1. Introduction

Flow over the finite wall-mounted cylinder (FWMC) exhibits complex flow structures and vortex–vortex interactions due to geometric modifications at the free end and the cylinder–wall junction (Finnigan Reference Finnigan2000; Krajnovic Reference Krajnovic2011; Nepf Reference Nepf2012). This phenomenon is widely observed in engineering applications, such as high-rise buildings and aquatic vegetation. Understanding the emergence, development and interaction of vortical structures with different rotations is crucial for advancing the fundamental theory of FWMC flow (Wang & Zhou Reference Wang and Zhou2009; Zhu et al. Reference Zhu, Wang, Wang and Wang2017; Yauwenas et al. Reference Yauwenas, Porteous, Moreau and Doolan2019; Cao et al. Reference Cao, Tamura, Zhou, Bao and Han2022). Over the past few decades, significant progress has been made in uncovering the underlying physics of FWMC flow (Adaramola et al. Reference Adaramola, Akinlade, Sumner, Bergstrom and Schenstead2006; Wang & Zhou Reference Wang and Zhou2009; Luhar & Nepf Reference Luhar and Nepf2011; Li & Fuhrman Reference Li and Fuhrman2022; Hu & Li Reference Hu and Li2023; Hu, Huang & Li Reference Hu, Huang and Li2023). A comprehensive review of these findings is essential to establish a foundational understanding before addressing more multifaceted configurations, such as fluid–structure interaction (FSI) of wall-mounted flexible structures with varying flexibility (or stiffness).

1.1. Flow over the finite wall-mounted rigid structure

Based on cross-sectional shape, structures can be classified into three categories (Derakhshandeh & Alam Reference Derakhshandeh and Alam2019). The first structure consists of a continuous and finite curvature shape, such as a circular or elliptical cylinder (e.g. most of the stems), while the second one is sharp edged with an infinitely large curvature, for example, a square or triangular cylinder (e.g. plates or walls). The third one is a hybrid of the two, and a typical case is a semi-circular cylinder (e.g. breakwater structures). Studies of FWMC have primarily focused on the first two categories, as they are more prevalent in natural and engineered environments. We start with these two types of wall-mounted structures, providing a detailed discussion of the flow structures of a rigid FWMC. Differences arising from cross-sectional shape are highlighted when relevant.

Flow structures around a circular FWMC are strongly influenced by the aspect ratio (AR

