1. Introduction

Despite nearly all natural and man-made granular materials being composed of grains of varying size, shape and frictional properties, the majority of continuum flow modelling has largely been restricted to perfectly monodisperse aggregates. The purpose of this work is therefore to extend the current granular flow models by introducing multiple phases, with different properties, and to model inter-phase segregation. Coupling the flow rheology to the local constituent concentrations is important because the mobility of a granular flow is strongly affected by the local frictional properties of the grains. In turn, the bulk flow controls the strength and direction of the segregation as well as the advection of the granular phases.

Striking examples of segregation induced feedback on the bulk flow are found during levee formation (Iverson & Vallance Reference Iverson and Vallance2001; Johnson et al. Reference Johnson, Kokelaar, Iverson, Logan, LaHusen and Gray2012; Kokelaar et al. Reference Kokelaar, Graham, Gray and Vallance2014) and fingering instabilities (Pouliquen, Delour & Savage Reference Pouliquen, Delour and Savage1997; Pouliquen & Vallance Reference Pouliquen and Vallance1999; Woodhouse et al. Reference Woodhouse, Thornton, Johnson, Kokelaar and Gray2012; Baker, Johnson & Gray Reference Baker, Johnson and Gray2016b), which commonly occur during the run-out of pyroclastic density currents, debris flows and snow avalanches. Many other examples of segregation–flow coupling occur in industrial settings (Williams Reference Williams1968; Gray & Hutter Reference Gray and Hutter1997; Makse et al. Reference Makse, Havlin, King and Stanley1997; Hill et al. Reference Hill, Khakhar, Gilchrist, McCarthy and Ottino1999; Ottino & Khakhar Reference Ottino and Khakhar2000; Zuriguel et al. Reference Zuriguel, Gray, Peixinho and Mullin2006). Storage silo filling and emptying, stirring mixers and rotating tumblers all have the common features of cyclic deformation and an ambition of generating well-mixed material. However, experiments consistently suggest that these processes have a tendency to promote local segregation, which can feedback on the bulk flow velocities. Considering the inherent destructive potential of geophysical phenomena and the implications of poor efficiency in industrial mixing, a continuum theory which captures the important physics of flow and of segregation simultaneously is therefore highly desirable.

To date, the leading approaches for solving coupled flow and segregation have come from either discrete particle simulations (Tripathi & Khakhar Reference Tripathi and Khakhar2011; Thornton et al. Reference Thornton, Weinhart, Luding and Bokhove2012) or from depth-averaged equations (Woodhouse et al. Reference Woodhouse, Thornton, Johnson, Kokelaar and Gray2012; Baker et al. Reference Baker, Johnson and Gray2016b; Viroulet et al. Reference Viroulet, Baker, Rocha, Johnson, Kokelaar and Gray2018). Particle simulations, using the discrete element method (DEM), provide important rheological information as evolving velocities, stresses and constituent concentrations can be directly computed given only minimal approximations. Such results can then be used to motivate models for the bulk flow (GDR MiDi 2004; Jop, Forterre & Pouliquen Reference Jop, Forterre and Pouliquen2006; Singh et al. Reference Singh, Magnanimo, Saitoh and Luding2015) and also to form connections between flow and segregation processes (Hill & Fan Reference Hill and Fan2008; Staron & Phillips Reference Staron and Phillips2015). Unfortunately, the discrete particle approach is naturally limited by computational expense as many flows of interest include such a large number of particles that direct DEM calculations are unfeasible. Recently efforts have been made to overcome this limitation with the development of hybrid schemes (e.g. Yue et al. Reference Yue, Smith, Chen, Chantharayukhonthorn, Kamrin and Grinspun2018; Xiao et al. Reference Xiao, Fan, Jacob, Umbanhowar, Kodam, Koch and Lueptow2019) which couple discrete particle dynamics to continuum solvers, but these approaches naturally invoke additional complexity and new assumptions are required in order to map properly and consistently between the somewhat disparate approaches.

Depth-averaged models, which reduce the full three-dimensional flow to two dimensions by integrating though the depth and assuming shallowness, lead to efficient numerical codes which are widely used in geophysical modelling (see e.g. Grigorian, Eglit & Iakimov Reference Grigorian, Eglit and Iakimov1967; Savage & Hutter Reference Savage and Hutter1989; Iverson Reference Iverson1997; Gray, Wieland & Hutter Reference Gray, Wieland and Hutter1999; Pouliquen & Forterre Reference Pouliquen and Forterre2002; Sheridan et al. Reference Sheridan, Stinton, Patra, Pitman, Bauer and Nichita2005; Mangeney et al. Reference Mangeney, Bouchut, Thomas, Vilotte and Bristeau2007; Christen, Kowalski & Bartelt Reference Christen, Kowalski and Bartelt2010; Gray & Edwards Reference Gray and Edwards2014; Delannay et al. Reference Delannay, Valance, Mangeney, Roche and Richard2017; Rauter & Tuković Reference Rauter and Tuković2018; Rocha, Johnson & Gray Reference Rocha, Johnson and Gray2019). However, depth-averaged approaches are limited to geometries in which there is a clear dimension that remains shallow throughout the dynamics. This approximation holds well for thin flows on inclined planes and for flows over certain gradually varying terrain, but breaks down in many flows of practical interest, such as those in hoppers, silos and rotating drums.

Historical attempts to construct three-dimensional continuum models for monodisperse granular materials focused on quasi-static deformations and lead to elasto-plastic formulations of models such as the Drucker–Prager yield condition (Lubliner Reference Lubliner2008) and critical state soil mechanics (Schofield & Wroth Reference Schofield and Wroth1968). Despite successes in modelling the point of failure of materials under load, calculations of the subsequent time-dependent flow proved to be problematic, because the results are grid-size dependent. Schaeffer (Reference Schaeffer1987) showed that this was because the underlying equations are mathematically ill posed, i.e. in the small wavelength limit the growth rate of linear instabilities becomes unbounded in certain directions.

Despite the Mohr–Coulomb/Drucker–Prager plasticity theory being designed for the flow of monodisperse grains, the grain diameter ![]() $d$ does not appear in the constitutive model. It can be incorporated by making the friction

$d$ does not appear in the constitutive model. It can be incorporated by making the friction ![]() $\mu$ a function of the non-dimensional inertial number, which is defined as

$\mu$ a function of the non-dimensional inertial number, which is defined as

where ![]() $\dot \gamma$ is the shear rate,

$\dot \gamma$ is the shear rate, ![]() $p$ is the pressure and

$p$ is the pressure and ![]() $\rho _*$ is the intrinsic grain density (Savage Reference Savage1984; Ancey, Coussot & Evesque Reference Ancey, Coussot and Evesque1999; GDR MiDi 2004). Jop et al. (Reference Jop, Forterre and Pouliquen2006) generalized the scalar

$\rho _*$ is the intrinsic grain density (Savage Reference Savage1984; Ancey, Coussot & Evesque Reference Ancey, Coussot and Evesque1999; GDR MiDi 2004). Jop et al. (Reference Jop, Forterre and Pouliquen2006) generalized the scalar ![]() $\mu (I)$-rheology to tensorial form. The resultant incompressible

$\mu (I)$-rheology to tensorial form. The resultant incompressible ![]() $\mu (I)$-rheology leads to a significantly better posed system of equations (Barker et al. Reference Barker, Schaeffer, Bohorquez and Gray2015). For the

$\mu (I)$-rheology leads to a significantly better posed system of equations (Barker et al. Reference Barker, Schaeffer, Bohorquez and Gray2015). For the ![]() $\mu (I)$ curve suggested by Jop, Forterre & Pouliquen (Reference Jop, Forterre and Pouliquen2005), the equations are well posed for a large range of intermediate values of

$\mu (I)$ curve suggested by Jop, Forterre & Pouliquen (Reference Jop, Forterre and Pouliquen2005), the equations are well posed for a large range of intermediate values of ![]() $I$ and are only ill posed for very low or relatively high inertial numbers.

$I$ and are only ill posed for very low or relatively high inertial numbers.

Barker & Gray (Reference Barker and Gray2017) derived a new functional form for the ![]() $\mu (I)$ relation, which is known as the partially regularized

$\mu (I)$ relation, which is known as the partially regularized ![]() $\mu (I)$-rheology. This ensures well posedness for

$\mu (I)$-rheology. This ensures well posedness for ![]() $0<I<I_{max}$, where

$0<I<I_{max}$, where ![]() $I_{max}$ is a very large value, and leads to stable and reliable numerical schemes. It also provides a better fit to experimental (Holyoake & McElwaine Reference Holyoake and McElwaine2012; Barker & Gray Reference Barker and Gray2017) and DEM data (Kamrin & Koval Reference Kamrin and Koval2012) than the original

$I_{max}$ is a very large value, and leads to stable and reliable numerical schemes. It also provides a better fit to experimental (Holyoake & McElwaine Reference Holyoake and McElwaine2012; Barker & Gray Reference Barker and Gray2017) and DEM data (Kamrin & Koval Reference Kamrin and Koval2012) than the original ![]() $\mu (I)$ curve, but also introduces a creep state (i.e.

