1. Introduction

Thanks to their remarkable features such as large surface-to-volume ratio and high porosity, nanofibre webs underpin many everyday technologies, from scaffold production for tissue regeneration in tissue engineering (Barbosa et al. Reference Barbosa, Villarreal, Rodriguez, De Leon, Gilkerson and Lozano2021), drug delivery in medical technologies and nano-filtration of water and air, to sensor production (Huang et al. Reference Huang, Zhang, Kotaki and Ramakrishna2003; Nayak et al. Reference Nayak, Padhye, Kyratzis, Truong and Arnold2011; Rogalski, Bastiaansen & Peijs Reference Rogalski, Bastiaansen and Peijs2017; Zhang et al. Reference Zhang, Duan, Xu and Zhang2019). The development of the recently invented centrifugal spinning (CS) methods (also known as forcespinning or rotary jet spinning), to fabricate non-woven nanofibre webs, brings important new opportunities for the mass production of nanofibres, from both polymer solutions and melts. In the CS process, jets of polymer melt or solution emerge from a rapidly rotating nozzle under the centrifugal force. As the jets evolve through the space, they stretch into very thin and long fibres, until they land on collectors where the resultant nanofibre web is assembled. However, despite its simplicity, the CS process suffers from jet instabilities which can cause the jet (throughout this work, the terms ‘fibre’ and ‘jet’ are used alternatively) to break into arrays of drops or lead to beaded fibre formation, in both of which scenarios the resultant web is considered low grade or even low quality. On the other hand, with the CS technology still being at the early development stages, several fundamental aspects of the CS process are still unknown to date, especially due to the complexity of the interconnected phenomena and the variety of competing forces involved (Noroozi & Taghavi Reference Noroozi and Taghavi2020).

Through the CS process, as the centrifugally driven jet evolves, it is influenced by a myriad of forces and phenomena, including e.g. inertial, viscous, surface tension, gravitational and centrifugal forces (Badrossamay et al. Reference Badrossamay, Mcllwee, Goss and Parker2010; Andrade et al. Reference Andrade, Santo, Costa and Lobo2017; Atıcı, Ünlü & Yanilmaz Reference Atıcı, Ünlü and Yanilmaz2021); there also exist other factors such as solvent evaporation, heat transfer effects (temperature variation) and geometrical parameters (Padron et al. Reference Padron, Fuentes, Caruntu and Lozano2013; Lai et al. Reference Lai, Wang, Liu, Li, Zhang and Chen2021). The interactions of these phenomena and forces, coupled with inherently complex viscoelastic features of the rotating fibre, may cloud our interpretation of the effects of each individual parameter on the process performance. Among the key forces and phenomena, investigating the viscoelastic properties of a rotating jet is of significance, due largely to their complex and nonlinear behaviours, which may even affect the jet dynamics in a counterintuitive way.

Although many experimental studies have been dedicated to characterizing the CS process, such as Chen et al. (Reference Chen, Wang, Lai, Zhang and Wu2021), Li et al. (Reference Li, Lu, Hou, Zhou, Wang, Zhang and Yang2020), Lu et al. (Reference Lu, Li, Zhang, Xu, Fu, Lee and Zhang2013), Ren et al. (Reference Ren, Pandit, Elkin, Denman, Cooper and Kotha2013), Weitz et al. (Reference Weitz, Harnau, Rauschenbach, Burghard and Kern2008), Mary et al. (Reference Mary, Senthilram, Suganya, Nagarajan, Venugopal, Ramakrishna and Giri Dev2013), Zhmayev et al. (Reference Zhmayev, Divvela, Ruo, Huang and Joo2015) and Ren et al. (Reference Ren, Ozisik, Kotha and Underhill2015), the experimental investigations require long-term investments of fund and time and, ultimately, they are not able to provide a rigorous prediction of the effects of key flow parameters on the resultant fibre and its web quality. On the other hand, although mathematical modelling of the CS process can provide promising insight into the process, there exist several limitations and constraints that one encounters when using mathematical modelling techniques to address thin viscous fibre flows.

There exist mainly two techniques that one can pursue to mathematically model the CS process, namely, the string models and the Cosserat rod models. At a first glance, thanks to its mathematical simplicity, it may seem straightforward/easy to use the classic string model approaches, also known as thin fibre or asymptotic models, to analyse the CS process. The string methods are based on slender body theories, providing a framework to predict the dynamic behaviour of a jet flow whose radius of curvature is large compared with its radius (see e.g. Noroozi et al. Reference Noroozi, Arne, Larson and Taghavi2020). However, the classic string models suffer from near-nozzle singularities that arise due to ignoring terms related to bending and twisting in these regions (Götz et al. Reference Götz, Klar, Unterreiter and Wegener2008; Arne et al. Reference Arne, Marheineke, Meister and Wegener2010; Noroozi et al. Reference Noroozi, Alamdari, Arne, Larson and Taghavi2017). Unless a remedy is used to overcome the near-nozzle singularities, the string models cannot be correctly applied to predict the viscous curved jet behaviours in the CS process.

During the last decade, several works have relied on the string models to investigate the impacts of different parameters in rotating jet systems, such as prilling or glass particle production processes, all sharing the same mechanism in producing micro- or nanofibres. Many studies such as Caruntu, Padron & Lozano (Reference Caruntu, Padron and Lozano2021), Shikhmurzaev & Sisoev (Reference Shikhmurzaev and Sisoev2017), Wallwork et al. (Reference Wallwork, Decent, King and Schulkes2002), Decent, King & Wallwork (Reference Decent, King and Wallwork2002), Panda (Reference Panda2006), Părău et al. (Reference Părău, Decent, Simmons, Wong and King2007) and Marheineke & Wegener (Reference Marheineke and Wegener2009) have considered the effects of gravity, surface tension and polymer solution viscosity on the jet morphology, radius and instability using the string model. Some non-Newtonian effects, such as shear thinning and viscoelastic effects, on the curved jet instability have been investigated by Uddin, Decent & Simmons (Reference Uddin, Decent and Simmons2008), Uddin & Decent (Reference Uddin and Decent2009, Reference Uddin and Decent2010), Hawkins et al. (Reference Hawkins, Gurney, Decent, Simmons and Uddin2010), Alsharif, Uddin & Afzaal (Reference Alsharif, Uddin and Afzaal2015), Alsharif & Uddin (Reference Alsharif and Uddin2015) and Marheineke et al. (Reference Marheineke, Liljegren-Sailer, Lorenz and Wegener2016). Nevertheless, a few studies have been dedicated to solving the singularity problem of the string techniques. To eliminate the near-nozzle singularity for the CS applications, Noroozi et al. (Reference Noroozi, Arne, Larson and Taghavi2020), Noroozi et al. (Reference Noroozi, Alamdari, Arne, Larson and Taghavi2017) and Taghavi & Larson (Reference Taghavi and Larson2014a,Reference Taghavi and Larsonb) have used a simple yet effective approach, known as the regularized string approach, to yield a stable solution even at regions adjacent to the nozzle.

As a promising approach, the Cosserat rod theory has been used so far with fewer limitations compared with its counterpart, i.e. the classical string model techniques, to study the CS process mathematically. In the Cosserat rod approach, the fully coupled conservation equations including mass, linear and angular momentum equations are solved (see e.g. Mahadevan & Keller Reference Mahadevan and Keller1996; Ribe Reference Ribe2004; Ribe, Habibi & Bonn Reference Ribe, Habibi and Bonn2006), avoiding singularities such as the ones observed in the classic string model; this is done via including the bending and twisting terms in the near-nozzle regions. Arne et al. (Reference Arne, Marheineke, Meister and Wegener2010) and Arne et al. (Reference Arne, Marheineke, Meister, Schiessl and Wegener2015) have used a Cosserat rod theory to model a curved jet in two-dimensional (2-D) stationary and 3-D transient frames, respectively, to study a viscous curved jet in the glass wool spinning process. In another attempt, Liu & Parker (Reference Liu and Parker2018) have developed a Cosserat beam theory to model a viscoelastic curved jet in a 2-D stationary frame, to study the CS process. However, compared with the string model, extending the rod model to include the surface forces and nonlinear viscoelastic models is more difficult and the resulting model equations are eventually more demanding to solve.

In the majority of the previous works, due to their limitations/singularities, the string model equations cannot be directly applied to study the CS process (which involves a rapidly rotating viscous flow). Therefore, in this work, we develop a rigorous mathematical model to remove the existing barriers to properly analyse the CS process. The novelties and contributions of the current work are as follows. First, when developing our mathematical model, we use the Bishop bases to define the jet baseline using its full curvature components; this enables us to develop and solve the final equations in the 2-D and 3-D spaces much easier since the jet baseline torsion is not dealt with explicitly. Second, we successfully remove the singularity problem of the classic asymptotic string equations via incorporating the angular momentum conservation equations into the model. As we consider viscoelastic slender jets, the first-order viscoelastic extra stress terms are also included into the angular momentum conservation equations; using this approach, the equations can also be easily extended in future to consider a jet with non-circular cross-sections. Furthermore, our model equations includes the Giesekus nonlinear constitutive model coupled with the energy equation, the kinematic expressions as well as the aerodynamic drag force relations; this inclusiveness, in return, allows us to predict the effects of viscoelastic, inertial, rotational, surface tension, gravitational, polymer melt/solution temperature and aerodynamic effects, on the fibre flow. Finally, we develop the model equations in their general form and in the 3-D space so that they can be easily tailored to study any spinning processes, in unsteady or in steady state conditions. Thanks to the comprehensiveness of the model developed, it is possible to explore the effects of a wide range of key dimensionless flow parameters. This makes it possible to rigorously analyse the performance of the CS process in the current work and similar processes (melt spinning, prilling, etc.) in future, for a wide range of material choices, from a Newtonian solvent to a highly viscoelastic solution to a viscoelastic polymer melt, not addressed in previous works.

The outline of the current paper is as follows. In § 2, we present the methods used to derive our mathematical model, comprising the assumptions, the governing equations, the boundary and initial conditions and finally the asymptotic method employed to simplify the resultant equations. In § 3, we first show the behaviour of a transient jet and then study parametrically the effects of various flow parameters on the steady jet dynamic behaviour. Finally in § 4, we conclude the paper with a brief summary of the main findings.

2. Problem formulation

In this work, we derive the asymptotic equations for a viscoelastic curved jet emanating from a rotating nozzle with the constant rotation speed ![]() $\varOmega$ rad s

$\varOmega$ rad s![]() $^{-1}$, diameter

$^{-1}$, diameter ![]() $a$ and length

$a$ and length ![]() $s_0$, as schematically shown in figure 1. Our derivation is based on the slender body approach consisting of projecting the equations in a 3-D space onto the Bishop basis vectors (Bishop Reference Bishop1975), used to eliminate the baseline torsion and accordingly ease the derivation procedure. In the next step, we use the cross-sectional averaging techniques followed by expansions of cross-averaged variables based on the slenderness parameter, i.e. the aspect ratio

$s_0$, as schematically shown in figure 1. Our derivation is based on the slender body approach consisting of projecting the equations in a 3-D space onto the Bishop basis vectors (Bishop Reference Bishop1975), used to eliminate the baseline torsion and accordingly ease the derivation procedure. In the next step, we use the cross-sectional averaging techniques followed by expansions of cross-averaged variables based on the slenderness parameter, i.e. the aspect ratio ![]() $\varepsilon =a/s_0$, to derive our set of asymptotic equations. Finally, we solve the leading-order equations in

$\varepsilon =a/s_0$, to derive our set of asymptotic equations. Finally, we solve the leading-order equations in ![]() $\varepsilon$ with the aid of numerical approaches.

$\varepsilon$ with the aid of numerical approaches.

