1. Introduction

The location of boundary layer transition at low chord Reynolds numbers (

![]() ${{Re}}_c\sim 1\times 10^5$

; Lissaman Reference Lissaman1983) is sensitive to changes in free stream velocity magnitude and direction (Ellsworth & Mueller Reference Ellsworth and Mueller1991; Burgmann & Schröder Reference Burgmann and Schröder2008; Coull & Hodson Reference Coull and Hodson2011). The wings and rotor blades of small unmanned aerial vehicles are examples of lifting surfaces that operate at low chord Reynolds numbers in unsteady conditions (Mueller & DeLaurier Reference Mueller and DeLaurier2003). On lifting surfaces at low Reynolds numbers, transition usually occurs downstream of laminar boundary layer separation (Carmichael Reference Carmichael1981). The highly unstable separated laminar shear layer rapidly transitions to turbulence and may reattach to the lifting surface if the adverse pressure gradient is not too severe (Horton Reference Horton1968). The region of recirculating flow bounded by the streamline that connects the separation and reattachment points is known as a laminar separation bubble (LSB) (Tani Reference Tani1964). LSBs may be classified as either short or long, depending on whether they have a relatively local or global influence on the pressure distribution over the lifting surface (Tani Reference Tani1964).

${{Re}}_c\sim 1\times 10^5$

; Lissaman Reference Lissaman1983) is sensitive to changes in free stream velocity magnitude and direction (Ellsworth & Mueller Reference Ellsworth and Mueller1991; Burgmann & Schröder Reference Burgmann and Schröder2008; Coull & Hodson Reference Coull and Hodson2011). The wings and rotor blades of small unmanned aerial vehicles are examples of lifting surfaces that operate at low chord Reynolds numbers in unsteady conditions (Mueller & DeLaurier Reference Mueller and DeLaurier2003). On lifting surfaces at low Reynolds numbers, transition usually occurs downstream of laminar boundary layer separation (Carmichael Reference Carmichael1981). The highly unstable separated laminar shear layer rapidly transitions to turbulence and may reattach to the lifting surface if the adverse pressure gradient is not too severe (Horton Reference Horton1968). The region of recirculating flow bounded by the streamline that connects the separation and reattachment points is known as a laminar separation bubble (LSB) (Tani Reference Tani1964). LSBs may be classified as either short or long, depending on whether they have a relatively local or global influence on the pressure distribution over the lifting surface (Tani Reference Tani1964).

Reattachment in LSBs is fundamentally a consequence of transition in the separated shear layer. The transition process in LSBs is preceded by the receptivity process in the attached laminar boundary layer upstream of the LSB (Jones et al. 2010). If the Reynolds number is sufficiently large, as is common for lifting surfaces in practice, the laminar boundary layer becomes unstable to Tollmien–Schichting (T-S) waves upstream of separation (Diwan & Ramesh Reference Diwan and Ramesh2009). Although oblique and normal modes both become amplified, the normal mode is the most unstable (Michelis et al. Reference Michelis, Yarusevych and Kotsonis2018). In the region of adverse pressure gradient, an inflection point in the streamwise velocity profile develops, activating the inviscid Kelvin–Helmholtz (K-H) instability mechanism. As the inflection point moves away from the wall, the K-H mechanism becomes stronger (Diwan & Ramesh Reference Diwan and Ramesh2009). If the magnitude of the reverse flow is greater than

![]() $6\,\%{-}8\,\%$

of the free stream velocity, a stationary global instability can lead to spanwise-periodic three-dimensional variations in LSB topology and reverse flow magnitude (Rodríguez & Theofilis Reference Rodríguez and Theofilis2010). In LSBs with relatively small reverse flow magnitudes, disturbance growth is convective. However, if the magnitude of the reverse flow exceeds

$6\,\%{-}8\,\%$

of the free stream velocity, a stationary global instability can lead to spanwise-periodic three-dimensional variations in LSB topology and reverse flow magnitude (Rodríguez & Theofilis Reference Rodríguez and Theofilis2010). In LSBs with relatively small reverse flow magnitudes, disturbance growth is convective. However, if the magnitude of the reverse flow exceeds

![]() $16\,\%{-}25\,\%$

of the free stream velocity, the LSB may become absolutely unstable, sustaining disturbances in the absence of external perturbations (Rodríguez et al. Reference Rodríguez, Gennaro and Souza2021). Following the initial growth of disturbances that agrees well with linear stability predictions (Dovgal et al. Reference Dovgal, Kozlov and Michalke1994; Diwan & Ramesh Reference Diwan and Ramesh2012), there is a progressive intensification of nonlinear interactions (Dovgal et al. Reference Dovgal, Kozlov and Michalke1994). The increase of perturbation amplitudes eventually leads to the formation of shear layer roll-up vortices near the location of maximum LSB height (Watmuff Reference Watmuff1999). At relatively low levels of free stream turbulence intensity, the roll-up vortices in short LSBs are largely two-dimensional at inception (Lengani & Simoni Reference Lengani and Simoni2015; Istvan & Yarusevych Reference Istvan and Yarusevych2018). However, the vortices undergo rapid deformations and breakdown in the vicinity of the mean reattachment location (Marxen et al. Reference Marxen, Lang and Rist2013). Several authors have linked sudden LSB expansion and stall to changes in the characteristics of the vortical structures produced during the transition process, with less coherent and upstream propagating vortices being observed in long LSBs (Marxen & Henningson Reference Marxen and Henningson2011; Dellacasagrande et al. 2024).

$16\,\%{-}25\,\%$

of the free stream velocity, the LSB may become absolutely unstable, sustaining disturbances in the absence of external perturbations (Rodríguez et al. Reference Rodríguez, Gennaro and Souza2021). Following the initial growth of disturbances that agrees well with linear stability predictions (Dovgal et al. Reference Dovgal, Kozlov and Michalke1994; Diwan & Ramesh Reference Diwan and Ramesh2012), there is a progressive intensification of nonlinear interactions (Dovgal et al. Reference Dovgal, Kozlov and Michalke1994). The increase of perturbation amplitudes eventually leads to the formation of shear layer roll-up vortices near the location of maximum LSB height (Watmuff Reference Watmuff1999). At relatively low levels of free stream turbulence intensity, the roll-up vortices in short LSBs are largely two-dimensional at inception (Lengani & Simoni Reference Lengani and Simoni2015; Istvan & Yarusevych Reference Istvan and Yarusevych2018). However, the vortices undergo rapid deformations and breakdown in the vicinity of the mean reattachment location (Marxen et al. Reference Marxen, Lang and Rist2013). Several authors have linked sudden LSB expansion and stall to changes in the characteristics of the vortical structures produced during the transition process, with less coherent and upstream propagating vortices being observed in long LSBs (Marxen & Henningson Reference Marxen and Henningson2011; Dellacasagrande et al. 2024).

For a given lifting surface geometry, the three principal factors influencing the location and size of the laminar separation bubble are the angle of attack, Reynolds number and disturbance environment. As the angle of attack is increased, the LSB shortens and moves upstream as the roll-up vortex shedding frequency increases due to the stronger adverse pressure gradient and increase in boundary layer edge velocity (Burgmann et al. Reference Burgmann, Dannemann and Schröder2008). An increase in Reynolds number also causes a decrease in LSB length due to earlier transition caused by more rapid disturbance amplification (O’Meara & Mueller Reference O’Meara and Mueller1987). However, the effect of Reynolds number on the location of separation is relatively weak (Dellacasagrande et al. Reference Dellacasagrande, Barsi, Lengani, Simoni and Verdoya2020).

In practice, low-Reynolds-number lifting surfaces often operate in unsteady environments (Coull & Hodson Reference Coull and Hodson2011; Jones et al. Reference Jones, Cetiner and Smith2022). Transient forces on a lifting surface in an unsteady flow differ from those under quasi-steady conditions due to time-lag effects and pressure gradient changes associated with fluid acceleration (Ericsson & Reding Reference Ericsson and Reding1988). One source of time-lag effects is the finite convection speed of pressure fluctuations in the boundary layer (Kistler & Chen Reference Kistler and Chen1963; Ericsson & Reding Reference Ericsson and Reding1988). Another time-lag effect is produced whenever the bound circulation of the lifting surface changes, because this must coincide with the shedding of opposite-signed vorticity into the wake (von Kármán & Sears Reference von Kármán and Sears1938; Ericsson & Reding Reference Ericsson and Reding1988). The induced velocity of the shed vorticity causes a change in effective angle of attack on the lifting surface (von Kármán & Sears Reference von Kármán and Sears1938). Additionally, added mass forces and moving wall effects may become significant for rapid lifting surface accelerations (Ericsson & Reding Reference Ericsson and Reding1988). Unsteady transient changes in operating conditions can lead to substantial changes in aerodynamic loads relative to steady conditions, particularly during the dynamic stall of lifting surfaces undergoing rapid increases in angle of attack (McCroskey Reference McCroskey1981). Although dynamic stall during cyclic pitching motions has received considerable attention (Corke & Thomas Reference Corke and Thomas2015), dynamic stall and reattachment occurring during isolated pitch-up or pitch-down ramps such as those that may occur during aircraft manoeuvres or wind gusts remain less well understood (Jones et al. Reference Jones, Cetiner and Smith2022).

Several studies have investigated LSB formation on pitching and surging lifting surfaces (Brendel & Mueller Reference Brendel and Mueller1988; Ellsworth & Mueller Reference Ellsworth and Mueller1991; Nati et al. Reference Nati, de Kat, Scarano and van Oudheusden2015). For unsteady motions that cause an increase in adverse pressure gradient relative to quasi-steady conditions, such as streamwise deceleration or decreasing angle of attack, the locations of separation, transition and reattachment shift upstream relative to their locations in quasi-steady conditions (Brendel & Mueller Reference Brendel and Mueller1988; Ellsworth & Mueller Reference Ellsworth and Mueller1991; Nati et al. Reference Nati, de Kat, Scarano and van Oudheusden2015). An opposite shift in these locations relative to quasi-steady conditions occurs for motions that cause a decrease in adverse pressure gradient relative to quasi-steady conditions, i.e. streamwise acceleration or increasing angle of attack. As a consequence, the separation, transition and reattachment points exhibit hysteresis loops with respect to these two parameters (Nati et al. Reference Nati, de Kat, Scarano and van Oudheusden2015; Toppings & Yarusevych Reference Toppings and Yarusevych2024). The hysteresis in LSB structure has been linked to hysteresis in transition dynamics, with a lag in shear layer vortex shedding frequency relative to quasi-steady conditions observed by Nati et al. (Reference Nati, de Kat, Scarano and van Oudheusden2015). Under certain conditions, the downstream movement of the transition and reattachment points during acceleration can result in ‘surge-induced stall’ (Greenblatt et al. Reference Greenblatt, Müller-Vahl and Strangfeld2023). Conversely, the delay in separation during an increase in the angle of attack may cause transient LSB formation under nominally stalled conditions, leading to a substantial increase in transient lift forces (Stutz et al. Reference Stutz, Hrynuk and Bohl2022). The presence of an LSB can cause substantial deviations of unsteady lift coefficients from inviscid aerofoil theories (Isaacs Reference Isaacs1945; Greenberg Reference Greenberg1947) for large free stream oscillation amplitudes and low Reynolds numbers, even at small angles of attack (Strangfeld et al. Reference Strangfeld, Müller-Vahl, Nayeri, Paschereit and Greenblatt2016).

Relatively large changes in lift and drag forces may result from relatively small changes in operating conditions if the change affects the ability of the developing turbulent shear layer to reattach (Tani Reference Tani1964). The rapid expansion of a short LSB and the formation of either a long LSB or complete cessation of reattachment is known as bubble bursting (Gaster Reference Gaster1967) and is associated with a substantial loss of lift and increase of drag (Tani Reference Tani1964; Mitra & Ramesh Reference Mitra and Ramesh2019). Bursting occurs when the turbulent shear layer cannot overcome the pressure increase required to form a short LSB (Horton Reference Horton1969). The distance between separation and transition is similar for both short and long bubbles because mean disturbance growth rates are similar in both types of LSBs (Gaster Reference Gaster1967; Horton Reference Horton1969). This is due to the stabilising effect of lower Reynolds number in long LSBs being counteracted by the increased distance of the separated shear layer from the surface (Gaster Reference Gaster1967).

At relatively high chord Reynolds numbers (

![]() ${{Re}}_c\sim 10^6$

), LSB bursting may initiate when the upstream movement of the turbulent separation point reaches the reattachment point of the LSB (Benton & Visbal Reference Benton and Visbal2019). The dynamic stall vortex (DSV) formed in such cases initially has a diameter of the order of the length of the LSB (Benton & Visbal Reference Benton and Visbal2019). At lower chord Reynolds numbers (

${{Re}}_c\sim 10^6$

), LSB bursting may initiate when the upstream movement of the turbulent separation point reaches the reattachment point of the LSB (Benton & Visbal Reference Benton and Visbal2019). The dynamic stall vortex (DSV) formed in such cases initially has a diameter of the order of the length of the LSB (Benton & Visbal Reference Benton and Visbal2019). At lower chord Reynolds numbers (

![]() ${{Re}}_c\sim 10^5$

), bursting initiates with a relatively slow downstream movement of the reattachment point at a nearly constant velocity (Alferez et al. Reference Alferez, Mary and Lamballais2013). Once a critical LSB length is reached, the downstream movement of the reattachment point rapidly accelerates (Alferez et al. Reference Alferez, Mary and Lamballais2013). The precise moment at which the reattachment point begins to rapidly move downstream is sensitive to the initial conditions of the boundary layer, making the bursting process non-deterministic (Alferez et al. Reference Alferez, Mary and Lamballais2013).

${{Re}}_c\sim 10^5$

), bursting initiates with a relatively slow downstream movement of the reattachment point at a nearly constant velocity (Alferez et al. Reference Alferez, Mary and Lamballais2013). Once a critical LSB length is reached, the downstream movement of the reattachment point rapidly accelerates (Alferez et al. Reference Alferez, Mary and Lamballais2013). The precise moment at which the reattachment point begins to rapidly move downstream is sensitive to the initial conditions of the boundary layer, making the bursting process non-deterministic (Alferez et al. Reference Alferez, Mary and Lamballais2013).

Unsteady effects can be significant during the change between reattaching and massively separated flow states. Cessation of reattachment during LSB bursting is followed by oscillations of the trajectory of the separated shear layer (Alferez et al. Reference Alferez, Mary and Lamballais2013; Toppings & Yarusevych Reference Toppings and Yarusevych2023), and these oscillations are associated with a non-monotonic decrease in the lift produced by the lifting surface after LSB bursting (Toppings & Yarusevych Reference Toppings and Yarusevych2024). During both LSB formation and bursting transients, there is an upstream movement in the location of transition, after which the transition location moves downstream to its steady-state position (Alferez et al. Reference Alferez, Mary and Lamballais2013; Toppings & Yarusevych Reference Toppings and Yarusevych2023).

In addition to changes in Reynolds number and adverse pressure gradient, LSB formation and bursting may also be triggered by a change in the initial amplitudes of boundary layer disturbances. In numerical simulations (Marxen & Henningson Reference Marxen and Henningson2011) and experiments (Yarusevych & Kotsonis Reference Yarusevych and Kotsonis2017) employing controlled forcing of boundary layer disturbances, LSB bursting has been observed to occur after the cessation of controlled disturbances. This is because a reduction in the amplitudes of disturbances in the boundary layer leads to a delay in transition and failure of reattachment (Marxen & Henningson Reference Marxen and Henningson2011; Yarusevych & Kotsonis Reference Yarusevych and Kotsonis2017).

The duration of the transient response of an LSB to a change in operating conditions is relatively large compared with the shear layer vortex shedding period. Yarusevych & Kotsonis (Reference Yarusevych and Kotsonis2017) reported transient durations of

![]() $23$

and

$23$

and

![]() $33$

shedding periods after the initiation and cessation of controlled disturbances, respectively. In their experiment, reattachment occurred in both the natural and controlled flows. For changes in operating conditions that cause cessation or initiation of reattachment, the transient durations are considerably longer. For ramp changes in free stream velocity leading to LSB formation and bursting, Toppings & Yarusevych (Reference Toppings and Yarusevych2023) reported transient durations of the order of

$33$

shedding periods after the initiation and cessation of controlled disturbances, respectively. In their experiment, reattachment occurred in both the natural and controlled flows. For changes in operating conditions that cause cessation or initiation of reattachment, the transient durations are considerably longer. For ramp changes in free stream velocity leading to LSB formation and bursting, Toppings & Yarusevych (Reference Toppings and Yarusevych2023) reported transient durations of the order of

![]() $100$

shedding periods. Consistent between the studies of Yarusevych & Kotsonis (Reference Yarusevych and Kotsonis2017) and Toppings & Yarusevych (Reference Toppings and Yarusevych2023) is the observation that transients leading to a reduction in the extent of separation are shorter than those leading to an increase in the extent of separation. This difference is attributed to the increase in stability of the separated shear layer that occurs when a reduction in the extent of separation causes the shear layer to move closer to the wall (Dovgal et al. Reference Dovgal, Kozlov and Michalke1994). Understanding the transient dynamics of LSB formation and bursting is foundational for the design of robust control systems for aircraft wings and turbine blades that operate in unsteady conditions at low Reynolds numbers. Furthermore, end effects are always present in these applications, which may modulate the LSB formation and bursting processes (Toppings & Yarusevych Reference Toppings and Yarusevych2024).

$100$

shedding periods. Consistent between the studies of Yarusevych & Kotsonis (Reference Yarusevych and Kotsonis2017) and Toppings & Yarusevych (Reference Toppings and Yarusevych2023) is the observation that transients leading to a reduction in the extent of separation are shorter than those leading to an increase in the extent of separation. This difference is attributed to the increase in stability of the separated shear layer that occurs when a reduction in the extent of separation causes the shear layer to move closer to the wall (Dovgal et al. Reference Dovgal, Kozlov and Michalke1994). Understanding the transient dynamics of LSB formation and bursting is foundational for the design of robust control systems for aircraft wings and turbine blades that operate in unsteady conditions at low Reynolds numbers. Furthermore, end effects are always present in these applications, which may modulate the LSB formation and bursting processes (Toppings & Yarusevych Reference Toppings and Yarusevych2024).