$\mu (I)$ curve, but also introduces a creep state (i.e. ![]() $\mu =0$ when

$\mu =0$ when ![]() $I=0$) so the granular material no longer has a yield stress. It is possible to formulate well-posed models with a yield stress by introducing bulk compressibility (Barker et al. Reference Barker, Schaeffer, Shearer and Gray2017; Schaeffer et al. Reference Schaeffer, Barker, Tsuji, Gremaud, Shearer and Gray2019) or non-locality (Henann & Kamrin Reference Henann and Kamrin2013). However, in this paper the partially regularized

$I=0$) so the granular material no longer has a yield stress. It is possible to formulate well-posed models with a yield stress by introducing bulk compressibility (Barker et al. Reference Barker, Schaeffer, Shearer and Gray2017; Schaeffer et al. Reference Schaeffer, Barker, Tsuji, Gremaud, Shearer and Gray2019) or non-locality (Henann & Kamrin Reference Henann and Kamrin2013). However, in this paper the partially regularized ![]() $\mu (I)$-rheology is chosen for the bulk flow, both for simplicity and because it is most readily compatible with existing numerical methods and particle segregation models.

$\mu (I)$-rheology is chosen for the bulk flow, both for simplicity and because it is most readily compatible with existing numerical methods and particle segregation models.

Initially well-mixed granular materials have a strong propensity of ordering spatially when they undergo flow. Chief among these effects is that of particle-size segregation, made famous through the moniker ‘the Brazil nut effect’ (Rosato et al. Reference Rosato, Strandburg, Prinz and Swendsen1987), whereby particles move relative to the bulk flow based on their size compared with their neighbours. The resultant vertical distribution, in which larger particles are often concentrated at the surface of a flow, can also be observed in many geophysical mass flows, forming so-called inversely graded deposits (e.g. Middleton Reference Middleton1970; Festa et al. Reference Festa, Ogata, Pini, Dilek and Codegone2015). The origin of this effect was explained through statistical entropic arguments by Savage & Lun (Reference Savage and Lun1988) who proposed a means of ‘kinetic sieving’ (Middleton Reference Middleton1970) in which smaller grains are more likely to fall (by gravity) into voids that are created as layers of particles are sheared over one another. Force imbalances then drive particles out of the denser layer, which is known as ‘squeeze expulsion’. The combination of kinetic sieving and squeeze expulsion produces a net upward motion of large particles as the smaller grains percolate downwards. These concepts formed the basis of the theory of Gray & Thornton (Reference Gray and Thornton2005) who focused on this form of gravity-driven segregation in granular free-surface flows. The theory was later extended by Gray & Chugunov (Reference Gray and Chugunov2006), in order to account for diffusive mixing, and has been successfully applied to a range of gravity-driven flows (Gray Reference Gray2018). However, Fan & Hill (Reference Fan and Hill2011) found that the direction of segregation was not always aligned with the vector of gravitational acceleration. Instead gradients in kinetic stress were found to drive and orient segregation in a range of geometries (Hill & Tan Reference Hill and Tan2014). These findings have since inspired many investigations into the micromechanical origin of size segregation (Staron & Phillips Reference Staron and Phillips2015; Guillard, Forterre & Pouliquen Reference Guillard, Forterre and Pouliquen2016; van der Vaart et al. Reference van der Vaart, van Schrojenstein Lantman, Weinhart, Luding, Ancey and Thornton2018), but a unified and compelling theory is still lacking.

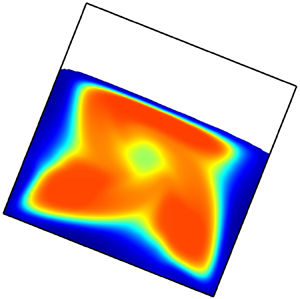

In order to accommodate different models for size segregation and different flow rheologies, this paper first introduces a very general framework for multi-component flows in § 2. In particular, the multicomponent segregation theory of Gray & Ancey (Reference Gray and Ancey2011) is generalized to allow sub-mixtures to segregate in different directions and with differing diffusion rates. In § 3 the three primary coupling mechanisms are discussed in detail. Section 4 documents the general numerical method, which is then extensively tested against the one-way coupled simulations in § 5. Two-way fully coupled simulations are then presented for flow down an inclined plane, in § 6, and in § 7 simulations are performed for a square rotating drum. The new experimental segregation law of Trewhela, Ancey & Gray (Reference Trewhela, Ancey and Gray2021) is tested against the steady-state DEM solutions of Tripathi & Khakhar (Reference Tripathi and Khakhar2011) in § 6.3 and then used in § 7 for the rotating drum simulations, which are able to spontaneously generate petal-like patterns that have previously been seen in the experiments of Hill et al. (Reference Hill, Khakhar, Gilchrist, McCarthy and Ottino1999), Ottino & Khakhar (Reference Ottino and Khakhar2000) and Mounty (Reference Mounty2007).

2. Governing equations

2.1. The partially regularized  $\mu (I)$-rheology for the bulk flow

$\mu (I)$-rheology for the bulk flow

The granular material is assumed to be composed of a mixture of particles that may differ in size, shape and surface properties, but have the same intrinsic particle density ![]() $\rho _*$. If the solids volume fraction

$\rho _*$. If the solids volume fraction ![]() $\varPhi$ is constant, which is a reasonable first approximation (GDR MiDi 2004; Tripathi & Khakhar Reference Tripathi and Khakhar2011; Thornton et al. Reference Thornton, Weinhart, Luding and Bokhove2012), then the bulk density

$\varPhi$ is constant, which is a reasonable first approximation (GDR MiDi 2004; Tripathi & Khakhar Reference Tripathi and Khakhar2011; Thornton et al. Reference Thornton, Weinhart, Luding and Bokhove2012), then the bulk density ![]() $\rho =\varPhi \rho _*$ is constant and uniform throughout the material. Mass balance then implies that the bulk velocity field

$\rho =\varPhi \rho _*$ is constant and uniform throughout the material. Mass balance then implies that the bulk velocity field ![]() $\boldsymbol {u}$ is incompressible

$\boldsymbol {u}$ is incompressible

where ![]() $\boldsymbol {\nabla }$ is the gradient and

$\boldsymbol {\nabla }$ is the gradient and ![]() $\boldsymbol {\cdot }$ is the dot product. The momentum balance is

$\boldsymbol {\cdot }$ is the dot product. The momentum balance is

where ![]() $p$ is the pressure,

$p$ is the pressure, ![]() $\eta$ is the viscosity,

$\eta$ is the viscosity, ![]() $\boldsymbol {D} = (\boldsymbol {\nabla } \boldsymbol {u} + (\boldsymbol {\nabla } \boldsymbol {u})^{T})/2$ is the strain-rate tensor and

$\boldsymbol {D} = (\boldsymbol {\nabla } \boldsymbol {u} + (\boldsymbol {\nabla } \boldsymbol {u})^{T})/2$ is the strain-rate tensor and ![]() $\boldsymbol {g}$ is the gravitational acceleration. Assuming alignment of the shear-stress and strain-rate tensors the

$\boldsymbol {g}$ is the gravitational acceleration. Assuming alignment of the shear-stress and strain-rate tensors the ![]() $\mu (I)$-rheology (Jop et al. Reference Jop, Forterre and Pouliquen2006) implies that the granular viscosity is

$\mu (I)$-rheology (Jop et al. Reference Jop, Forterre and Pouliquen2006) implies that the granular viscosity is

where the second invariant of the strain-rate tensor is defined as

and the inertial number, defined in (1.1), in this notation becomes

The meaning of the particle size ![]() $d$ in a polydisperse mixture will be clarified in § 3.2. Note that this paper is restricted to two-dimensional deformations with an isotropic Drucker–Prager yield surface. However, as shown by Rauter, Barker & Fellin (Reference Rauter, Barker and Fellin2020), this framework can be extended to include three-dimensional deformations through further modification of the granular viscosity i.e. dependence on

$d$ in a polydisperse mixture will be clarified in § 3.2. Note that this paper is restricted to two-dimensional deformations with an isotropic Drucker–Prager yield surface. However, as shown by Rauter, Barker & Fellin (Reference Rauter, Barker and Fellin2020), this framework can be extended to include three-dimensional deformations through further modification of the granular viscosity i.e. dependence on ![]() $\det (\boldsymbol {D})$.

$\det (\boldsymbol {D})$.

The viscosity (2.3) is a highly nonlinear function of the inertial-number-dependent friction ![]() $\mu =\mu (I)$, pressure

$\mu =\mu (I)$, pressure ![]() $p$ and the second invariant of the strain rate

$p$ and the second invariant of the strain rate ![]() $\|\boldsymbol {D}\|$. Barker et al. (Reference Barker, Schaeffer, Bohorquez and Gray2015) examined the linear instability of the system, to show that the growth rate becomes unbounded in the high wavenumber limit, and hence the incompressible

$\|\boldsymbol {D}\|$. Barker et al. (Reference Barker, Schaeffer, Bohorquez and Gray2015) examined the linear instability of the system, to show that the growth rate becomes unbounded in the high wavenumber limit, and hence the incompressible ![]() $\mu (I)$-rheology is mathematically ill posed, when the inequality

$\mu (I)$-rheology is mathematically ill posed, when the inequality

is satisfied, where ![]() $\mu ^{\prime }=\partial \mu /\partial I$. Ill posedness of this type is not only unphysical, but results in two-dimensional time-dependent numerical computations that do not converge with mesh refinement (see e.g. Barker et al. Reference Barker, Schaeffer, Bohorquez and Gray2015; Barker & Gray Reference Barker and Gray2017; Martin et al. Reference Martin, Ionescu, Mangeney, Bouchut and Farin2017). If the friction is not inertial number dependent (

$\mu ^{\prime }=\partial \mu /\partial I$. Ill posedness of this type is not only unphysical, but results in two-dimensional time-dependent numerical computations that do not converge with mesh refinement (see e.g. Barker et al. Reference Barker, Schaeffer, Bohorquez and Gray2015; Barker & Gray Reference Barker and Gray2017; Martin et al. Reference Martin, Ionescu, Mangeney, Bouchut and Farin2017). If the friction is not inertial number dependent (![]() $\mu =\text {const.}$) the ill-posedness condition (2.6) is satisfied for all inertial numbers and the system of equations is always ill posed (Schaeffer Reference Schaeffer1987). The equations are also ill posed if the friction

$\mu =\text {const.}$) the ill-posedness condition (2.6) is satisfied for all inertial numbers and the system of equations is always ill posed (Schaeffer Reference Schaeffer1987). The equations are also ill posed if the friction ![]() $\mu$ is a decreasing function of

$\mu$ is a decreasing function of ![]() $I$, since all the terms in (2.6) are strictly positive.