![]() $=l/D$

, where

$=l/D$

, where

![]() $l$

is the height of the structure and

$l$

is the height of the structure and

![]() $D$

is the diameter or side length), Reynolds number (

$D$

is the diameter or side length), Reynolds number (

![]() $Re = U_\infty D/\nu$

, where

$Re = U_\infty D/\nu$

, where

![]() $U_\infty$

is incoming flow velocity and

$U_\infty$

is incoming flow velocity and

![]() $\nu$

is the fluid kinematic viscosity), boundary layer thickness (

$\nu$

is the fluid kinematic viscosity), boundary layer thickness (

![]() $\delta /D$

), and turbulent intensity (

$\delta /D$

), and turbulent intensity (

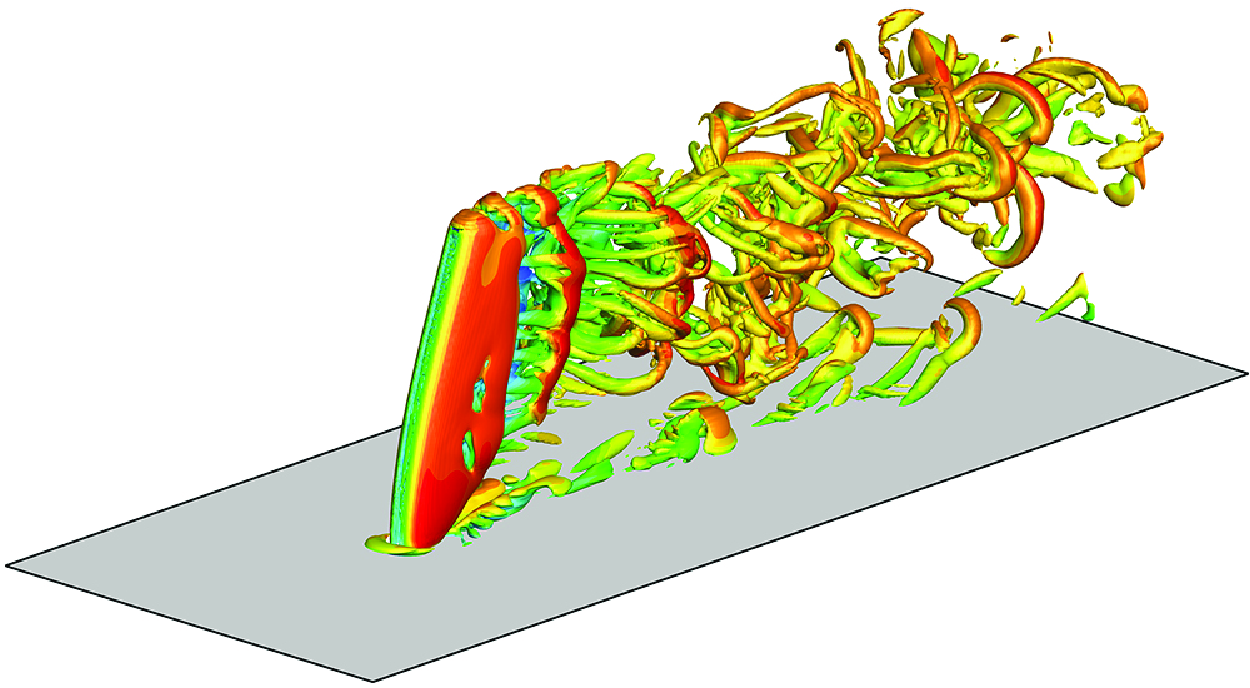

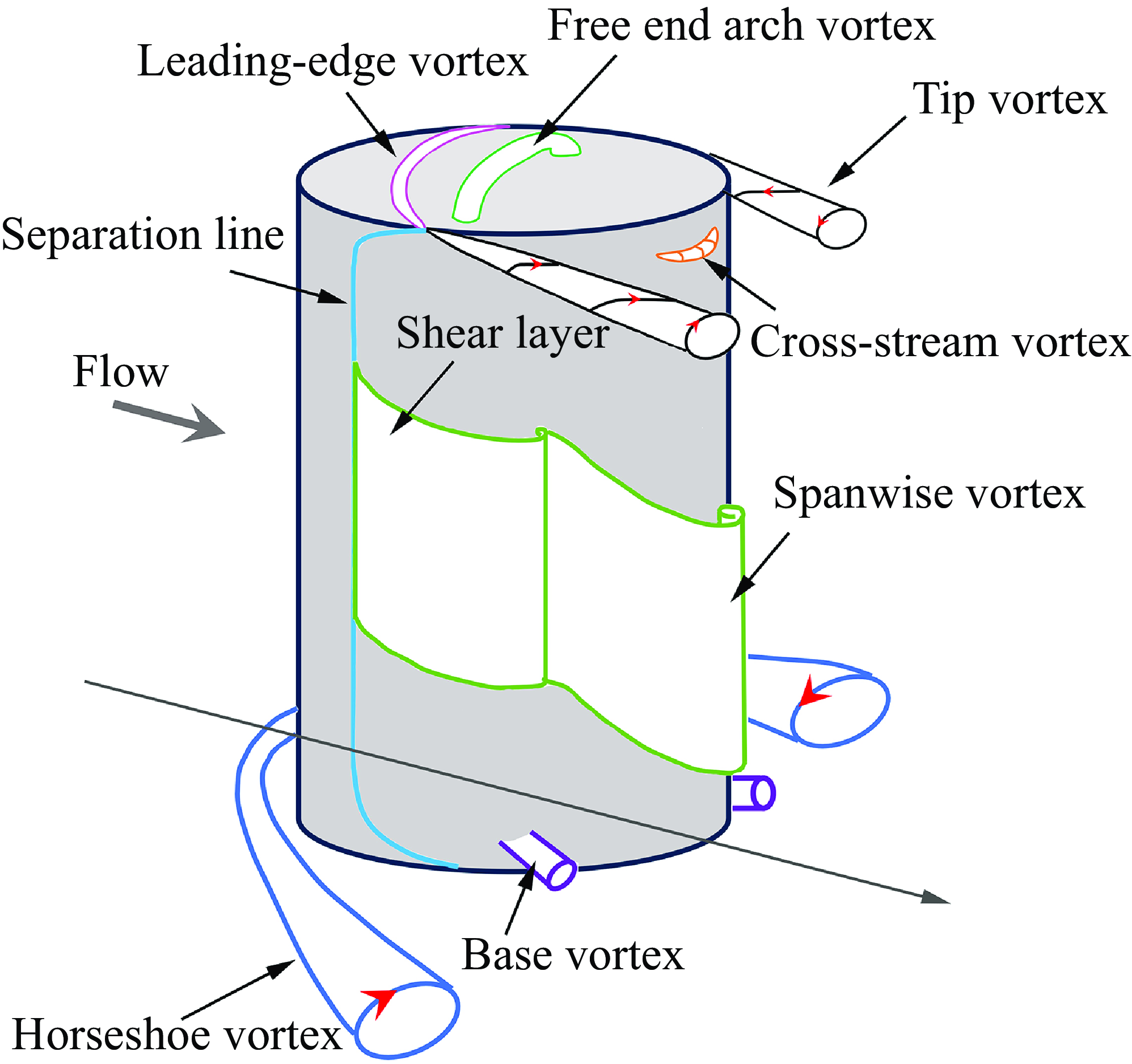

![]() $T_i = u^{\prime }/U_\infty$

, where

$T_i = u^{\prime }/U_\infty$

, where

![]() $u^{\prime }$

is the root-mean-square (r.m.s.) of the turbulent velocity fluctuation), among other factors (Sakamoto & Arie Reference Sakamoto and Arie1983; Bourgeois, Sattari & Martinuzzi Reference Bourgeois, Sattari and Martinuzzi2011; Porteous, Moreau & Doolan Reference Porteous, Moreau and Doolan2014; Hearst, Gomit & Ganapathisubramani Reference Hearst, Gomit and Ganapathisubramani2016). Based on the time-averaged distribution of vortical structures, the wake of an FWMC can be divided into three types (Zhang et al. Reference Zhang, Cheng, An and Zhao2017), i.e. dipole type (i.e. one pair of the streamwise vortices at the upper part), quadrupole type (i.e. two pairs of the streamwise vortices at the upper and lower parts) and six-vortex type (i.e. transitional structures involved). Particular vortical structures of the FWMC with a height over the critical value are presented in figure 1. The transition from dipole to quadrupole is marked by a critical aspect ratio (Sumner, Heseltine & Dansereau Reference Sumner, Heseltine and Dansereau2004; Wang & Zhou Reference Wang and Zhou2009; Hosseini, Bourgeois & Martinuzzi Reference Hosseini, Bourgeois and Martinuzzi2013; Sumner Reference Sumner2013). When the height exceeds this critical value, a tip vortex pair and a base vortex pair appear at the free end and junction, respectively (Bourgeois et al. Reference Bourgeois, Sattari and Martinuzzi2011; Hajimirzaie, Wojcik & Buchholz Reference Hajimirzaie, Wojcik and Buchholz2012; Porteous et al. Reference Porteous, Moreau and Doolan2014). The appearance of these vortex pairs is highly dependent on the AR. A sufficiently thick boundary layer and AR above the critical value promote the formation of the tip vortex pair at the free end (Sumner et al. Reference Sumner, Heseltine and Dansereau2004; Adaramola et al. Reference Adaramola, Akinlade, Sumner, Bergstrom and Schenstead2006; Sumner & Heseltine Reference Sumner and Heseltine2008; Bourgeois et al. Reference Bourgeois, Sattari and Martinuzzi2011, Reference Bourgeois, Sattari and Martinuzzi2012; Sumner Reference Sumner2013). The origin of the tip vortex differs depending on the cross-sectional shape. In a square FWMC, streamwise vorticity near the free end arises from the reorientation of vertical vorticity in the sidewall shear layers due to lateral vorticity of the free-end shear layer (Bourgeois et al. Reference Bourgeois, Sattari and Martinuzzi2011). Here, the tip vortex is essentially a deformed Kármán vortex. In contrast, for a circular FWMC, the tip vortex originates from the leading or trailing edge of the free end and is not associated with the Kármán vortex (Hunt et al. Reference Hunt, Abell, Peterka and Woo1978; Kawamura et al. Reference Kawamura, Hiwada, Hibino, Mabuchi and Kumada1984; Hwang & Yang Reference Hwang and Yang2004; Pattenden, Turnock & Zhang Reference Pattenden, Turnock and Zhang2005; Hain, Kahler & Michaelis Reference Hain, Kahler and Michaelis2008; Palau-Salvador et al. Reference Palau-Salvador, Stoesser, Frohlich, Kappler and Rodi2010; Krajnovic Reference Krajnovic2011; Saeedi, LePoudre & Wang Reference Saeedi, LePoudre and Wang2014). This highlights the pivotal role of cross-sectional shape in the tip vortex generation.