Through their influence on the streamwise and spanwise pressure gradients on a lifting surface, end effects substantially affect the transition process near the root and tip of a lifting surface (Awasthi et al. Reference Awasthi, Moreau and Doolan2018). Due to larger changes to the spanwise pressure gradient near the wing tip, the spanwise extent of tip effects exceeds that of root effects (Toppings & Yarusevych Reference Toppings and Yarusevych2022). Outside of the end affected regions, the streamwise pressure distribution of a lifting surface operating at low Reynolds number is equivalent to that of a two-dimensional aerofoil at a reduced effective angle of attack (Bastedo & Mueller Reference Bastedo and Mueller1986), and LSB structure and vortex shedding dynamics are analogous to those observed on two-dimensional geometries (Toppings & Yarusevych Reference Toppings and Yarusevych2022). However, in the regions within approximately

![]() $0.5c$

of a wing or blade tip or root, the flow-field becomes highly three-dimensional (Huang & Lin Reference Huang and Lin1995; Awasthi et al. Reference Awasthi, Moreau and Doolan2018), and distance of the separated shear layer from the wall decreases (Toppings & Yarusevych Reference Toppings and Yarusevych2022). The reduction in local effective angle of attack near the tip produces a downstream shift in separation and a lengthening of the LSB (Bastedo & Mueller Reference Bastedo and Mueller1986). The spanwise flow present near a tip or root may cause reattachment prior to transition, and the downwash produced by the tip vortex may entirely eliminate the LSB in proximity to the tip (Huang & Lin Reference Huang and Lin1995; Toppings & Yarusevych Reference Toppings and Yarusevych2021). Near the root of a lifting surface, junction flow effects may also inhibit laminar separation (Awasthi et al. Reference Awasthi, Moreau and Doolan2018), and transition may be accelerated due to the influence of disturbances from the end-wall boundary layer (Toppings & Yarusevych Reference Toppings and Yarusevych2022).

$0.5c$

of a wing or blade tip or root, the flow-field becomes highly three-dimensional (Huang & Lin Reference Huang and Lin1995; Awasthi et al. Reference Awasthi, Moreau and Doolan2018), and distance of the separated shear layer from the wall decreases (Toppings & Yarusevych Reference Toppings and Yarusevych2022). The reduction in local effective angle of attack near the tip produces a downstream shift in separation and a lengthening of the LSB (Bastedo & Mueller Reference Bastedo and Mueller1986). The spanwise flow present near a tip or root may cause reattachment prior to transition, and the downwash produced by the tip vortex may entirely eliminate the LSB in proximity to the tip (Huang & Lin Reference Huang and Lin1995; Toppings & Yarusevych Reference Toppings and Yarusevych2021). Near the root of a lifting surface, junction flow effects may also inhibit laminar separation (Awasthi et al. Reference Awasthi, Moreau and Doolan2018), and transition may be accelerated due to the influence of disturbances from the end-wall boundary layer (Toppings & Yarusevych Reference Toppings and Yarusevych2022).

Both tip and root effects are known to influence the stall dynamics of finite-span lifting surfaces. Due to the increase in local effective angle of attack near the wing root, massive separation on full-scale aircraft wings typically begins near the root and progresses towards the tip (Gudmundsson Reference Gudmundsson2014; Andreu Angulo & Ansell Reference Angulo Andreu and Ansell2019). However, at low Reynolds numbers where stall is precipitated by LSB bursting due to a decrease in Reynolds number, massive separation initiates around the location of maximum LSB thickness, which may be located closer to the mid-span than the wing root (Toppings & Yarusevych Reference Toppings and Yarusevych2024). Subsequently, the region of massively separated flow expands towards the root and tip as the stall develops (Toppings & Yarusevych Reference Toppings and Yarusevych2024). During LSB formation during an increase in Reynolds number, this progression is reversed, with reattachment initiating near the root and tip and progressing towards the location of maximum thickness of the resulting LSB (Toppings & Yarusevych Reference Toppings and Yarusevych2024). A limited number of experimental studies have considered the spanwise propagation of dynamic stall during isolated pitching motions, reporting substantial three-dimensionality of the DSV (Coton & Galbraith Reference Coton and Galbraith1999). Since those studies focused on surface pressure measurements (Schreck & Hellin Reference Schreck and Hellin1994; Schreck et al. Reference Schreck, Faller and Luttges1996; Coton & Galbraith Reference Coton and Galbraith1999) and flow visualisations (Moir & Coton Reference Moir and Coton1995), knowledge of the spanwise velocity field development during isolated pitching motions remains limited.

Because LSB formation or bursting can be caused by changes in Reynolds number, angle of attack or external disturbances, there are multiple pathways between short and long LSB flow configurations. However, our knowledge of how LSB formation and bursting dynamics is affected by the way in which the external operating conditions change remains limited, impeding more accurate prediction of LSB formation and bursting in unsteady real-world conditions. The objective of this study is to understand how the type and rate of change of operating conditions affect transient LSB development. Specifically, we compare the transient dynamics of LSB formation and bursting on a lifting surface resulting from changes in Reynolds number to those resulting from changes in angle of attack, focussing on the relationship between the flow field development and the aerodynamic loads. The effect of varying pitch rate is also studied to understand how the duration of a change in operating conditions affects the duration of the flow response. A secondary objective is to elucidate the influence of finite aspect ratio on the LSB formation and bursting processes. These objectives are achieved through wind tunnel experiments on two-dimensional aerofoil and finite wing models, employing lift force measurements simultaneously with particle image velocimetry (PIV).

2. Experimental methods

Experiments were performed in the recirculating wind tunnel at the University of Waterloo. The turbulence intensity in the centre of the empty test section measured using a single hot-wire anemometer with the signal low-pass filtered at 10 kHz was less than

![]() $0.09\,\%$

. The integral length scale of the turbulence was estimated using Taylor’s frozen turbulence approximation (Taylor Reference Taylor1938) to be approximately

$0.09\,\%$

. The integral length scale of the turbulence was estimated using Taylor’s frozen turbulence approximation (Taylor Reference Taylor1938) to be approximately

![]() $0.3c$

.

$0.3c$

.

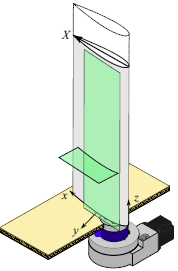

An aspect ratio

![]() $2.5$

wing model of chord

$2.5$

wing model of chord

![]() $c= 0.2\,\textrm {m}$

with a NACA 0018 cross-section was cantilevered vertically from the floor of the 0.61 m

$c= 0.2\,\textrm {m}$

with a NACA 0018 cross-section was cantilevered vertically from the floor of the 0.61 m

![]() $\times$

0.61 m test section. A schematic of the model set-up is presented in figure 1. A two-dimensional aerofoil model was approximated by attaching an extension to the end of the wing model (dashed line in figure 1), so that the model spanned the entire height of the test section. The wing model and extension were machined from acrylic, polished iteratively with sandpaper to 1500 grit and finally polished with a finer polishing paste. The angle of attack of the wing and aerofoil models was controlled through a stepper motor connected to a Velmex B48 rotary table and measured by an incremental encoder with a resolution of

$\times$

0.61 m test section. A schematic of the model set-up is presented in figure 1. A two-dimensional aerofoil model was approximated by attaching an extension to the end of the wing model (dashed line in figure 1), so that the model spanned the entire height of the test section. The wing model and extension were machined from acrylic, polished iteratively with sandpaper to 1500 grit and finally polished with a finer polishing paste. The angle of attack of the wing and aerofoil models was controlled through a stepper motor connected to a Velmex B48 rotary table and measured by an incremental encoder with a resolution of

![]() ${0.036}^{\circ }$

. Angles of attack of the wing and aerofoil models were set relative to the measured zero-lift angle. The uncertainty of the angle of attack is estimated to be

${0.036}^{\circ }$

. Angles of attack of the wing and aerofoil models were set relative to the measured zero-lift angle. The uncertainty of the angle of attack is estimated to be

![]() $0.06^{\circ }$

(

$0.06^{\circ }$

(

![]() $95\,\%$

confidence). The wing model was attached to the rotary table through a 6-axis JR3 30E12A4 load cell. The voltage signals from the load cell were amplified using a JR3 amplifier and recorded using a

$95\,\%$

confidence). The wing model was attached to the rotary table through a 6-axis JR3 30E12A4 load cell. The voltage signals from the load cell were amplified using a JR3 amplifier and recorded using a

![]() $24$

-bit National Instruments PCI-4472 data acquisition card at a sampling rate of 10 kHz. The absolute uncertainty in instantaneous lift force measurements is estimated to be less than 0.2 N. However, since the assumed constant bias error of the load cell does not affect comparisons between force measurements, the presented uncertainties in aerodynamic coefficients account solely for random errors in the measurements. The reference velocity used in the calculation of lift coefficients was obtained from a single hot-wire anemometer located in the test section

$24$

-bit National Instruments PCI-4472 data acquisition card at a sampling rate of 10 kHz. The absolute uncertainty in instantaneous lift force measurements is estimated to be less than 0.2 N. However, since the assumed constant bias error of the load cell does not affect comparisons between force measurements, the presented uncertainties in aerodynamic coefficients account solely for random errors in the measurements. The reference velocity used in the calculation of lift coefficients was obtained from a single hot-wire anemometer located in the test section

![]() $2.75c$

upstream of the model.

$2.75c$

upstream of the model.

Figure 1. Model set-up and coordinate system definition. PIV measurement planes in green.

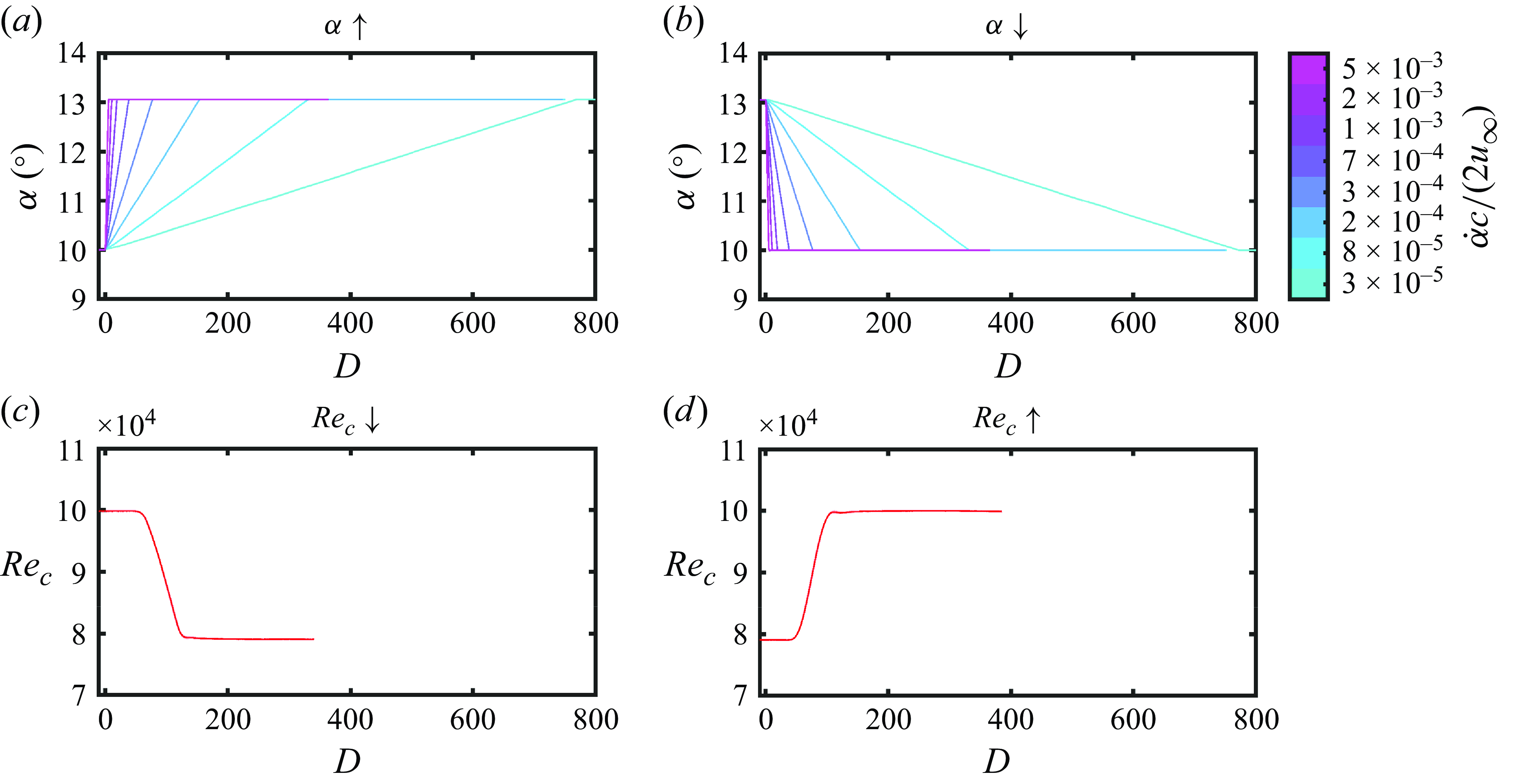

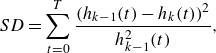

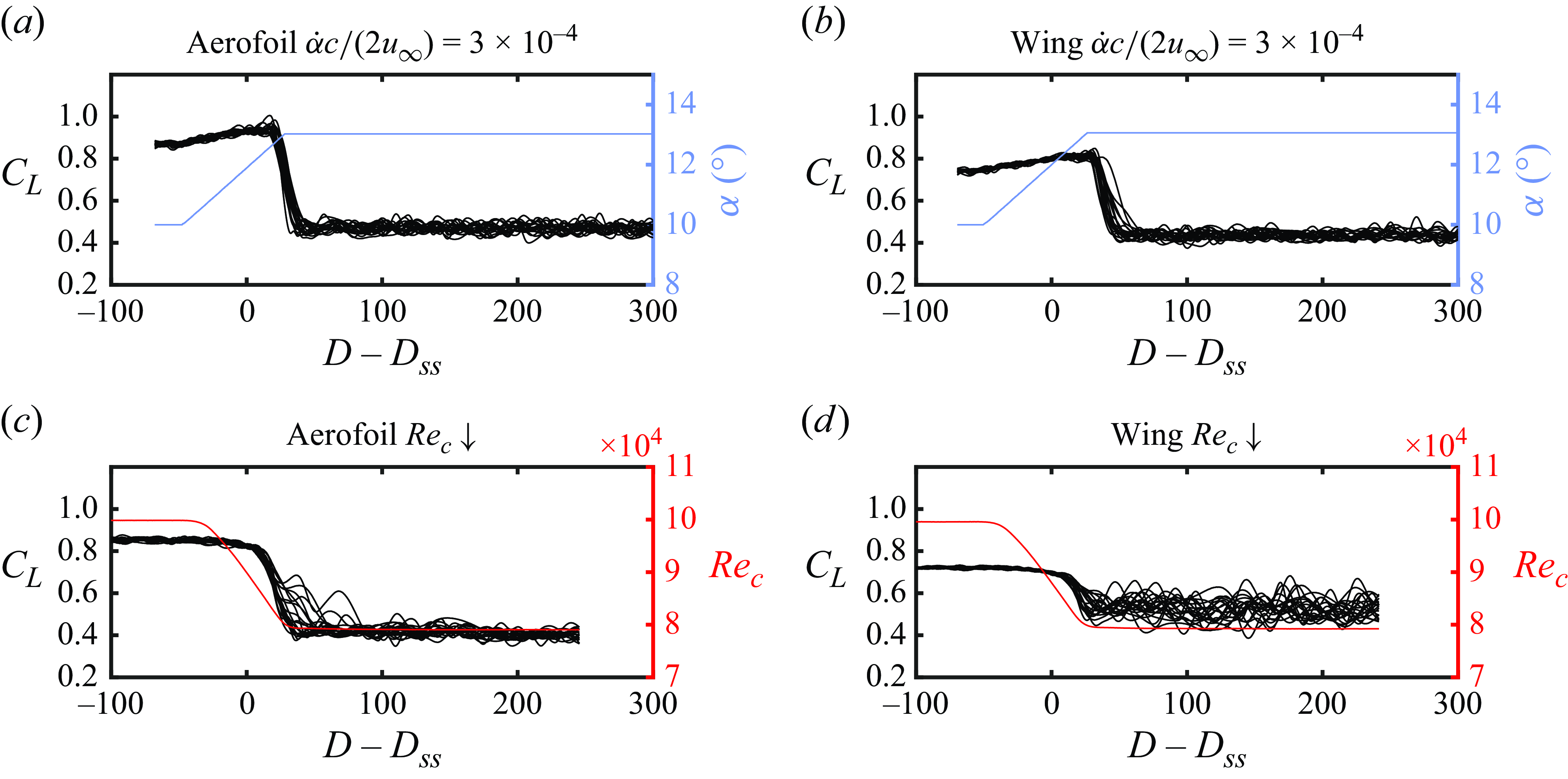

Figure 2. Controlled (a,b) angle of attack and (c,d) Reynolds number changes leading to (a,c) LSB bursting and (b,d) formation on the suction surface of the aerofoil and wing models. Colours in panels (a) and (b) correspond to different pitch rates.

The wing and aerofoil models were subject to two types of unsteadiness: (i) changes in angle of attack at constant Reynolds number and (ii) changes in Reynolds number at constant angle of attack. The effect of the Reynolds number on the transient flow development and aerodynamic loading was considered in separate tests from the changes in angle of attack. The changes in angle of attack were performed between

![]() $10^{\circ }$

and

$10^{\circ }$

and

![]() $13^{\circ }$

at pitch rates in the range of

$13^{\circ }$

at pitch rates in the range of

![]() $3\times 10^{-5}\leqslant \vert \dot {\alpha }c/2u_\infty \vert \leqslant 5\times 10^{-3}$

. The slowest pitch rate was selected to approximate a quasi-steady change in angle of attack (Le Fouest et al. Reference Le Fouest, Deparday and Mulleners2021), whereas the fastest pitch rate was limited by the inertial forces of the model on the load cell. The time history of the angle of attack for all pitch rates tested is shown in figures 2(a) and 2(b), where the temporal data are presented in terms of the convective time

$3\times 10^{-5}\leqslant \vert \dot {\alpha }c/2u_\infty \vert \leqslant 5\times 10^{-3}$

. The slowest pitch rate was selected to approximate a quasi-steady change in angle of attack (Le Fouest et al. Reference Le Fouest, Deparday and Mulleners2021), whereas the fastest pitch rate was limited by the inertial forces of the model on the load cell. The time history of the angle of attack for all pitch rates tested is shown in figures 2(a) and 2(b), where the temporal data are presented in terms of the convective time

![]() $D=\frac {1}{c}\int _{0}^{t}u_\infty (\tau ){\rm d}\tau$

, equivalent to the number of chord lengths that the free stream has travelled at time

$D=\frac {1}{c}\int _{0}^{t}u_\infty (\tau ){\rm d}\tau$

, equivalent to the number of chord lengths that the free stream has travelled at time

![]() $t$

after the beginning of the commanded pitching motion or Reynolds number change. The Reynolds number was maintained at

$t$

after the beginning of the commanded pitching motion or Reynolds number change. The Reynolds number was maintained at

![]() $1\times 10^5\pm 1.5\times 10^3$

during the pitching motions.