$I$, since all the terms in (2.6) are strictly positive.

The original form of the ![]() $\mu (I)$-curve proposed by Jop et al. (Reference Jop, Forterre and Pouliquen2005) is a monotonically increasing function of

$\mu (I)$-curve proposed by Jop et al. (Reference Jop, Forterre and Pouliquen2005) is a monotonically increasing function of ![]() $I$ starting at

$I$ starting at ![]() $\mu _{s}$ at

$\mu _{s}$ at ![]() $I=0$ and asymptoting to

$I=0$ and asymptoting to ![]() $\mu _{d}$ at large

$\mu _{d}$ at large ![]() $I$,

$I$,

where ![]() $I_{0}$ is a material specific constant. The inertial number dependence in (2.7) gives the rheology considerably better properties than the original, constant friction coefficient, Mohr–Coulomb/Drucker–Prager theory. Provided

$I_{0}$ is a material specific constant. The inertial number dependence in (2.7) gives the rheology considerably better properties than the original, constant friction coefficient, Mohr–Coulomb/Drucker–Prager theory. Provided ![]() $\mu _{d}-\mu _{s}$ is large enough, the system is well-posed when the inertial number lies in a large intermediate range of inertial numbers

$\mu _{d}-\mu _{s}$ is large enough, the system is well-posed when the inertial number lies in a large intermediate range of inertial numbers ![]() $I\in [I_1^{N},I_2^{N}]$. The equations are, however, ill posed if either the inertial number is too low

$I\in [I_1^{N},I_2^{N}]$. The equations are, however, ill posed if either the inertial number is too low ![]() $I<I_1^{N}$ or too high

$I<I_1^{N}$ or too high ![]() $I>I_2^{N}$, or if

$I>I_2^{N}$, or if ![]() $\mu _{d}-\mu _{s}$ is not large enough. For the parameter values given in table 1 the

$\mu _{d}-\mu _{s}$ is not large enough. For the parameter values given in table 1 the ![]() $\mu (I)$ rheology is well posed for

$\mu (I)$ rheology is well posed for ![]() $I\in [0.00397, 0.28016]$.

$I\in [0.00397, 0.28016]$.

Table 1. The frictional parameters ![]() $\mu _s$,

$\mu _s$, ![]() $\mu _d$,

$\mu _d$, ![]() $\mu _{\infty }$,

$\mu _{\infty }$, ![]() $I_0$ and

$I_0$ and ![]() $\alpha$ in Barker & Gray's (Reference Barker and Gray2017) friction law, which were measured for

$\alpha$ in Barker & Gray's (Reference Barker and Gray2017) friction law, which were measured for ![]() $143\ \mathrm {\mu }\textrm {m}$ glass beads. The value

$143\ \mathrm {\mu }\textrm {m}$ glass beads. The value ![]() $I_1\simeq I_1^{N}$ is set by the lower bound for well posedness in Jop et al.'s (Reference Jop, Forterre and Pouliquen2006) friction law using the parameters above. Unless stated otherwise, the remaining parameters are the values chosen in the numerical simulations. Note that the air viscosity is higher than the physical value of

$I_1\simeq I_1^{N}$ is set by the lower bound for well posedness in Jop et al.'s (Reference Jop, Forterre and Pouliquen2006) friction law using the parameters above. Unless stated otherwise, the remaining parameters are the values chosen in the numerical simulations. Note that the air viscosity is higher than the physical value of ![]() $\eta _*^{a}=1.81\times 10^{-5}\ \textrm {kg}\,(\textrm {ms})^{-1}$ to prevent the convective Courant number limiting the time-step size.

$\eta _*^{a}=1.81\times 10^{-5}\ \textrm {kg}\,(\textrm {ms})^{-1}$ to prevent the convective Courant number limiting the time-step size.

The range of well posedness was extended by Barker & Gray (Reference Barker and Gray2017) to ![]() $0\leq I \leq I_{max}$, where

$0\leq I \leq I_{max}$, where ![]() $I_{max}$ is a large maximal value, by changing the shape of the

$I_{max}$ is a large maximal value, by changing the shape of the ![]() $\mu (I)$-curve. This paper uses the

$\mu (I)$-curve. This paper uses the ![]() $\mu (I)$-curve proposed by Barker & Gray (Reference Barker and Gray2017)

$\mu (I)$-curve proposed by Barker & Gray (Reference Barker and Gray2017)

\begin{equation} \mu = \begin{cases} \displaystyle \sqrt{\frac{\alpha}{\log\left(\dfrac{A}{I}\right)}}, & \text{for } I \leq I_1,\\ \displaystyle \frac{\mu_{s} I_{0}+\mu_{d} I+\mu_{\infty} I^{2}}{I_{0}+I}, & \text{for } I > I_1, \end{cases} \end{equation}

\begin{equation} \mu = \begin{cases} \displaystyle \sqrt{\frac{\alpha}{\log\left(\dfrac{A}{I}\right)}}, & \text{for } I \leq I_1,\\ \displaystyle \frac{\mu_{s} I_{0}+\mu_{d} I+\mu_{\infty} I^{2}}{I_{0}+I}, & \text{for } I > I_1, \end{cases} \end{equation}

where ![]() $\alpha$ and

$\alpha$ and ![]() $\mu _{\infty }$ are new material constants and

$\mu _{\infty }$ are new material constants and

is chosen to ensure continuity between the two branches at ![]() $I=I_1$. As shown in figure 1 this curve stays close to (2.7) in the well-posed region of parameter space, but passes though

$I=I_1$. As shown in figure 1 this curve stays close to (2.7) in the well-posed region of parameter space, but passes though ![]() $\mu =0$ at

$\mu =0$ at ![]() $I=0$ and is asymptotically linear in

$I=0$ and is asymptotically linear in ![]() $I$ at large inertial numbers. For the parameters given in table 1, the matching occurs at

$I$ at large inertial numbers. For the parameters given in table 1, the matching occurs at ![]() $I_1=0.004$ (which is very slightly larger than

$I_1=0.004$ (which is very slightly larger than ![]() $I_1^{N}$) and the maximum well-posed inertial number is

$I_1^{N}$) and the maximum well-posed inertial number is ![]() $I_{max}=16.9918$.

$I_{max}=16.9918$.

Figure 1. Comparison between the friction law of Jop et al. (Reference Jop, Forterre and Pouliquen2006) (red line) and the partially regularized law of Barker & Gray (Reference Barker and Gray2017) (blue line). The Jop et al. (Reference Jop, Forterre and Pouliquen2006) curve has a finite yield stress ![]() $\mu _s$ (red dot) and asymptotes to

$\mu _s$ (red dot) and asymptotes to ![]() $\mu _d$ at large inertial number (dashed line). For the parameters summarized in table 1, it is well posed in the range

$\mu _d$ at large inertial number (dashed line). For the parameters summarized in table 1, it is well posed in the range ![]() $[I_1^{N},I_2^{N}]= [0.00397, 0.28016]$ (red shaded region). A necessary condition for well posedness is that the friction

$[I_1^{N},I_2^{N}]= [0.00397, 0.28016]$ (red shaded region). A necessary condition for well posedness is that the friction ![]() $\mu$ is zero at

$\mu$ is zero at ![]() $I=0$ (blue dot). Barker & Gray's (Reference Barker and Gray2017) curve therefore introduces a creep state for

$I=0$ (blue dot). Barker & Gray's (Reference Barker and Gray2017) curve therefore introduces a creep state for ![]() $I\in [0,I_1]$ to the left of the green dot (see inset) and becomes linear at large inertial numbers. The value of

$I\in [0,I_1]$ to the left of the green dot (see inset) and becomes linear at large inertial numbers. The value of ![]() $I_1=0.004$ is chosen to be very slightly larger than

$I_1=0.004$ is chosen to be very slightly larger than ![]() $I_1^{N}$. The resulting partially regularized law is well posed for

$I_1^{N}$. The resulting partially regularized law is well posed for ![]() $I\in [0, 16.9918]$.

$I\in [0, 16.9918]$.

The partially regularized ![]() $\mu (I)$-rheology not only ensures well posedness for

$\mu (I)$-rheology not only ensures well posedness for ![]() $I<I_{max}$, but it also provides better fitting to experimental and DEM results. For instance, relative to (2.7) the new

$I<I_{max}$, but it also provides better fitting to experimental and DEM results. For instance, relative to (2.7) the new ![]() $\mu (I)$-curve (2.8) predicts higher viscosities for large values of

$\mu (I)$-curve (2.8) predicts higher viscosities for large values of ![]() $I$, as seen in the chute flow experiments of Holyoake & McElwaine (Reference Holyoake and McElwaine2012) and Barker & Gray (Reference Barker and Gray2017). For low values of

$I$, as seen in the chute flow experiments of Holyoake & McElwaine (Reference Holyoake and McElwaine2012) and Barker & Gray (Reference Barker and Gray2017). For low values of ![]() $I$, the partially regularized

$I$, the partially regularized ![]() $\mu (I)$-rheology predicts very slow creeping flow, since

$\mu (I)$-rheology predicts very slow creeping flow, since ![]() $\mu \to 0$ as

$\mu \to 0$ as ![]() $I\to 0$. This behaviour is seen, to a certain extent, in DEM simulations (Kamrin & Koval Reference Kamrin and Koval2012; Singh et al. Reference Singh, Magnanimo, Saitoh and Luding2015) and has been postulated by Jerolmack & Daniels (Reference Jerolmack and Daniels2019) to play an important role in soil creep. The lack of a yield stress may, however, be viewed as a disadvantage of the theory. It is important to note that by allowing some bulk compressibility, it is possible to formulate granular rheologies that are always well posed mathematically (Barker et al. Reference Barker, Schaeffer, Shearer and Gray2017; Heyman et al. Reference Heyman, Delannay, Tabuteau and Valance2017; Goddard & Lee Reference Goddard and Lee2018; Schaeffer et al. Reference Schaeffer, Barker, Tsuji, Gremaud, Shearer and Gray2019) and support a yield stress.

