis

An analysis of the primary blanket heat exchanger between the blanket and the intermediate loop was performed to understand performance discrepancies between concepts. The outlet temperature of the blanket/intermediate heat exchanger shown in table 4 was calculated using the effectiveness-number of transfer units (

![]() $\epsilon$

-NTUs) method. As shown in table 4, the DCLL blanket requires the smallest intermediate coolant mass flow rate due to the usage of dual coolants and heat exchangers for the transfer of heat to the intermediate loop. Since the heat is divided across two different coolants (46 % of the heat removed by He and the rest by PbLi (Wang et al. Reference Wang, Tillack, Koehly, Malang, Toudeshki and Najmabadi2015)), the heat capacity rate of the PbLi is the smallest out of all the analyzed designs, meaning that it is more suitable for transferring heat. The end result is that less intermediate coolant is needed to extract heat in the PbLi heat exchanger. The He heat exchanger is then used to further heat the intermediate coolant after the PbLi heat exchanger. Although the SCLL is also cooled by PbLi, its blanket mass flow rate is almost double that of the DCLL resulting in a higher heat capacity rate than the DCLL. As a result, the SCLL requires approximately twice as much intermediate coolant as the DCLL. The HCPB, HCLL and SCLL all have similar heat capacity rates leading to similar intermediate coolant mass flow rates. In contrast, the SCLV and FLiBe blanket will require the largest intermediate loop, as they need the most intermediate coolant due to their higher heat capacity rate.