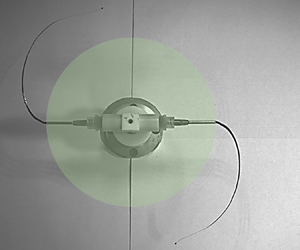

Figure 1. Left image: a schematic view of a typical laboratory scale CS process. The nozzle inner diameter is marked by ![]() $a$, the spinneret radius by

$a$, the spinneret radius by ![]() $s_0$ and the fibre angles by

$s_0$ and the fibre angles by ![]() $\alpha$ and

$\alpha$ and ![]() $\beta$. Right image: a segment of the jet with the reference frames. In the left and right images, we show several parameters related to the model explained in the model section;

$\beta$. Right image: a segment of the jet with the reference frames. In the left and right images, we show several parameters related to the model explained in the model section; ![]() $\omega _{N_1}, \omega _{N_2}, \omega _{T}$ are the components of the jet cross-section angular velocity vector.

$\omega _{N_1}, \omega _{N_2}, \omega _{T}$ are the components of the jet cross-section angular velocity vector.

2.1. Controlling parameters of the CS process

In the CS process, under a centrifugal force, a polymer solution or melt emerges from a nozzle of a rapidly rotating reservoir, also known as the spinneret, forming a nanosized curved jet as schematically sketched in figure 1. As the jet emerges from the nozzle (regime 1), it starts to stretch and it develops a time and position dependent trajectory and radius. However, at long times when the fibre touches the collectors, its behaviour becomes steady (regime 2) in a way that the jet trajectory does not change with time anymore, provided that there are no perturbations or jet breakups. To better visualize how the jet is initially developed and reaches the steady state, figure 2 shows the formation of a growing polymer solution jet over time, in our laboratory CS set-up, a detailed description of which can be found in Noroozi et al. (Reference Noroozi, Arne, Larson and Taghavi2020). As observed, at short times, the polymer solution is extruded into a straight jet and starts to bend in the anti-rotation direction. With increasing time, the fibre goes through a range of transient shapes, from a pedant drop, to an anti-S shape jet (Li et al. Reference Li, Lu, Hou, Zhou, Wang, Zhang and Yang2020), to a necking point, etc. Next, the fibre continues to grow until it finally reaches the steady condition where its trajectory no longer changes with time. According to the figure, one can realize that the transient part of the fibre formation in the CS process, i.e. regime 1, is very fast and it merely takes one or two spinning cycles for a growing fibre to turn into a steady jet (regime 2). Although the major part of the process occurs in regime 2, studying regime 1 is also of importance, since it will eventually make the analysis of the jet stability possible. Thus, in this work, we derive a complete set of model equations including the transient forms, to set the stage for future analysis of jet stability.

Figure 2. Experimental observation of a growing fibre over time in a typical CS experiment, using a poly(ethylene oxide) (PEO) solution. The field of view in all images is ![]() $140\,{\rm mm}\times 250\,{\rm mm}$. The solution is

$140\,{\rm mm}\times 250\,{\rm mm}$. The solution is ![]() $7\,\%$wt PEO (with the molecular weight of

$7\,\%$wt PEO (with the molecular weight of ![]() $M_{v}=9 \times 10^{5}$ (g mol

$M_{v}=9 \times 10^{5}$ (g mol![]() $^{-1}$)), and the experimental parameters are

$^{-1}$)), and the experimental parameters are ![]() $\varOmega =370$ (rad s

$\varOmega =370$ (rad s![]() $^{-1}$),

$^{-1}$), ![]() $s_0=8$ (cm) and

$s_0=8$ (cm) and ![]() $a=1$ (mm). The times with respect to the beginning of the experiment are given in seconds in the corner of each image.

$a=1$ (mm). The times with respect to the beginning of the experiment are given in seconds in the corner of each image.

During jet flight time, many parameters affect the jet dynamic behaviour and, consequently, its size (radius) and shape; these parameters may include rotational (comprising centrifugal and Coriolis effects), viscoelastic, inertial, gravitational, aerodynamic (air drag), surface tension and jet temperature variation effects. In this study, the effects of these parameters will be taken into account in our model, through several dimensionless numbers as the input parameters of the model, listed in Table 1. These dimensionless numbers quantify the aforementioned phenomena and forces. In particular, ![]() $Rb$,

$Rb$, ![]() $Fr$,

$Fr$, ![]() $Re$,

$Re$, ![]() $We$,

$We$, ![]() $Pe^*$ and

$Pe^*$ and ![]() $Re^*$ can be interpreted as the inverse dimensionless rotation rate, gravitational acceleration, polymer solution viscosity, surface tension, air thermal diffusivity and air viscosity, respectively, provided that the flow rate, density and geometrical parameters are constant. Also,

$Re^*$ can be interpreted as the inverse dimensionless rotation rate, gravitational acceleration, polymer solution viscosity, surface tension, air thermal diffusivity and air viscosity, respectively, provided that the flow rate, density and geometrical parameters are constant. Also, ![]() $Wi$ is similarly a representative of the polymer solution/melt relaxation time,

$Wi$ is similarly a representative of the polymer solution/melt relaxation time, ![]() $\lambda$.

$\lambda$.

Table 1. Definitions of the dimensionless groups along with their typical ranges in a typical CS process. The subscript ‘![]() $noz$’ marks the polymer solution/melt jet parameters at the nozzle exit and the dimensional and dimensionless parameters describing properties in the air are marked with an asterisk (

$noz$’ marks the polymer solution/melt jet parameters at the nozzle exit and the dimensional and dimensionless parameters describing properties in the air are marked with an asterisk (![]() $*$). We also use the subscript ‘

$*$). We also use the subscript ‘![]() $p$’ to mark the polymer properties and ‘

$p$’ to mark the polymer properties and ‘![]() $s$’ to mark the solvent properties. Here,

$s$’ to mark the solvent properties. Here, ![]() $\rho$ stands for the density,

$\rho$ stands for the density, ![]() $U$ the velocity,

$U$ the velocity, ![]() $\bar {\sigma }$ the surface tension,

$\bar {\sigma }$ the surface tension, ![]() $\mu =\mu _{s}+\mu _{p}$ the zero-shear viscosity (with

$\mu =\mu _{s}+\mu _{p}$ the zero-shear viscosity (with ![]() $\mu _s$ and

$\mu _s$ and ![]() $\mu _p$ being the solvent and polymer contributions to the zero-shear viscosity, respectively),

$\mu _p$ being the solvent and polymer contributions to the zero-shear viscosity, respectively), ![]() $\lambda$ the relaxation time,

$\lambda$ the relaxation time, ![]() $\theta$ the temperature,

$\theta$ the temperature, ![]() ${c_{p}}$ the specific heat capacity,

${c_{p}}$ the specific heat capacity, ![]() $k$ the conductivity and

$k$ the conductivity and ![]() $\mathrm {g}$ the gravitational acceleration. In addition to the parameters presented, our steady state and transient models will respectively use

$\mathrm {g}$ the gravitational acceleration. In addition to the parameters presented, our steady state and transient models will respectively use ![]() $\ell =L/s_0$ and

$\ell =L/s_0$ and ![]() $\tau _{end}$ (the end time, made dimensionless using the characteristic time

$\tau _{end}$ (the end time, made dimensionless using the characteristic time ![]() $s_0/U_{noz}$), as additional input parameters.

$s_0/U_{noz}$), as additional input parameters.

To preserve the generality of the results, we present all the variables and equations in their dimensionless forms throughout this study. To do so, we use the nozzle diameter (![]() $a$) to scale the fibre radius and we use

$a$) to scale the fibre radius and we use ![]() $s_0$ as a length scale,

$s_0$ as a length scale, ![]() $s_0/U_{noz}$ as the time scale,

$s_0/U_{noz}$ as the time scale, ![]() $U_{noz}$ as the velocity scale,

$U_{noz}$ as the velocity scale, ![]() $U_{noz}/s_0$ as the angular velocity scale,

$U_{noz}/s_0$ as the angular velocity scale, ![]() $A_{ref}={\rm \pi} a^2/4$ as the reference area,

$A_{ref}={\rm \pi} a^2/4$ as the reference area, ![]() $\mu _{noz} U_{noz}/s_0$ as the stress scale and, finally,

$\mu _{noz} U_{noz}/s_0$ as the stress scale and, finally, ![]() $\theta _{noz}$ as the temperature scale.

$\theta _{noz}$ as the temperature scale.

2.2. Governing equations

The CS of a viscoelastic fibre can be described using the transient three-dimensional conservation equations, along with viscoelastic constitutive equations of the polymer solution/melt. To write out the governing equations, we treat the jet as a single incompressible phase and ignore the effects of the solvent evaporation on the fibre behaviour. Therefore, the dimensionless continuity, momentum, angular momentum, energy and Giesekus viscoelastic constitutive equations can be represented respectively as

in which ![]() $\boldsymbol {v}$ denotes the velocity vector,

$\boldsymbol {v}$ denotes the velocity vector, ![]() $\bar {\rho }=\rho (\theta )/\rho _{noz}$ the relative density,

$\bar {\rho }=\rho (\theta )/\rho _{noz}$ the relative density, ![]() $\boldsymbol {d}$ the position vector,

$\boldsymbol {d}$ the position vector, ![]() $\boldsymbol {\varPi }$ the stress tensor (yet to be determined),

$\boldsymbol {\varPi }$ the stress tensor (yet to be determined), ![]() $\boldsymbol{\mathsf{S}}$ the extra stress tensor related to viscoelasticity,

$\boldsymbol{\mathsf{S}}$ the extra stress tensor related to viscoelasticity, ![]() $\theta$ the dimensionless jet temperature,

$\theta$ the dimensionless jet temperature, ![]() $\boldsymbol {\gamma }$ the strain rate tensor,

$\boldsymbol {\gamma }$ the strain rate tensor, ![]() $\chi$ the mobility factor,

$\chi$ the mobility factor, ![]() $\bar {\lambda }=\lambda (\theta )/\lambda _{noz}$ the relative relaxation time,

$\bar {\lambda }=\lambda (\theta )/\lambda _{noz}$ the relative relaxation time, ![]() $\delta _s$ the viscosity ratio; also,

$\delta _s$ the viscosity ratio; also, ![]() $\bar {\mu }=\mu _p(\theta )/\mu _{pnoz}$ stands for the relative polymer zero-shear viscosity; see table 1 for the definitions of the dimensionless numbers. We also define

$\bar {\mu }=\mu _p(\theta )/\mu _{pnoz}$ stands for the relative polymer zero-shear viscosity; see table 1 for the definitions of the dimensionless numbers. We also define ![]() $Wi=\lambda _{noz} U_{noz}/s_0$ in which

$Wi=\lambda _{noz} U_{noz}/s_0$ in which ![]() $\lambda _{noz}$ is the polymer relaxation time at the nozzle. Finally,

$\lambda _{noz}$ is the polymer relaxation time at the nozzle. Finally, ![]() $\boldsymbol {F}$ stands for the external force vectors consisting of the Coriolis, centrifugal, gravitational and drag forces, defined as

$\boldsymbol {F}$ stands for the external force vectors consisting of the Coriolis, centrifugal, gravitational and drag forces, defined as

where ![]() $\boldsymbol {\varOmega }=(1,0,0)$ denotes the angular velocity vector,

$\boldsymbol {\varOmega }=(1,0,0)$ denotes the angular velocity vector, ![]() $\boldsymbol {g}=(-1,0,0)$ is the gravity acceleration vector and

$\boldsymbol {g}=(-1,0,0)$ is the gravity acceleration vector and ![]() $\boldsymbol {F}_{{drag}}$ stands for the aerodynamic drag force vector, yet to be defined. Solving the full 3-D set of equations coupled with the viscoelastic constitutive relations and the boundary conditions at the jet free surface (to be defined) is not feasible, in a transient or even stationary frame. Therefore, in this work, we define the variables based on the cross-averaged values in the axial direction and then develop a set of quasi-1-D equations using the asymptotic estimations of the key parameters. Prior to deriving the governing equations, however, we need to define some geometrical and kinematic relations to frame an unsteady viscoelastic curved jet, presented in the following.