$I\to 0$. This behaviour is seen, to a certain extent, in DEM simulations (Kamrin & Koval Reference Kamrin and Koval2012; Singh et al. Reference Singh, Magnanimo, Saitoh and Luding2015) and has been postulated by Jerolmack & Daniels (Reference Jerolmack and Daniels2019) to play an important role in soil creep. The lack of a yield stress may, however, be viewed as a disadvantage of the theory. It is important to note that by allowing some bulk compressibility, it is possible to formulate granular rheologies that are always well posed mathematically (Barker et al. Reference Barker, Schaeffer, Shearer and Gray2017; Heyman et al. Reference Heyman, Delannay, Tabuteau and Valance2017; Goddard & Lee Reference Goddard and Lee2018; Schaeffer et al. Reference Schaeffer, Barker, Tsuji, Gremaud, Shearer and Gray2019) and support a yield stress.

2.2. Generalized polydisperse segregation theory

The granular material is assumed to be composed of a finite number of grain-size classes, or species ![]() $\nu$, which have different sizes

$\nu$, which have different sizes ![]() $d^{\nu }$, but all have the same intrinsic density

$d^{\nu }$, but all have the same intrinsic density ![]() $\rho ^{\nu }_*=\rho _*$. Note that the inclusion of density differences between the particles implies that the bulk velocity field is compressible, which significantly complicates the theory (Tripathi & Khakhar Reference Tripathi and Khakhar2013; Gray & Ancey Reference Gray and Ancey2015; Gilberg & Steiner Reference Gilberg and Steiner2020) and is therefore neglected. Even for a bidisperse mixture of particles of the same density, the grains can pack slightly denser in a mixed state than in a segregated one (Golick & Daniels Reference Golick and Daniels2009). However, the DEM simulations (Tripathi & Khakhar Reference Tripathi and Khakhar2011; Thornton et al. Reference Thornton, Weinhart, Luding and Bokhove2012) suggest these packing effects are small, and for simplicity, and compatibility with the incompressible

$\rho ^{\nu }_*=\rho _*$. Note that the inclusion of density differences between the particles implies that the bulk velocity field is compressible, which significantly complicates the theory (Tripathi & Khakhar Reference Tripathi and Khakhar2013; Gray & Ancey Reference Gray and Ancey2015; Gilberg & Steiner Reference Gilberg and Steiner2020) and is therefore neglected. Even for a bidisperse mixture of particles of the same density, the grains can pack slightly denser in a mixed state than in a segregated one (Golick & Daniels Reference Golick and Daniels2009). However, the DEM simulations (Tripathi & Khakhar Reference Tripathi and Khakhar2011; Thornton et al. Reference Thornton, Weinhart, Luding and Bokhove2012) suggest these packing effects are small, and for simplicity, and compatibility with the incompressible ![]() $\mu (I)$-rheology, these solids volume fraction changes are neglected. Each grain-size class is therefore assumed to occupy a volume fraction

$\mu (I)$-rheology, these solids volume fraction changes are neglected. Each grain-size class is therefore assumed to occupy a volume fraction ![]() $\phi ^{\nu }\in [0,1]$ per unit granular volume, and the sum over all grain sizes therefore equals unity

$\phi ^{\nu }\in [0,1]$ per unit granular volume, and the sum over all grain sizes therefore equals unity

Many models to describe particle segregation have been proposed (see e.g. Bridgwater, Foo & Stephens Reference Bridgwater, Foo and Stephens1985; Savage & Lun Reference Savage and Lun1988; Dolgunin & Ukolov Reference Dolgunin and Ukolov1995; Khakhar, Orpe & Hajra Reference Khakhar, Orpe and Hajra2003; Gray & Thornton Reference Gray and Thornton2005; Gray & Chugunov Reference Gray and Chugunov2006; Fan & Hill Reference Fan and Hill2011; Gray & Ancey Reference Gray and Ancey2011; Schlick et al. Reference Schlick, Fan, Umbanhowar, Ottino and Lueptow2015) and these all have the general form of an advection–segregation–diffusion equation

where ![]() $\boldsymbol {F}^{\nu }$ is the segregation flux and

$\boldsymbol {F}^{\nu }$ is the segregation flux and ![]() $\boldsymbol {\mathcal {D}}^{\nu }$ is the diffusive flux. Provided that these fluxes are independent, this formulation is compatible with the bulk incompressibility provided

$\boldsymbol {\mathcal {D}}^{\nu }$ is the diffusive flux. Provided that these fluxes are independent, this formulation is compatible with the bulk incompressibility provided

The form of the segregation flux is motivated by early bidisperse models (Bridgwater et al. Reference Bridgwater, Foo and Stephens1985; Dolgunin & Ukolov Reference Dolgunin and Ukolov1995; Gray & Thornton Reference Gray and Thornton2005). These all had the property that the segregation shut off when the volume fraction of either species reached zero. This is satisfied if the segregation flux for species ![]() $\nu$ and

$\nu$ and ![]() $\lambda$ is proportional to

$\lambda$ is proportional to ![]() $\phi ^{\nu }\phi ^{\lambda }$. In polydisperse systems, Gray & Ancey (Reference Gray and Ancey2011) proposed that the segregation flux for species

$\phi ^{\nu }\phi ^{\lambda }$. In polydisperse systems, Gray & Ancey (Reference Gray and Ancey2011) proposed that the segregation flux for species ![]() $\nu$ was simply the sum of the bidisperse segregation fluxes with all the remaining constituents

$\nu$ was simply the sum of the bidisperse segregation fluxes with all the remaining constituents ![]() $\lambda$. This paper proposes a significant generalization of this concept, by allowing the local direction of segregation to be different for each bidisperse sub-mixture, so that the segregation flux takes the general polydisperse form

$\lambda$. This paper proposes a significant generalization of this concept, by allowing the local direction of segregation to be different for each bidisperse sub-mixture, so that the segregation flux takes the general polydisperse form

where ![]() $f_{\nu \lambda }$ is the segregation velocity magnitude and

$f_{\nu \lambda }$ is the segregation velocity magnitude and ![]() $\boldsymbol {e}_{\nu \lambda }$ is the unit vector in the direction of segregation, for species

$\boldsymbol {e}_{\nu \lambda }$ is the unit vector in the direction of segregation, for species ![]() $\nu$ relative to species

$\nu$ relative to species ![]() $\lambda$. This segregation flux function satisfies the summation constraint (2.12a,b) provided

$\lambda$. This segregation flux function satisfies the summation constraint (2.12a,b) provided

In contrast to the theory of Gray & Ancey (Reference Gray and Ancey2011) the segregation velocity magnitude is the same for species ![]() $\nu$ with species

$\nu$ with species ![]() $\lambda$ and species

$\lambda$ and species ![]() $\lambda$ with species

$\lambda$ with species ![]() $\nu$, and it is instead the direction of segregation that now points in the opposite sense. This approach has the property that individual sub-mixtures may segregate in different directions, which allows the theory to be applied to polydisperse problems where gravity-driven segregation (e.g. Gray Reference Gray2018) competes against segregation driven by gradients in kinetic stress (Fan & Hill Reference Fan and Hill2011). This would require the constituent vector momentum balance to be solved in order to determine the resultant magnitude and direction of segregation (Hill & Tan Reference Hill and Tan2014; Tunuguntla, Weinhart & Thornton Reference Tunuguntla, Weinhart and Thornton2017). In this paper the inter-particle segregation is always assumed to align with gravity. However, the direction of segregation for the particles and air can be chosen to be different. This proves to be advantageous in the numerical method that will be developed to solve the coupled system of equations in § 4.

$\nu$, and it is instead the direction of segregation that now points in the opposite sense. This approach has the property that individual sub-mixtures may segregate in different directions, which allows the theory to be applied to polydisperse problems where gravity-driven segregation (e.g. Gray Reference Gray2018) competes against segregation driven by gradients in kinetic stress (Fan & Hill Reference Fan and Hill2011). This would require the constituent vector momentum balance to be solved in order to determine the resultant magnitude and direction of segregation (Hill & Tan Reference Hill and Tan2014; Tunuguntla, Weinhart & Thornton Reference Tunuguntla, Weinhart and Thornton2017). In this paper the inter-particle segregation is always assumed to align with gravity. However, the direction of segregation for the particles and air can be chosen to be different. This proves to be advantageous in the numerical method that will be developed to solve the coupled system of equations in § 4.