$u^{\prime }$

is the root-mean-square (r.m.s.) of the turbulent velocity fluctuation), among other factors (Sakamoto & Arie Reference Sakamoto and Arie1983; Bourgeois, Sattari & Martinuzzi Reference Bourgeois, Sattari and Martinuzzi2011; Porteous, Moreau & Doolan Reference Porteous, Moreau and Doolan2014; Hearst, Gomit & Ganapathisubramani Reference Hearst, Gomit and Ganapathisubramani2016). Based on the time-averaged distribution of vortical structures, the wake of an FWMC can be divided into three types (Zhang et al. Reference Zhang, Cheng, An and Zhao2017), i.e. dipole type (i.e. one pair of the streamwise vortices at the upper part), quadrupole type (i.e. two pairs of the streamwise vortices at the upper and lower parts) and six-vortex type (i.e. transitional structures involved). Particular vortical structures of the FWMC with a height over the critical value are presented in figure 1. The transition from dipole to quadrupole is marked by a critical aspect ratio (Sumner, Heseltine & Dansereau Reference Sumner, Heseltine and Dansereau2004; Wang & Zhou Reference Wang and Zhou2009; Hosseini, Bourgeois & Martinuzzi Reference Hosseini, Bourgeois and Martinuzzi2013; Sumner Reference Sumner2013). When the height exceeds this critical value, a tip vortex pair and a base vortex pair appear at the free end and junction, respectively (Bourgeois et al. Reference Bourgeois, Sattari and Martinuzzi2011; Hajimirzaie, Wojcik & Buchholz Reference Hajimirzaie, Wojcik and Buchholz2012; Porteous et al. Reference Porteous, Moreau and Doolan2014). The appearance of these vortex pairs is highly dependent on the AR. A sufficiently thick boundary layer and AR above the critical value promote the formation of the tip vortex pair at the free end (Sumner et al. Reference Sumner, Heseltine and Dansereau2004; Adaramola et al. Reference Adaramola, Akinlade, Sumner, Bergstrom and Schenstead2006; Sumner & Heseltine Reference Sumner and Heseltine2008; Bourgeois et al. Reference Bourgeois, Sattari and Martinuzzi2011, Reference Bourgeois, Sattari and Martinuzzi2012; Sumner Reference Sumner2013). The origin of the tip vortex differs depending on the cross-sectional shape. In a square FWMC, streamwise vorticity near the free end arises from the reorientation of vertical vorticity in the sidewall shear layers due to lateral vorticity of the free-end shear layer (Bourgeois et al. Reference Bourgeois, Sattari and Martinuzzi2011). Here, the tip vortex is essentially a deformed Kármán vortex. In contrast, for a circular FWMC, the tip vortex originates from the leading or trailing edge of the free end and is not associated with the Kármán vortex (Hunt et al. Reference Hunt, Abell, Peterka and Woo1978; Kawamura et al. Reference Kawamura, Hiwada, Hibino, Mabuchi and Kumada1984; Hwang & Yang Reference Hwang and Yang2004; Pattenden, Turnock & Zhang Reference Pattenden, Turnock and Zhang2005; Hain, Kahler & Michaelis Reference Hain, Kahler and Michaelis2008; Palau-Salvador et al. Reference Palau-Salvador, Stoesser, Frohlich, Kappler and Rodi2010; Krajnovic Reference Krajnovic2011; Saeedi, LePoudre & Wang Reference Saeedi, LePoudre and Wang2014). This highlights the pivotal role of cross-sectional shape in the tip vortex generation.