$\epsilon$

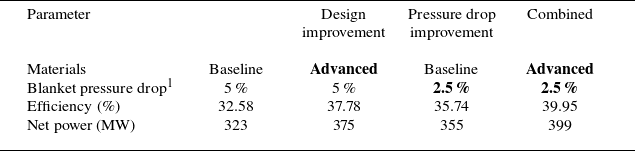

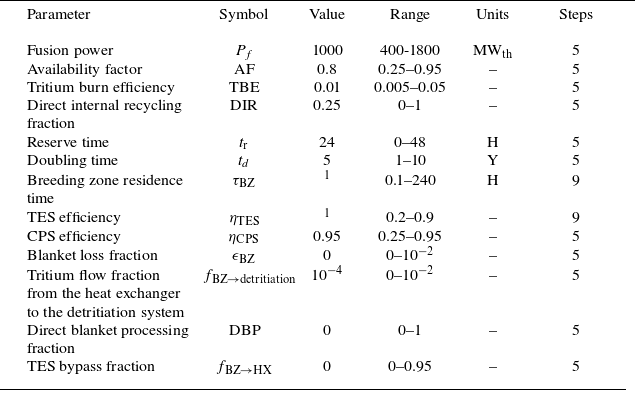

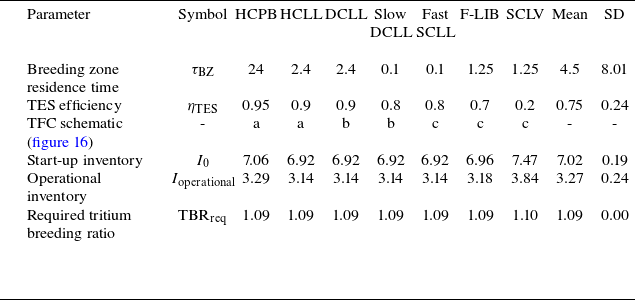

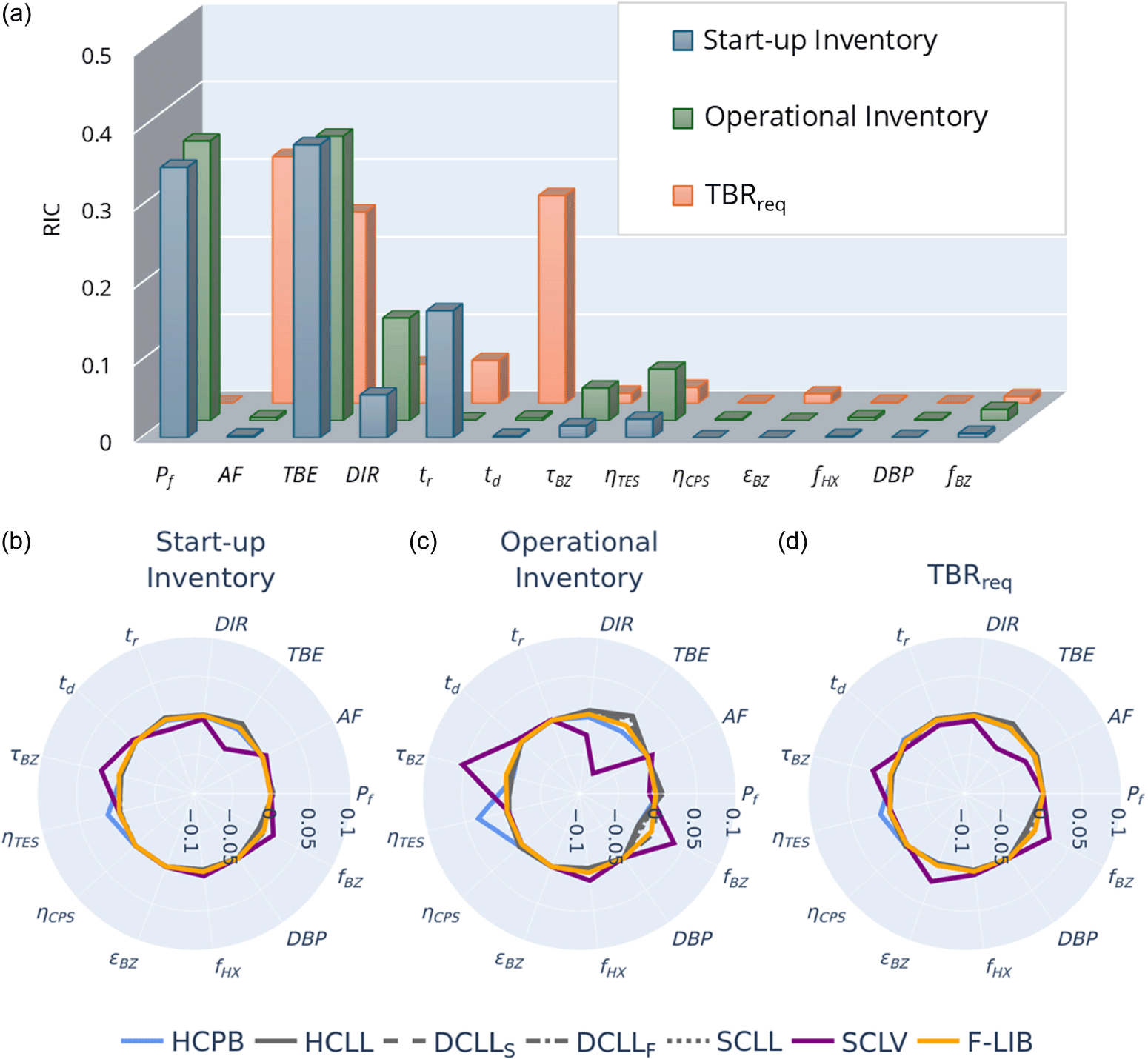

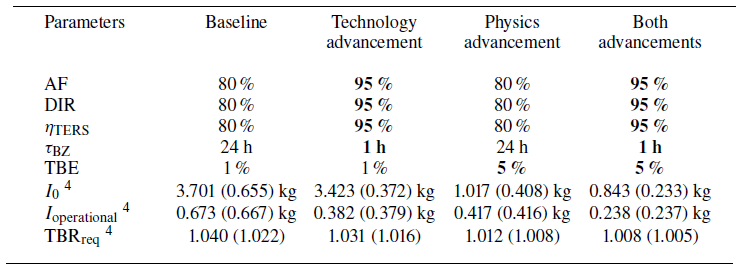

-NTUs) method. As shown in table 4, the DCLL blanket requires the smallest intermediate coolant mass flow rate due to the usage of dual coolants and heat exchangers for the transfer of heat to the intermediate loop. Since the heat is divided across two different coolants (46 % of the heat removed by He and the rest by PbLi (Wang et al. Reference Wang, Tillack, Koehly, Malang, Toudeshki and Najmabadi2015)), the heat capacity rate of the PbLi is the smallest out of all the analyzed designs, meaning that it is more suitable for transferring heat. The end result is that less intermediate coolant is needed to extract heat in the PbLi heat exchanger. The He heat exchanger is then used to further heat the intermediate coolant after the PbLi heat exchanger. Although the SCLL is also cooled by PbLi, its blanket mass flow rate is almost double that of the DCLL resulting in a higher heat capacity rate than the DCLL. As a result, the SCLL requires approximately twice as much intermediate coolant as the DCLL. The HCPB, HCLL and SCLL all have similar heat capacity rates leading to similar intermediate coolant mass flow rates. In contrast, the SCLV and FLiBe blanket will require the largest intermediate loop, as they need the most intermediate coolant due to their higher heat capacity rate.