$\boldsymbol {F}_{{drag}}$ stands for the aerodynamic drag force vector, yet to be defined. Solving the full 3-D set of equations coupled with the viscoelastic constitutive relations and the boundary conditions at the jet free surface (to be defined) is not feasible, in a transient or even stationary frame. Therefore, in this work, we define the variables based on the cross-averaged values in the axial direction and then develop a set of quasi-1-D equations using the asymptotic estimations of the key parameters. Prior to deriving the governing equations, however, we need to define some geometrical and kinematic relations to frame an unsteady viscoelastic curved jet, presented in the following.

2.3. Coordinate systems and basis vectors

In this section, we introduce the coordinate systems and their corresponding bases to frame our unsteady curved jet. To this aim, we use 3-tuple ![]() $(n_1, n_2, s)$ as our curvilinear coordinate system so that

$(n_1, n_2, s)$ as our curvilinear coordinate system so that ![]() $s$ defines the arc length and

$s$ defines the arc length and ![]() $(n_1, n_2)$ defines the jet cross-section as rectangular coordinates normal to the jet baseline. When defining the jet cross-section, we can also find it helpful to use polar coordinates

$(n_1, n_2)$ defines the jet cross-section as rectangular coordinates normal to the jet baseline. When defining the jet cross-section, we can also find it helpful to use polar coordinates ![]() $(r, \varphi )$ whose relations with

$(r, \varphi )$ whose relations with ![]() $(n_1, n_2)$ are

$(n_1, n_2)$ are

\begin{equation} \left.\begin{gathered} r = \sqrt {n_1^2 + n_2^2},\quad \varphi = {\tan ^{ - 1}} \left( {\frac{{{n_1}}}{{{n_2}}}} \right),\quad \text{or} \\ {n_1} = r\sin (\varphi ),\quad {n_2} = r\cos (\varphi). \end{gathered}\right\} \end{equation}

\begin{equation} \left.\begin{gathered} r = \sqrt {n_1^2 + n_2^2},\quad \varphi = {\tan ^{ - 1}} \left( {\frac{{{n_1}}}{{{n_2}}}} \right),\quad \text{or} \\ {n_1} = r\sin (\varphi ),\quad {n_2} = r\cos (\varphi). \end{gathered}\right\} \end{equation}In this study, whenever more appropriate, we use the polar coordinates to describe the jet cross-section using back-and-forth transformation relations expressed in (2.7).

Next, we present the basis vector expressions to define the baseline of the jet. We choose the Cartesian coordinate system as an outer frame to define the jet baseline, so that the nozzle, from which the jet emerges, is fixed. Given this, we can introduce a time-dependent three-dimensional curve function

as the jet baseline position in which ![]() $t$ is time and

$t$ is time and ![]() $(\boldsymbol {\hat x}, \boldsymbol {\hat y}, \boldsymbol {\hat z})$ are the Cartesian basis vectors. We also use the Bishop basis vectors

$(\boldsymbol {\hat x}, \boldsymbol {\hat y}, \boldsymbol {\hat z})$ are the Cartesian basis vectors. We also use the Bishop basis vectors ![]() $(\boldsymbol {N_1}, \boldsymbol {N_2}, \boldsymbol {T})$, which are orthonormal, as the moving frame of reference for our curved jet centreline and derive the final uniaxial equations. In this work, we use the Bishop basis vectors instead of the commonly used Frenet basis vectors to frame our curved baseline for two reasons: first, we would like to exclude the baseline torsion from our calculation when deriving our set of equations and, second, we would like to ease the cumbersome derivation procedure of the governing equations in the previous works in this area; see for instance Noroozi et al. (Reference Noroozi, Arne, Larson and Taghavi2020) or Shikhmurzaev & Sisoev (Reference Shikhmurzaev and Sisoev2017). Furthermore, to simplify the basis vector derivatives with respect to time and space and also the kinematic expressions (yet to be introduced), it may be a good idea to use the fibre angles (

$(\boldsymbol {N_1}, \boldsymbol {N_2}, \boldsymbol {T})$, which are orthonormal, as the moving frame of reference for our curved jet centreline and derive the final uniaxial equations. In this work, we use the Bishop basis vectors instead of the commonly used Frenet basis vectors to frame our curved baseline for two reasons: first, we would like to exclude the baseline torsion from our calculation when deriving our set of equations and, second, we would like to ease the cumbersome derivation procedure of the governing equations in the previous works in this area; see for instance Noroozi et al. (Reference Noroozi, Arne, Larson and Taghavi2020) or Shikhmurzaev & Sisoev (Reference Shikhmurzaev and Sisoev2017). Furthermore, to simplify the basis vector derivatives with respect to time and space and also the kinematic expressions (yet to be introduced), it may be a good idea to use the fibre angles (![]() $\alpha, \beta$; see figure 1), to compute the baseline function derivatives as

$\alpha, \beta$; see figure 1), to compute the baseline function derivatives as

\begin{equation} \left.\begin{gathered} {X_{,s}} = \cos (\beta),\\ {Y_{,s}} = \cos (\alpha )\sin (\beta),\\ {Z_{,s}} = \sin (\alpha )\sin (\beta), \end{gathered}\right\} \end{equation}

\begin{equation} \left.\begin{gathered} {X_{,s}} = \cos (\beta),\\ {Y_{,s}} = \cos (\alpha )\sin (\beta),\\ {Z_{,s}} = \sin (\alpha )\sin (\beta), \end{gathered}\right\} \end{equation}which automatically satisfy the arc length condition expressed as

It is noted that, herein, for convenience we use ![]() $H_{,s}$ or

$H_{,s}$ or ![]() $H_{,t}$ as the partial derivative of an arbitrary function

$H_{,t}$ as the partial derivative of an arbitrary function ![]() $H(s, t)$ with respect to

$H(s, t)$ with respect to ![]() $s$ or

$s$ or ![]() $t$. We also define

$t$. We also define ![]() ${\langle {H} \rangle _T}$ as the projection of a given vector

${\langle {H} \rangle _T}$ as the projection of a given vector ![]() $\boldsymbol {H}$ onto an arbitrary base vector such as

$\boldsymbol {H}$ onto an arbitrary base vector such as ![]() $\boldsymbol {T}$. We further introduce the baseline curvature components, i.e.

$\boldsymbol {T}$. We further introduce the baseline curvature components, i.e. ![]() $\kappa _i,\ i=1, 2, 3$, determined as

$\kappa _i,\ i=1, 2, 3$, determined as

The two former components are also known as the Bishop curvatures. Using (2.11a–c) the baseline curvature ![]() $\kappa$ and torsion

$\kappa$ and torsion ![]() $\mathcal {T}$ can be obtained as

$\mathcal {T}$ can be obtained as

Now, using the aforementioned expressions, we can define the Bishop basis vectors ![]() $({\boldsymbol {N}}_1, {\boldsymbol {N}}_2, \boldsymbol {T})$ as (Bishop Reference Bishop1975):

$({\boldsymbol {N}}_1, {\boldsymbol {N}}_2, \boldsymbol {T})$ as (Bishop Reference Bishop1975):

in which ![]() $(\boldsymbol {T}, \boldsymbol {N}, \boldsymbol {B})$ are the Frenet basis vectors, i.e. the tangent, normal and binormal unit vectors, respectively, defined as

$(\boldsymbol {T}, \boldsymbol {N}, \boldsymbol {B})$ are the Frenet basis vectors, i.e. the tangent, normal and binormal unit vectors, respectively, defined as

$$\begin{gather}\boldsymbol{N} = \frac{{{\rm d}\boldsymbol{T}}}{{{\rm d} s}}{\left|{\frac{{{\rm d}\boldsymbol{T}}}{{{\rm d} s}}} \right|^{ - 1}} = \frac{{{X_{,ss}}\boldsymbol{\hat x} + {Y_{,ss}}\boldsymbol{\hat y } + {Z_{,ss}}\boldsymbol{\hat z }}}{{\sqrt {{{\left( {{X_{,ss}}} \right)}^2} + {{\left( {{Y_{,ss}}}\right)}^2} + {{\left( {{Z_{,ss}}} \right)}^2}} }}, \end{gather}$$

$$\begin{gather}\boldsymbol{N} = \frac{{{\rm d}\boldsymbol{T}}}{{{\rm d} s}}{\left|{\frac{{{\rm d}\boldsymbol{T}}}{{{\rm d} s}}} \right|^{ - 1}} = \frac{{{X_{,ss}}\boldsymbol{\hat x} + {Y_{,ss}}\boldsymbol{\hat y } + {Z_{,ss}}\boldsymbol{\hat z }}}{{\sqrt {{{\left( {{X_{,ss}}} \right)}^2} + {{\left( {{Y_{,ss}}}\right)}^2} + {{\left( {{Z_{,ss}}} \right)}^2}} }}, \end{gather}$$ $$\begin{gather}\boldsymbol{B} = \boldsymbol{T} \times \boldsymbol{N} = \frac{{\left({{Y_{,s}}{Z_{,ss}} - {Y_{,ss}}{Z_{,s}}} \right)\boldsymbol{\hat x } + \left( {{Z_{,s}}{X_{,ss}} - {Z_{,ss}}{X_{,s}}} \right)\boldsymbol{\hat y } + \left( {{X_{,s}}{Y_{,ss}} - {X_{,ss}}{Y_{,s}}} \right) \boldsymbol{\hat z }}}{{\sqrt {{{\left({{X_{,ss}}} \right)}^2} + {{\left( {{Y_{,ss}}} \right)}^2} + {{\left({{Z_{,ss}}} \right)}^2}} }}. \end{gather}$$

$$\begin{gather}\boldsymbol{B} = \boldsymbol{T} \times \boldsymbol{N} = \frac{{\left({{Y_{,s}}{Z_{,ss}} - {Y_{,ss}}{Z_{,s}}} \right)\boldsymbol{\hat x } + \left( {{Z_{,s}}{X_{,ss}} - {Z_{,ss}}{X_{,s}}} \right)\boldsymbol{\hat y } + \left( {{X_{,s}}{Y_{,ss}} - {X_{,ss}}{Y_{,s}}} \right) \boldsymbol{\hat z }}}{{\sqrt {{{\left({{X_{,ss}}} \right)}^2} + {{\left( {{Y_{,ss}}} \right)}^2} + {{\left({{Z_{,ss}}} \right)}^2}} }}. \end{gather}$$Using (2.9), (2.11a–c) and (2.14)–(2.19), we can find

\begin{equation} \left.\begin{gathered} {{\boldsymbol{N}}_1} = \left( {\sin (\beta )} \right){\boldsymbol{\hat x}} - (\cos (\alpha )\cos (\beta )){\boldsymbol{\hat y}}- \left( {\sin (\alpha )\cos (\beta )} \right){\boldsymbol{\hat z}}, \\ {{\boldsymbol{N}}_2} = (\sin (\alpha )){\boldsymbol{\hat y}} - \left( { \cos (\alpha )} \right){\boldsymbol{\hat z}}, \\ {\boldsymbol{T}} = \left( {\cos (\beta )} \right){\boldsymbol{\hat x}}+(\cos (\alpha )\sin (\beta )){\boldsymbol{\hat y}} + \left( {\sin (\alpha )\sin (\beta )} \right){\boldsymbol{\hat z}}. \end{gathered}\right\} \end{equation}

\begin{equation} \left.\begin{gathered} {{\boldsymbol{N}}_1} = \left( {\sin (\beta )} \right){\boldsymbol{\hat x}} - (\cos (\alpha )\cos (\beta )){\boldsymbol{\hat y}}- \left( {\sin (\alpha )\cos (\beta )} \right){\boldsymbol{\hat z}}, \\ {{\boldsymbol{N}}_2} = (\sin (\alpha )){\boldsymbol{\hat y}} - \left( { \cos (\alpha )} \right){\boldsymbol{\hat z}}, \\ {\boldsymbol{T}} = \left( {\cos (\beta )} \right){\boldsymbol{\hat x}}+(\cos (\alpha )\sin (\beta )){\boldsymbol{\hat y}} + \left( {\sin (\alpha )\sin (\beta )} \right){\boldsymbol{\hat z}}. \end{gathered}\right\} \end{equation}