$1\times 10^5\pm 1.5\times 10^3$

during the pitching motions.

Changes in Reynolds number were performed in the range of

![]() $8\times 10^4\leqslant {\text{Re}}_c\leqslant 1\times 10^5$

by changing the wind tunnel fan speed at the maximum rate allowed by the electric drive motor (figures 2

c and 2

d). The

$8\times 10^4\leqslant {\text{Re}}_c\leqslant 1\times 10^5$

by changing the wind tunnel fan speed at the maximum rate allowed by the electric drive motor (figures 2

c and 2

d). The

![]() $10\,\%-90\,\%$

rise-time for the increase in Reynolds number was

$10\,\%-90\,\%$

rise-time for the increase in Reynolds number was

![]() $39$

convective time units and the

$39$

convective time units and the

![]() $90\,\%-10\,\%$

fall-time for the decrease in Reynolds number was

$90\,\%-10\,\%$

fall-time for the decrease in Reynolds number was

![]() $49$

convective time units. The maximum non-dimensional free stream accelerations were

$49$

convective time units. The maximum non-dimensional free stream accelerations were

![]() $\vert \partial u /\partial t\vert (c/u_\infty ^2) = 0.008$

and

$\vert \partial u /\partial t\vert (c/u_\infty ^2) = 0.008$

and

![]() $0.007$

for the ramp up and down, respectively, meaning that the imposed Reynolds number changes were virtually quasi-steady. The ramp changes in Reynolds number were highly repeatable with an ensemble standard deviation accommodated by the line width in figure 2. Time

$0.007$

for the ramp up and down, respectively, meaning that the imposed Reynolds number changes were virtually quasi-steady. The ramp changes in Reynolds number were highly repeatable with an ensemble standard deviation accommodated by the line width in figure 2. Time

![]() $t=0$

is defined as the time that the rotary table or wind tunnel fan was commanded to begin changing the angle of attack or Reynolds number, respectively. The time lag between the commanded angle change and the beginning of the actual angle change measured by the encoder was negligible. However, the lag between the commanded fan speed change and measured change in Reynolds number was more substantial, yet consistent between runs. To account for this lag, § 3.2 presents results that have been shifted in time according to the response of the measured lift force. To obtain ensemble statistics, measurements were performed for each pitch rate or Reynolds number change over an ensemble of

$t=0$

is defined as the time that the rotary table or wind tunnel fan was commanded to begin changing the angle of attack or Reynolds number, respectively. The time lag between the commanded angle change and the beginning of the actual angle change measured by the encoder was negligible. However, the lag between the commanded fan speed change and measured change in Reynolds number was more substantial, yet consistent between runs. To account for this lag, § 3.2 presents results that have been shifted in time according to the response of the measured lift force. To obtain ensemble statistics, measurements were performed for each pitch rate or Reynolds number change over an ensemble of

![]() $20$

runs. Ensemble averages are denoted with a tilde (∼), and time averages are denoted with an over-bar (-). The measurements were performed as a cyclic motion, with measurements of increases in angle of attack or Reynolds number alternating with decreases in angle of attack or Reynolds number. Between each transient, the flow was allowed to stabilise for approximately

$20$

runs. Ensemble averages are denoted with a tilde (∼), and time averages are denoted with an over-bar (-). The measurements were performed as a cyclic motion, with measurements of increases in angle of attack or Reynolds number alternating with decreases in angle of attack or Reynolds number. Between each transient, the flow was allowed to stabilise for approximately

![]() $760c/u_\infty$

. For the transient cases with simultaneous force and PIV measurements, the wind tunnel fan was turned off after each transient while the particle images were downloaded from the cameras. Before each PIV measurement, the wind tunnel fan was turned on and the flow was allowed to stabilise for approximately

$760c/u_\infty$

. For the transient cases with simultaneous force and PIV measurements, the wind tunnel fan was turned off after each transient while the particle images were downloaded from the cameras. Before each PIV measurement, the wind tunnel fan was turned on and the flow was allowed to stabilise for approximately

![]() $386c/u_\infty$

. Comparison of the mean velocity fields of the initial conditions obtained after turning on the wind tunnel from rest with those obtained at the end of transient pitching motions indicated that turning off the wind tunnel between transients had negligible effect on the initial conditions.

$386c/u_\infty$

. Comparison of the mean velocity fields of the initial conditions obtained after turning on the wind tunnel from rest with those obtained at the end of transient pitching motions indicated that turning off the wind tunnel between transients had negligible effect on the initial conditions.

Two-component PIV measurements were acquired during the pitching motions at reduced pitch rates of

![]() $\dot {\alpha }c/(2u_\infty )=\pm 3\times 10^{-4}$

and

$\dot {\alpha }c/(2u_\infty )=\pm 3\times 10^{-4}$

and

![]() $\pm 5\times 10^{-3}$

, and during Reynolds number changes between

$\pm 5\times 10^{-3}$

, and during Reynolds number changes between

![]() ${{Re}}_c=8.0\times 10^4$

and

${{Re}}_c=8.0\times 10^4$

and

![]() $1.0\times 10^5$

. For all PIV measurements, the flow was seeded with water–glycol fog particles measured with a particle analyser to have a mean diameter of approximately

$1.0\times 10^5$

. For all PIV measurements, the flow was seeded with water–glycol fog particles measured with a particle analyser to have a mean diameter of approximately

![]() $0.7\,\mu \text{m}$

. The particles were illuminated with a Photonics DM20–527 Nd:YLF pulsed laser forming a light sheet with a thickness of approximately

$0.7\,\mu \text{m}$

. The particles were illuminated with a Photonics DM20–527 Nd:YLF pulsed laser forming a light sheet with a thickness of approximately

![]() $0.01c$

. Spurious light reflections in the particle images were mitigated using ensemble minimum background subtraction. All particle images were processed using the multi-pass cross-correlation algorithm with window deformation as implemented in the DaVis 10 software. Erroneous vectors were removed using universal outlier detection (Westerweel & Scarano Reference Westerweel and Scarano2005).

$0.01c$

. Spurious light reflections in the particle images were mitigated using ensemble minimum background subtraction. All particle images were processed using the multi-pass cross-correlation algorithm with window deformation as implemented in the DaVis 10 software. Erroneous vectors were removed using universal outlier detection (Westerweel & Scarano Reference Westerweel and Scarano2005).

The PIV measurements were performed in two orthogonal planes (figure 1). Measurements in each plane were obtained during separate runs. The plane tangent to and offset from the suction surface is termed the top-view plane. The laser sheet for the top-view plane was positioned parallel to the model chord and the minimum distance between the model surface and the laser sheet was 3 mm. Top-view particle images were acquired using a side-by-side arrangement of three LaVision sCMOS

![]() $5.5$

megapixel cameras, operating in double-frame mode with a sampling frequency of 25 Hz and a laser pulse separation interval of

$5.5$

megapixel cameras, operating in double-frame mode with a sampling frequency of 25 Hz and a laser pulse separation interval of

![]() $80\,\mu \text{s}$

. All three cameras were equipped with Nikon 50 mm focal length lenses with the apertures set to

$80\,\mu \text{s}$

. All three cameras were equipped with Nikon 50 mm focal length lenses with the apertures set to

![]() $f/4$

. The combined field of view covered

$f/4$

. The combined field of view covered

![]() $0.03\lt X/c\lt 0.77$

in the streamwise direction and

$0.03\lt X/c\lt 0.77$

in the streamwise direction and

![]() $0\lt z/c\lt 2.5$

in the spanwise direction, and the dimensionless magnification factor was

$0\lt z/c\lt 2.5$

in the spanwise direction, and the dimensionless magnification factor was

![]() $0.10$

. The maximum particle image displacement in the top-view images was

$0.10$

. The maximum particle image displacement in the top-view images was

![]() $16$

pixels. The initial and final correlation window sizes were

$16$

pixels. The initial and final correlation window sizes were

![]() $64\,\text{px}\times 64\,\text{px}$

and

$64\,\text{px}\times 64\,\text{px}$

and

![]() $24\,\text{px}\times 24\,\text{px}$

, respectively, yielding a vector pitch of

$24\,\text{px}\times 24\,\text{px}$

, respectively, yielding a vector pitch of

![]() $0.002c$

. A total of

$0.002c$

. A total of

![]() $250$

samples were acquired during each transient pitching motion or Reynolds number change. Data from the top-view PIV plane are presented in a chord-based coordinate system, with the origin at the model root leading edge, the

$250$

samples were acquired during each transient pitching motion or Reynolds number change. Data from the top-view PIV plane are presented in a chord-based coordinate system, with the origin at the model root leading edge, the

![]() $X$

axis parallel to the chord, and the

$X$

axis parallel to the chord, and the

![]() $z$

axis parallel to the span (figure 1). The velocity components in the

$z$

axis parallel to the span (figure 1). The velocity components in the

![]() $X$

and

$X$

and

![]() $z$

directions are denoted as

$z$

directions are denoted as

![]() $u$

and

$u$

and

![]() $w$

, respectively.

$w$

, respectively.

The PIV measurement plane normal to the span of the model is termed the side-view plane. The laser sheet for the side-view plane was positioned at

![]() $z/c=1.5$

and at

$z/c=1.5$

and at

![]() $z/c=1$

for measurements on the aerofoil and wing, respectively. These locations were selected to reduce the influence of spanwise flow due to end effects on the two-component PIV measurements. Side-view particle images were acquired using two side-by-side Photron Fastcam SA4

$z/c=1$

for measurements on the aerofoil and wing, respectively. These locations were selected to reduce the influence of spanwise flow due to end effects on the two-component PIV measurements. Side-view particle images were acquired using two side-by-side Photron Fastcam SA4

![]() $1$

-megapixel cameras operated in double-frame mode with a laser pulse separation interval of

$1$

-megapixel cameras operated in double-frame mode with a laser pulse separation interval of

![]() $60\,\mu \text{s}$

. The sampling frequency was 2500 Hz. The side-view cameras were equipped with 200 mm focal length Nikon micro lenses with the apertures set to

$60\,\mu \text{s}$

. The sampling frequency was 2500 Hz. The side-view cameras were equipped with 200 mm focal length Nikon micro lenses with the apertures set to

![]() $f/4$

. The combined field of view was

$f/4$

. The combined field of view was

![]() $0.15\lt x/c\lt 0.52$

in the streamwise direction and

$0.15\lt x/c\lt 0.52$

in the streamwise direction and

![]() $0\lt y/c\lt 0.7$

in the wall-normal direction, and the dimensionless magnification factor was

$0\lt y/c\lt 0.7$

in the wall-normal direction, and the dimensionless magnification factor was

![]() $0.15$

. The maximum particle displacement was

$0.15$

. The maximum particle displacement was

![]() $18$

pixels, and the initial and final correlation window sizes were

$18$

pixels, and the initial and final correlation window sizes were

![]() $24\,\text{px}\times 24\,\text{px}$

and

$24\,\text{px}\times 24\,\text{px}$

and

![]() $16\,\text{px}\times 16\,\text{px}$

, yielding vector pitches of

$16\,\text{px}\times 16\,\text{px}$

, yielding vector pitches of

![]() $0.003c$

. A total of

$0.003c$

. A total of

![]() $5457$

samples were acquired during each transient pitching motion or Reynolds number change and for steady-state measurements of the initial and final flow conditions. Essential PIV set-up parameters are listed in table 1. Data from the side-view PIV plane are presented in a surface-attached coordinate system, with the origin at the model root leading edge, the

$5457$

samples were acquired during each transient pitching motion or Reynolds number change and for steady-state measurements of the initial and final flow conditions. Essential PIV set-up parameters are listed in table 1. Data from the side-view PIV plane are presented in a surface-attached coordinate system, with the origin at the model root leading edge, the

![]() $x$

axis tangent to the suction surface, the

$x$

axis tangent to the suction surface, the

![]() $y$

axis normal to the suction surface and the

$y$

axis normal to the suction surface and the

![]() $z$

axis parallel to the span (figure 1). The velocity components in the

$z$

axis parallel to the span (figure 1). The velocity components in the

![]() $x$

,

$x$

,

![]() $y$

and

$y$

and

![]() $z$

directions are denoted as

$z$

directions are denoted as

![]() $u$

,

$u$

,

![]() $v$

and

$v$

and

![]() $w$

, respectively.

$w$

, respectively.

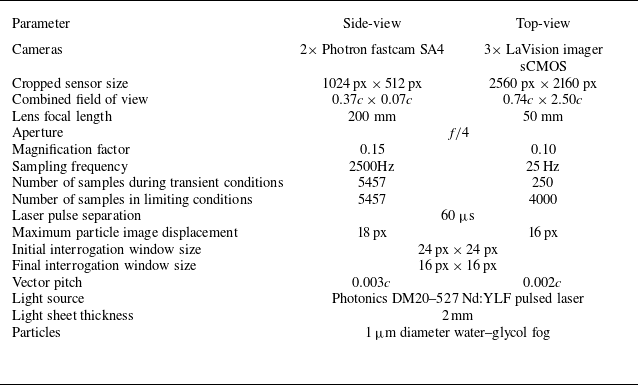

Table 1. PIV parameters.

The uncertainty in each velocity vector field was estimated using the correlation statistics method (Wieneke Reference Wieneke2015). For the side-view PIV configuration, the uncertainty in the

![]() $u$

and

$u$

and

![]() $v$

velocity components in the vicinity of the separated shear layer is less than

$v$

velocity components in the vicinity of the separated shear layer is less than

![]() $0.1u_\infty$

at a confidence level of

$0.1u_\infty$

at a confidence level of

![]() $95\,\%$

. For the top-view PIV configuration, the uncertainty in the

$95\,\%$

. For the top-view PIV configuration, the uncertainty in the

![]() $u$

and

$u$

and

![]() $w$

velocity components in the vicinity of the separated shear layer is less than

$w$

velocity components in the vicinity of the separated shear layer is less than

![]() $0.13u_\infty$

at a confidence level of

$0.13u_\infty$

at a confidence level of

![]() $95\,\%$

. The higher uncertainty in the top-view measurements is attributed to the strong streamwise velocity gradient and out of plane particle motion where the separated shear layer intersects the top-view measurement plane.

$95\,\%$

. The higher uncertainty in the top-view measurements is attributed to the strong streamwise velocity gradient and out of plane particle motion where the separated shear layer intersects the top-view measurement plane.

2.1. Data processing techniques

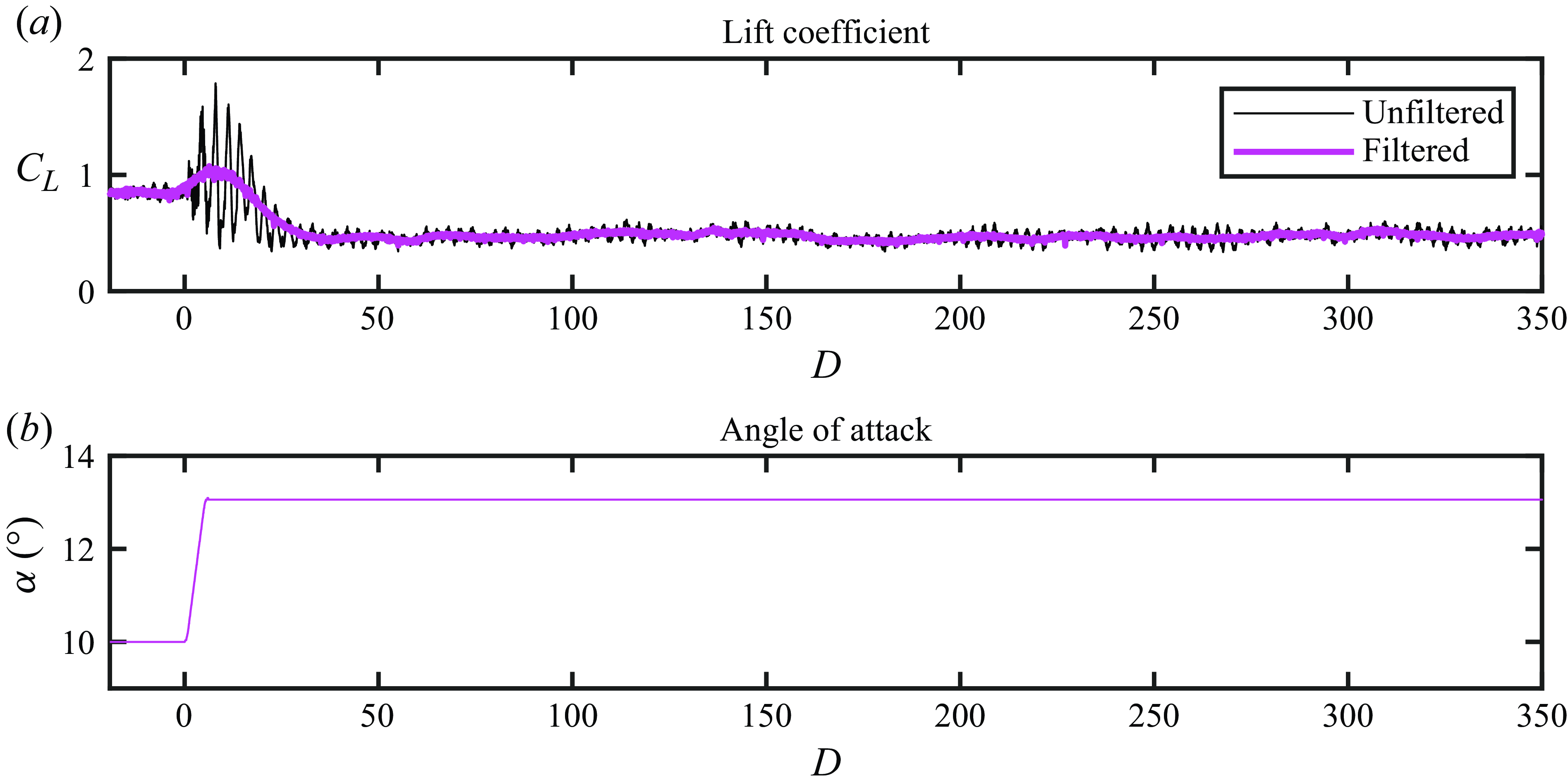

Figure 3. Unfiltered and filtered lift coefficients for the aerofoil undergoing a pitch up manoeuvre at

![]() $\dot {\alpha }c/(2u_\infty )=5\times 10^{-3}$

. The forces measured in quiescent conditions have been subtracted from the forces used to calculate the unfiltered and filtered force coefficients.

$\dot {\alpha }c/(2u_\infty )=5\times 10^{-3}$

. The forces measured in quiescent conditions have been subtracted from the forces used to calculate the unfiltered and filtered force coefficients.