It is also very useful in the numerical method to allow the rate of diffusion between the various sub-mixtures to be different. By direct analogy with the Maxwell–Stefan equations (Maxwell Reference Maxwell1867) for multi-component gas diffusion, the diffusive flux vector is therefore assumed to take the form

where ![]() $\mathcal {D}_{\nu \lambda }$ is the diffusion coefficient of species

$\mathcal {D}_{\nu \lambda }$ is the diffusion coefficient of species ![]() $\nu$ with species

$\nu$ with species ![]() $\lambda$. Equation (2.15) satisfies the summation constraint (2.12a,b), provided

$\lambda$. Equation (2.15) satisfies the summation constraint (2.12a,b), provided ![]() $\mathcal {D}_{\nu \lambda }=\mathcal {D}_{\lambda \nu }$, and reduces to the usual Fickian diffusion for the case of bidisperse mixtures (see e.g. Gray & Chugunov Reference Gray and Chugunov2006). For a mixture of

$\mathcal {D}_{\nu \lambda }=\mathcal {D}_{\lambda \nu }$, and reduces to the usual Fickian diffusion for the case of bidisperse mixtures (see e.g. Gray & Chugunov Reference Gray and Chugunov2006). For a mixture of ![]() $n$ distinct species, it is necessary to solve

$n$ distinct species, it is necessary to solve ![]() $n-1$ separate equations of the form (2.11) together with the summation constraint (2.10) for the

$n-1$ separate equations of the form (2.11) together with the summation constraint (2.10) for the ![]() $n$ concentrations

$n$ concentrations ![]() $\phi ^{\nu }$, assuming that the bulk velocity field

$\phi ^{\nu }$, assuming that the bulk velocity field ![]() $\boldsymbol {u}$ is given.

$\boldsymbol {u}$ is given.

In the absence of diffusion, concentration shocks form naturally in the system (see e.g. Gray & Thornton Reference Gray and Thornton2005; Thornton, Gray & Hogg Reference Thornton, Gray and Hogg2006; Gray & Ancey Reference Gray and Ancey2011). The jumps in concentration across such boundaries can be determined using jump conditions that are derived from the conservation law (2.11) (see e.g. Chadwick Reference Chadwick1976). These jump conditions are also useful when formulating boundary conditions with diffusion. The most general form of the jump condition for species ![]() $\nu$ is

$\nu$ is

\begin{align} [\kern-1pt[ \phi^{\nu}(\boldsymbol{u}\boldsymbol{\cdot} \boldsymbol{n}-v_n)]\kern-1pt]+ \left[\!\!\left[ \sum_{\forall\lambda\ne\nu} f_{\nu\lambda}\phi^{\nu}\phi^{\lambda}\boldsymbol{e}_{\nu\lambda}\boldsymbol{\cdot} \boldsymbol{n}\right]\!\!\right]= \left[\!\!\left[ \sum_{\forall\lambda\ne\nu} \mathcal{D}_{\nu\lambda}\left(\phi^{\lambda}\boldsymbol{\nabla}\phi^{\nu} - \phi^{\nu}\boldsymbol{\nabla}\phi^{\lambda}\right)\boldsymbol{\cdot} \boldsymbol{n}\right]\!\!\right], \end{align}

\begin{align} [\kern-1pt[ \phi^{\nu}(\boldsymbol{u}\boldsymbol{\cdot} \boldsymbol{n}-v_n)]\kern-1pt]+ \left[\!\!\left[ \sum_{\forall\lambda\ne\nu} f_{\nu\lambda}\phi^{\nu}\phi^{\lambda}\boldsymbol{e}_{\nu\lambda}\boldsymbol{\cdot} \boldsymbol{n}\right]\!\!\right]= \left[\!\!\left[ \sum_{\forall\lambda\ne\nu} \mathcal{D}_{\nu\lambda}\left(\phi^{\lambda}\boldsymbol{\nabla}\phi^{\nu} - \phi^{\nu}\boldsymbol{\nabla}\phi^{\lambda}\right)\boldsymbol{\cdot} \boldsymbol{n}\right]\!\!\right], \end{align}

where ![]() $\boldsymbol {n}$ is the normal to the shock,

$\boldsymbol {n}$ is the normal to the shock, ![]() $v_n$ is the normal speed of the shock and the jump bracket

$v_n$ is the normal speed of the shock and the jump bracket ![]() $[\kern-1pt[ \ ]\kern-1pt]$ is the difference of the enclosed quantity on the forward and rearward sides of the shock. In particular, if the flow is moving parallel to a solid stationary wall, then the jump condition reduces to the one-sided boundary condition

$[\kern-1pt[ \ ]\kern-1pt]$ is the difference of the enclosed quantity on the forward and rearward sides of the shock. In particular, if the flow is moving parallel to a solid stationary wall, then the jump condition reduces to the one-sided boundary condition

This implies that the segregation and diffusive fluxes balance and that there is no mass lost or gained through the wall.

2.3. Reduction to the bidisperse case

For the case of a mixture of large and small particles, which will be referred to by the constituent letters ![]() $\nu =s,l$ respectively, the summation constraint (2.10) becomes

$\nu =s,l$ respectively, the summation constraint (2.10) becomes

Assuming that the gravitational acceleration vector ![]() $\boldsymbol {g}$ points downwards and that the segregation aligns with this direction, the concentration equation (2.11) for small particles reduces to

$\boldsymbol {g}$ points downwards and that the segregation aligns with this direction, the concentration equation (2.11) for small particles reduces to

where ![]() $f_{sl}$ is the segregation velocity magnitude and

$f_{sl}$ is the segregation velocity magnitude and ![]() $\mathcal {D}_{sl}$ is the diffusivity of the small and large particles. The functional dependence of these quantities on the shear rate, pressure, gravity, particle size and the particle-size ratio, will be discussed in detail in § 3.3.

$\mathcal {D}_{sl}$ is the diffusivity of the small and large particles. The functional dependence of these quantities on the shear rate, pressure, gravity, particle size and the particle-size ratio, will be discussed in detail in § 3.3.

3. Coupling the bulk flow with the segregation

One of the key advances of this paper is to develop a coupled framework that solves for the bulk velocity field ![]() $\boldsymbol {u}$, the pressure

$\boldsymbol {u}$, the pressure ![]() $p$ and the particle concentrations

$p$ and the particle concentrations ![]() $\phi ^{\nu }$ at the same time. This framework allows us to explore some of the intimate couplings between the segregation and the bulk flow. A variety of couplings are envisaged, that may act singly or all at once, to generate very complex behaviour. The models fall into two classes: (i) one-way coupled and (ii) two-way coupled, and both forms of coupling are investigated in this paper.

$\phi ^{\nu }$ at the same time. This framework allows us to explore some of the intimate couplings between the segregation and the bulk flow. A variety of couplings are envisaged, that may act singly or all at once, to generate very complex behaviour. The models fall into two classes: (i) one-way coupled and (ii) two-way coupled, and both forms of coupling are investigated in this paper.

3.1. Advection by the bulk flow field

Many important practical segregation problems involve a time-dependent spatially evolving bulk flow that cannot easily be prescribed or determined from DEM simulations. Since the particle concentrations are advected by the bulk velocity ![]() $\boldsymbol {u}$, the most basic one-way coupling involves the solution of the mass (2.1) and momentum (2.2) balances to determine this velocity field. This enables the segregation equation (2.11) to be solved within a physically relevant flow field, provided the segregation velocity magnitudes and diffusivities are prescribed. Computations of this nature may give a good indication of where differently sized particles are transported, in a flow field that does not experience strong frictional feedback from the evolving species concentrations. This simplification implicitly assumes that an essentially monodisperse flow field provides a reasonable approximation for the dynamics of a much more complex polydisperse mixture of particles, and that there is no feedback of this local flow field on the segregation and diffusion rates. This simple coupling is investigated in § 5 for a time-dependent spatially evolving flow down an inclined plane. Importantly, this simple one-way coupling also enables the accuracy of the numerical method to be tested against known exact travelling wave and steady-state solutions for the bulk flow field and the particle concentrations. In general, the particle concentrations are always transported by the bulk flow field, so this mechanism is also active in models with more complex couplings, which will be investigated in §§ 6 and 7.

$\boldsymbol {u}$, the most basic one-way coupling involves the solution of the mass (2.1) and momentum (2.2) balances to determine this velocity field. This enables the segregation equation (2.11) to be solved within a physically relevant flow field, provided the segregation velocity magnitudes and diffusivities are prescribed. Computations of this nature may give a good indication of where differently sized particles are transported, in a flow field that does not experience strong frictional feedback from the evolving species concentrations. This simplification implicitly assumes that an essentially monodisperse flow field provides a reasonable approximation for the dynamics of a much more complex polydisperse mixture of particles, and that there is no feedback of this local flow field on the segregation and diffusion rates. This simple coupling is investigated in § 5 for a time-dependent spatially evolving flow down an inclined plane. Importantly, this simple one-way coupling also enables the accuracy of the numerical method to be tested against known exact travelling wave and steady-state solutions for the bulk flow field and the particle concentrations. In general, the particle concentrations are always transported by the bulk flow field, so this mechanism is also active in models with more complex couplings, which will be investigated in §§ 6 and 7.

3.2. Segregation induced frictional feedback on the bulk flow

Each distinct granular phase may have differing particle size, shapes or surface properties, that lead to different macroscopic friction and/or rheological parameters. In this next stage of coupling these rheological differences are built into the model, so that the evolving particle concentrations feedback on the bulk flow through the evolving macroscopic friction of the mixture. There are two basic ways to introduce this coupling.