Figure 1. The sketch of the vortical structures for flow over a wall-mounted rigid circular cylinder. The sketch is based on the models proposed by Pattenden et al. (Reference Pattenden, Turnock and Zhang2005), Frederich et al. (2007), Krajnovic (Reference Krajnovic2011), Zhu et al. (Reference Zhu, Wang, Wang and Wang2017) and Essel, Tachie & Balachandar (Reference Essel, Tachie and Balachandar2021). Note that only part of the shear layer and spanwise vortex are shown.

When AR

![]() $\gt$

3, the base vortex pair forms at the junction (Sumner et al. Reference Sumner, Heseltine and Dansereau2004; Adaramola et al. Reference Adaramola, Akinlade, Sumner, Bergstrom and Schenstead2006), developing behind the cylinder and inducing an upwash flow (Etzold & Fiedler Reference Etzold and Fiedler1976; Hajimirzaie et al. Reference Hajimirzaie, Wojcik and Buchholz2012). Its formation is strongly influenced by

$\gt$

3, the base vortex pair forms at the junction (Sumner et al. Reference Sumner, Heseltine and Dansereau2004; Adaramola et al. Reference Adaramola, Akinlade, Sumner, Bergstrom and Schenstead2006), developing behind the cylinder and inducing an upwash flow (Etzold & Fiedler Reference Etzold and Fiedler1976; Hajimirzaie et al. Reference Hajimirzaie, Wojcik and Buchholz2012). Its formation is strongly influenced by

![]() $\delta /D$

(Wang et al. Reference Wang, Zhou, Chan and Lam2006). Compared with the tip vortex pair, the base vortex pair is weaker and dissipates more quickly downstream.

$\delta /D$

(Wang et al. Reference Wang, Zhou, Chan and Lam2006). Compared with the tip vortex pair, the base vortex pair is weaker and dissipates more quickly downstream.

The trailing vortex (not shown in figure 1), which is typically located far from the free end, is not a continuation of the tip vortex pair. According to Frederich, Wassen & Thiele (Reference Frederich, Wassen and Thiele2008) and Palau-Salvador et al. (Reference Palau-Salvador, Stoesser, Frohlich, Kappler and Rodi2010), it arises from strong downwash effects and associated upwash motion away from the wake centreline, triggered by the finite cylinder width. Initially believed to be visible only in the mean flow field (Fröhlich & Rodi Reference Fröhlich and Rodi2004), tomographic particle image velocimetry results from Zhu et al. (Reference Zhu, Wang, Wang and Wang2017) suggest that this structure can also be observed in the instantaneous flow field where AR is low.

Vortex shedding from FWMC sidewalls is influenced by the AR and boundary layer conditions, primarily due to variations in downwash flow and near-wake base vortices (Fröhlich and Rodi, 2004; Pattenden et al. Reference Pattenden, Turnock and Zhang2005; Wang et al. Reference Wang, Zhou, Chan and Lam2006; Palau-Salvador et al. Reference Palau-Salvador, Stoesser, Frohlich, Kappler and Rodi2010; Tsutsui Reference Tsutsui2012). A thick boundary layer could enhance the base vortex and induce upwash flow. Spanwise vortices can adopt antisymmetric and/or symmetric patterns depending on upwash and downwash flow (Wang et al. Reference Wang, Zhou, Chan and Lam2006; Wang & Zhou Reference Wang and Zhou2009). For FWMC with larger AR, both types of vortex shedding may coexist. Wang, Cao & Zhou (Reference Wang, Cao and Zhou2014) found that vortex shedding near the free end is predominantly symmetric, whereas alternating vortex shedding dominates the wake near the centre and lower regions. The separation line (shown in figure 1), corresponding to points where the shear layers detach from the side surface, indicates that separation occurs earlier around the centre than near the free end or lower part due to the influences of downwash and upwash flow.