To isolate the aerodynamic loads from the inertial loads acting on the load cell during pitching motions, the lift forces measured in quiescent conditions were subtracted from the lift forces obtained during flow measurements. The structural natural frequency of both the aerofoil and wing models was measured to be approximately 12 Hz. To attenuate fluctuations in the measured force coefficients caused by random noise and structural vibrations, the lift coefficients were filtered using the empirical mode decomposition described by Huang et al. (Reference Huang, Shen, Long, Wu, Shih, Zheng, Yen, Tung and Liu1998). The filtering procedure used here involved subtracting the first six intrinsic mode functions (IMFs) from the raw force coefficient data. Cubic spline interpolation was used to compute the signal envelope. The sifting process for each IMF was stopped when the relative tolerance between consecutive sifting results (

![]() $SD$

) was less than

$SD$

) was less than

![]() $0.15$

or at a maximum of

$0.15$

or at a maximum of

![]() $50$

sifting iterations, whichever occurred first. The relative tolerance is defined as (Huang et al. Reference Huang, Shen, Long, Wu, Shih, Zheng, Yen, Tung and Liu1998)

$50$

sifting iterations, whichever occurred first. The relative tolerance is defined as (Huang et al. Reference Huang, Shen, Long, Wu, Shih, Zheng, Yen, Tung and Liu1998)

\begin{equation} SD = \sum _{t=0}^{T}\frac {\left (h_{k-1}(t)-h_{k}(t)\right )^2}{h_{k-1}^2(t)}, \end{equation}

\begin{equation} SD = \sum _{t=0}^{T}\frac {\left (h_{k-1}(t)-h_{k}(t)\right )^2}{h_{k-1}^2(t)}, \end{equation}

where

![]() $h_{k-1}$

is the result of the previous sifting iteration,

$h_{k-1}$

is the result of the previous sifting iteration,

![]() $h_k$

is the result of the current sifting iteration and

$h_k$

is the result of the current sifting iteration and

![]() $T$

is the sampling period. A comparison of the unfiltered lift coefficient data with the quiescent load subtracted and the filtered lift coefficient with the quiescent load subtracted for the aerofoil undergoing a pitch up manoeuvre for

$T$

is the sampling period. A comparison of the unfiltered lift coefficient data with the quiescent load subtracted and the filtered lift coefficient with the quiescent load subtracted for the aerofoil undergoing a pitch up manoeuvre for

![]() $\dot {\alpha }c/(2u_\infty )=5\times 10^{-3}$

is presented in figure 3 versus the non-dimensional convective time

$\dot {\alpha }c/(2u_\infty )=5\times 10^{-3}$

is presented in figure 3 versus the non-dimensional convective time

![]() $D$

. The effective low-pass cut-off frequency of this filtering method is of the order of

$D$

. The effective low-pass cut-off frequency of this filtering method is of the order of

![]() $0.1u_\infty /c$

, corresponding to a period of approximately

$0.1u_\infty /c$

, corresponding to a period of approximately

![]() $10c/u_\infty$

. The cutoff frequency is defined as the frequency for which the ratio of the squared amplitude of the output and input signals drops below a threshold of

$10c/u_\infty$

. The cutoff frequency is defined as the frequency for which the ratio of the squared amplitude of the output and input signals drops below a threshold of

![]() $-3\,\text{dB}$

.

$-3\,\text{dB}$

.

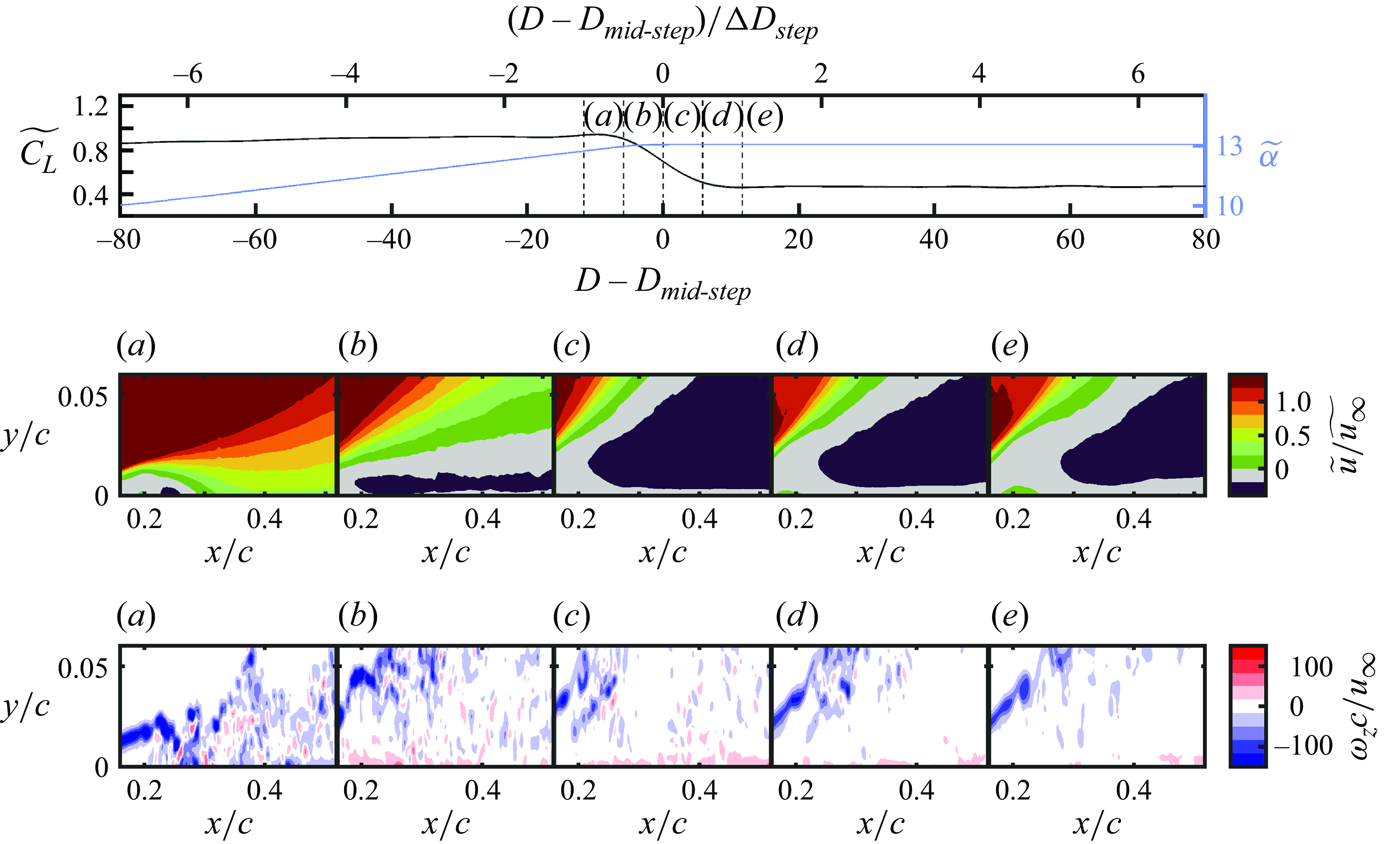

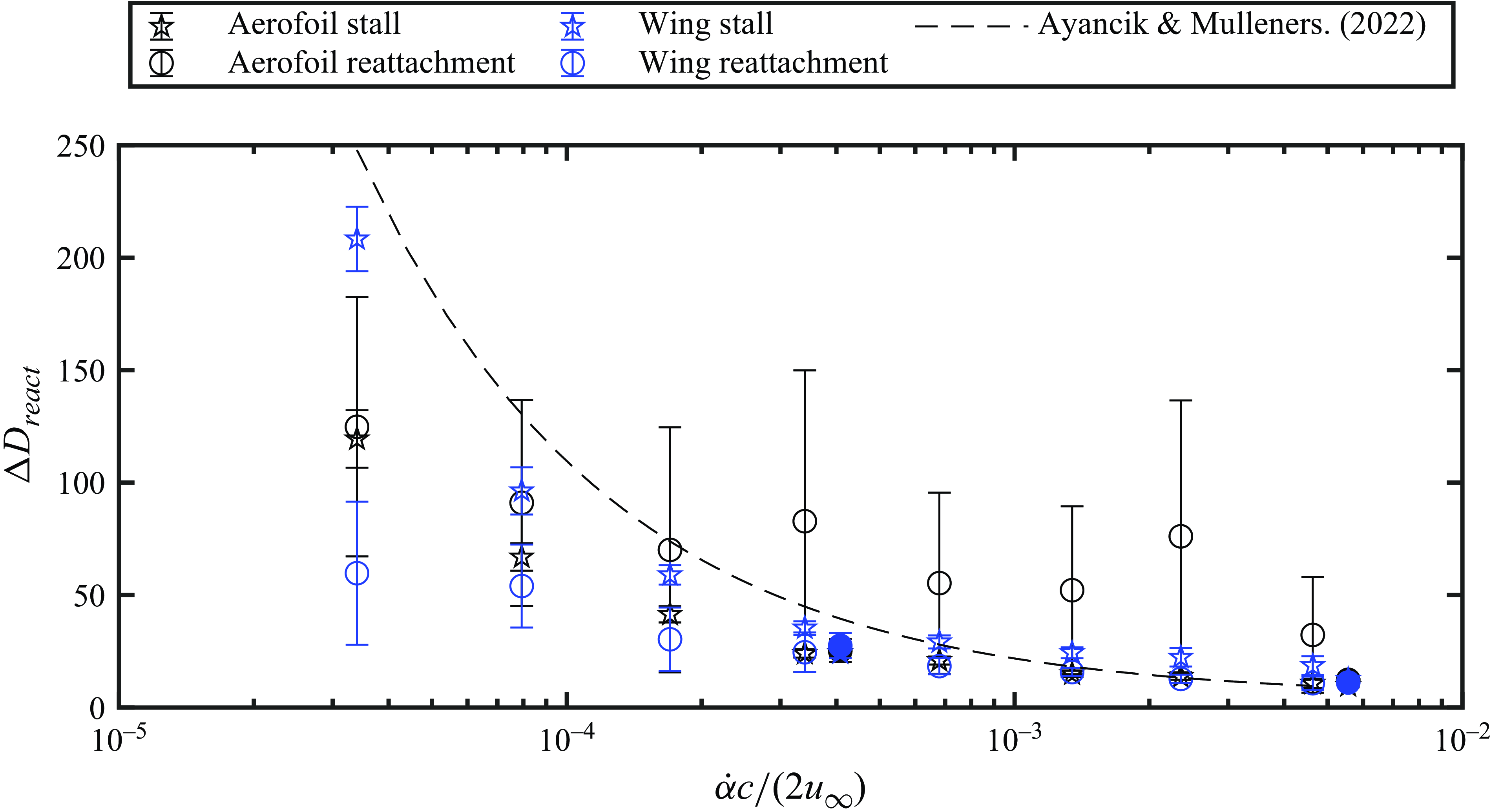

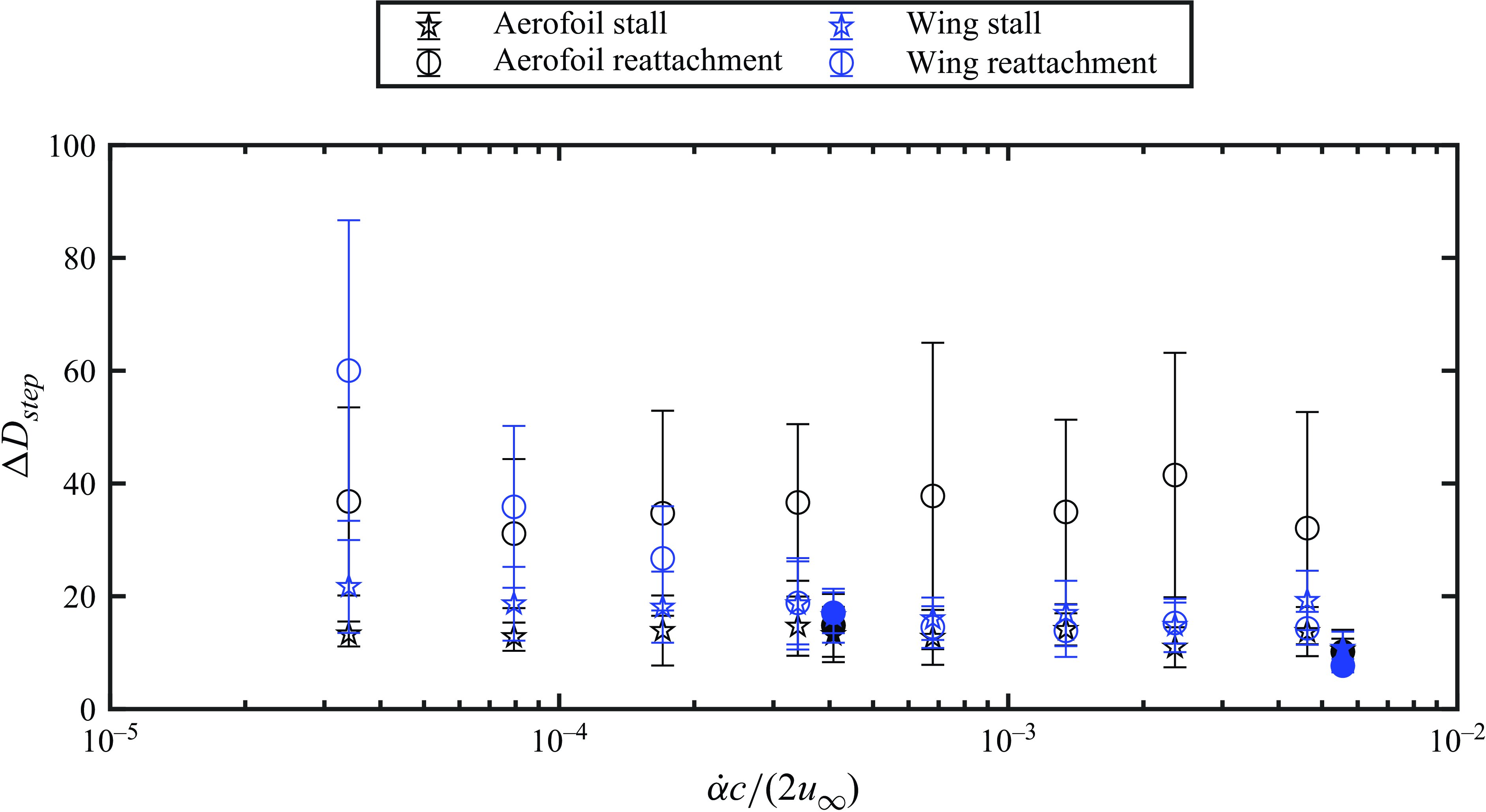

To quantitatively compare the time history of the lift coefficient between different transients, the duration of the step change in lift coefficient (

![]() $\Delta D_{{step}}$

) and the time delay of the reaction of the lift coefficient to the change in operating conditions (

$\Delta D_{{step}}$

) and the time delay of the reaction of the lift coefficient to the change in operating conditions (

![]() $\Delta D_{{react}}$

) were computed using a method based on that used by Le Fouest et al. (Reference Le Fouest, Deparday and Mulleners2021). In figure 4, which illustrates this method, the temporal evolution of the lift coefficients has been shifted by the time of passing the static reattachment condition (

$\Delta D_{{react}}$

) were computed using a method based on that used by Le Fouest et al. (Reference Le Fouest, Deparday and Mulleners2021). In figure 4, which illustrates this method, the temporal evolution of the lift coefficients has been shifted by the time of passing the static reattachment condition (

![]() $D_{sr}$

, figure 4

b) and by the time of passing the static stall condition (

$D_{sr}$

, figure 4

b) and by the time of passing the static stall condition (

![]() $D_{ss}$

figure 4

d). The static stall and reattachment angles of attack are defined as the angles of attack immediately preceding the largest magnitude rate of change of lift coefficient for increasing and decreasing angle of attack, respectively. Analogously, the static stall and reattachment Reynolds numbers are defined as the Reynolds numbers immediately following and preceding the largest magnitude rate of change of lift coefficient, respectively.

$D_{ss}$

figure 4

d). The static stall and reattachment angles of attack are defined as the angles of attack immediately preceding the largest magnitude rate of change of lift coefficient for increasing and decreasing angle of attack, respectively. Analogously, the static stall and reattachment Reynolds numbers are defined as the Reynolds numbers immediately following and preceding the largest magnitude rate of change of lift coefficient, respectively.

Figure 4. Definition of reaction and step times. Cyan line, lift coefficient during pitch down motion at

![]() $\dot {\alpha }c/(2u_\infty )=3\times 10^{-4}$

; red line, lift coefficient during decrease in

$\dot {\alpha }c/(2u_\infty )=3\times 10^{-4}$

; red line, lift coefficient during decrease in

![]() $Re_c$

; solid blue lines, pre-stall and post-stall lift coefficients; dashed blue lines, thresholds for defining

$Re_c$

; solid blue lines, pre-stall and post-stall lift coefficients; dashed blue lines, thresholds for defining

![]() $D_{{pre{-}step}}$

and

$D_{{pre{-}step}}$

and

![]() $D_{{post{-}step}}$

;

$D_{{post{-}step}}$

;

![]() $\triangle$

, quasi-steady

$\triangle$

, quasi-steady

![]() $C_L$

for increasing

$C_L$

for increasing

![]() $\alpha$

or

$\alpha$

or

![]() ${{Re}}_c$

;

${{Re}}_c$

;

![]() $\triangledown$

, quasi-steady

$\triangledown$

, quasi-steady

![]() $C_L$

for decreasing

$C_L$

for decreasing

![]() $\alpha$

or

$\alpha$

or

![]() ${{Re}}_c$

.

${{Re}}_c$

.