A key finding of the ![]() $\mu (I)$-rheology (GDR MiDi 2004) was that the inertial number (2.5) is a function of the particle size

$\mu (I)$-rheology (GDR MiDi 2004) was that the inertial number (2.5) is a function of the particle size ![]() $d$. This is clearly defined in a monodisperse mixture, but an important generalization is needed for polydisperse systems. Based on DEM simulations of bidisperse two-dimensional assemblies of disks, Rognon et al. (Reference Rognon, Roux, Naaïm and Chevoir2007) proposed an inertial number in which the particle size

$d$. This is clearly defined in a monodisperse mixture, but an important generalization is needed for polydisperse systems. Based on DEM simulations of bidisperse two-dimensional assemblies of disks, Rognon et al. (Reference Rognon, Roux, Naaïm and Chevoir2007) proposed an inertial number in which the particle size ![]() $d$ was replaced by the local volume fraction weighted average particle size

$d$ was replaced by the local volume fraction weighted average particle size ![]() $\bar {d}$. The same law was also proposed by Tripathi & Khakhar (Reference Tripathi and Khakhar2011) and shown to agree with three-dimensional DEM simulations of spheres. Generalizing this concept to polydisperse systems, implies that the average particle size

$\bar {d}$. The same law was also proposed by Tripathi & Khakhar (Reference Tripathi and Khakhar2011) and shown to agree with three-dimensional DEM simulations of spheres. Generalizing this concept to polydisperse systems, implies that the average particle size

evolves as the local concentrations ![]() $\phi ^{\nu }$ of each particle species change. As a result, given the same local shear rate

$\phi ^{\nu }$ of each particle species change. As a result, given the same local shear rate ![]() $2\|\boldsymbol {D}\|$, pressure

$2\|\boldsymbol {D}\|$, pressure ![]() $p$ and intrinsic grain density

$p$ and intrinsic grain density ![]() $\rho _*$, the new inertial number

$\rho _*$, the new inertial number

\begin{equation} I = \frac{2\bar{d} \|\boldsymbol{D}\|}{\sqrt{p/\rho_*}} \end{equation}

\begin{equation} I = \frac{2\bar{d} \|\boldsymbol{D}\|}{\sqrt{p/\rho_*}} \end{equation}will be larger for a mixture composed of larger particles than one made of smaller grains.

As well as differences in size, the particles may also differ in shape and/or surface properties. A prime example of this are segregation induced fingering instabilities, which develop with large angular (resistive) particles and finer spherical particles (Pouliquen et al. Reference Pouliquen, Delour and Savage1997; Pouliquen & Vallance Reference Pouliquen and Vallance1999; Woodhouse et al. Reference Woodhouse, Thornton, Johnson, Kokelaar and Gray2012; Baker et al. Reference Baker, Johnson and Gray2016b). The effect of particle shape and surface properties can certainly be modelled in monodisperse flows by changing the assumed macroscopic frictional parameters (see e.g. Pouliquen & Forterre Reference Pouliquen and Forterre2002; Forterre Reference Forterre2006; Edwards et al. Reference Edwards, Russell, Johnson and Gray2019; Rocha et al. Reference Rocha, Johnson and Gray2019). Furthermore, the results of Baker et al.'s (Reference Baker, Johnson and Gray2016b) granular fingering model suggest that a good approach is to assume that each phase satisfies a monodisperse friction law ![]() $\mu ^{\nu }=\mu ^{\nu }(I)$ of the form (2.8) and then compute the effective friction by the weighted sum of these laws, i.e.

$\mu ^{\nu }=\mu ^{\nu }(I)$ of the form (2.8) and then compute the effective friction by the weighted sum of these laws, i.e.

On the other hand, it is also possible to assume that there is a single ![]() $\mu (I)$-curve, given by (2.8), but that the parameters in it evolve as the mixture composition changes, i.e.

$\mu (I)$-curve, given by (2.8), but that the parameters in it evolve as the mixture composition changes, i.e.

where ![]() $\mu _{s}^{\nu }$,

$\mu _{s}^{\nu }$, ![]() $\mu _{d}^{\nu }$,

$\mu _{d}^{\nu }$, ![]() $\mu _{\infty }^{\nu }$ and

$\mu _{\infty }^{\nu }$ and ![]() $I_0^{\nu }$ are the frictional parameters for a pure phase of constituent

$I_0^{\nu }$ are the frictional parameters for a pure phase of constituent ![]() $\nu$. There is clearly potential for a great deal of complexity here that needs to be explored. However, to the best of our knowledge there are no DEM studies that measure the effective frictional properties of mixtures of particles of different sizes, shapes and surface properties that could further guide the model formulation. Segregation mobility feedback on the bulk flow will be investigated further in § 6.

$\nu$. There is clearly potential for a great deal of complexity here that needs to be explored. However, to the best of our knowledge there are no DEM studies that measure the effective frictional properties of mixtures of particles of different sizes, shapes and surface properties that could further guide the model formulation. Segregation mobility feedback on the bulk flow will be investigated further in § 6.

3.3. Feedback of the bulk flow on the segregation rate and diffusivity

The shear rate ![]() $\dot \gamma =2\|\boldsymbol {D}\|$, the pressure

$\dot \gamma =2\|\boldsymbol {D}\|$, the pressure ![]() $p$, gravity

$p$, gravity ![]() $g$ and the particle properties also enter the equations more subtly through the functional dependence of the segregation velocity magnitude

$g$ and the particle properties also enter the equations more subtly through the functional dependence of the segregation velocity magnitude ![]() $f_{\nu \lambda }$ and diffusivity

$f_{\nu \lambda }$ and diffusivity ![]() $\mathcal {D}_{\nu \lambda }$ in the fluxes (2.13) and (2.15). Even in bidisperse granular mixtures very little is known about their precise functional dependencies. However, dimensional analysis is very helpful in constraining the allowable forms.

$\mathcal {D}_{\nu \lambda }$ in the fluxes (2.13) and (2.15). Even in bidisperse granular mixtures very little is known about their precise functional dependencies. However, dimensional analysis is very helpful in constraining the allowable forms.

Consider a bidisperse mixture of large and small grains of sizes ![]() $d^{l}$ and

$d^{l}$ and ![]() $d^{s}$, respectively, which have the same intrinsic density

$d^{s}$, respectively, which have the same intrinsic density ![]() $\rho _*$. The small particles occupy a volume fraction

$\rho _*$. The small particles occupy a volume fraction ![]() $\phi ^{s}=1-\phi ^{l}$ per unit granular volume and the total solids volume fraction is

$\phi ^{s}=1-\phi ^{l}$ per unit granular volume and the total solids volume fraction is ![]() $\varPhi$. The system is subject to a bulk shear stress

$\varPhi$. The system is subject to a bulk shear stress ![]() $\tau$, a pressure

$\tau$, a pressure ![]() $p$ and gravity

$p$ and gravity ![]() $g$, which results in a shear rate

$g$, which results in a shear rate ![]() $\dot {\gamma }$. Even though these variables are spatially varying, they are considered here as inputs to the system, whereas the segregation velocity magnitude

$\dot {\gamma }$. Even though these variables are spatially varying, they are considered here as inputs to the system, whereas the segregation velocity magnitude ![]() $f_{sl}$ and the diffusivity

$f_{sl}$ and the diffusivity ![]() $\mathcal {D}_{sl}$ are outputs. Since there are nine variables, with three primary dimensions (mass, length and time), dimensional analysis implies that there are six independent non-dimensional quantities

$\mathcal {D}_{sl}$ are outputs. Since there are nine variables, with three primary dimensions (mass, length and time), dimensional analysis implies that there are six independent non-dimensional quantities

\begin{equation} \mu=\frac{\tau}{p},\quad I=\frac{\dot\gamma \bar{d}}{\sqrt{p/\rho_*}},\quad \varPhi, \quad P = \frac{p}{\rho_* g \bar{d}},\quad R=\frac{d^{l}}{d^{s}},\quad \phi^{s}, \end{equation}

\begin{equation} \mu=\frac{\tau}{p},\quad I=\frac{\dot\gamma \bar{d}}{\sqrt{p/\rho_*}},\quad \varPhi, \quad P = \frac{p}{\rho_* g \bar{d}},\quad R=\frac{d^{l}}{d^{s}},\quad \phi^{s}, \end{equation}

where ![]() $\bar {d}$ is the volume fraction weighted average grain size defined in (3.1),

$\bar {d}$ is the volume fraction weighted average grain size defined in (3.1), ![]() $P$ is the non-dimensional pressure and

$P$ is the non-dimensional pressure and ![]() $R$ is the grain-size ratio. For a monodisperse system in the absence of gravity, only the first three quantities are relevant and GDR MiDi (2004) made a strong case for the friction

$R$ is the grain-size ratio. For a monodisperse system in the absence of gravity, only the first three quantities are relevant and GDR MiDi (2004) made a strong case for the friction ![]() $\mu$ being purely a function of the inertial number

$\mu$ being purely a function of the inertial number ![]() $I$. This led to the development of the incompressible

$I$. This led to the development of the incompressible ![]() $\mu (I)$-rheology (GDR MiDi 2004; Jop et al. Reference Jop, Forterre and Pouliquen2006; Barker & Gray Reference Barker and Gray2017), which is used in this paper.

$\mu (I)$-rheology (GDR MiDi 2004; Jop et al. Reference Jop, Forterre and Pouliquen2006; Barker & Gray Reference Barker and Gray2017), which is used in this paper.