Next, using (2.11a–c) and (2.20), the derivatives of the Bishop basis vectors can be obtained with respect to the arc length ![]() $s$ as

$s$ as

\begin{equation} \left.\begin{gathered} \frac{{\partial {{\boldsymbol{N}}_1}(s,t)}}{{\partial s}} = {\kappa _1}{\boldsymbol{T}} + {\kappa _3}{{\boldsymbol{N}}_2}, \\ \frac{{\partial {{\boldsymbol{N}}_2}(s,t)}}{{\partial s}} = {\kappa _2}{\boldsymbol{T}} - {\kappa _3}{{\boldsymbol{N}}_1}, \\ \frac{{\partial {\boldsymbol{T}}(s,t)}}{{\partial s}} ={-} {\kappa _1}{{\boldsymbol{N}}_1} - {\kappa _2}{{\boldsymbol{N}}_2}, \end{gathered}\right\} \end{equation}

\begin{equation} \left.\begin{gathered} \frac{{\partial {{\boldsymbol{N}}_1}(s,t)}}{{\partial s}} = {\kappa _1}{\boldsymbol{T}} + {\kappa _3}{{\boldsymbol{N}}_2}, \\ \frac{{\partial {{\boldsymbol{N}}_2}(s,t)}}{{\partial s}} = {\kappa _2}{\boldsymbol{T}} - {\kappa _3}{{\boldsymbol{N}}_1}, \\ \frac{{\partial {\boldsymbol{T}}(s,t)}}{{\partial s}} ={-} {\kappa _1}{{\boldsymbol{N}}_1} - {\kappa _2}{{\boldsymbol{N}}_2}, \end{gathered}\right\} \end{equation}

and with respect to time ![]() $t$ as

$t$ as

\begin{equation} \left.\begin{gathered} \frac{{\partial {{\boldsymbol{N}}_1}(s,t)}}{{\partial t}} = \left( {{\beta _{,t}}} \right){\boldsymbol{T}} + \left( {{\alpha _{,t}}\cos (\beta )} \right){{\boldsymbol{N}}_2}, \\ \frac{{\partial {{\boldsymbol{N}}_2}(s,t)}}{{\partial t}} = \left( {{\alpha _{,t}}\sin (\beta )} \right){\boldsymbol{T}} - \left( {{\alpha _{,t}}\cos (\beta )} \right){{\boldsymbol{N}}_1}, \\ \frac{{\partial {\boldsymbol{T}}(s,t)}}{{\partial t}} ={-} \left( {{\alpha _{,t}}\sin (\beta )} \right){{\boldsymbol{N}}_2} - \left( {{\beta _{,t}}} \right){{\boldsymbol{N}}_1}. \end{gathered}\right\} \end{equation}

\begin{equation} \left.\begin{gathered} \frac{{\partial {{\boldsymbol{N}}_1}(s,t)}}{{\partial t}} = \left( {{\beta _{,t}}} \right){\boldsymbol{T}} + \left( {{\alpha _{,t}}\cos (\beta )} \right){{\boldsymbol{N}}_2}, \\ \frac{{\partial {{\boldsymbol{N}}_2}(s,t)}}{{\partial t}} = \left( {{\alpha _{,t}}\sin (\beta )} \right){\boldsymbol{T}} - \left( {{\alpha _{,t}}\cos (\beta )} \right){{\boldsymbol{N}}_1}, \\ \frac{{\partial {\boldsymbol{T}}(s,t)}}{{\partial t}} ={-} \left( {{\alpha _{,t}}\sin (\beta )} \right){{\boldsymbol{N}}_2} - \left( {{\beta _{,t}}} \right){{\boldsymbol{N}}_1}. \end{gathered}\right\} \end{equation} Now, we turn from the baseline geometry to that of the fibre as a whole, for the definition of which we use the covariant basis vectors, ![]() ${\boldsymbol {g}_{1}}$,

${\boldsymbol {g}_{1}}$, ![]() ${\boldsymbol {g}_{2}}$ and

${\boldsymbol {g}_{2}}$ and ![]() ${\boldsymbol {g}_{3}}$ corresponding to

${\boldsymbol {g}_{3}}$ corresponding to ![]() $n_1$,

$n_1$, ![]() $n_2$ and

$n_2$ and ![]() $s$ directions, respectively; see figure 1. Based on our definition here, the time-dependent position vector of an arbitrary point

$s$ directions, respectively; see figure 1. Based on our definition here, the time-dependent position vector of an arbitrary point ![]() $\boldsymbol {d}$ inside the fibre at a given time

$\boldsymbol {d}$ inside the fibre at a given time ![]() $t$ can be expressed as

$t$ can be expressed as

in which ![]() $\boldsymbol {r}$ is

$\boldsymbol {r}$ is ![]() $(n_1, n_2, 0)$, so as

$(n_1, n_2, 0)$, so as ![]() $| {\boldsymbol {r}} |=r$, and

$| {\boldsymbol {r}} |=r$, and ![]() $\varepsilon$ is the aspect ratio. Given the position vector of an arbitrary point

$\varepsilon$ is the aspect ratio. Given the position vector of an arbitrary point ![]() $\boldsymbol {d}$, i.e. (2.23), we can define the covariant basis vectors as

$\boldsymbol {d}$, i.e. (2.23), we can define the covariant basis vectors as

and therefore we have

\begin{equation} \left.\begin{gathered} {{\boldsymbol{g}}_1} = \frac{{\partial {\boldsymbol{d}}}}{{\partial {n_1}}} = {\varepsilon{\boldsymbol{N}}_1},\quad {{\boldsymbol{g}}_2} = \frac{{\partial {\boldsymbol{d}}}}{{\partial {n_2}}} = {\varepsilon{\boldsymbol{N}}_2}, \\ {{\boldsymbol{g}}_3} = \frac{{\partial {\boldsymbol{d}}}}{{\partial s}} ={-} \left( {\varepsilon {n_2}{\kappa _3}} \right){{\boldsymbol{N}}_1} + \left( {\varepsilon {n_1}{\kappa _3}} \right){{\boldsymbol{N}}_2} + \left( {1 + \varepsilon {n_1}{\kappa _1} + \varepsilon {n_2}{\kappa _2}} \right){\boldsymbol{T}}. \end{gathered}\right\} \end{equation}

\begin{equation} \left.\begin{gathered} {{\boldsymbol{g}}_1} = \frac{{\partial {\boldsymbol{d}}}}{{\partial {n_1}}} = {\varepsilon{\boldsymbol{N}}_1},\quad {{\boldsymbol{g}}_2} = \frac{{\partial {\boldsymbol{d}}}}{{\partial {n_2}}} = {\varepsilon{\boldsymbol{N}}_2}, \\ {{\boldsymbol{g}}_3} = \frac{{\partial {\boldsymbol{d}}}}{{\partial s}} ={-} \left( {\varepsilon {n_2}{\kappa _3}} \right){{\boldsymbol{N}}_1} + \left( {\varepsilon {n_1}{\kappa _3}} \right){{\boldsymbol{N}}_2} + \left( {1 + \varepsilon {n_1}{\kappa _1} + \varepsilon {n_2}{\kappa _2}} \right){\boldsymbol{T}}. \end{gathered}\right\} \end{equation}Thus, we can define the metric tensor as

\begin{equation} \left.\begin{gathered}

({g_{ij}})=

{{\boldsymbol{g}}_i}\boldsymbol{\cdot}{{\boldsymbol{g}}_j}

= \begin{pmatrix} {{\varepsilon ^2}} & 0 &

{ - {\varepsilon ^2}{n_2}{\kappa _3}}\\ 0 & {{\varepsilon

^2}} & {{\varepsilon ^2}{n_1}{\kappa _3}}\\ { -

{\varepsilon ^2}{n_2}{\kappa _3}} & {{\varepsilon

^2}{n_1}{\kappa _3}} & {{h^2} + {\varepsilon ^2}{r^2}\kappa

_3^2}\end{pmatrix}, \\ \left| {{g_{ij}}}

\right| = \varepsilon^4 {h^2},\quad h = \left( {1 +

\varepsilon{n_1}{\kappa _1} + \varepsilon{n_2}{\kappa _2}}

\right), \end{gathered}\right\} \end{equation}

\begin{equation} \left.\begin{gathered}

({g_{ij}})=

{{\boldsymbol{g}}_i}\boldsymbol{\cdot}{{\boldsymbol{g}}_j}

= \begin{pmatrix} {{\varepsilon ^2}} & 0 &

{ - {\varepsilon ^2}{n_2}{\kappa _3}}\\ 0 & {{\varepsilon

^2}} & {{\varepsilon ^2}{n_1}{\kappa _3}}\\ { -

{\varepsilon ^2}{n_2}{\kappa _3}} & {{\varepsilon

^2}{n_1}{\kappa _3}} & {{h^2} + {\varepsilon ^2}{r^2}\kappa

_3^2}\end{pmatrix}, \\ \left| {{g_{ij}}}

\right| = \varepsilon^4 {h^2},\quad h = \left( {1 +

\varepsilon{n_1}{\kappa _1} + \varepsilon{n_2}{\kappa _2}}

\right), \end{gathered}\right\} \end{equation}

in which ![]() $| {{g_{ij}}} |$ denotes the determinant of the metric tensor. As vividly seen, our local bases are neither orthogonal nor normalized due to non-zero off-diagonal elements and non-unity of the diagonal ones. Using (2.26), we can attain the conjugate metric tensor

$| {{g_{ij}}} |$ denotes the determinant of the metric tensor. As vividly seen, our local bases are neither orthogonal nor normalized due to non-zero off-diagonal elements and non-unity of the diagonal ones. Using (2.26), we can attain the conjugate metric tensor ![]() ${{g}}^{ij}$ such that

${{g}}^{ij}$ such that

where ![]() $\delta ^{i}_{j}$ stands for the Kronecker delta; therefore, we arrive at

$\delta ^{i}_{j}$ stands for the Kronecker delta; therefore, we arrive at

\begin{equation} ({g^{ij}}) =

\frac{{{\varepsilon ^2}}}{{\left| {{g_{ij}}} \right|}}

\begin{pmatrix} {{h^2} + {\varepsilon

^2}n_2^2\kappa _3^2} & { - {\varepsilon ^2}{n_1}{n_2}\kappa

_3^2} & {{\varepsilon ^2}{n_2}{\kappa _3}}\\ { -

{\varepsilon ^2}{n_1}{n_2}\kappa _3^2} & {{h^2} +

{\varepsilon ^2}n_1^2\kappa _3^2} & { - {\varepsilon

^2}{n_1}{\kappa _3}}\\ {{\varepsilon ^2}{n_2}{\kappa _3}} &

{ - {\varepsilon ^2}{n_1}{\kappa _3}} & {{\varepsilon ^2}} \end{pmatrix}. \end{equation}

\begin{equation} ({g^{ij}}) =

\frac{{{\varepsilon ^2}}}{{\left| {{g_{ij}}} \right|}}

\begin{pmatrix} {{h^2} + {\varepsilon

^2}n_2^2\kappa _3^2} & { - {\varepsilon ^2}{n_1}{n_2}\kappa

_3^2} & {{\varepsilon ^2}{n_2}{\kappa _3}}\\ { -

{\varepsilon ^2}{n_1}{n_2}\kappa _3^2} & {{h^2} +

{\varepsilon ^2}n_1^2\kappa _3^2} & { - {\varepsilon

^2}{n_1}{\kappa _3}}\\ {{\varepsilon ^2}{n_2}{\kappa _3}} &

{ - {\varepsilon ^2}{n_1}{\kappa _3}} & {{\varepsilon ^2}} \end{pmatrix}. \end{equation}

Using (2.25), (2.26) and (2.28), we can obtain the gradient operator in our curvilinear coordinate system as

from which we can later determine the strain rate tensor. In the next step, we derive the corresponding kinematic relations, the stress tensor and the dynamic boundary condition equations using the aforementioned expressions.