The step times (

![]() $\Delta D_{{step}}$

) are defined as the difference between the post-step time (

$\Delta D_{{step}}$

) are defined as the difference between the post-step time (

![]() $D_{{post-step}}$

) and the pre-step (

$D_{{post-step}}$

) and the pre-step (

![]() $D_{{pre-step}}$

) time, which correspond to the end and the beginning of the step change in lift coefficient, respectively. The procedure for computing

$D_{{pre-step}}$

) time, which correspond to the end and the beginning of the step change in lift coefficient, respectively. The procedure for computing

![]() $D_{{pre-step}}$

and

$D_{{pre-step}}$

and

![]() $D_{{post-step}}$

requires the definition of pre- and post-stall lift coefficients (

$D_{{post-step}}$

requires the definition of pre- and post-stall lift coefficients (

![]() $C_{L,{pre-stall}}$

and

$C_{L,{pre-stall}}$

and

![]() $C_{L,{post-stall}}$

). Because the quasi-steady pre-stall and post-stall lift coefficients vary with angle of attack and Reynolds number, the employed stall and reattachment thresholds for the lift coefficient are also defined as functions of the angle of attack and Reynolds number using the following procedure. In the case of pitching transients, for angles of attack below the static stall angle,

$C_{L,{post-stall}}$

). Because the quasi-steady pre-stall and post-stall lift coefficients vary with angle of attack and Reynolds number, the employed stall and reattachment thresholds for the lift coefficient are also defined as functions of the angle of attack and Reynolds number using the following procedure. In the case of pitching transients, for angles of attack below the static stall angle,

![]() $C_{L,{pre-stall}}$

is defined equal to the quasi-steady lift coefficient during quasi-steady upward pitching. For angles of attack above the static stall angle,

$C_{L,{pre-stall}}$

is defined equal to the quasi-steady lift coefficient during quasi-steady upward pitching. For angles of attack above the static stall angle,

![]() $C_{L,{pre-stall}}$

is defined equal to the lift coefficient at the static stall angle. Similarly,

$C_{L,{pre-stall}}$

is defined equal to the lift coefficient at the static stall angle. Similarly,

![]() $C_{L,{post-stall}}$

is defined as equal to the quasi-steady lift coefficient during downward pitching for angles of attack greater than the quasi-steady reattachment angle, and equal to the lift coefficient at the quasi-steady reattachment angle for angles of attack less than the quasi-steady reattachment angle. These definitions of

$C_{L,{post-stall}}$

is defined as equal to the quasi-steady lift coefficient during downward pitching for angles of attack greater than the quasi-steady reattachment angle, and equal to the lift coefficient at the quasi-steady reattachment angle for angles of attack less than the quasi-steady reattachment angle. These definitions of

![]() $C_{L,{pre-stall}}$

and

$C_{L,{pre-stall}}$

and

![]() $C_{L,{post-stall}}$

are plotted as solid blue lines in figure 4(a). The pre-stall and post-stall lift coefficients for the transient changes in Reynolds number (figure 4

c) are defined analogously.

$C_{L,{post-stall}}$

are plotted as solid blue lines in figure 4(a). The pre-stall and post-stall lift coefficients for the transient changes in Reynolds number (figure 4

c) are defined analogously.

For transients leading to stall, the start of the step change in lift coefficient (

![]() $D_{{pre-step}}$

) is defined as the first time after the initiation of the change in operating conditions that the lift coefficient was less than

$D_{{pre-step}}$

) is defined as the first time after the initiation of the change in operating conditions that the lift coefficient was less than

![]() $C_{L,{pre-stall}}-0.1 (C_{L,{pre-stall}}-C_{L,{post-stall}} )$

, and the end of the step change in lift coefficient (

$C_{L,{pre-stall}}-0.1 (C_{L,{pre-stall}}-C_{L,{post-stall}} )$

, and the end of the step change in lift coefficient (

![]() $D_{{post-step}}$

) is defined as the first time that the lift coefficient was less than

$D_{{post-step}}$

) is defined as the first time that the lift coefficient was less than

![]() $C_{L,{post-stall}}+0.1 (C_{L,{pre-stall}}-C_{L,{post-stall}} )$

. For the transients leading to reattachment,

$C_{L,{post-stall}}+0.1 (C_{L,{pre-stall}}-C_{L,{post-stall}} )$

. For the transients leading to reattachment,

![]() $D_{{pre-step}}$

is defined as the last time that the lift coefficient was less than

$D_{{pre-step}}$

is defined as the last time that the lift coefficient was less than

![]() $C_{L,{post-stall}}+0.1 (C_{L,{pre-stall}}-C_{L,{post-stall}} )$

and

$C_{L,{post-stall}}+0.1 (C_{L,{pre-stall}}-C_{L,{post-stall}} )$

and

![]() $D_{{post-step}}$

is defined as the first time that the lift coefficient was greater than

$D_{{post-step}}$

is defined as the first time that the lift coefficient was greater than

![]() $C_{L,{pre-stall}}-0.1 (C_{L,{pre-stall}}-C_{L,{post-stall}} )$

. These thresholds are plotted as dashed blue lines in figure 4. Representative runs for LSB formation and bursting are presented in figures 4(b) and 4(d). The reaction delay (

$C_{L,{pre-stall}}-0.1 (C_{L,{pre-stall}}-C_{L,{post-stall}} )$

. These thresholds are plotted as dashed blue lines in figure 4. Representative runs for LSB formation and bursting are presented in figures 4(b) and 4(d). The reaction delay (

![]() $\Delta D_{{react}}$

) is defined as the time difference between

$\Delta D_{{react}}$

) is defined as the time difference between

![]() $D_{{pre-step}}$

and the passing of the static stall or reattachment condition. The definitions of the start and end of the step changes where formulated with the goal of reducing erroneous measurements of

$D_{{pre-step}}$

and the passing of the static stall or reattachment condition. The definitions of the start and end of the step changes where formulated with the goal of reducing erroneous measurements of

![]() $\Delta D_{{react}}$

caused by the relatively large random fluctuations in lift coefficient that occur in the stalled limiting state.

$\Delta D_{{react}}$

caused by the relatively large random fluctuations in lift coefficient that occur in the stalled limiting state.

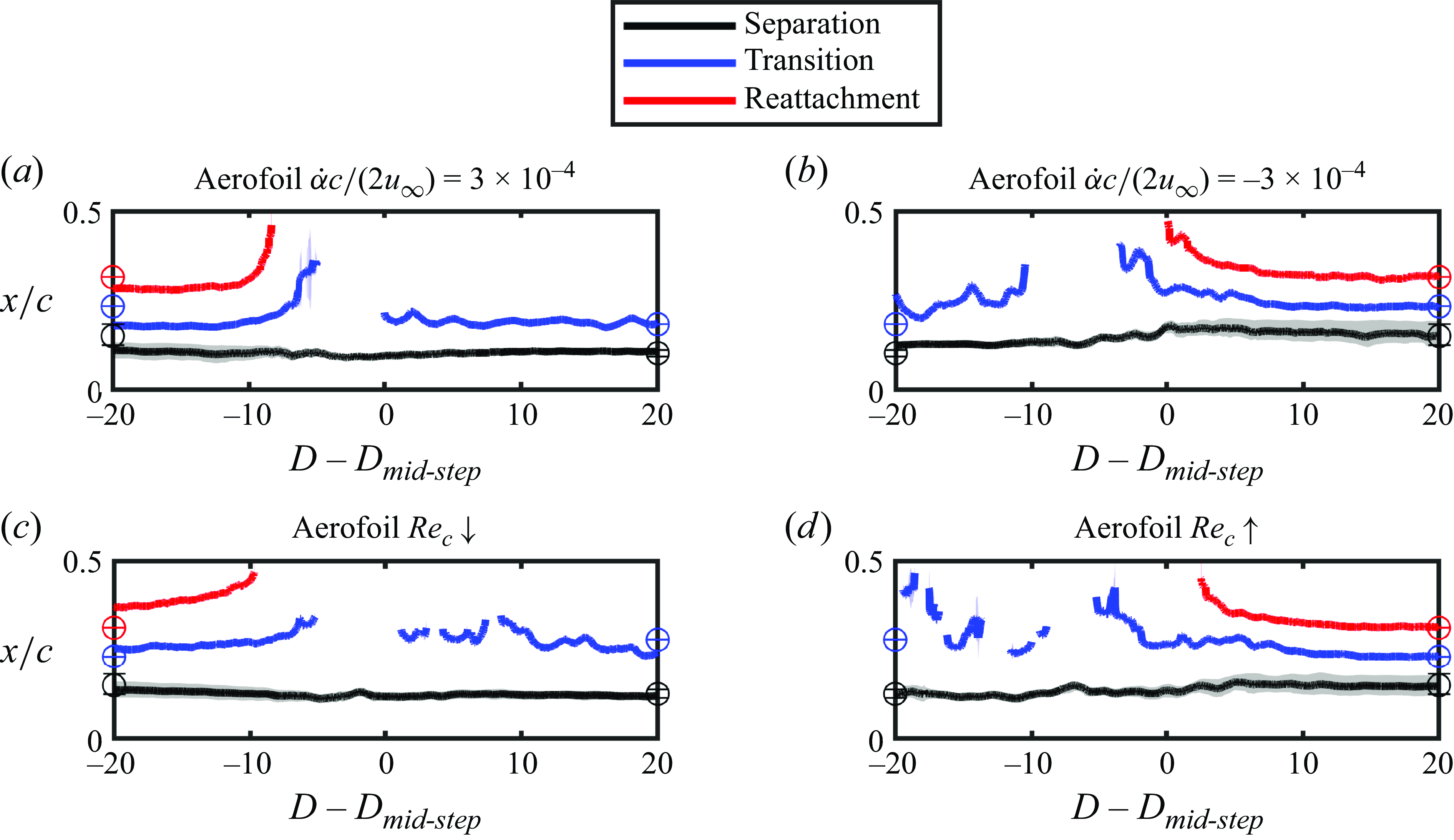

In § 3.2, ensemble statistics are presented after shifting data from individual runs in time using the mid-step time (

![]() $D_{{mid-step}}$

) so that the step change in lift coefficient occurs at the same time for each run. Here,

$D_{{mid-step}}$

) so that the step change in lift coefficient occurs at the same time for each run. Here,

![]() $D_{{mid-step}}$

is defined as the first time the lift coefficient was equal to

$D_{{mid-step}}$

is defined as the first time the lift coefficient was equal to

![]() $1/2 (C_{L,{post-stall}}+C_{L,{pre-stall}} )$

.

$1/2 (C_{L,{post-stall}}+C_{L,{pre-stall}} )$

.

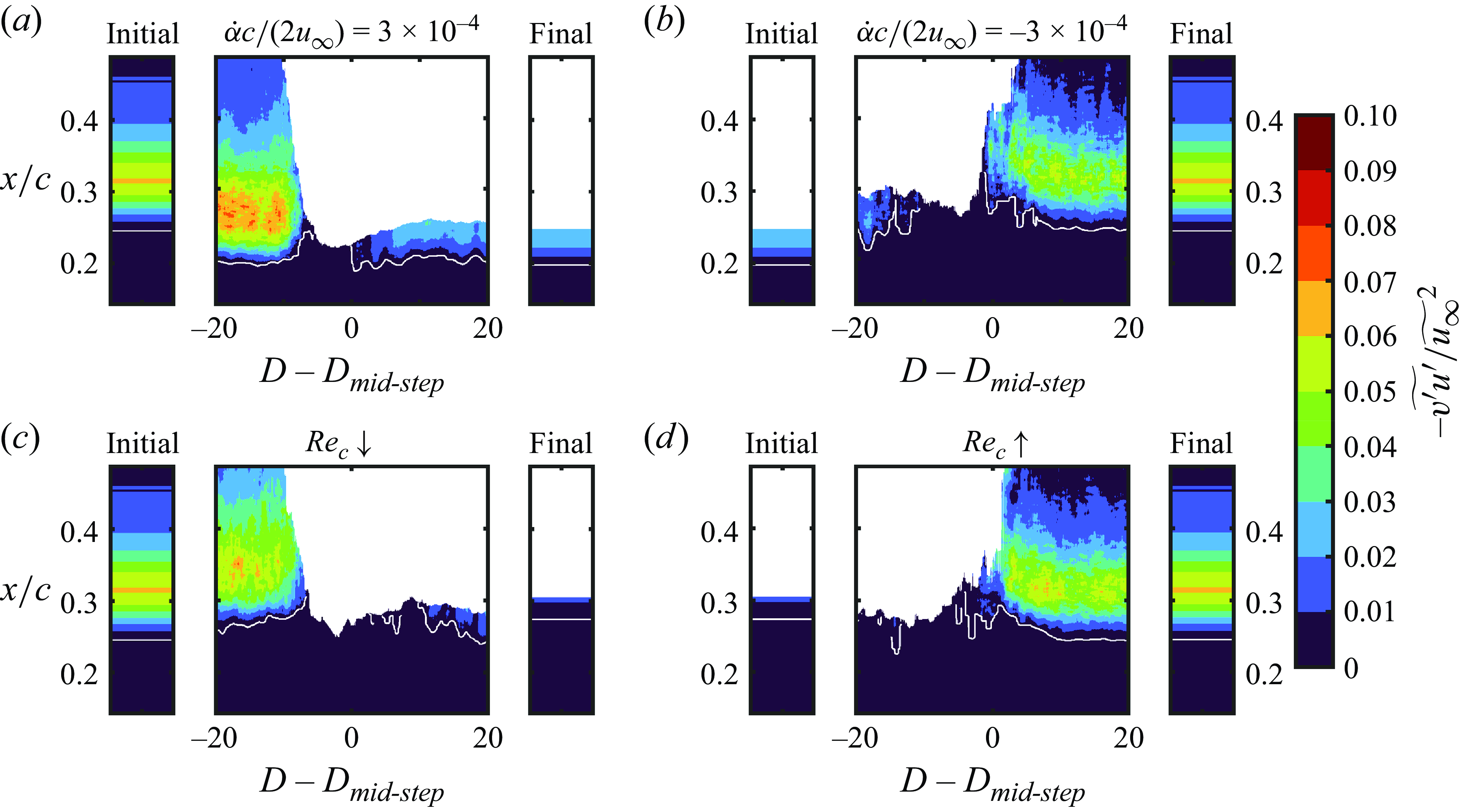

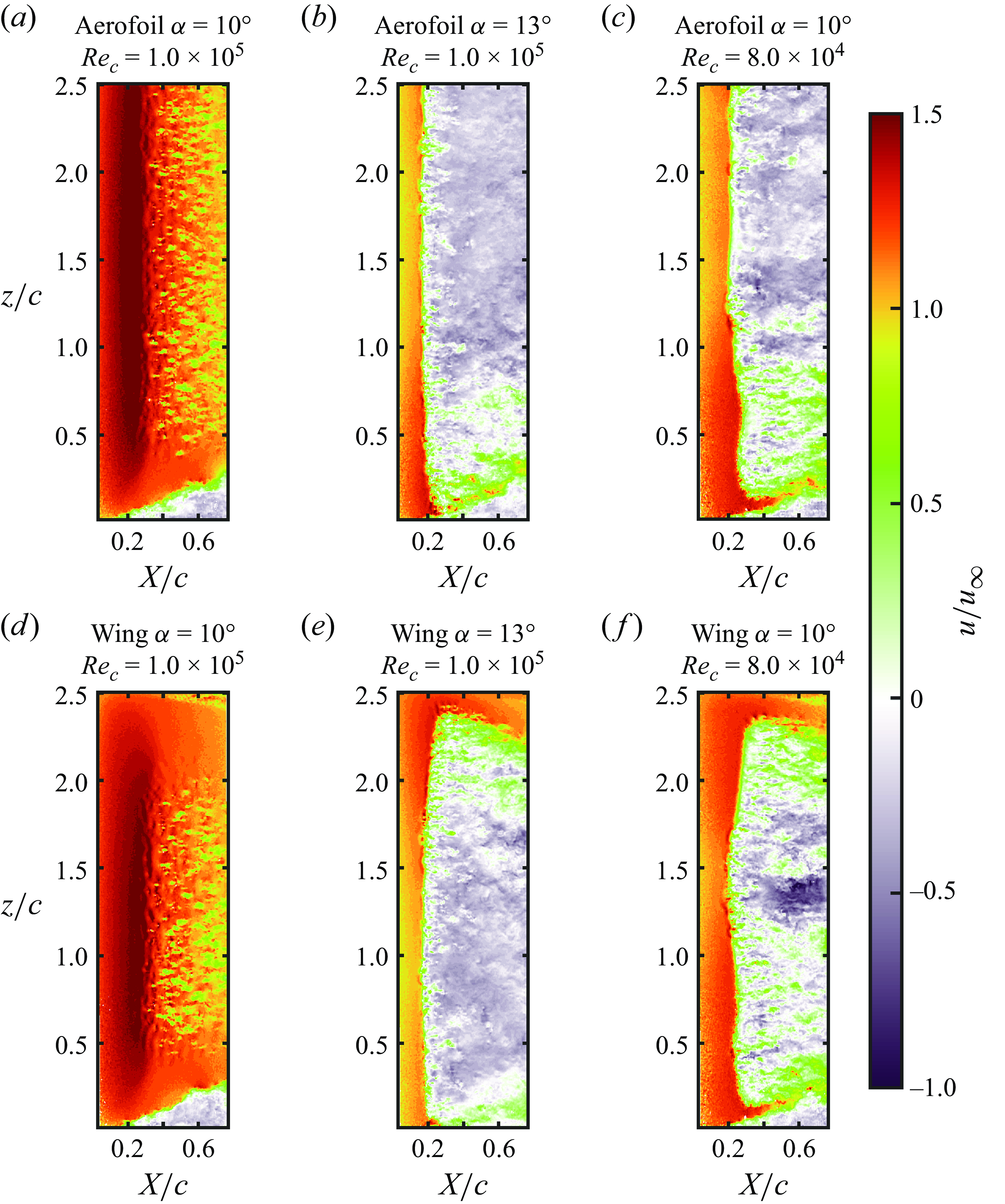

Figure 5. Mean streamwise velocity contours in steady conditions measured by side-view PIV configuration.