The free-end arch vortex appears in the mean wake field when AR

![]() $\lt$

3 (Lee Reference Lee1997; Krajnovic Reference Krajnovic2011). This vortex takes on a reversed U-shape (Fröhlich and Rodi, 2004). The legs of the mean arch vortex are inclined in the streamwise direction at a relatively constant angle (Krajnovic Reference Krajnovic2011). For low AR cases, the dominant downwash effect increases the likelihood of symmetric vortex shedding (Wang et al. Reference Wang, Cao and Zhou2014). This symmetric shedding may induce instantaneous arch vortex formation in short cylinders (Zhu et al. Reference Zhu, Wang, Wang and Wang2017).

$\lt$

3 (Lee Reference Lee1997; Krajnovic Reference Krajnovic2011). This vortex takes on a reversed U-shape (Fröhlich and Rodi, 2004). The legs of the mean arch vortex are inclined in the streamwise direction at a relatively constant angle (Krajnovic Reference Krajnovic2011). For low AR cases, the dominant downwash effect increases the likelihood of symmetric vortex shedding (Wang et al. Reference Wang, Cao and Zhou2014). This symmetric shedding may induce instantaneous arch vortex formation in short cylinders (Zhu et al. Reference Zhu, Wang, Wang and Wang2017).

In front of the arch vortex, the leading-edge vortex forms at the forward half of the free end surface (Kawamura et al. Reference Kawamura, Hiwada, Hibino, Mabuchi and Kumada1984; Krajnovic Reference Krajnovic2011). This vortex is attributed to the reverse flow along the centre of the free end surface, which is entrained by the separated flow from the leading edge (Kawamura et al. Reference Kawamura, Hiwada, Hibino, Mabuchi and Kumada1984; Pattenden et al. Reference Pattenden, Turnock and Zhang2005; Palau-Salvador et al. Reference Palau-Salvador, Stoesser, Frohlich, Kappler and Rodi2010; Krajnovic Reference Krajnovic2011). The attachment length of this vortex is strongly affected by both AR and

![]() $Re$

(Sumner Reference Sumner2013). Downstream of the surface, the forward free-end flow interacts with the wake behind the FWMC, leading to the emergence of the upper near-wake cross-stream vortex (as shown in figure 1). Additional vortices may also form, such as the horseshoe vortex at the junction. The horseshoe vortex may interact with the vortices behind the FWMC, significantly influencing the overall wake dynamics.

$Re$

(Sumner Reference Sumner2013). Downstream of the surface, the forward free-end flow interacts with the wake behind the FWMC, leading to the emergence of the upper near-wake cross-stream vortex (as shown in figure 1). Additional vortices may also form, such as the horseshoe vortex at the junction. The horseshoe vortex may interact with the vortices behind the FWMC, significantly influencing the overall wake dynamics.