2.4. Kinematic relations

To study an unsteady growing curved jet, two kinds of velocities can be realized at each point inside the liquid jet. The first one is the fluid velocity and it can be expressed as the material derivative of the position vector ![]() $\boldsymbol {d}$ as

$\boldsymbol {d}$ as

in which ![]() $u_i$ stands for the convectional velocity vector, i.e.

$u_i$ stands for the convectional velocity vector, i.e. ![]() $u_i = ({{{\partial {n_1}}}/{{\partial t}}, {{\partial {n_2}}}/{{\partial t}}, {{\partial s}}/{{\partial t}}})=(u_1, u_2, u_3)$. The second velocity field is the coordinate velocity

$u_i = ({{{\partial {n_1}}}/{{\partial t}}, {{\partial {n_2}}}/{{\partial t}}, {{\partial s}}/{{\partial t}}})=(u_1, u_2, u_3)$. The second velocity field is the coordinate velocity ![]() $\boldsymbol {w}$ expressed as

$\boldsymbol {w}$ expressed as

Now, the fluid velocity can be calculated using the coordinate velocity ![]() $\boldsymbol {w}$ and the convectional velocity

$\boldsymbol {w}$ and the convectional velocity ![]() $\boldsymbol {u}$ vectors, with the help of (2.30); in the steady state condition, however, the coordinate velocity is zero. In this work, to avoid an arduous procedure to derive the dynamic equations and deviatoric stress terms, we use the velocity projections onto the Bishop basis vectors so as

$\boldsymbol {u}$ vectors, with the help of (2.30); in the steady state condition, however, the coordinate velocity is zero. In this work, to avoid an arduous procedure to derive the dynamic equations and deviatoric stress terms, we use the velocity projections onto the Bishop basis vectors so as ![]() ${\boldsymbol {v}} = ( {{v_{{N_1}}},{v_{{N_2}}},{v_T}} )$. However, one can also easily obtain the equations based on the velocity vector projections onto the covariant basis vectors using (2.25).

${\boldsymbol {v}} = ( {{v_{{N_1}}},{v_{{N_2}}},{v_T}} )$. However, one can also easily obtain the equations based on the velocity vector projections onto the covariant basis vectors using (2.25).

2.5. Stress tensor

The stress tensor ![]() $\boldsymbol {\varPi }$ in our curvilinear coordinate system is defined as

$\boldsymbol {\varPi }$ in our curvilinear coordinate system is defined as

in which ![]() $P$ is the pressure,

$P$ is the pressure, ![]() $\boldsymbol {I}$ the identity matrix and

$\boldsymbol {I}$ the identity matrix and ![]() $\delta _s$ the viscosity ratio. Also,

$\delta _s$ the viscosity ratio. Also, ![]() $\boldsymbol {\gamma }$ stands for the strain rate tensor whose components can be obtained with the help of (2.29) as

$\boldsymbol {\gamma }$ stands for the strain rate tensor whose components can be obtained with the help of (2.29) as

\begin{equation} \left.\begin{gathered} {\gamma _{TT}} = \frac{1}{h}\left( {{v_{T,s}} + {\kappa _2}{v_{{N_2}}} + {\kappa _1}{v_{{N_1}}}} \right) + \frac{{{\kappa _3}}}{h} \left( {{n_2}{v_{T,{n_1}}} - {n_1}{v_{T,{n_2}}}} \right), \\ {\gamma _{{N_1}{N_1}}} = \frac{1}{\varepsilon }{v_{{N_1},{n_1}}},\quad {\gamma _{{N_2}{N_2}}} = \frac{1}{\varepsilon }{v_{{N_2},{n_2}}}, \\ {\gamma _{T{N_1}}} = {\gamma _{{N_1}T}} = \frac{1}{{2h}}\left( { - {\kappa _1}{v_T} + {v_{{N_1},s}} + \frac{h}{\varepsilon }{v_{T,{n_1}}}} \right) + \frac{{{\kappa _3}}}{{2h}} \left( {{n_2}{v_{{N_1},{n_1}}} - {n_1}{v_{{N_1},{n_2}}} - {v_{{N_2}}}} \right), \\ {\gamma _{{N_2}T}} = {\gamma _{T{N_2}}} = \frac{1}{{2h}}\left( { - {\kappa _2}{v_T} + {v_{{N_2},s}} + \frac{h}{\varepsilon }{v_{T,{n_2}}}} \right) + \frac{{{\kappa _3}}}{{2h}} \left( {{n_2}{v_{{N_2},{n_1}}} - {n_1}{v_{{N_2},{n_2}}} + {v_{{N_1}}}} \right), \\ {\gamma _{{N_1}{N_2}}} = {\gamma _{{N_2}{N_1}}} = \frac{1}{{2\varepsilon }} \left( {{v_{{N_1},{n_2}}} + {v_{{N_2},{n_1}}}} \right). \end{gathered}\right\} \end{equation}

\begin{equation} \left.\begin{gathered} {\gamma _{TT}} = \frac{1}{h}\left( {{v_{T,s}} + {\kappa _2}{v_{{N_2}}} + {\kappa _1}{v_{{N_1}}}} \right) + \frac{{{\kappa _3}}}{h} \left( {{n_2}{v_{T,{n_1}}} - {n_1}{v_{T,{n_2}}}} \right), \\ {\gamma _{{N_1}{N_1}}} = \frac{1}{\varepsilon }{v_{{N_1},{n_1}}},\quad {\gamma _{{N_2}{N_2}}} = \frac{1}{\varepsilon }{v_{{N_2},{n_2}}}, \\ {\gamma _{T{N_1}}} = {\gamma _{{N_1}T}} = \frac{1}{{2h}}\left( { - {\kappa _1}{v_T} + {v_{{N_1},s}} + \frac{h}{\varepsilon }{v_{T,{n_1}}}} \right) + \frac{{{\kappa _3}}}{{2h}} \left( {{n_2}{v_{{N_1},{n_1}}} - {n_1}{v_{{N_1},{n_2}}} - {v_{{N_2}}}} \right), \\ {\gamma _{{N_2}T}} = {\gamma _{T{N_2}}} = \frac{1}{{2h}}\left( { - {\kappa _2}{v_T} + {v_{{N_2},s}} + \frac{h}{\varepsilon }{v_{T,{n_2}}}} \right) + \frac{{{\kappa _3}}}{{2h}} \left( {{n_2}{v_{{N_2},{n_1}}} - {n_1}{v_{{N_2},{n_2}}} + {v_{{N_1}}}} \right), \\ {\gamma _{{N_1}{N_2}}} = {\gamma _{{N_2}{N_1}}} = \frac{1}{{2\varepsilon }} \left( {{v_{{N_1},{n_2}}} + {v_{{N_2},{n_1}}}} \right). \end{gathered}\right\} \end{equation}2.6. Dynamic boundary conditions

Due to the existence of the surface tension, at the jet free surface, we have a stress balance equation known as dynamic boundary conditions. The interface causes a jump in the normal component of the stress, leading to altering the mean interface curvature, expressed as

where ![]() $R(s,t)$ is a function characterizing the free surface of the jet and

$R(s,t)$ is a function characterizing the free surface of the jet and ![]() $\boldsymbol {\varPi }^*$ indicates the stresses exerted by air on the jet interface; we also have

$\boldsymbol {\varPi }^*$ indicates the stresses exerted by air on the jet interface; we also have ![]() $\boldsymbol {f}_{drag}={{\boldsymbol {\varPi }}^*}\boldsymbol {\cdot }{\boldsymbol {n}}$, which is the air drag force per unit area. Furthermore,

$\boldsymbol {f}_{drag}={{\boldsymbol {\varPi }}^*}\boldsymbol {\cdot }{\boldsymbol {n}}$, which is the air drag force per unit area. Furthermore, ![]() $\boldsymbol {n}$ is the unit normal vector to the interface pointing outwards from the jet surface, and

$\boldsymbol {n}$ is the unit normal vector to the interface pointing outwards from the jet surface, and ![]() $\mathcal {H}$ is the mean local curvature of the interface which can be obtained as

$\mathcal {H}$ is the mean local curvature of the interface which can be obtained as

where

\begin{equation} \left.\begin{gathered} \mathbb{I}_1 = \frac{{\partial \boldsymbol{d}}}{{\partial s}}\boldsymbol{\cdot} \frac{{\partial \boldsymbol{d}}}{{\partial s}},\quad \mathbb{I}_2 = \frac{{\partial \boldsymbol{d}}}{{\partial s}}\boldsymbol{\cdot} \frac{{\partial \boldsymbol{d}}}{{\partial \varphi }},\quad \mathbb{I}_3 = \frac{{\partial \boldsymbol{d}}}{{\partial \varphi }}\boldsymbol{\cdot} \frac{{\partial \boldsymbol{d}}}{{\partial \varphi }}\quad {\rm{at}}\ r = R(s,t), \\ \mathbb{J}_1 = \frac{{{\partial ^2}\boldsymbol{d}}}{{\partial {s^2}}}\boldsymbol{\cdot}\boldsymbol{n},\quad \mathbb{J}_2 = \frac{{{\partial ^2}\boldsymbol{d}}}{{\partial s\partial \varphi }}\boldsymbol{\cdot} \boldsymbol{n},\quad \mathbb{J}_3 = \frac{{{\partial ^2}\boldsymbol{d}}}{{\partial {\varphi ^2}}}\boldsymbol{\cdot} \boldsymbol{n}\quad {\rm{at}}\ r = R(s,t), \\ \boldsymbol{n} = \left( {\frac{{\partial \boldsymbol{d}}}{{\partial s}} \times \frac{{\partial \boldsymbol{d}}}{{\partial \varphi }}} \right){\left| {\frac{{\partial \boldsymbol{d}}}{{\partial s}} \times \frac{{\partial \boldsymbol{d}}}{{\partial \varphi }}} \right|^{ - 1}} \quad {\rm{at}}\ r = R(s,t), \end{gathered}\right\} \end{equation}

\begin{equation} \left.\begin{gathered} \mathbb{I}_1 = \frac{{\partial \boldsymbol{d}}}{{\partial s}}\boldsymbol{\cdot} \frac{{\partial \boldsymbol{d}}}{{\partial s}},\quad \mathbb{I}_2 = \frac{{\partial \boldsymbol{d}}}{{\partial s}}\boldsymbol{\cdot} \frac{{\partial \boldsymbol{d}}}{{\partial \varphi }},\quad \mathbb{I}_3 = \frac{{\partial \boldsymbol{d}}}{{\partial \varphi }}\boldsymbol{\cdot} \frac{{\partial \boldsymbol{d}}}{{\partial \varphi }}\quad {\rm{at}}\ r = R(s,t), \\ \mathbb{J}_1 = \frac{{{\partial ^2}\boldsymbol{d}}}{{\partial {s^2}}}\boldsymbol{\cdot}\boldsymbol{n},\quad \mathbb{J}_2 = \frac{{{\partial ^2}\boldsymbol{d}}}{{\partial s\partial \varphi }}\boldsymbol{\cdot} \boldsymbol{n},\quad \mathbb{J}_3 = \frac{{{\partial ^2}\boldsymbol{d}}}{{\partial {\varphi ^2}}}\boldsymbol{\cdot} \boldsymbol{n}\quad {\rm{at}}\ r = R(s,t), \\ \boldsymbol{n} = \left( {\frac{{\partial \boldsymbol{d}}}{{\partial s}} \times \frac{{\partial \boldsymbol{d}}}{{\partial \varphi }}} \right){\left| {\frac{{\partial \boldsymbol{d}}}{{\partial s}} \times \frac{{\partial \boldsymbol{d}}}{{\partial \varphi }}} \right|^{ - 1}} \quad {\rm{at}}\ r = R(s,t), \end{gathered}\right\} \end{equation}

wherein ![]() $\{{\mathbb {I}_1,\ \mathbb {I}_2,\ \mathbb {I}_3}\}$ and

$\{{\mathbb {I}_1,\ \mathbb {I}_2,\ \mathbb {I}_3}\}$ and ![]() $\{{\mathbb {J}_1,\ \mathbb {J}_2,\ \mathbb {J}_3}\}$ stand for the first and second fundamental forms. It is noted that, when setting the dynamic boundary conditions to describe the jet cross-section, one finds the polar coordinates (