Using the monodisperse scalings, it follows that in the absence of gravity the self-diffusion of grains should scale as

where ![]() $\mathcal {F}$ is an arbitrary function of the friction, the inertial number and the solids volume fraction, and with no dependence on

$\mathcal {F}$ is an arbitrary function of the friction, the inertial number and the solids volume fraction, and with no dependence on ![]() $P$,

$P$, ![]() $R$ and

$R$ and ![]() $\phi ^{s}$. In both the incompressible and compressible

$\phi ^{s}$. In both the incompressible and compressible ![]() $\mu (I)$-rheologies (GDR MiDi 2004; da Cruz et al. Reference da Cruz, Emam, Prochnow, Roux and Chevoir2005; Jop et al. Reference Jop, Forterre and Pouliquen2006; Forterre & Pouliquen Reference Forterre and Pouliquen2008) the friction

$\mu (I)$-rheologies (GDR MiDi 2004; da Cruz et al. Reference da Cruz, Emam, Prochnow, Roux and Chevoir2005; Jop et al. Reference Jop, Forterre and Pouliquen2006; Forterre & Pouliquen Reference Forterre and Pouliquen2008) the friction ![]() $\mu$ and the solids volume fraction

$\mu$ and the solids volume fraction ![]() $\varPhi$ are rigidly bound to the inertial number

$\varPhi$ are rigidly bound to the inertial number ![]() $I$, so it is not necessary to retain their dependence in (3.6). However, in the latest well-posed compressible theories (e.g. Barker & Gray Reference Barker and Gray2017; Heyman et al. Reference Heyman, Delannay, Tabuteau and Valance2017; Schaeffer et al. Reference Schaeffer, Barker, Tsuji, Gremaud, Shearer and Gray2019) the

$I$, so it is not necessary to retain their dependence in (3.6). However, in the latest well-posed compressible theories (e.g. Barker & Gray Reference Barker and Gray2017; Heyman et al. Reference Heyman, Delannay, Tabuteau and Valance2017; Schaeffer et al. Reference Schaeffer, Barker, Tsuji, Gremaud, Shearer and Gray2019) the ![]() $\mu =\mu (I)$ and

$\mu =\mu (I)$ and ![]() $\varPhi =\varPhi (I)$ laws only hold at steady state, and so the general form of the diffusivity (3.6) applies.

$\varPhi =\varPhi (I)$ laws only hold at steady state, and so the general form of the diffusivity (3.6) applies.

Utter & Behringer (Reference Utter and Behringer2004) showed experimentally that the self-diffusion coefficient scaled with the shear rate and the particle size squared. This suggests that the simplest model for the diffusion of the grains in a polydisperse system is

where ![]() $\mathcal {A}=0.108$ is a universal constant (Utter & Behringer Reference Utter and Behringer2004) and

$\mathcal {A}=0.108$ is a universal constant (Utter & Behringer Reference Utter and Behringer2004) and ![]() $\bar {d}$ is now interpreted as the average, locally evolving, particle size defined in (3.1). Some evidence for this is provided by the experiments of Trewhela et al. (Reference Trewhela, Ancey and Gray2021) which show that a single small intruder in a matrix of large grains performs larger random walks than a single large intruder in a matrix of fine grains. In general, however, the diffusivity could be multiplied by an arbitrary function of the other non-dimensional quantities in (3.5a–f).

$\bar {d}$ is now interpreted as the average, locally evolving, particle size defined in (3.1). Some evidence for this is provided by the experiments of Trewhela et al. (Reference Trewhela, Ancey and Gray2021) which show that a single small intruder in a matrix of large grains performs larger random walks than a single large intruder in a matrix of fine grains. In general, however, the diffusivity could be multiplied by an arbitrary function of the other non-dimensional quantities in (3.5a–f).

Gravity-driven percolation (kinetic sieving) and squeeze expulsion (Middleton Reference Middleton1970; Bridgwater et al. Reference Bridgwater, Foo and Stephens1985; Savage & Lun Reference Savage and Lun1988; Gray & Thornton Reference Gray and Thornton2005; Gray Reference Gray2018) combine to create the dominant mechanism for segregation in dense sheared granular flows. Assuming that the segregation is independent of the diffusion, dimensional analysis suggests that the segregation velocity magnitude in a bidisperse mixture of large and small particles should scale as

where ![]() $\mathcal {G}$ is an arbitrary function. It has long been known that the segregation velocity magnitude

$\mathcal {G}$ is an arbitrary function. It has long been known that the segregation velocity magnitude ![]() $f_{sl}$ is strongly dependent on the strain rate and the particle-size ratio (see e.g. Bridgwater et al. Reference Bridgwater, Foo and Stephens1985; Savage & Lun Reference Savage and Lun1988). Gray & Thornton (Reference Gray and Thornton2005) also suggested that there should be a dependence on gravity. Evidence for this is provided by the fact that granular segregation experiments, with a density matched interstitial fluid, do not segregate (Vallance & Savage Reference Vallance and Savage2000; Thornton et al. Reference Thornton, Gray and Hogg2006), i.e. when gravity is effectively reduced, so is the rate of segregation. Inclusion of the gravitational acceleration suggests that the segregation velocity magnitude should also be pressure dependent, since

$f_{sl}$ is strongly dependent on the strain rate and the particle-size ratio (see e.g. Bridgwater et al. Reference Bridgwater, Foo and Stephens1985; Savage & Lun Reference Savage and Lun1988). Gray & Thornton (Reference Gray and Thornton2005) also suggested that there should be a dependence on gravity. Evidence for this is provided by the fact that granular segregation experiments, with a density matched interstitial fluid, do not segregate (Vallance & Savage Reference Vallance and Savage2000; Thornton et al. Reference Thornton, Gray and Hogg2006), i.e. when gravity is effectively reduced, so is the rate of segregation. Inclusion of the gravitational acceleration suggests that the segregation velocity magnitude should also be pressure dependent, since ![]() $g$ only appears in the non-dimensional pressure

$g$ only appears in the non-dimensional pressure ![]() $P$. This is supported by the experiments of Golick & Daniels (Reference Golick and Daniels2009), who observed a dramatic slowing in the segregation rate when they applied a normal force on their ring shear cell. This pressure-dependent suppression of segregation has been investigated further in the DEM simulations of Fry et al. (Reference Fry, Umbanhowar, Ottino and Lueptow2018), who suggested that the segregation velocity magnitude should scale with the reciprocal of the square root of the pressure. When this is combined with the shear-rate dependence this implies that

$P$. This is supported by the experiments of Golick & Daniels (Reference Golick and Daniels2009), who observed a dramatic slowing in the segregation rate when they applied a normal force on their ring shear cell. This pressure-dependent suppression of segregation has been investigated further in the DEM simulations of Fry et al. (Reference Fry, Umbanhowar, Ottino and Lueptow2018), who suggested that the segregation velocity magnitude should scale with the reciprocal of the square root of the pressure. When this is combined with the shear-rate dependence this implies that ![]() $f_{sl}$ is linear in the inertial number.

$f_{sl}$ is linear in the inertial number.

In this paper, the segregation velocity magnitude is based on the refractive index matched shear box experiments of Trewhela et al. (Reference Trewhela, Ancey and Gray2021). They measured the trajectories of (i) a single large and (ii) a single small intruder for a wide range of shear-rates ![]() $\dot \gamma \in [0.26,2.3]$ and size ratios

$\dot \gamma \in [0.26,2.3]$ and size ratios ![]() $R\in [1.17,4.17]$. Trewhela et al. (Reference Trewhela, Ancey and Gray2021) made four key observations (a–d below) that allowed them to collapse all their data. (a) Both the large and small intruder data showed a linear dependence of

$R\in [1.17,4.17]$. Trewhela et al. (Reference Trewhela, Ancey and Gray2021) made four key observations (a–d below) that allowed them to collapse all their data. (a) Both the large and small intruder data showed a linear dependence of ![]() $f_{sl}$ on the shear rate

$f_{sl}$ on the shear rate ![]() $\dot \gamma$. (b) Large intruders have a linear dependence on the size ratio that shuts off when

$\dot \gamma$. (b) Large intruders have a linear dependence on the size ratio that shuts off when ![]() $R$ equals unity, i.e. linear in

$R$ equals unity, i.e. linear in ![]() $(R-1)$, while (c) small intruders have the same linear dependence at small size ratios, but develop a quadratic dependence on

$(R-1)$, while (c) small intruders have the same linear dependence at small size ratios, but develop a quadratic dependence on ![]() $(R-1)$ at larger size ratios. Finally, (d) both large and small intruders do not move linearly through the depth of the cell, but describe approximately quadratic curves as they rise up, or percolate down, through it. Since the pressure is linear with depth, this suggests a

$(R-1)$ at larger size ratios. Finally, (d) both large and small intruders do not move linearly through the depth of the cell, but describe approximately quadratic curves as they rise up, or percolate down, through it. Since the pressure is linear with depth, this suggests a ![]() $1/(\mathcal {C}+P)$ dependence, where the non-dimensional constant

$1/(\mathcal {C}+P)$ dependence, where the non-dimensional constant ![]() $\mathcal {C}$ is introduced to prevent a singularity when the pressure is equal to zero. Trewhela et al. (Reference Trewhela, Ancey and Gray2021) therefore suggested that the segregation velocity magnitude has the form

$\mathcal {C}$ is introduced to prevent a singularity when the pressure is equal to zero. Trewhela et al. (Reference Trewhela, Ancey and Gray2021) therefore suggested that the segregation velocity magnitude has the form

where ![]() $\mathcal {B}$,

$\mathcal {B}$, ![]() $\mathcal {C}$ and

$\mathcal {C}$ and ![]() $\mathcal {E}$ are universal constants. This expression encapsulates the key processes of gravity, shear and pressure, which drive the dominant mechanism for gravity-driven segregation of particles of different sizes and size ratios in shear flows. Moreover, as a consequence of the