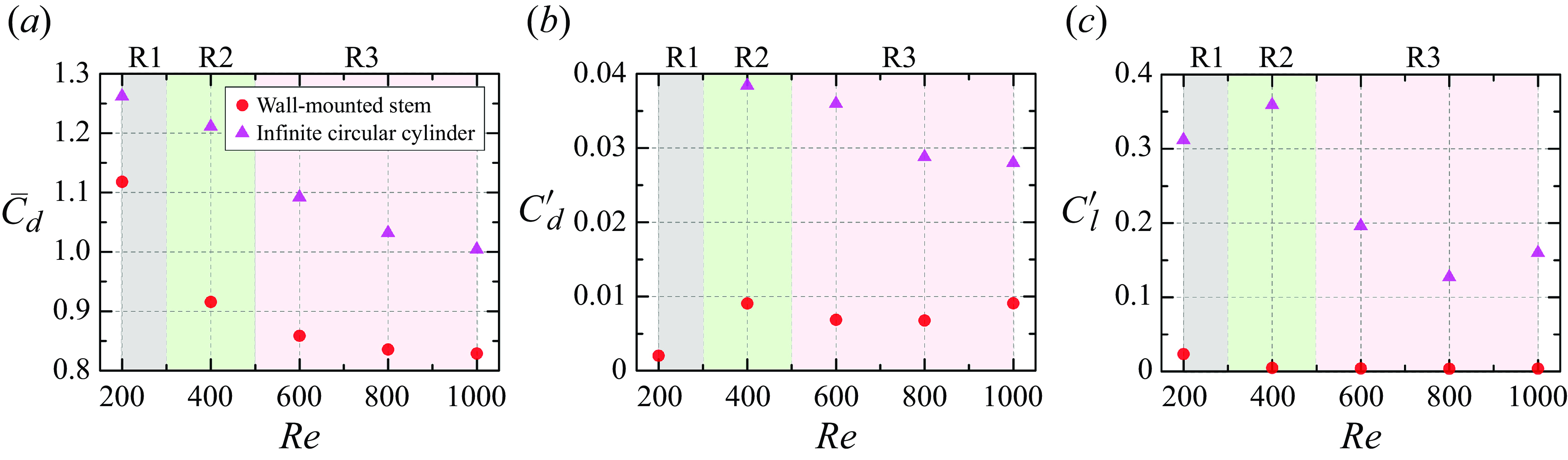

The flow structures around the FWMC are highly complex, with their formation, development and dissipation closely tied to the vortex interactions, including rotational effects, upwash and downwash flows. The FWMC height and boundary layer conditions play crucial roles in this dynamics. In this study, we focus on the hydrodynamic forces and vortex dynamics of a circular FWMC across a wide range of

![]() $Re$

. Specific flow behaviours are analysed, and distinctive vortex structures are reported.

$Re$

. Specific flow behaviours are analysed, and distinctive vortex structures are reported.

1.2. Flow over the finite wall-mounted flexible structure

When the structure is flexible, FSI becomes significant. In nature, wall-mounted structures appear in various forms, such as flexible plate, blade, filament, aquatic plant and stem. Research on these structures is essential for understanding their behaviours under different flow conditions. However, most studies have focused on predicting drag, wave attenuation, flow profiles and structural reconfiguration, with relatively few investigations into their vortex dynamics. Furthermore, the parameters considered in these studies are scattered, making it difficult to establish a comprehensive understanding of FSI of wall-mounted flexible structures.

Zeller et al. (Reference Zeller, Weitzman, Abbett, Zarama, Fringer and Koseff2014) proposed a novel formulation of the Keulegan–Carpenter number (

![]() $KC=$

$KC=$

![]() $U_m T/D$

, where

$U_m T/D$

, where

![]() $U_m$

is the maximum flow velocity and

$U_m$

is the maximum flow velocity and

![]() $T$

is the oscillatory period) for predicting drag coefficients and developed a model for wave attenuation. They estimated the averaged turbulence production over the wave period using the maximum flow velocity and the relative velocity between the current and waves. Mullarney et al. (Reference Mullarney and Henderson2010) demonstrated that stem stiffness significantly affects its motion relative to the wave under wave forcing. A highly flexible stem moves with the surrounding water, whereas a stiff stem exhibits minimal motion, leading the surrounding water by

$T$

is the oscillatory period) for predicting drag coefficients and developed a model for wave attenuation. They estimated the averaged turbulence production over the wave period using the maximum flow velocity and the relative velocity between the current and waves. Mullarney et al. (Reference Mullarney and Henderson2010) demonstrated that stem stiffness significantly affects its motion relative to the wave under wave forcing. A highly flexible stem moves with the surrounding water, whereas a stiff stem exhibits minimal motion, leading the surrounding water by

![]() $90^{\circ }$

. They developed an analytical model to describe the wave-forced motion of a single stem and derived an equation to predict frequency-dependent wave dissipation. Luhar & Nepf (Reference Luhar and Nepf2016) observed that blade motion is governed mainly by two dimensionless parameters: (i) the Cauchy number (

$90^{\circ }$

. They developed an analytical model to describe the wave-forced motion of a single stem and derived an equation to predict frequency-dependent wave dissipation. Luhar & Nepf (Reference Luhar and Nepf2016) observed that blade motion is governed mainly by two dimensionless parameters: (i) the Cauchy number (

![]() $Ca$

) and (ii) the ratio of the blade length to wave orbital excursion. Here,

$Ca$

) and (ii) the ratio of the blade length to wave orbital excursion. Here,

![]() $Ca$

is defined as

$Ca$

is defined as

![]() $C a=0.5 \rho _f D l^3 U_{ref}^2 / E I$

, where

$C a=0.5 \rho _f D l^3 U_{ref}^2 / E I$

, where

![]() $\rho _f$

is the fluid density,

$\rho _f$

is the fluid density,

![]() $D$

is the side length or stem diameter,

$D$

is the side length or stem diameter,

![]() $l$

is the stem height,

$l$

is the stem height,

![]() $E$

is Young’s modulus,

$E$

is Young’s modulus,

![]() $I$

is the cross-sectional momentum of inertia and

$I$

is the cross-sectional momentum of inertia and

![]() $U_{ref}$

is the incoming flow velocity. When

$U_{ref}$

is the incoming flow velocity. When

![]() $Ca$

$Ca$

![]() $\gg$

1, drag on the flexible blade is lower. However, when

$\gg$

1, drag on the flexible blade is lower. However, when

![]() $Ca\sim$

O(1), drag is higher than that of a rigid blade. Hu et al. (Reference Hu, Mei, Chang and Liu2021) developed a theoretical model to predict the motion of rigid and flexible stems under wave conditions, identifying a phase lag between flow motion and stem response. Zhang & Nepf (Reference Zhang and Nepf2022) developed a scaling equation to predict the reconfiguration of flexible plants with leaves due to the hydrodynamic drag using water channel experiments and numerical simulations.