$\{{\mathbb {J}_1,\ \mathbb {J}_2,\ \mathbb {J}_3}\}$ stand for the first and second fundamental forms. It is noted that, when setting the dynamic boundary conditions to describe the jet cross-section, one finds the polar coordinates (![]() $r, \varphi$) to be more appropriate than the rectangular coordinate (

$r, \varphi$) to be more appropriate than the rectangular coordinate (![]() $n_1, n_2$). In this sense, one can simply use (2.7) and (2.23) to attain corresponding expressions for

$n_1, n_2$). In this sense, one can simply use (2.7) and (2.23) to attain corresponding expressions for ![]() $\boldsymbol {d}$ and then compute the related terms in mean curvature and normal vector definitions (see, for example, Marheineke & Wegener (Reference Marheineke and Wegener2007) and Shikhmurzaev & Sisoev (Reference Shikhmurzaev and Sisoev2017)). To write out the stress jumps in the normal and tangential directions, one can simply take the inner product of (2.34) with the unit normal

$\boldsymbol {d}$ and then compute the related terms in mean curvature and normal vector definitions (see, for example, Marheineke & Wegener (Reference Marheineke and Wegener2007) and Shikhmurzaev & Sisoev (Reference Shikhmurzaev and Sisoev2017)). To write out the stress jumps in the normal and tangential directions, one can simply take the inner product of (2.34) with the unit normal ![]() $\boldsymbol {n}$ and tangent

$\boldsymbol {n}$ and tangent ![]() $\boldsymbol {t}_i$ vectors to the interface. The latter has two components in the

$\boldsymbol {t}_i$ vectors to the interface. The latter has two components in the ![]() $s$ and

$s$ and ![]() $\varphi$ directions defined as

$\varphi$ directions defined as

Therefore, the jump conditions in the normal and tangential directions at the jet surface can be expressed as

In what follows, we will express the relations needed to simplify our equations presented so far by integrating the equations over the jet cross-section and then using asymptotic series to estimate the key variables.

2.7. Asymptotic analysis

The uniaxial asymptotic model to be developed here is first based on the cross-sectional averaging of the conservation equations, followed by use of asymptotic expansions of cross-averaged variables in the leading-, first- and second-order terms; this allows one to more easily evaluate the key variables throughout the computational domain. Here, the cross-sectional averaging is performed to dimensionally reduce the conservation equations; to do so, we use the Reynolds transport theorem as our averaging rule (see also Marheineke et al. Reference Marheineke, Liljegren-Sailer, Lorenz and Wegener2016) expressed as

in which ![]() $A=R^2$ is the given dimensionless cross-section of the jet and

$A=R^2$ is the given dimensionless cross-section of the jet and ![]() $l$ is its perimeter and

$l$ is its perimeter and ![]() $\boldsymbol {u}=(u_1, u_2, u_3)$ is the convectional velocity vector. Additionally,

$\boldsymbol {u}=(u_1, u_2, u_3)$ is the convectional velocity vector. Additionally, ![]() $f$ stands for any differentiable and integrable scalar, vector or tensor valued function. Applying these averaging rules on our three-dimensional set of equations, under the assumption of radial symmetry, leads to a set of uniaxial equations.

$f$ stands for any differentiable and integrable scalar, vector or tensor valued function. Applying these averaging rules on our three-dimensional set of equations, under the assumption of radial symmetry, leads to a set of uniaxial equations.

2.7.1. Asymptotic expansion

Considering the jet as a long thin object with the aspect ratio ![]() $\varepsilon$, we can expand the governing equations based on the asymptotic series of the cross-averaged key parameters and use the dominant terms as a reasonable approximation to the jet behaviour. To do so, we assume that the velocity components can be expanded as (see Yarin Reference Yarin1993; Marheineke et al. Reference Marheineke, Liljegren-Sailer, Lorenz and Wegener2016)

$\varepsilon$, we can expand the governing equations based on the asymptotic series of the cross-averaged key parameters and use the dominant terms as a reasonable approximation to the jet behaviour. To do so, we assume that the velocity components can be expanded as (see Yarin Reference Yarin1993; Marheineke et al. Reference Marheineke, Liljegren-Sailer, Lorenz and Wegener2016)

where ![]() $v_1$ is the first-order velocity expansion term in the

$v_1$ is the first-order velocity expansion term in the ![]() $\boldsymbol {N}_1$ and

$\boldsymbol {N}_1$ and ![]() $\boldsymbol {N}_2$ directions and

$\boldsymbol {N}_2$ directions and ![]() $\boldsymbol {\varPhi }$ is the second-order velocity expansion in

$\boldsymbol {\varPhi }$ is the second-order velocity expansion in ![]() $\boldsymbol {r}$. In addition,

$\boldsymbol {r}$. In addition, ![]() $\boldsymbol {\omega }$ denotes the angular velocity of the cross-section whose components, i.e.

$\boldsymbol {\omega }$ denotes the angular velocity of the cross-section whose components, i.e. ![]() $(\omega _{N_1}, \omega _{N_2}, \omega _{T})$, can be defined using

$(\omega _{N_1}, \omega _{N_2}, \omega _{T})$, can be defined using ![]() ${{\partial {{\boldsymbol {N}}_1}}}/{{\partial t}}$ and

${{\partial {{\boldsymbol {N}}_1}}}/{{\partial t}}$ and ![]() ${{\partial {{\boldsymbol {N}}_2}}}/{{\partial t}}$; see (2.31) and figure 1. Next, we expand stress and pressure terms in powers of

${{\partial {{\boldsymbol {N}}_2}}}/{{\partial t}}$; see (2.31) and figure 1. Next, we expand stress and pressure terms in powers of ![]() $\varepsilon \boldsymbol {r}$ and

$\varepsilon \boldsymbol {r}$ and ![]() $R, X, Z, Y, \theta$ in powers of

$R, X, Z, Y, \theta$ in powers of ![]() $\varepsilon$ (see Eggers Reference Eggers1997; Hohman et al. Reference Hohman, Shin, Rutledge and Brenner2001); therefore,

$\varepsilon$ (see Eggers Reference Eggers1997; Hohman et al. Reference Hohman, Shin, Rutledge and Brenner2001); therefore,

\begin{equation} \left.\begin{gathered}

{v_{{N_1}}} = {v_{0{N_1}}} + \varepsilon \left( {{n_1}{v_1}

- {n_2}{\omega _T}} \right) + {\varepsilon ^2}{\varPhi

_{{N_1}}} + O\left( {{{({{\varepsilon \boldsymbol{r} }})}^3}} \right),

\\ {v_{{N_2}}} = {v_{0{N_2}}} + \varepsilon \left(

{{n_2}{v_1} + {n_1}{\omega _T}} \right) + {\varepsilon

^2}{\varPhi _{{N_2}}} + O\left( {{{({{\varepsilon \boldsymbol{r}

}})}^3}} \right), \\ {v_T} = {v_{0T}} + \varepsilon \left(

{{n_2}{\omega _{{N_1}}} - {n_1}{\omega _{{N_2}}}} \right) +

{\varepsilon ^2}{\varPhi _T} + O\left( {{{({{\varepsilon \boldsymbol{r}

}})}^3}} \right), \\ {S_{TT}} = S_{TT}^{(0)} + \varepsilon

{n_1}S_{TT1}^{(1)} + \varepsilon {n_2}S_{TT2}^{(1)} +

O\left( {{{\left( {\varepsilon {\boldsymbol{r}}}

\right)}^2}} \right), \\ {S_{NN}} = S_{NN}^{(0)} +

\varepsilon {n_1}S_{NN1}^{(1)} + \varepsilon

{n_2}S_{NN2}^{(1)} + O\left( {{{\left( {\varepsilon

{\boldsymbol{r}}} \right)}^2}} \right), \\ {S_{ij}} =

\left( {\varepsilon {\boldsymbol{r}}} \right)S_{ij}^{(1)} +

O\left( {{{\left( {\varepsilon {\boldsymbol{r}}}

\right)}^2}} \right),\quad i \ne j, \\ P = {P_0} +

(\varepsilon {\boldsymbol{r}}){P_1} + O\left( {{{\left(

{\varepsilon {\boldsymbol{r}}} \right)}^2}} \right), \\ C =

{C_0} + \varepsilon {C_1} + O\left( {{\varepsilon ^2}}

\right),\quad C = \{ \theta,A, X, Z, Y\}.

\end{gathered}\right\}

\end{equation}

\begin{equation} \left.\begin{gathered}

{v_{{N_1}}} = {v_{0{N_1}}} + \varepsilon \left( {{n_1}{v_1}

- {n_2}{\omega _T}} \right) + {\varepsilon ^2}{\varPhi

_{{N_1}}} + O\left( {{{({{\varepsilon \boldsymbol{r} }})}^3}} \right),

\\ {v_{{N_2}}} = {v_{0{N_2}}} + \varepsilon \left(

{{n_2}{v_1} + {n_1}{\omega _T}} \right) + {\varepsilon

^2}{\varPhi _{{N_2}}} + O\left( {{{({{\varepsilon \boldsymbol{r}

}})}^3}} \right), \\ {v_T} = {v_{0T}} + \varepsilon \left(

{{n_2}{\omega _{{N_1}}} - {n_1}{\omega _{{N_2}}}} \right) +

{\varepsilon ^2}{\varPhi _T} + O\left( {{{({{\varepsilon \boldsymbol{r}

}})}^3}} \right), \\ {S_{TT}} = S_{TT}^{(0)} + \varepsilon

{n_1}S_{TT1}^{(1)} + \varepsilon {n_2}S_{TT2}^{(1)} +

O\left( {{{\left( {\varepsilon {\boldsymbol{r}}}

\right)}^2}} \right), \\ {S_{NN}} = S_{NN}^{(0)} +

\varepsilon {n_1}S_{NN1}^{(1)} + \varepsilon

{n_2}S_{NN2}^{(1)} + O\left( {{{\left( {\varepsilon

{\boldsymbol{r}}} \right)}^2}} \right), \\ {S_{ij}} =

\left( {\varepsilon {\boldsymbol{r}}} \right)S_{ij}^{(1)} +

O\left( {{{\left( {\varepsilon {\boldsymbol{r}}}

\right)}^2}} \right),\quad i \ne j, \\ P = {P_0} +

(\varepsilon {\boldsymbol{r}}){P_1} + O\left( {{{\left(

{\varepsilon {\boldsymbol{r}}} \right)}^2}} \right), \\ C =

{C_0} + \varepsilon {C_1} + O\left( {{\varepsilon ^2}}

\right),\quad C = \{ \theta,A, X, Z, Y\}.