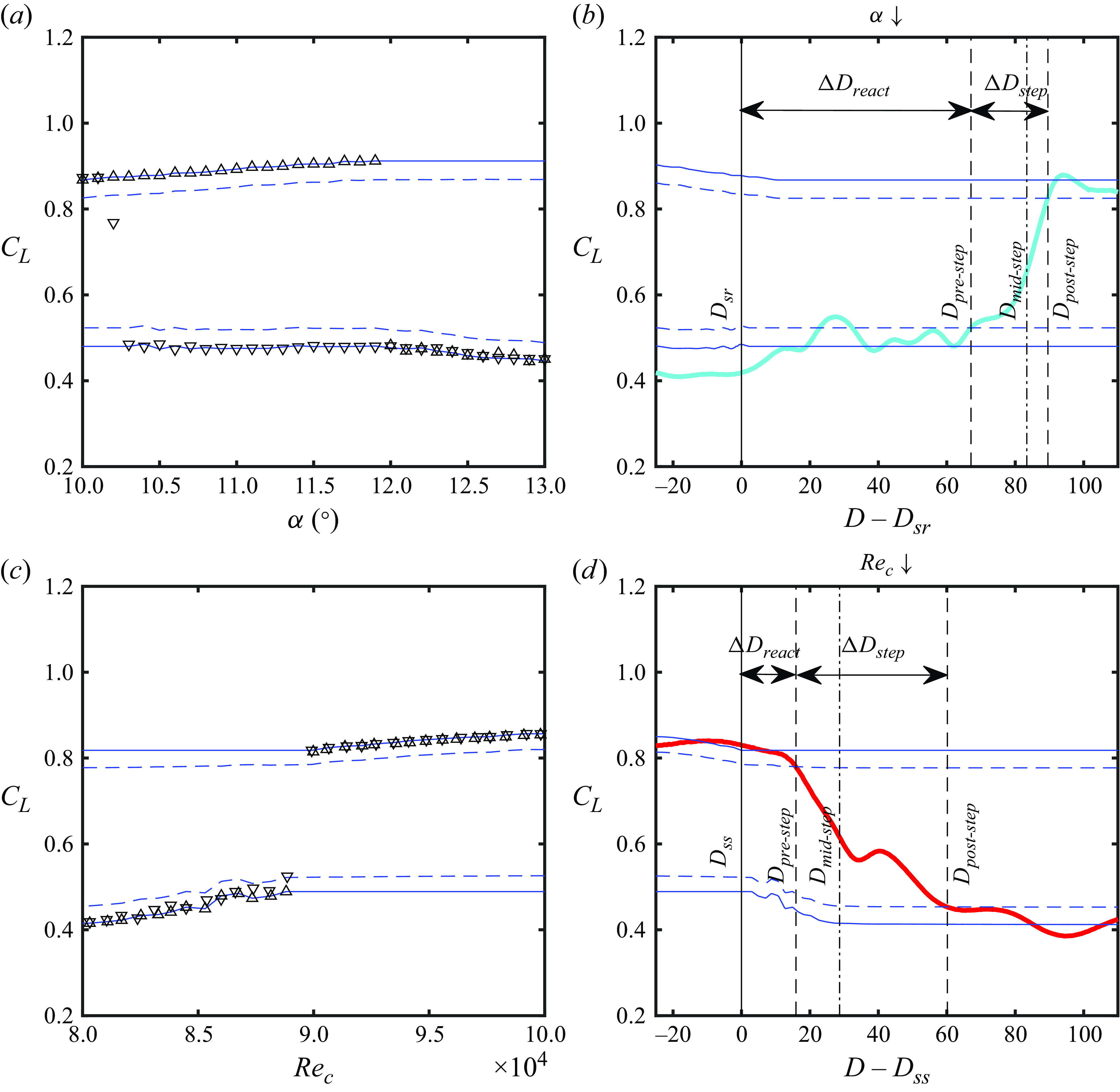

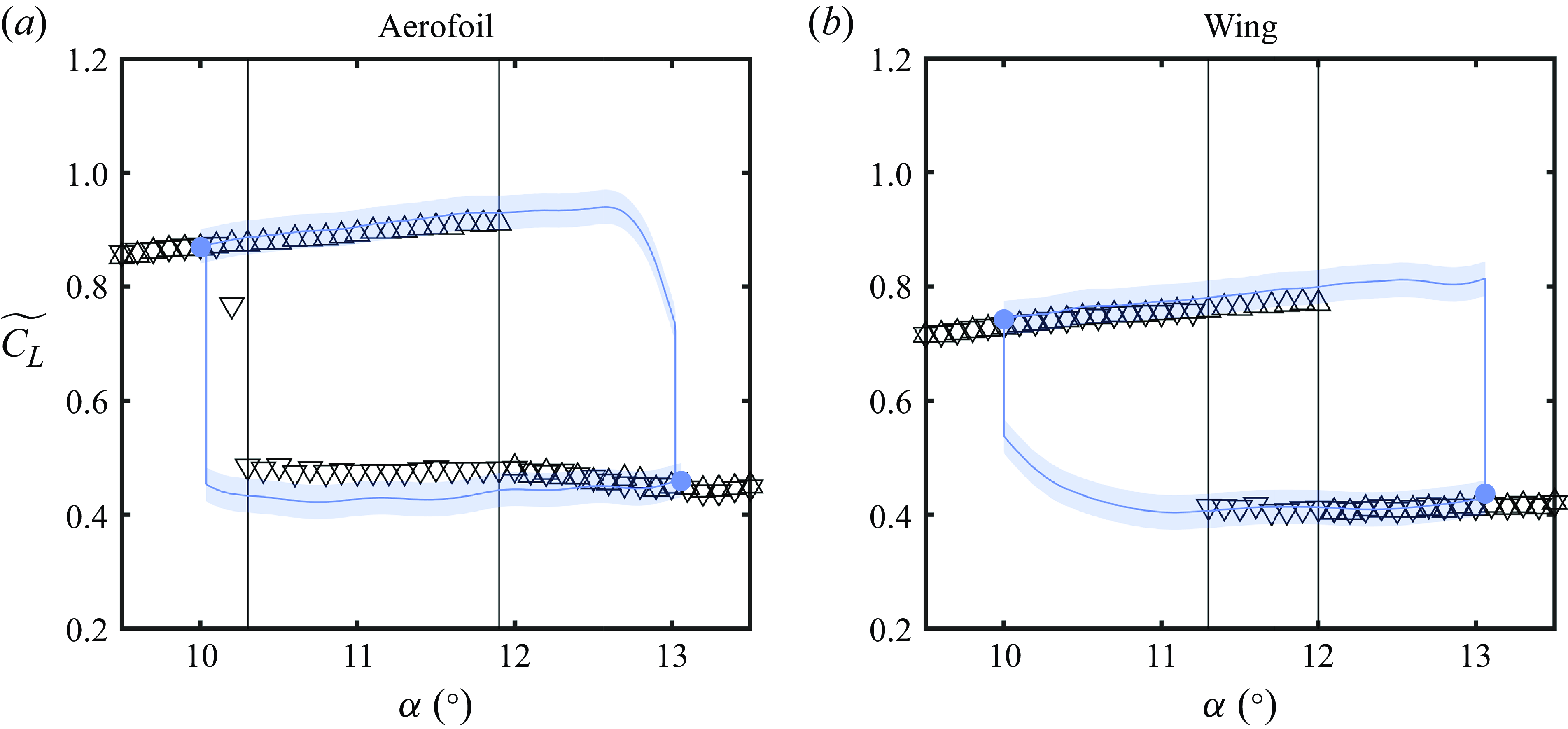

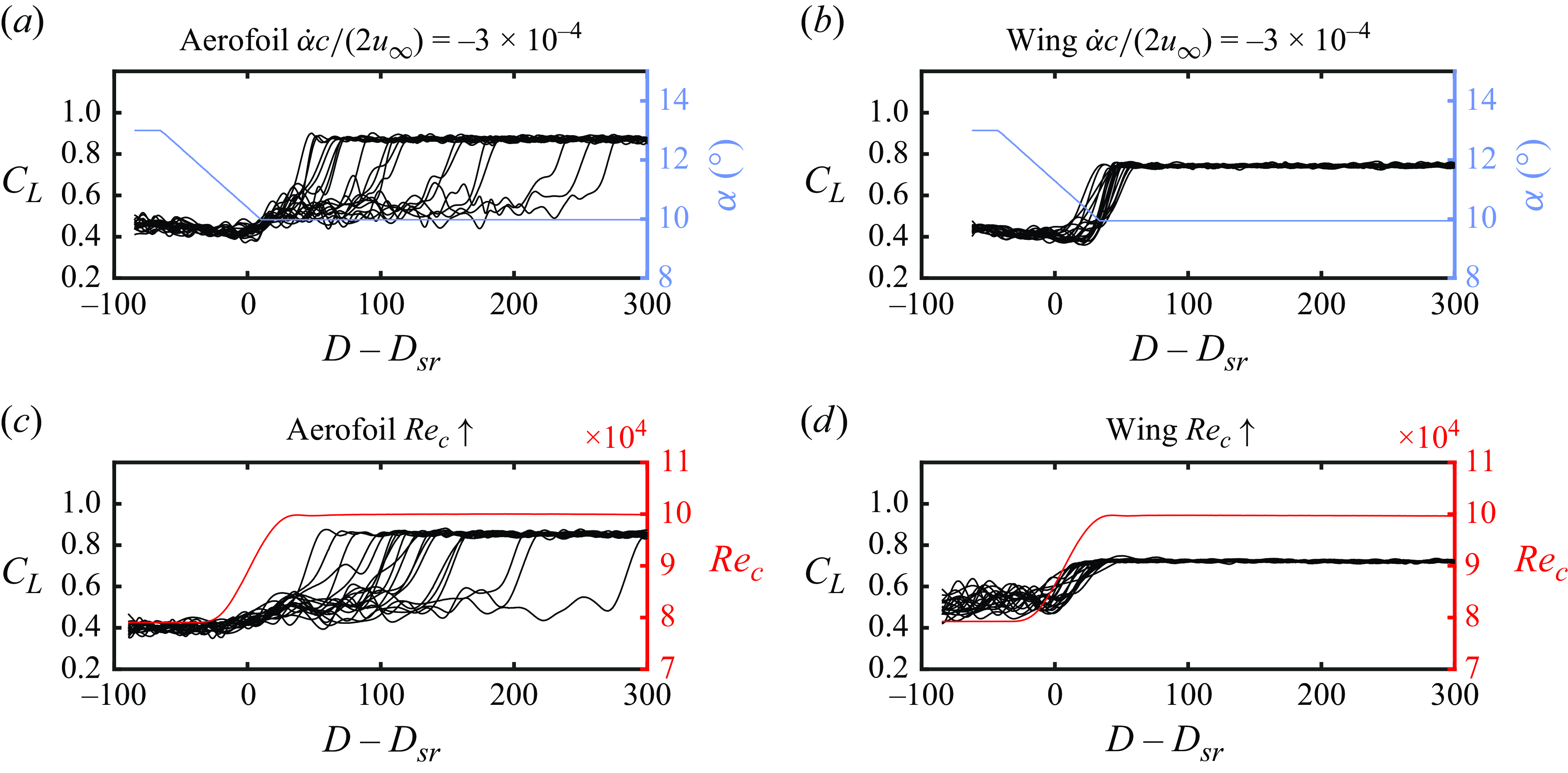

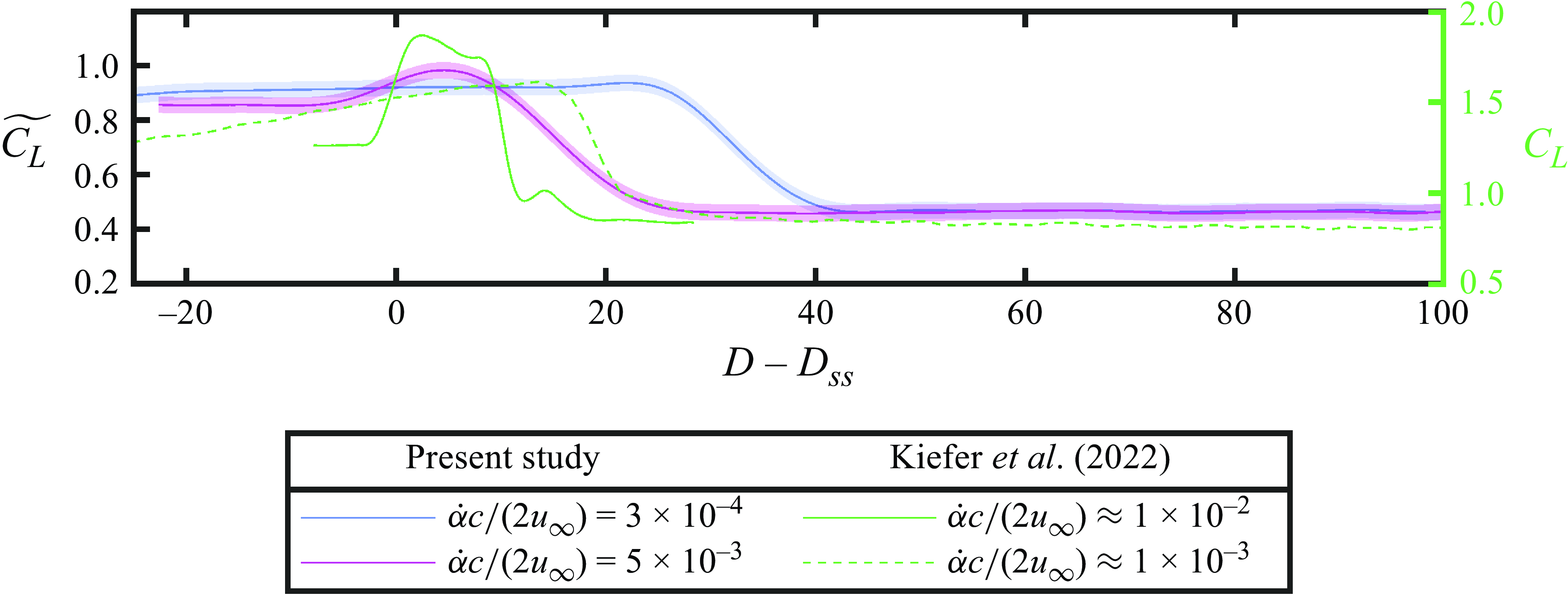

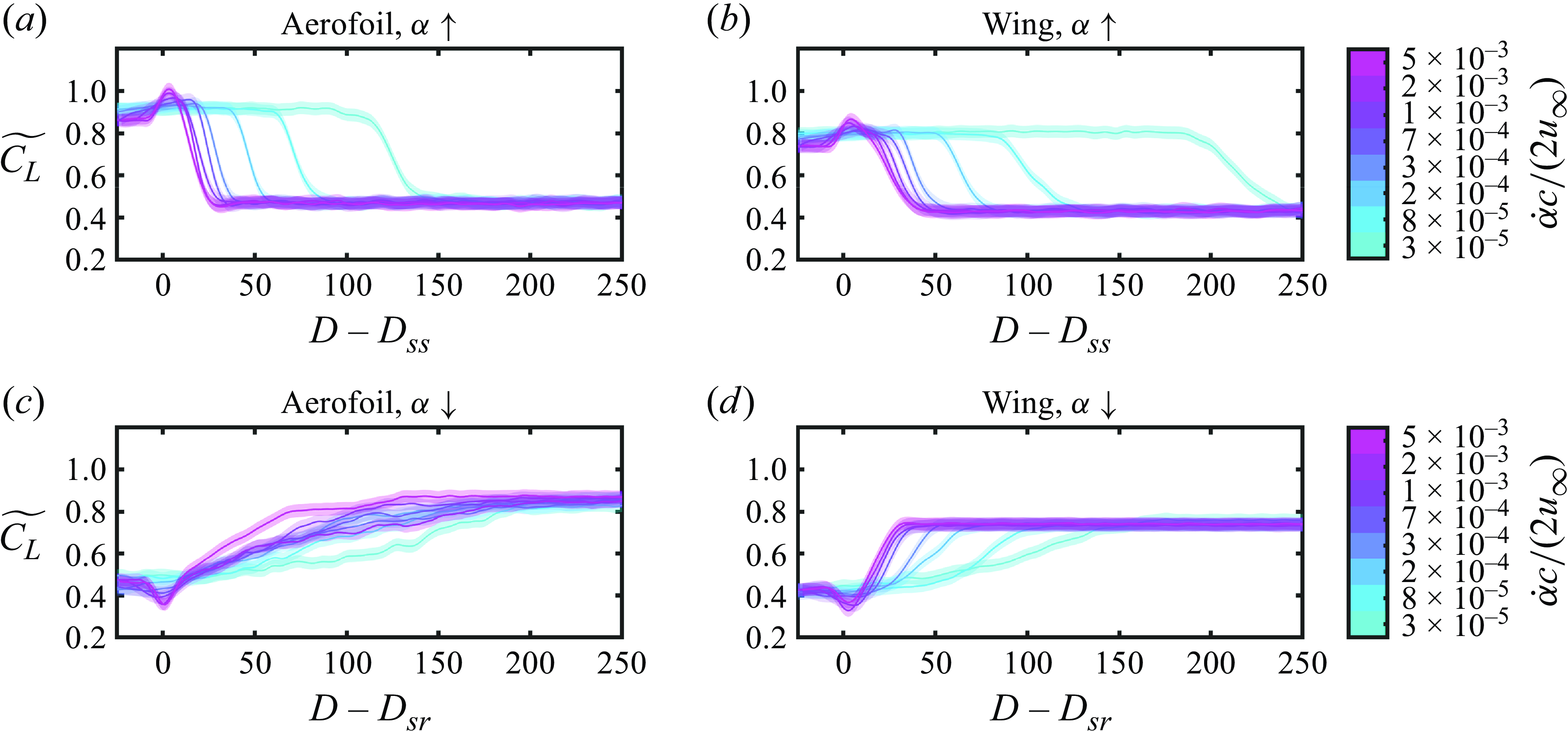

Figure 6. Quasi-steady (black markers) and ensemble-averaged transient (coloured lines) lift coefficients for (a) pitching aerofoil and (b) wing at

![]() ${{Re}}_c=1\times 10^5$

.

${{Re}}_c=1\times 10^5$

.

![]() $\triangle$

, increasing

$\triangle$

, increasing

![]() $\alpha$

;

$\alpha$

;

![]() $\triangledown$

, decreasing

$\triangledown$

, decreasing

![]() $\alpha$

; black lines, static reattachment stall angles; coloured markers, limiting flow states. Shaded areas denote uncertainty (

$\alpha$

; black lines, static reattachment stall angles; coloured markers, limiting flow states. Shaded areas denote uncertainty (

![]() $95\,\%$

confidence).

$95\,\%$

confidence).