$\mathcal {E}$ are universal constants. This expression encapsulates the key processes of gravity, shear and pressure, which drive the dominant mechanism for gravity-driven segregation of particles of different sizes and size ratios in shear flows. Moreover, as a consequence of the ![]() $\bar {d}^{2}$ dependence, (3.9) automatically gives rise to asymmetric flux functions (Gajjar & Gray Reference Gajjar and Gray2014; van der Vaart et al. Reference van der Vaart, Gajjar, Épely-Chauvin, Andreini, Gray and Ancey2015), whose asymmetry is size-ratio dependent (Trewhela et al. Reference Trewhela, Ancey and Gray2021). The function (3.9) not only collapses all the single intruder experiments of Trewhela et al. (Reference Trewhela, Ancey and Gray2021), but it also quantitatively matches the time and spatial evolution of van der Vaart et al.'s (Reference van der Vaart, Gajjar, Épely-Chauvin, Andreini, Gray and Ancey2015) shear box experiments, with a

$\bar {d}^{2}$ dependence, (3.9) automatically gives rise to asymmetric flux functions (Gajjar & Gray Reference Gajjar and Gray2014; van der Vaart et al. Reference van der Vaart, Gajjar, Épely-Chauvin, Andreini, Gray and Ancey2015), whose asymmetry is size-ratio dependent (Trewhela et al. Reference Trewhela, Ancey and Gray2021). The function (3.9) not only collapses all the single intruder experiments of Trewhela et al. (Reference Trewhela, Ancey and Gray2021), but it also quantitatively matches the time and spatial evolution of van der Vaart et al.'s (Reference van der Vaart, Gajjar, Épely-Chauvin, Andreini, Gray and Ancey2015) shear box experiments, with a ![]() $50:50$ mix of 4 mm and 8 mm glass beads, using the same values of

$50:50$ mix of 4 mm and 8 mm glass beads, using the same values of ![]() $\mathcal {B}$,

$\mathcal {B}$, ![]() $\mathcal {C}$ and

$\mathcal {C}$ and ![]() $\mathcal {E}$ and the generalized diffusion law (3.7). The values of all the non-dimensional parameters are given in table 2. Note that, since the segregation velocity magnitude (3.9) is pressure dependent, but the generalized diffusivity (3.7) is not, Trewhela et al.'s (Reference Trewhela, Ancey and Gray2021) theory also exhibits the segregation suppression with increased pressure, observed by Golick & Daniels (Reference Golick and Daniels2009) and Fry et al. (Reference Fry, Umbanhowar, Ottino and Lueptow2018). The formula (3.9) cannot be pushed too far, because, for size ratios greater than five, spontaneous percolation is known to occur for low small particle concentrations (Cooke, Bridgwater & Scott Reference Cooke, Bridgwater and Scott1978), while isolated large intruders may exhibit intermediate or reverse segregation (Thomas Reference Thomas2000; Thomas & D'Ortona Reference Thomas and D'Ortona2018).

$\mathcal {E}$ and the generalized diffusion law (3.7). The values of all the non-dimensional parameters are given in table 2. Note that, since the segregation velocity magnitude (3.9) is pressure dependent, but the generalized diffusivity (3.7) is not, Trewhela et al.'s (Reference Trewhela, Ancey and Gray2021) theory also exhibits the segregation suppression with increased pressure, observed by Golick & Daniels (Reference Golick and Daniels2009) and Fry et al. (Reference Fry, Umbanhowar, Ottino and Lueptow2018). The formula (3.9) cannot be pushed too far, because, for size ratios greater than five, spontaneous percolation is known to occur for low small particle concentrations (Cooke, Bridgwater & Scott Reference Cooke, Bridgwater and Scott1978), while isolated large intruders may exhibit intermediate or reverse segregation (Thomas Reference Thomas2000; Thomas & D'Ortona Reference Thomas and D'Ortona2018).

Table 2. Non-dimensional constants ![]() $\mathcal {A}$,

$\mathcal {A}$, ![]() $\mathcal {B}$,

$\mathcal {B}$, ![]() $\mathcal {C}$ and

$\mathcal {C}$ and ![]() $\mathcal {E}$ in the diffusion (3.7) and segregation laws (3.9) of Trewhela et al. (Reference Trewhela, Ancey and Gray2021).

$\mathcal {E}$ in the diffusion (3.7) and segregation laws (3.9) of Trewhela et al. (Reference Trewhela, Ancey and Gray2021).

4. Numerical method

In order to solve the coupled system of equations the mass and momentum equations (2.1) and (2.2) are written in conservative form

where ![]() $\varrho$ is now the mixture density and

$\varrho$ is now the mixture density and ![]() $\otimes$ is the dyadic product. This paper focusses on solving fully coupled bidisperse segregation problems with an evolving free surface using a multiphase approach based on the segregation theory of § 2.2.

$\otimes$ is the dyadic product. This paper focusses on solving fully coupled bidisperse segregation problems with an evolving free surface using a multiphase approach based on the segregation theory of § 2.2.

The method assumes that there are three coexisting phases; large particles, small particles and excess air, which occupy volume fractions ![]() $\varphi ^{l}$,

$\varphi ^{l}$, ![]() $\varphi ^{s}$ and

$\varphi ^{s}$ and ![]() $\varphi ^{a}$ per unit mixture volume, respectively. In this representation the granular phases are implicitly assumed to retain some air between the grains, so that the overall solids volume fraction in a purely granular state is still

$\varphi ^{a}$ per unit mixture volume, respectively. In this representation the granular phases are implicitly assumed to retain some air between the grains, so that the overall solids volume fraction in a purely granular state is still ![]() $\varPhi$ as before. Assuming that there is no diffusion of the excess air phase with respect to the particles (i.e.

$\varPhi$ as before. Assuming that there is no diffusion of the excess air phase with respect to the particles (i.e. ![]() $\mathcal {D}_{al}=\mathcal {D}_{as}=0$) the three conservation laws (2.11) for large particles, small particles and excess air are

$\mathcal {D}_{al}=\mathcal {D}_{as}=0$) the three conservation laws (2.11) for large particles, small particles and excess air are

respectively, where the concentration of grains is defined as

When ![]() $\varphi ^{a}=0$, both the large and small particle segregation equations, (4.3) and (4.4), reduce to the bidisperse segregation equation (2.19), and (4.5) is trivially satisfied. As will be demonstrated in § 5, this approach provides a simple and effective way of segregating the large and small particles from one another, while simultaneously expelling unwanted air bubbles and sharpening the free-surface interface.

$\varphi ^{a}=0$, both the large and small particle segregation equations, (4.3) and (4.4), reduce to the bidisperse segregation equation (2.19), and (4.5) is trivially satisfied. As will be demonstrated in § 5, this approach provides a simple and effective way of segregating the large and small particles from one another, while simultaneously expelling unwanted air bubbles and sharpening the free-surface interface.

The excess air is assumed to segregate from the grains with constant segregation velocity magnitude ![]() $f_{ag}$ along the direction

$f_{ag}$ along the direction ![]() $\boldsymbol {e}$. The excess air segregation velocity magnitude has no physical significance and the approach should be thought of as a convenient numerical interface sharpening method. The rate is chosen to expel the excess air quickly enough to prevent bubble trapping. For the inclined plane simulations in §§ 5 and 6, the direction

$\boldsymbol {e}$. The excess air segregation velocity magnitude has no physical significance and the approach should be thought of as a convenient numerical interface sharpening method. The rate is chosen to expel the excess air quickly enough to prevent bubble trapping. For the inclined plane simulations in §§ 5 and 6, the direction ![]() $\boldsymbol {e}$ is chosen to be the upwards pointing normal to the plane in order to avoid air being segregated through the advancing front. This is not a concern in the rotating drum simulations in § 7 and the direction

$\boldsymbol {e}$ is chosen to be the upwards pointing normal to the plane in order to avoid air being segregated through the advancing front. This is not a concern in the rotating drum simulations in § 7 and the direction ![]() $\boldsymbol {e}$ is therefore chosen to point in the opposite direction to gravity

$\boldsymbol {e}$ is therefore chosen to point in the opposite direction to gravity ![]() $\boldsymbol {g}$.

$\boldsymbol {g}$.

The system of (4.1)–(4.5) is solved numerically with OpenFOAM assuming that the density and viscosity are given by the local volume fraction weighted averaged values

The intrinsic density of the air ![]() $\varrho ^{a}_*$ is equal to a constant and the intrinsic densities of the large and small particles are both constant and equal to one another, i.e.

$\varrho ^{a}_*$ is equal to a constant and the intrinsic densities of the large and small particles are both constant and equal to one another, i.e. ![]() $\varrho ^{l}_*=\varrho ^{s}_*=\varPhi \rho _*\gg \varrho _*^{a}$, where the solids volume fraction

$\varrho ^{l}_*=\varrho ^{s}_*=\varPhi \rho _*\gg \varrho _*^{a}$, where the solids volume fraction ![]() $\varPhi$ accounts for the interstitial air that is always present in the granular matrix. The intrinsic viscosity of the air

$\varPhi$ accounts for the interstitial air that is always present in the granular matrix. The intrinsic viscosity of the air ![]() $\eta _*^{a}$ is also assumed to be constant, while the intrinsic viscosity of the grains is calculated from the viscosity (2.3) of the

$\eta _*^{a}$ is also assumed to be constant, while the intrinsic viscosity of the grains is calculated from the viscosity (2.3) of the ![]() $\mu (I)$-rheology, with the friction

$\mu (I)$-rheology, with the friction ![]() $\mu$ and inertial number

$\mu$ and inertial number ![]() $I$ calculated using the couplings discussed in § 3.2. The parameters used in the simulations in §§ 5 and 6 are summarized in tables 1 and 3.

$I$ calculated using the couplings discussed in § 3.2. The parameters used in the simulations in §§ 5 and 6 are summarized in tables 1 and 3.