\end{gathered}\right\}

\end{equation}

Now, we compute the governing equations using the velocity expansion relation in our coordinate system. Starting from the strain rate tensor, we obtain the projection of its components onto the Bishop basis vectors as

\begin{gather} \left.\begin{gathered}

{\gamma _{{N_1}T}} = {\gamma _{T{N_1}}} =

\tfrac{1}{2}\left( {{v_{0{N_1},s}} - {\kappa _1}{v_{0T}} -

{\kappa _3}{v_{0{N_2}}} - {\omega _{{N_2}}}} \right) \\

\quad + \tfrac{1}{2}\left( {{\varPhi _{T,{n_1}}} +

{n_2}\left( {{\kappa _1}{\kappa _2}{v_{0T}} - {\kappa

_1}{\omega _{{N_1}}} - {\omega _{T,s}} - {\kappa

_2}{v_{0{N_1},s}} + {\kappa _3}{\kappa _2}{v_{0{N_2}}}}

\right)} \right. \\ \quad + {n_1}\left. {\left( {\kappa

_1^2{v_{0T}} + {\kappa _1}{\omega _{{N_2}}} + {v_{1,s}} -

{\kappa _1}{v_{0{N_1},s}} + {\kappa _3}{\kappa

_1}{v_{0{N_2}}}} \right)} \right) \varepsilon + O\left(

{{\varepsilon ^2}} \right), \\ {\gamma _{{N_2}T}} = {\gamma

_{T{N_2}}} = \tfrac{1}{2}\left( {{v_{0{N_2},s}} - {\kappa

_2}{v_{0T}}+ {\kappa _3}{v_{0{N_1}}} + {\omega _{{N_1}}}}

\right) \\ \quad + \tfrac{1}{2}\left( {{n_1}\left( {{\kappa

_2}{\omega _{{N_2}}} + {\omega _{T,s}} - {\kappa

_1}{v_{0{N_2},s}} + {\kappa _1}{\kappa _2}{v_{0T}}}-{\kappa

_3}{\kappa _1}{v_{0{N_1}}} \right)} \right. \\ \quad +

{n_2}\left( {\kappa _2^2{v_{0T}} - {\kappa _2}{\omega

_{{N_1}}} + {v_{1,s}} - {\kappa _2}{v_{0{N_2},s}}-{\kappa

_3}{\kappa _2}{v_{0{N_1}}}} \right) + \left. {{\varPhi

_{T,{n_2}}}} \right)\varepsilon + O\left( {{\varepsilon

^2}} \right), \\ {\gamma _{{N_2}{N_1}}} = {\gamma

_{{N_1}{N_2}}} = \tfrac{1}{2}\left( {{\varPhi

_{{N_2},{n_1}}} + {\varPhi _{{N_1},{n_2}}}}

\right)\varepsilon+ O\left( {{\varepsilon ^2}} \right), \\

{\gamma _{TT}} = {v_{0T,s}} + {\kappa _1}{v_{0{N_1}}} +

{\kappa _2}{v_{0{N_2}}} \\ \quad + \left( {{n_2}\left(

{{\omega _{{N_1},s}} - {\kappa _1}{\omega _T}-{\kappa

_3}{\omega _{N_2}} + {\kappa _2}{v_1} - {\kappa

_2}{v_{0T,s}} - \kappa _2^2{v_{0{N_2}}} - {\kappa

_1}{\kappa _2}{v_{0{N_1}}}} \right)} \right. \\ \quad +

\left. {\left. { {n_1}\left( { {\kappa _2}{\omega _T}-

{\omega _{{N_2},s}} -{\kappa _3}{\omega _{N_1}} + {\kappa

_1}{v_1} - {\kappa _1}{v_{0T,s}} - \kappa _1^2{v_{0{N_1}}}

- {\kappa _1}{\kappa _2}{v_{0{N_2}}}} \right)}

\right)\varepsilon + O\left( {{\varepsilon ^2}} \right)}

\right), \\ {\gamma _{{N_1}{N_1}}} = {v_1} + ({\varPhi

_{{N_1},{n_1}}})\varepsilon+ O\left( {{\varepsilon ^2}}

\right), \\ {\gamma _{{N_2}{N_2}}} = {v_1} + ({\varPhi

_{{N_2},{n_2}}})\varepsilon+ O\left( {{\varepsilon ^2}}

\right). \end{gathered}\right\} \end{gather}

\begin{gather} \left.\begin{gathered}

{\gamma _{{N_1}T}} = {\gamma _{T{N_1}}} =

\tfrac{1}{2}\left( {{v_{0{N_1},s}} - {\kappa _1}{v_{0T}} -

{\kappa _3}{v_{0{N_2}}} - {\omega _{{N_2}}}} \right) \\

\quad + \tfrac{1}{2}\left( {{\varPhi _{T,{n_1}}} +

{n_2}\left( {{\kappa _1}{\kappa _2}{v_{0T}} - {\kappa

_1}{\omega _{{N_1}}} - {\omega _{T,s}} - {\kappa

_2}{v_{0{N_1},s}} + {\kappa _3}{\kappa _2}{v_{0{N_2}}}}

\right)} \right. \\ \quad + {n_1}\left. {\left( {\kappa

_1^2{v_{0T}} + {\kappa _1}{\omega _{{N_2}}} + {v_{1,s}} -

{\kappa _1}{v_{0{N_1},s}} + {\kappa _3}{\kappa

_1}{v_{0{N_2}}}} \right)} \right) \varepsilon + O\left(

{{\varepsilon ^2}} \right), \\ {\gamma _{{N_2}T}} = {\gamma

_{T{N_2}}} = \tfrac{1}{2}\left( {{v_{0{N_2},s}} - {\kappa

_2}{v_{0T}}+ {\kappa _3}{v_{0{N_1}}} + {\omega _{{N_1}}}}

\right) \\ \quad + \tfrac{1}{2}\left( {{n_1}\left( {{\kappa

_2}{\omega _{{N_2}}} + {\omega _{T,s}} - {\kappa

_1}{v_{0{N_2},s}} + {\kappa _1}{\kappa _2}{v_{0T}}}-{\kappa

_3}{\kappa _1}{v_{0{N_1}}} \right)} \right. \\ \quad +

{n_2}\left( {\kappa _2^2{v_{0T}} - {\kappa _2}{\omega

_{{N_1}}} + {v_{1,s}} - {\kappa _2}{v_{0{N_2},s}}-{\kappa

_3}{\kappa _2}{v_{0{N_1}}}} \right) + \left. {{\varPhi

_{T,{n_2}}}} \right)\varepsilon + O\left( {{\varepsilon

^2}} \right), \\ {\gamma _{{N_2}{N_1}}} = {\gamma

_{{N_1}{N_2}}} = \tfrac{1}{2}\left( {{\varPhi

_{{N_2},{n_1}}} + {\varPhi _{{N_1},{n_2}}}}

\right)\varepsilon+ O\left( {{\varepsilon ^2}} \right), \\

{\gamma _{TT}} = {v_{0T,s}} + {\kappa _1}{v_{0{N_1}}} +

{\kappa _2}{v_{0{N_2}}} \\ \quad + \left( {{n_2}\left(

{{\omega _{{N_1},s}} - {\kappa _1}{\omega _T}-{\kappa

_3}{\omega _{N_2}} + {\kappa _2}{v_1} - {\kappa

_2}{v_{0T,s}} - \kappa _2^2{v_{0{N_2}}} - {\kappa

_1}{\kappa _2}{v_{0{N_1}}}} \right)} \right. \\ \quad +

\left. {\left. { {n_1}\left( { {\kappa _2}{\omega _T}-

{\omega _{{N_2},s}} -{\kappa _3}{\omega _{N_1}} + {\kappa

_1}{v_1} - {\kappa _1}{v_{0T,s}} - \kappa _1^2{v_{0{N_1}}}

- {\kappa _1}{\kappa _2}{v_{0{N_2}}}} \right)}

\right)\varepsilon + O\left( {{\varepsilon ^2}} \right)}

\right), \\ {\gamma _{{N_1}{N_1}}} = {v_1} + ({\varPhi

_{{N_1},{n_1}}})\varepsilon+ O\left( {{\varepsilon ^2}}

\right), \\ {\gamma _{{N_2}{N_2}}} = {v_1} + ({\varPhi

_{{N_2},{n_2}}})\varepsilon+ O\left( {{\varepsilon ^2}}

\right). \end{gathered}\right\} \end{gather}

Next, we proceed to evaluate the leading-order terms to simplify our equations. First, the incompressibility condition, i.e. ![]() $\textrm {tr}(\boldsymbol \gamma )=0$, at the leading and first order reads

$\textrm {tr}(\boldsymbol \gamma )=0$, at the leading and first order reads

\begin{equation} \left.\begin{gathered} {v_1} ={-} \tfrac{1}{2}\left( {{v_{0T,s}} + {\kappa _1}{v_{0{N_1}}} + {\kappa _2}{v_{0{N_2}}}} \right), \\ {\varPhi _{{N_1},{n_1}}} + {\varPhi _{{N_2},{n_2}}} = {n_2}\left( {{\omega _{{N_1},s}} - {\kappa _1}{\omega _T} - {\kappa _3}{\omega _{{N_2}}} + 3{\kappa _2}{v_1}} \right) \\ + {n_1}\left( { - {\omega _{{N_2},s}} + {\kappa _2}{\omega _T} - {\kappa _3}{\omega _{{N_1}}} + 3{\kappa _1}{v_1}} \right). \end{gathered}\right\} \end{equation}

\begin{equation} \left.\begin{gathered} {v_1} ={-} \tfrac{1}{2}\left( {{v_{0T,s}} + {\kappa _1}{v_{0{N_1}}} + {\kappa _2}{v_{0{N_2}}}} \right), \\ {\varPhi _{{N_1},{n_1}}} + {\varPhi _{{N_2},{n_2}}} = {n_2}\left( {{\omega _{{N_1},s}} - {\kappa _1}{\omega _T} - {\kappa _3}{\omega _{{N_2}}} + 3{\kappa _2}{v_1}} \right) \\ + {n_1}\left( { - {\omega _{{N_2},s}} + {\kappa _2}{\omega _T} - {\kappa _3}{\omega _{{N_1}}} + 3{\kappa _1}{v_1}} \right). \end{gathered}\right\} \end{equation}Afterwards, from the normal stress jump condition at the jet surface, we have

\begin{align} P &={-} \frac{1}{{{{Re}}}}\left( {{\delta _s}\bar \mu \left( {{v_{0T,s}} + {\kappa _1}{v_{0{N_1}}} + {\kappa _2}{v_{0{N_2}}}} \right) - S_{NN}^{(0)}} \right) + \frac{1}{{We\sqrt A_0 }} - {\boldsymbol{f}_{{drag}}}\boldsymbol{\cdot}\boldsymbol{n} \nonumber\\ &\quad + \varepsilon {n_1}\left( {\frac{{{\delta _s}\bar \mu }}{{Re}} \left( { - {\omega _{{N_2},s}} + {\kappa _2}{\omega _T} - {\kappa _3}{\omega _{{N_1}}} + 3{\kappa _1}{v_1}} \right) - \frac{1}{{Re}}S_{NN1}^{(1)} + \frac{{{\kappa _1}}}{{We{{\sqrt A }_0}}}} \right) \nonumber\\ &\quad - \varepsilon {n_2}\left( {\frac{{{\delta _s}\bar \mu }}{{Re}}\left( {{\omega _{{N_1},s}} - {\kappa _1}{\omega _T} - {\kappa _3}{\omega _{{N_2}}} + 3{\kappa _2}{v_1}} \right) - \frac{1}{{Re}}S_{NN2}^{(1)} + \frac{{{\kappa _2}}}{{We{{\sqrt A }_0}}}} \right). \end{align}