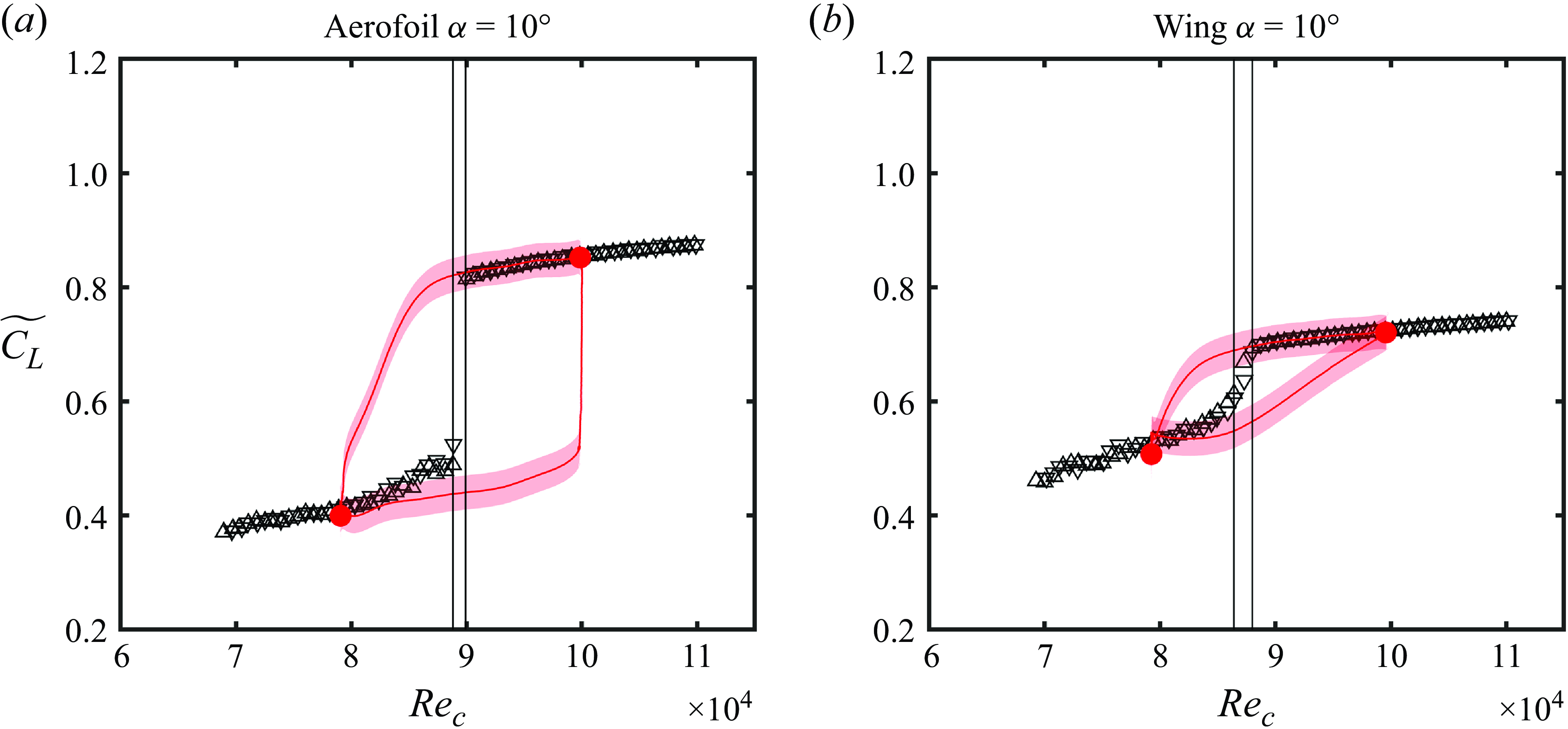

Figure 7. Quasi-steady (markers) and ensemble-averaged transient (red lines) lift coefficients for (a) aerofoil and (b) wing for changes in

![]() ${{Re}}_c$

.

${{Re}}_c$

.

![]() $\triangle$

, increasing

$\triangle$

, increasing

![]() ${{Re}}_c$

;

${{Re}}_c$

;

![]() $\triangledown$

, decreasing

$\triangledown$

, decreasing

![]() ${{Re}}_c$

; black lines, static reattachment and stall

${{Re}}_c$

; black lines, static reattachment and stall

![]() ${{Re}}_c$

; coloured markers, limiting flow states. Shaded areas denote uncertainty (

${{Re}}_c$

; coloured markers, limiting flow states. Shaded areas denote uncertainty (

![]() $95\,\%$

confidence).

$95\,\%$

confidence).

3. Results and discussion

3.1. Limiting flow states

The transient changes in angle of attack and Reynolds number used to investigate LSB formation and bursting involve changes between statistically stationary limiting flow states. The wall-normal structure of the flow development on the aerofoil and wing in the limiting flow states is illustrated by the contours of mean streamwise velocity from the side-view PIV presented in figure 5. The side-view measurements were taken at

![]() $z/c=1.5$

and

$z/c=1.5$

and

![]() $z/c=1$

for the aerofoil and wing models, respectively. At

$z/c=1$

for the aerofoil and wing models, respectively. At

![]() $\alpha = 10^{\circ }$

and

$\alpha = 10^{\circ }$

and

![]() ${{Re}}_c=1.0\times 10^5$

(figures 5

a and 5

d), the laminar boundary layer separates upstream of the field of view, and reattaches in the mean sense at

${{Re}}_c=1.0\times 10^5$

(figures 5

a and 5

d), the laminar boundary layer separates upstream of the field of view, and reattaches in the mean sense at

![]() $x/c=0.32$

and

$x/c=0.32$

and

![]() $x/c=0.37$

on the aerofoil and wing models, respectively. The delay in reattachment on the wing relative to the aerofoil is attributed to the reduction in effective angle of attack on the wing model caused by the presence of the wing tip, which reduces the streamwise adverse pressure gradient and is expected to delay separation and transition (Bastedo & Mueller Reference Bastedo and Mueller1986). In the stalled limiting states (figures 5

b, 5

c, 5

e and 5

f), reattachment does not occur, and the magnitude and spatial extent of reverse flow are substantially increased. The flow field development at

$x/c=0.37$

on the aerofoil and wing models, respectively. The delay in reattachment on the wing relative to the aerofoil is attributed to the reduction in effective angle of attack on the wing model caused by the presence of the wing tip, which reduces the streamwise adverse pressure gradient and is expected to delay separation and transition (Bastedo & Mueller Reference Bastedo and Mueller1986). In the stalled limiting states (figures 5

b, 5

c, 5

e and 5

f), reattachment does not occur, and the magnitude and spatial extent of reverse flow are substantially increased. The flow field development at

![]() $\alpha = 13^\circ$

and

$\alpha = 13^\circ$

and

![]() ${{Re}}_c=1.0\times 10^5$

(figures 5

b and 5

e) is largely similar to that at

${{Re}}_c=1.0\times 10^5$

(figures 5

b and 5

e) is largely similar to that at

![]() $\alpha =10^\circ$

and

$\alpha =10^\circ$

and

![]() ${{Re}}_c=8.0\times 10^4$

(figures 5

c and 5

f), except that the separated shear layer remains closer to the model surface at the lower Reynolds number.

${{Re}}_c=8.0\times 10^4$

(figures 5

c and 5

f), except that the separated shear layer remains closer to the model surface at the lower Reynolds number.

Quasi-steady lift coefficient measurements for the wing and aerofoil models versus angle of attack and Reynolds number are presented in figures 6 and 7, respectively. The expected reduction in quasi-steady lift of the finite wing relative to the aerofoil at pre-stall angles of attack is evident from the lift polars in figure 6. The limiting flow states (coloured markers) straddle the quasi-steady stall and reattachment angles and Reynolds numbers (vertical black lines, as defined in § 2.1) for the aerofoil and wing for changes in angle of attack (figure 6) and changes in Reynolds number (figure 7). The differences between the limiting flow states measured during transients and the quasi-steady measurements are within the experimental uncertainty. The static stall angles for increasing angle of attack for the aerofoil and wing models are

![]() $11.9^{\circ }$

and

$11.9^{\circ }$

and

![]() $12.0^{\circ }$

, respectively, and the static reattachment angles for decreasing angle of attack are

$12.0^{\circ }$

, respectively, and the static reattachment angles for decreasing angle of attack are

![]() $10.3^{\circ }$

and

$10.3^{\circ }$

and

![]() $11.3^\circ$

, respectively. The static stall Reynolds numbers for decreasing Reynolds number for the aerofoil and wing are

$11.3^\circ$

, respectively. The static stall Reynolds numbers for decreasing Reynolds number for the aerofoil and wing are

![]() $9.0\times 10^4$

and

$9.0\times 10^4$

and

![]() $8.8\times 10^4$

, respectively, and the static reattachment Reynolds numbers for increasing Reynolds number are

$8.8\times 10^4$

, respectively, and the static reattachment Reynolds numbers for increasing Reynolds number are

![]() $8.9\times 10^4$

and

$8.9\times 10^4$

and

![]() $8.6\times 10^4$

, respectively. The increase in the stall and reattachment angles and decrease in the stall and reattachment Reynolds numbers of the wing relative to the aerofoil areattributed to the reduction in effective angle of attack caused by the presence of the wing tip. For both models, there is substantial hysteresis in the lift coefficient for quasi-steady changes in angle of attack. The existence of a quasi-steady hysteresis loop is characteristic of lifting surfaces operating at low Reynolds numbers (Mueller Reference Mueller1985) and suggests the presence of an LSB on both models under the conditions investigated. The area of the quasi-steady hysteresis loop of the aerofoil is 2.6 times that of the wing. In contrast to the lift coefficient hysteresis observed for quasi-steady changes in angle of attack, no significant hysteresis was observed for quasi-steady changes in Reynolds number (figure 7).

$8.6\times 10^4$

, respectively. The increase in the stall and reattachment angles and decrease in the stall and reattachment Reynolds numbers of the wing relative to the aerofoil areattributed to the reduction in effective angle of attack caused by the presence of the wing tip. For both models, there is substantial hysteresis in the lift coefficient for quasi-steady changes in angle of attack. The existence of a quasi-steady hysteresis loop is characteristic of lifting surfaces operating at low Reynolds numbers (Mueller Reference Mueller1985) and suggests the presence of an LSB on both models under the conditions investigated. The area of the quasi-steady hysteresis loop of the aerofoil is 2.6 times that of the wing. In contrast to the lift coefficient hysteresis observed for quasi-steady changes in angle of attack, no significant hysteresis was observed for quasi-steady changes in Reynolds number (figure 7).

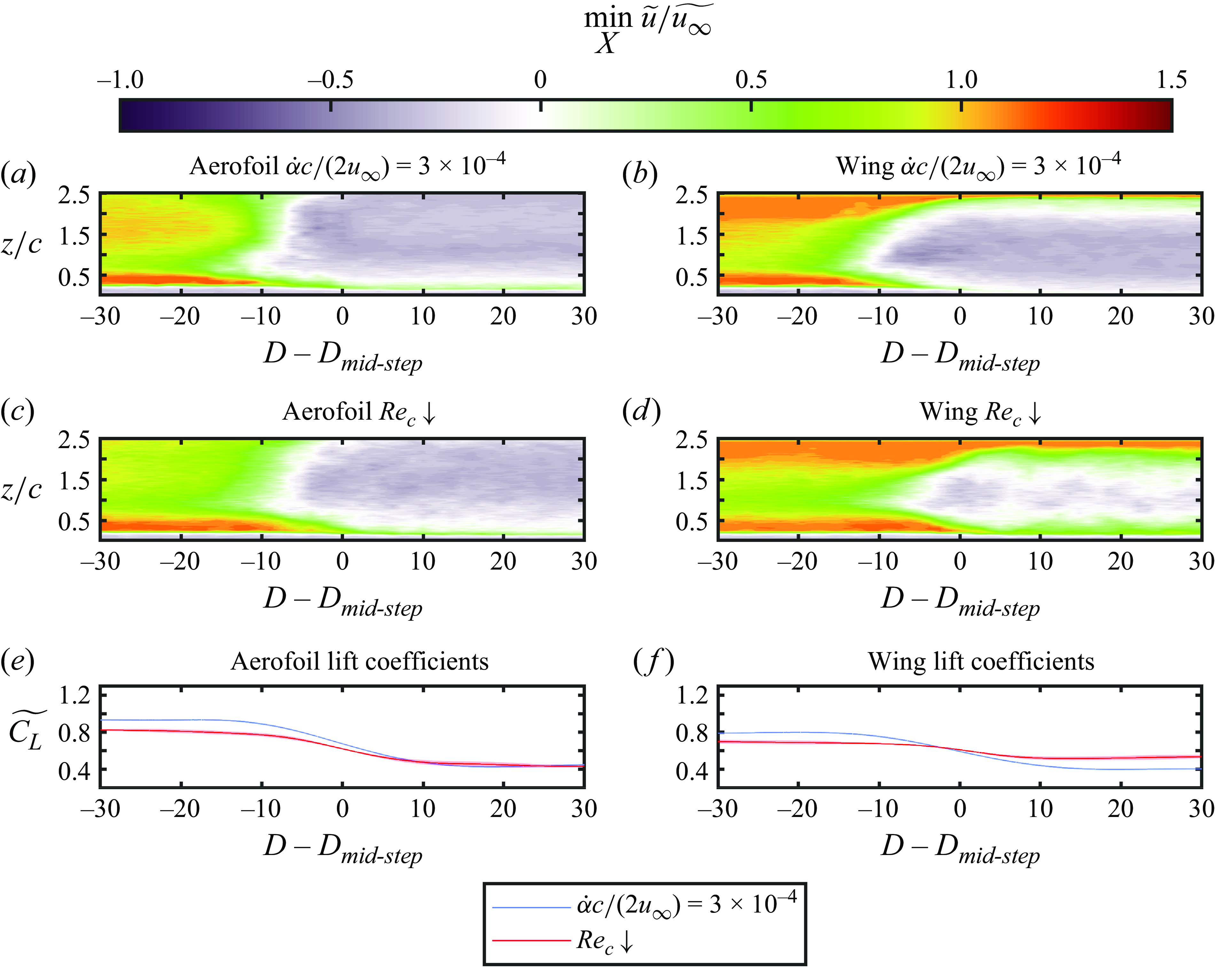

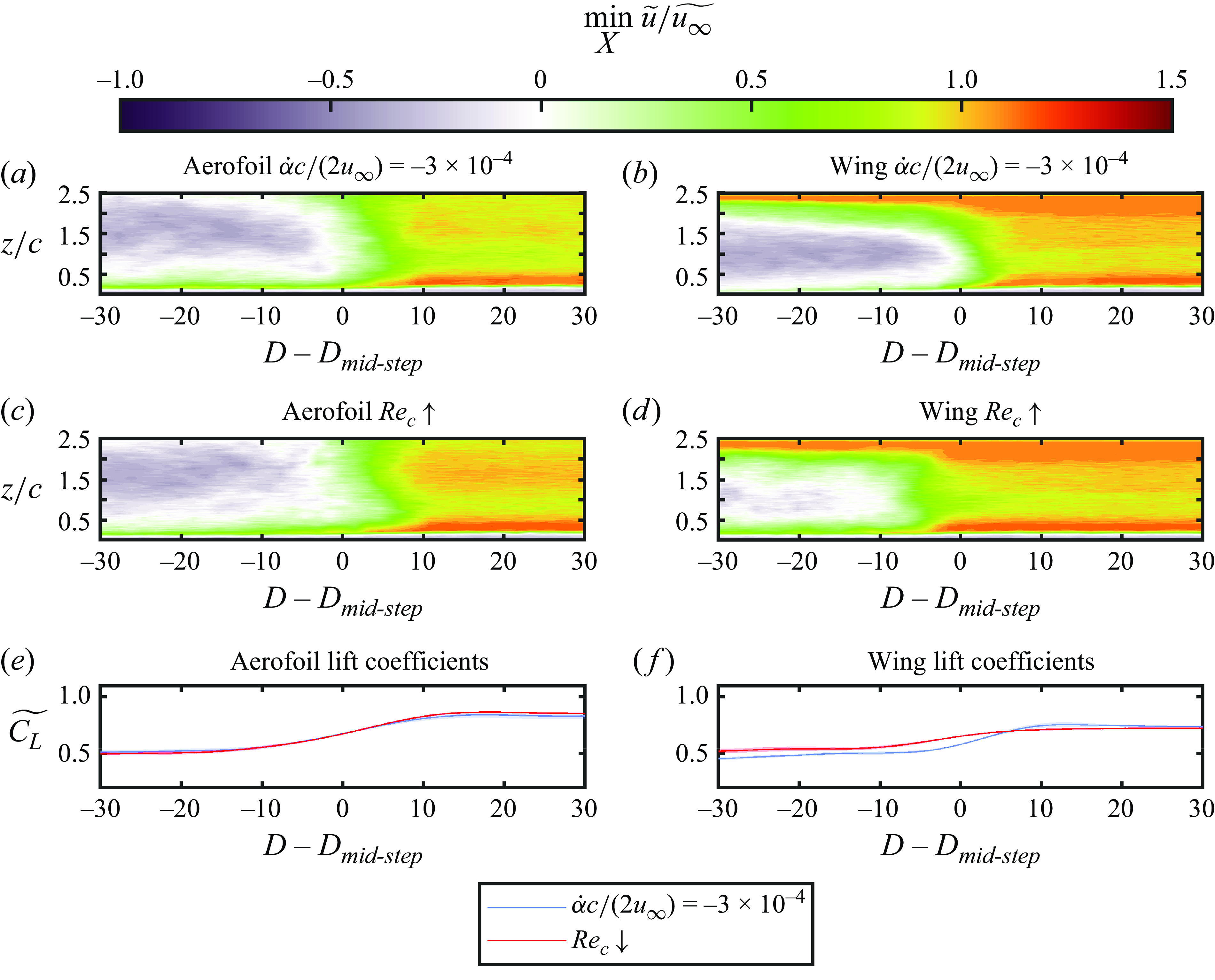

3.2. Transient flow development

The relationship between ensemble-averaged unsteady and quasi-steady lift coefficients of the aerofoil and wing models are examined in figures 6 and 7. The pitching motion shown for comparison is that for

![]() $\dot {\alpha }c/ (2u_\infty )=\pm 3\times 10^{-4}$

, which has a duration of

$\dot {\alpha }c/ (2u_\infty )=\pm 3\times 10^{-4}$

, which has a duration of

![]() $75c/u_\infty$

that is approximately equal to the duration of the transient Reynolds number change. The ensemble-averaged lift coefficients from the transient pitching motions exhibit an enlargement of the hysteresis loop compared with the quasi-steady measurements. The area of the transient hysteresis loop of the aerofoil is 1.3 times that of the wing. Note that the uncertainty of the ensemble average (shaded area) is significantly less than the variations between individual runs because of the sample size of

$75c/u_\infty$

that is approximately equal to the duration of the transient Reynolds number change. The ensemble-averaged lift coefficients from the transient pitching motions exhibit an enlargement of the hysteresis loop compared with the quasi-steady measurements. The area of the transient hysteresis loop of the aerofoil is 1.3 times that of the wing. Note that the uncertainty of the ensemble average (shaded area) is significantly less than the variations between individual runs because of the sample size of

![]() $20$

runs. The nearly monotonic change in ensemble-averaged lift coefficient between

$20$

runs. The nearly monotonic change in ensemble-averaged lift coefficient between

![]() $\alpha = 10^\circ$

and

$\alpha = 10^\circ$

and

![]() $13^\circ$

for upward pitching of the wing (figure 6

b) indicates that stall does not occur until after the final angle of attack is reached. However, for the aerofoil, loss of lift begins prior to reaching

$13^\circ$

for upward pitching of the wing (figure 6

b) indicates that stall does not occur until after the final angle of attack is reached. However, for the aerofoil, loss of lift begins prior to reaching

![]() $\alpha = 13^\circ$

. As expected for lifting surfaces undergoing dynamic stall and reattachment, the transient pitching motions produce overshoots and undershoots relative to the quasi-steady lift coefficients (McCroskey Reference McCroskey1981; Green & Galbraith Reference Green and Galbraith1995).

$\alpha = 13^\circ$

. As expected for lifting surfaces undergoing dynamic stall and reattachment, the transient pitching motions produce overshoots and undershoots relative to the quasi-steady lift coefficients (McCroskey Reference McCroskey1981; Green & Galbraith Reference Green and Galbraith1995).