$Ca\sim$

O(1), drag is higher than that of a rigid blade. Hu et al. (Reference Hu, Mei, Chang and Liu2021) developed a theoretical model to predict the motion of rigid and flexible stems under wave conditions, identifying a phase lag between flow motion and stem response. Zhang & Nepf (Reference Zhang and Nepf2022) developed a scaling equation to predict the reconfiguration of flexible plants with leaves due to the hydrodynamic drag using water channel experiments and numerical simulations.

In terms of flexible filaments, Silva-Leon & Cioncolini (Reference Silva-Leon and Cioncolini2020) experimentally investigated their motions and identified different filament responses, including static reconfiguration, small-amplitude vibration, large-amplitude periodic vibration and large-amplitude aperiodic vibration. These behaviours were found to be influenced by

![]() $Re$

and the filament length (

$Re$

and the filament length (

![]() $l$

). Huang, Shin & Sung (Reference Huang, Shin and Sung2007) numerically observed bistability in flexible filaments by varying their length. Revstedt (Reference Revstedt2013) studied the deformation of a flexible cantilever at

$l$

). Huang, Shin & Sung (Reference Huang, Shin and Sung2007) numerically observed bistability in flexible filaments by varying their length. Revstedt (Reference Revstedt2013) studied the deformation of a flexible cantilever at

![]() $Re=$

400 and a reduced velocity range of

$Re=$

400 and a reduced velocity range of

![]() $\pi /4-2\pi$

. In the desynchronisation regime, the stem motion has negligible effects on vortical structures, whereas in the synchronisation regime, the stem significantly alters the mean flow field, frequencies and vortical structures. Zhang, He & Zhang (Reference Zhang, He and Zhang2020) explored the dynamics of a wall-mounted flexible filament by varying the bending rigidity, mass ratio (

$\pi /4-2\pi$

. In the desynchronisation regime, the stem motion has negligible effects on vortical structures, whereas in the synchronisation regime, the stem significantly alters the mean flow field, frequencies and vortical structures. Zhang, He & Zhang (Reference Zhang, He and Zhang2020) explored the dynamics of a wall-mounted flexible filament by varying the bending rigidity, mass ratio (

![]() $m^{*} = m/m_f$

, where

$m^{*} = m/m_f$

, where

![]() $m$

is the structure mass and

$m$

is the structure mass and

![]() $m_f$

is the displaced fluid mass) and

$m_f$

is the displaced fluid mass) and

![]() $Re$

. They observed three distinct dynamic modes, referred to as lodging, regular vortex-induced vibration (VIV) and static reconfiguration. In regular VIV, the filament frequency locks onto the second natural frequency. However, when the filament is with a nearly upright orientation, the vortex shedding is weak and no lock-in is observed. At higher

$Re$

. They observed three distinct dynamic modes, referred to as lodging, regular vortex-induced vibration (VIV) and static reconfiguration. In regular VIV, the filament frequency locks onto the second natural frequency. However, when the filament is with a nearly upright orientation, the vortex shedding is weak and no lock-in is observed. At higher

![]() $Re$

, vortex shedding intensifies, leading to first-mode frequency lock-in, as reported in Py, De Langre & Moulia (Reference Py, De Langre and Moulia2006) and Jin et al. (Reference Jin, Kim, Mao and Chamorro2018). Rota et al. (Reference Rota, Koseki, Agrawal, Olivieri and Rosti2024) observed two flapping states of a wall-mounted flexible filament in turbulent wall flow by direct numerical simulations. One state is with a more flexible filament which oscillates at the frequency of the largest eddies, and the other is with a more rigid filament which is governed by the structural natural frequency.

$Re$

, vortex shedding intensifies, leading to first-mode frequency lock-in, as reported in Py, De Langre & Moulia (Reference Py, De Langre and Moulia2006) and Jin et al. (Reference Jin, Kim, Mao and Chamorro2018). Rota et al. (Reference Rota, Koseki, Agrawal, Olivieri and Rosti2024) observed two flapping states of a wall-mounted flexible filament in turbulent wall flow by direct numerical simulations. One state is with a more flexible filament which oscillates at the frequency of the largest eddies, and the other is with a more rigid filament which is governed by the structural natural frequency.

For a single stem, Jacobsen et al. (Reference Jacobsen, Bakker, Uijttewaal and Uittenbogaard2019) experimentally studied its motion subjected to regular waves, focusing on several critical aspects: (i) predicting the stem motion and static shape, (ii) force reduction due to flexibility, (iii) hydrodynamic forces on the flexible stem, (iv) estimating external hydrodynamic loading and internal shear forces and (v) examining the relationship between phase lags and internal shear forces. They found that when the stem is stiffer, the phase lags remain nearly uniform along its length, whereas in more flexible stem, phase lags vary. The drag force shows better overall coherence with varying