\begin{align} P &={-} \frac{1}{{{{Re}}}}\left( {{\delta _s}\bar \mu \left( {{v_{0T,s}} + {\kappa _1}{v_{0{N_1}}} + {\kappa _2}{v_{0{N_2}}}} \right) - S_{NN}^{(0)}} \right) + \frac{1}{{We\sqrt A_0 }} - {\boldsymbol{f}_{{drag}}}\boldsymbol{\cdot}\boldsymbol{n} \nonumber\\ &\quad + \varepsilon {n_1}\left( {\frac{{{\delta _s}\bar \mu }}{{Re}} \left( { - {\omega _{{N_2},s}} + {\kappa _2}{\omega _T} - {\kappa _3}{\omega _{{N_1}}} + 3{\kappa _1}{v_1}} \right) - \frac{1}{{Re}}S_{NN1}^{(1)} + \frac{{{\kappa _1}}}{{We{{\sqrt A }_0}}}} \right) \nonumber\\ &\quad - \varepsilon {n_2}\left( {\frac{{{\delta _s}\bar \mu }}{{Re}}\left( {{\omega _{{N_1},s}} - {\kappa _1}{\omega _T} - {\kappa _3}{\omega _{{N_2}}} + 3{\kappa _2}{v_1}} \right) - \frac{1}{{Re}}S_{NN2}^{(1)} + \frac{{{\kappa _2}}}{{We{{\sqrt A }_0}}}} \right). \end{align}From the tangential stress balances, we can obtain

\begin{gather} \left.\begin{gathered} {\omega _{{N_1}}} ={-} {v_{0{N_2},s}} + {\kappa _2}{v_{0T}} - {\kappa _3}{v_{0{N_1}}}, \\ {\omega _{{N_2}}} = {v_{0{N_1},s}} - {\kappa _1}{v_{0T}} - {\kappa _3}{v_{0{N_2}}}, \end{gathered}\right\} \end{gather}

\begin{gather} \left.\begin{gathered} {\omega _{{N_1}}} ={-} {v_{0{N_2},s}} + {\kappa _2}{v_{0T}} - {\kappa _3}{v_{0{N_1}}}, \\ {\omega _{{N_2}}} = {v_{0{N_1},s}} - {\kappa _1}{v_{0T}} - {\kappa _3}{v_{0{N_2}}}, \end{gathered}\right\} \end{gather}Using (2.45) and (2.48), we can simply obtain

\begin{equation} \left.\begin{gathered} {\varPhi _{{N_1}}} ={-} \tfrac{1}{2}{n_1}{n_2}\left( {{\omega _{{N_1},s}} - {\kappa _1}{\omega _T} - {\kappa _3}{\omega _{{N_2}}} + 3{\kappa _2}{v_1}} \right) \\ \quad + \tfrac{1}{4}\left( {n_1^2 - n_2^2} \right)\left( { - {\omega _{{N_2},s}} + {\kappa _2}{\omega _T} - {\kappa _3}{\omega _{{N_1}}} + 3{\kappa _1}{v_1}} \right), \\ {\varPhi _{{N_2}}} = \tfrac{1}{2}{n_1}{n_2}\left( { - {\omega _{{N_2},s}} + {\kappa _2}{\omega _T} - {\kappa _3}{\omega _{{N_1}}} + 3{\kappa _1}{v_1}} \right) \\ \quad + \tfrac{1}{4}\left( {n_2^2 - n_1^2} \right)\left( {{\omega _{{N_1},s}} - {\kappa _1}{\omega _T} - {\kappa _3}{\omega _{{N_2}}} + 3{\kappa _2}{v_1}} \right). \end{gathered}\right\} \end{equation}

\begin{equation} \left.\begin{gathered} {\varPhi _{{N_1}}} ={-} \tfrac{1}{2}{n_1}{n_2}\left( {{\omega _{{N_1},s}} - {\kappa _1}{\omega _T} - {\kappa _3}{\omega _{{N_2}}} + 3{\kappa _2}{v_1}} \right) \\ \quad + \tfrac{1}{4}\left( {n_1^2 - n_2^2} \right)\left( { - {\omega _{{N_2},s}} + {\kappa _2}{\omega _T} - {\kappa _3}{\omega _{{N_1}}} + 3{\kappa _1}{v_1}} \right), \\ {\varPhi _{{N_2}}} = \tfrac{1}{2}{n_1}{n_2}\left( { - {\omega _{{N_2},s}} + {\kappa _2}{\omega _T} - {\kappa _3}{\omega _{{N_1}}} + 3{\kappa _1}{v_1}} \right) \\ \quad + \tfrac{1}{4}\left( {n_2^2 - n_1^2} \right)\left( {{\omega _{{N_1},s}} - {\kappa _1}{\omega _T} - {\kappa _3}{\omega _{{N_2}}} + 3{\kappa _2}{v_1}} \right). \end{gathered}\right\} \end{equation}Now, using the relations presented, we derive the kinematic and dynamic equations.

2.8. Kinematic expressions

As a next step, we derive the kinematic equations in the leading order. To do so, starting from the projections of (2.30) onto the Cartesian basis vectors, we have at the leading order

\begin{equation} \left.\begin{gathered} {X_{0,t}} + u{X_{0,s}} = {v_{0{N_1}}}\sin (\beta ) + {v_{0T}}\cos (\beta ), \\ {Y_{0,t}} + u{Y_{0,s}} ={-} {v_{0{N_1}}}\cos (\alpha )\cos (\beta ) + {v_{0{N_2}}}\sin (\alpha ) + {v_{0T}}\cos (\alpha )\sin (\beta ), \\ {Z_{0,t}} + u{Z_{0,s}} ={-} {v_{0{N_1}}}\sin (\alpha )\cos (\beta ) - {v_{0{N_2}}}\cos (\alpha ) + {v_{0T}}\sin (\alpha )\sin (\beta ). \end{gathered}\right\} \end{equation}

\begin{equation} \left.\begin{gathered} {X_{0,t}} + u{X_{0,s}} = {v_{0{N_1}}}\sin (\beta ) + {v_{0T}}\cos (\beta ), \\ {Y_{0,t}} + u{Y_{0,s}} ={-} {v_{0{N_1}}}\cos (\alpha )\cos (\beta ) + {v_{0{N_2}}}\sin (\alpha ) + {v_{0T}}\cos (\alpha )\sin (\beta ), \\ {Z_{0,t}} + u{Z_{0,s}} ={-} {v_{0{N_1}}}\sin (\alpha )\cos (\beta ) - {v_{0{N_2}}}\cos (\alpha ) + {v_{0T}}\sin (\alpha )\sin (\beta ). \end{gathered}\right\} \end{equation}

Differentiating the expressions in (2.50) with respect to ![]() $s$ and after some manipulation, we end up with

$s$ and after some manipulation, we end up with

and consequently from (2.11a–c) we arrive at

In the following, we derive the dynamic equations that govern the behaviours of a slender curved jet and, afterwards, we present the corresponding constitutive relations to capture the rheological features of a viscoelastic jet through the CS process.

2.9. Dynamic equations

In this section, using the asymptotic expressions for pressure (2.46) and velocity (2.43) we deliver the dynamic equations of a viscoelastic curved jet consisting of mass, momentum and angular momentum equations. Considering a control volume ![]() $V$ bounded by the jet lateral surface and two cross-sections,

$V$ bounded by the jet lateral surface and two cross-sections, ![]() $A_1$ and

$A_1$ and ![]() $A_2$ corresponding to

$A_2$ corresponding to ![]() $s_1$ and

$s_1$ and ![]() $s_2$ in figure 1, and ignoring the density change by temperature variations, i.e.

$s_2$ in figure 1, and ignoring the density change by temperature variations, i.e. ![]() $\bar {\rho }=1$, the mass conservation equation reads

$\bar {\rho }=1$, the mass conservation equation reads

It is worth mentioning that mass transfer velocity through the boundary of our infinitesimal element is equal to ![]() $({\boldsymbol {v}} - \boldsymbol {w})\boldsymbol {\cdot }{\boldsymbol {T}}$, which, in the leading order, is the convectional velocity at the baseline

$({\boldsymbol {v}} - \boldsymbol {w})\boldsymbol {\cdot }{\boldsymbol {T}}$, which, in the leading order, is the convectional velocity at the baseline ![]() $u_3$; hereafter, for simplicity of the presentation, we use

$u_3$; hereafter, for simplicity of the presentation, we use ![]() $u$ instead of

$u$ instead of ![]() $u_3$, representing the projection of the convectional velocity onto the Bishop frame in the tangential direction. Using the cross-sectional averaging rules, i.e. (2.40) and (2.41), and the asymptotic expansion expressions (2.43), we have

$u_3$, representing the projection of the convectional velocity onto the Bishop frame in the tangential direction. Using the cross-sectional averaging rules, i.e. (2.40) and (2.41), and the asymptotic expansion expressions (2.43), we have

Now, we turn to derive the momentum balance equations. After integrating (2.2) over our control volume and using the averaging rule (2.40) and (2.41), we arrive at

\begin{align} \frac{\partial }{{\partial t}}\left[ {\int_V {{\boldsymbol{v}}\,{\rm d} V}} \right] + \frac{\partial }{{\partial s}}\left[ {\int_{{A_1}}^{{A_2}} {\left( {({\boldsymbol{v}} - {\boldsymbol{w}})\boldsymbol{\cdot}{\boldsymbol{T}}} \right){\boldsymbol{v}}\,{\rm d} A} } \right] = \frac{\partial }{{\partial s}}\left[ {\int_{{A_1}}^{{A_2}} {\left( {{\boldsymbol{\varPi}}\boldsymbol{\cdot}{\boldsymbol{T}}} \right)\,{\rm d} A}} \right] + \int_V {{\boldsymbol{F}}\,{\rm d} V}.\end{align}

\begin{align} \frac{\partial }{{\partial t}}\left[ {\int_V {{\boldsymbol{v}}\,{\rm d} V}} \right] + \frac{\partial }{{\partial s}}\left[ {\int_{{A_1}}^{{A_2}} {\left( {({\boldsymbol{v}} - {\boldsymbol{w}})\boldsymbol{\cdot}{\boldsymbol{T}}} \right){\boldsymbol{v}}\,{\rm d} A} } \right] = \frac{\partial }{{\partial s}}\left[ {\int_{{A_1}}^{{A_2}} {\left( {{\boldsymbol{\varPi}}\boldsymbol{\cdot}{\boldsymbol{T}}} \right)\,{\rm d} A}} \right] + \int_V {{\boldsymbol{F}}\,{\rm d} V}.\end{align}After applying the asymptotic expressions and some manipulations, we end up having

in which ![]() ${\boldsymbol {\eta }} = \int _A {{{\langle \boldsymbol {\varPi } \rangle }_T}\,\textrm {d} A} = ( {{\eta _{{N_1}}},\ {\eta _{{N_2}}},\ {\eta _T}})$ denotes the tensile force vector, in which

${\boldsymbol {\eta }} = \int _A {{{\langle \boldsymbol {\varPi } \rangle }_T}\,\textrm {d} A} = ( {{\eta _{{N_1}}},\ {\eta _{{N_2}}},\ {\eta _T}})$ denotes the tensile force vector, in which ![]() $\eta _{N_1}$ and

$\eta _{N_1}$ and ![]() $\eta _{N_2}$ stand for the shearing forces and

$\eta _{N_2}$ stand for the shearing forces and ![]() ${\eta _T}$ stands for the longitudinal force. From the definition of

${\eta _T}$ stands for the longitudinal force. From the definition of ![]() $\boldsymbol {\eta }$, we have

$\boldsymbol {\eta }$, we have

It is noted that the shearing force components, i.e. ![]() ${\eta _{{N_1}}}$ and

${\eta _{{N_1}}}$ and ![]() ${\eta _{{N_2}}}$, are rather complicated and thus cannot be obtained explicitly. Next, to attain the external forces

${\eta _{{N_2}}}$, are rather complicated and thus cannot be obtained explicitly. Next, to attain the external forces ![]() $\boldsymbol {F}$, we project the related terms in the outer bases (here Cartesian bases) onto the Bishop basis vectors; in doing so, we arrive at

$\boldsymbol {F}$, we project the related terms in the outer bases (here Cartesian bases) onto the Bishop basis vectors; in doing so, we arrive at