Although there is no quasi-steady hysteresis in the lift coefficient with respect to Reynolds number, transient changes in Reynolds number exhibit hysteresis for the wing and the aerofoil (figure 7). However, the reduction in effective angle of attack of the wing reduces the area of its hysteresis loop to approximately

![]() $1/4$

of the area of the aerofoil’s hysteresis loop. This suggests that the difference in lift coefficient between the upper and lower branches of the hysteresis loop with respect to Reynolds number increases with increasing effective angle of attack.

$1/4$

of the area of the aerofoil’s hysteresis loop. This suggests that the difference in lift coefficient between the upper and lower branches of the hysteresis loop with respect to Reynolds number increases with increasing effective angle of attack.

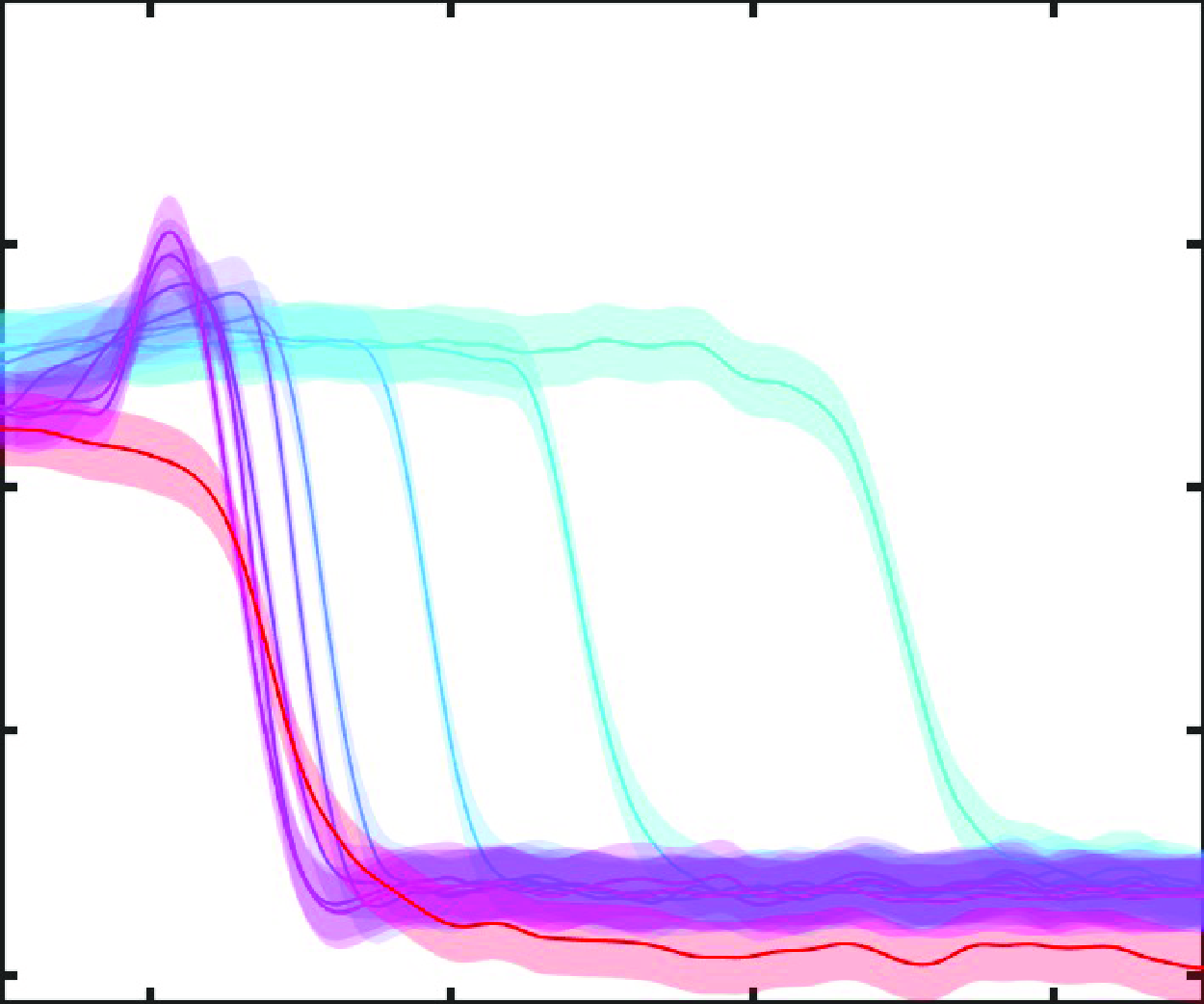

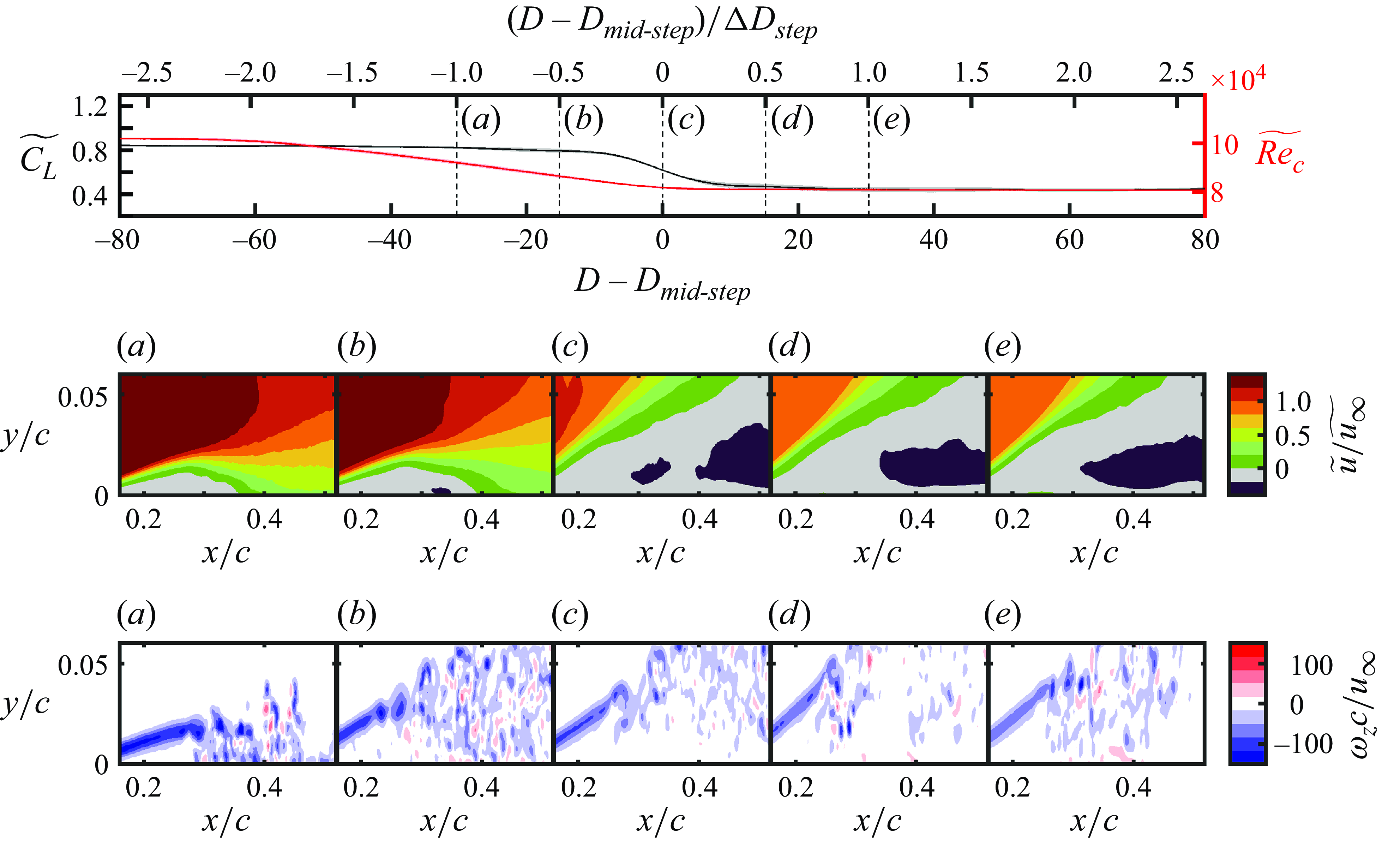

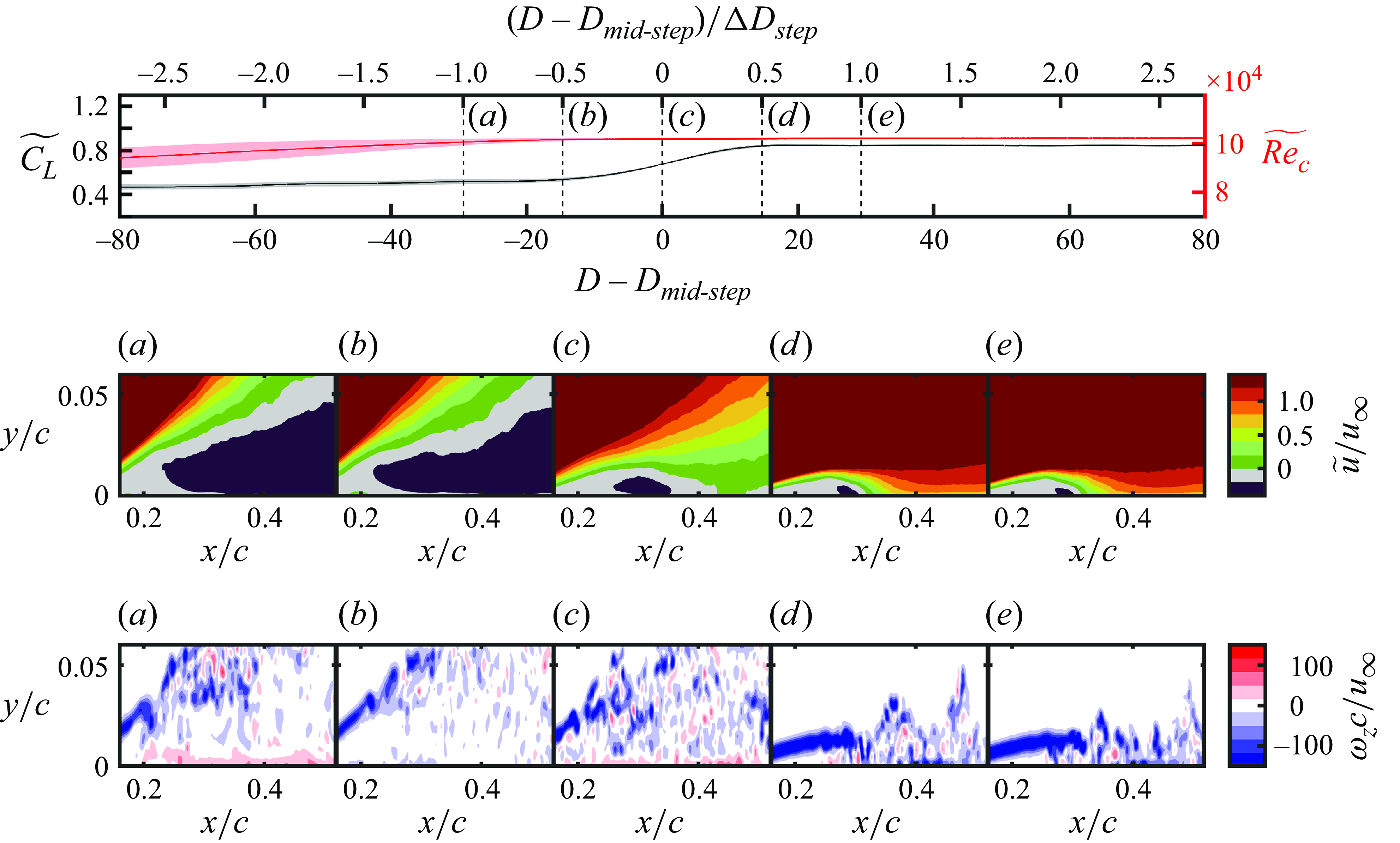

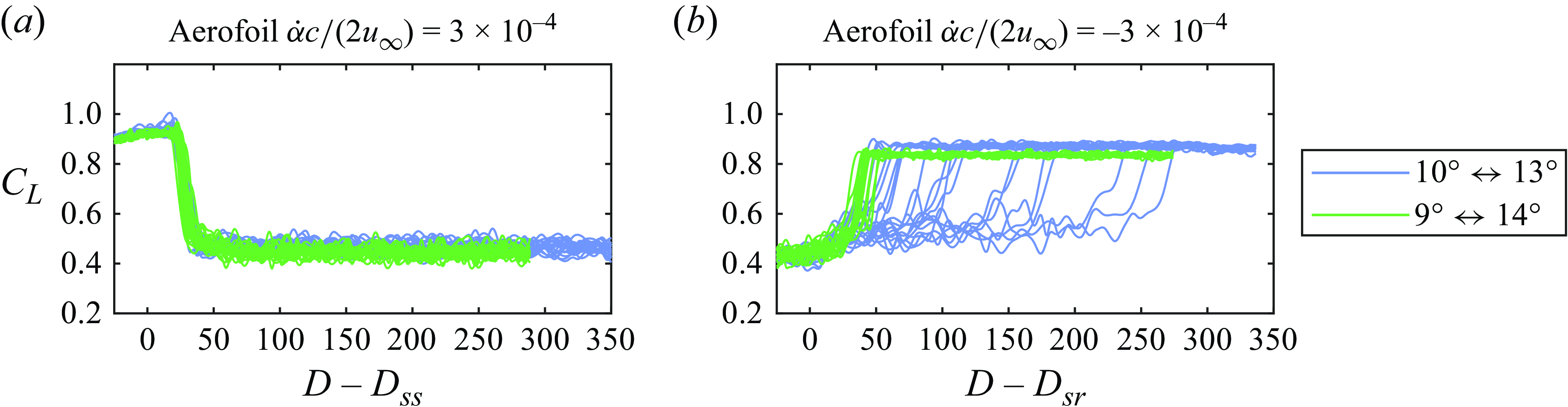

Figure 8. Lift coefficients from individual runs of the pitching motion with rate

![]() $\dot {\alpha }c/(2u_\infty )=3\times 10^{-5}$

and Reynolds number decrease.

$\dot {\alpha }c/(2u_\infty )=3\times 10^{-5}$

and Reynolds number decrease.

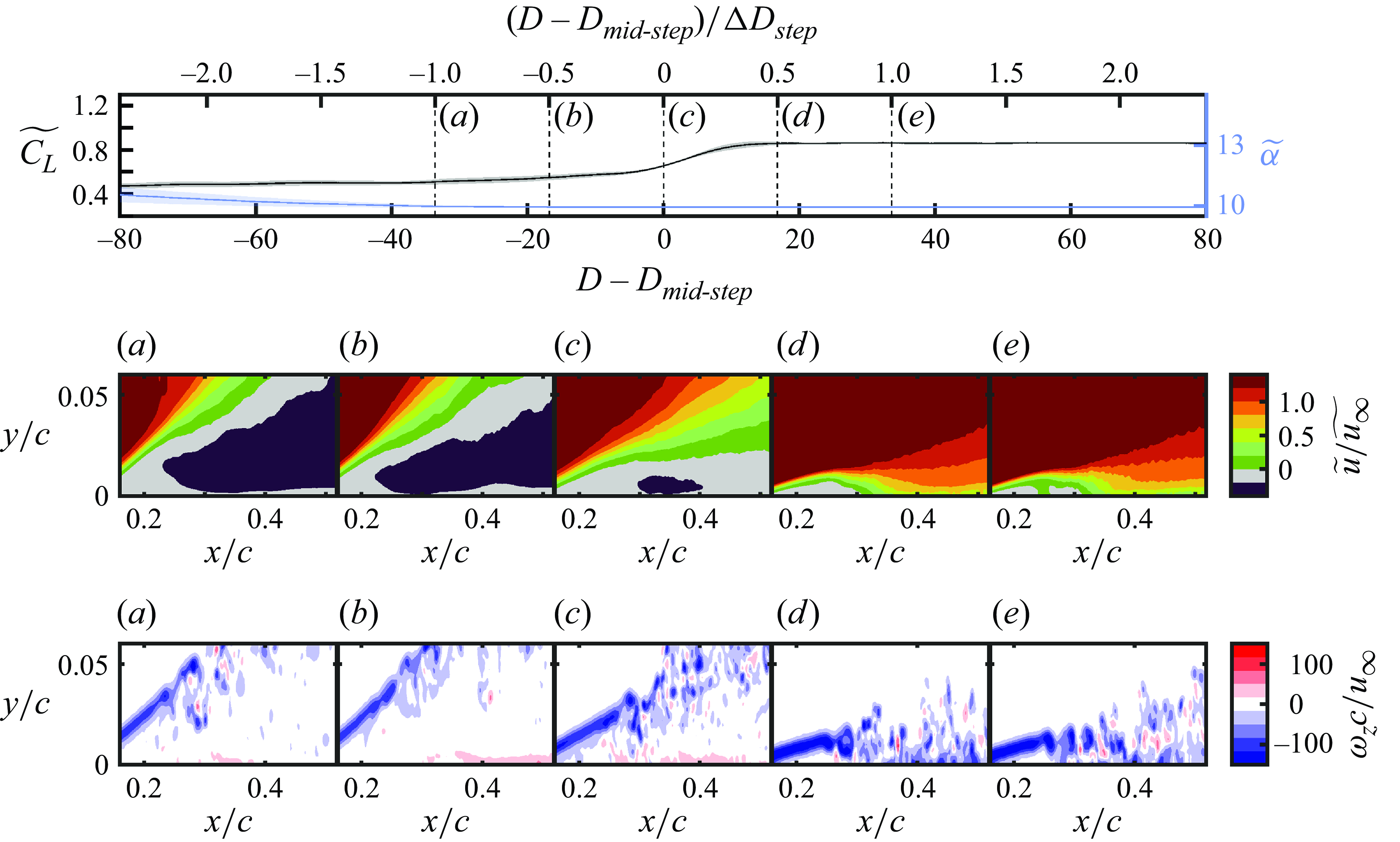

Figure 9. Lift coefficients from individual runs of the pitching motion with rate

![]() $\dot {\alpha }c/(2u_\infty )=-3\times 10^{-5}$

and Reynolds number increase.

$\dot {\alpha }c/(2u_\infty )=-3\times 10^{-5}$

and Reynolds number increase.

Lift coefficients obtained from individual runs for the aerofoil and wing during transients leading to stall are plotted in figure 8 versus the non-dimensional convective time. The uncertainty in instantaneous lift coefficient measurements is estimated to be less than

![]() $0.05$

. The pitching motions and Reynolds number changes in the figure have been shifted in time so that the static stall condition is passed at

$0.05$

. The pitching motions and Reynolds number changes in the figure have been shifted in time so that the static stall condition is passed at

![]() $D-D_{\textrm {ss}}=0$