![]() $KC$

. Toward the stem base, shear force increases monotonically for certain stems; however, it reaches local maximum near the stem tip. Zhu et al. (Reference Zhu, Zou, Huguenard and Fredriksson2020) developed a consistent-mass cable model to solve the flow and flexible stem interaction. They observed that, even under symmetric waves, the blade can experience asymmetric motion, with asymmetry of the tip motion growing with wave height and blade length but reducing as flexural rigidity increases. Using numerical simulations, O’Connor & Revell (Reference O’Connor and Revell2019) investigated the dynamic behaviours of a two-dimensional (2-D) flexible flap in channel flow. They identified four different response modes: static, flapping, period doubling and chaotic motion. Additionally, they discussed the stabilising and destabilising effects of the bending stiffness and mass ratio. Leclercq & de Langre (Reference Leclercq and De Langre2018) observed four kinematic regimes, referred to as the fully static, large-amplitude, convective and modal regimes, based on the flow oscillation amplitude and frequency relative to the blade dimensions and natural frequency. Jin et al. (Reference Jin, Kim, Fu and Chamorro2019) experimentally examined the unsteady dynamics of individual wall-mounted flexible plates with varying rigidities. They identified three dominant modes of tip oscillation: flutter, twisting and orbital modes. Neshamar et al. (Reference Neshamar, van der A and O’Donoghue2022) experimentally investigated the flow-induced oscillation of a cantilevered cylinder. They found that, depending on the reduced velocity, the dominant response could manifest as in-line vibration, figure-eight vibration or transverse vibration, each with distinct features. They further developed an empirical model to reasonably predict the amplitude of in-line vibration.

$KC$

. Toward the stem base, shear force increases monotonically for certain stems; however, it reaches local maximum near the stem tip. Zhu et al. (Reference Zhu, Zou, Huguenard and Fredriksson2020) developed a consistent-mass cable model to solve the flow and flexible stem interaction. They observed that, even under symmetric waves, the blade can experience asymmetric motion, with asymmetry of the tip motion growing with wave height and blade length but reducing as flexural rigidity increases. Using numerical simulations, O’Connor & Revell (Reference O’Connor and Revell2019) investigated the dynamic behaviours of a two-dimensional (2-D) flexible flap in channel flow. They identified four different response modes: static, flapping, period doubling and chaotic motion. Additionally, they discussed the stabilising and destabilising effects of the bending stiffness and mass ratio. Leclercq & de Langre (Reference Leclercq and De Langre2018) observed four kinematic regimes, referred to as the fully static, large-amplitude, convective and modal regimes, based on the flow oscillation amplitude and frequency relative to the blade dimensions and natural frequency. Jin et al. (Reference Jin, Kim, Fu and Chamorro2019) experimentally examined the unsteady dynamics of individual wall-mounted flexible plates with varying rigidities. They identified three dominant modes of tip oscillation: flutter, twisting and orbital modes. Neshamar et al. (Reference Neshamar, van der A and O’Donoghue2022) experimentally investigated the flow-induced oscillation of a cantilevered cylinder. They found that, depending on the reduced velocity, the dominant response could manifest as in-line vibration, figure-eight vibration or transverse vibration, each with distinct features. They further developed an empirical model to reasonably predict the amplitude of in-line vibration.

Although significant progress has been made in recent years, several key questions remain unsolved, which are critical for both engineering applications and theoretical advancements. (i) Amongst existing studies, the three-dimensional (3-D) vortical structures, particularly their spatial evolution, remain largely unexplored, despite their central role in flow physics. (ii) The complex dynamics of a flexible stem is closely associated with unsteady vortex shedding events (Lunar and Nepf, 2016), and these interactions play a crucial role in regulating the system’s behaviour. (iii) Most theoretical and experimental studies have overlooked motion-induced forces, despite their demonstrated significance in force amplification (Triantafyllou et al. Reference Triantafyllou, Bourguet, Dahl and Modarres-Sadeghi2016). Among the different motion components, transverse motion makes the greatest contribution to force amplification, exceeding the streamwise and vertical motion effects. (iv) The tip motion and dynamic distributions along the vertical direction need to be clarified.

1.3. The objective of the present study

In this study, we introduce, for the first time, a coupled immersed boundary method (IBM)–vector form intrinsic finite element (VFIFE) method to simulate wall-mounted structures. This novel approach enables us to address several unexplored aspects of uniform flow over a circular FWMC. We start with a wall-mounted rigid stem to provide a foundational understanding of the vortex dynamics and to facilitate comparisons with flexible stems. We then shift our focus to the FSI of a wall-mounted flexible stem. The remains of this study are structured as follows. In § 2, we provide the details of the numerical methodology adopted in this study. In § 3, we validate the developed model through a comparison with theoretical and experimental results. In § 4, we present the details of the parameters applied in the simulation of the wall-mounted stem. In § 5, we present the flow over the rigid stem and discuss the evolution of the 3-D vortical structures. Additionally, we analyse the development of upwash and downwash flows and inherent 3-D wake instabilities. In § 6, the FSI response and vortex dynamics of a flexible stem are presented. In § 7, we further discuss several phenomena in the flexible case. In § 8, the main findings of this study are summarised.

2. Methodology

In this section, we present the adopted numerical method for simulating the wall-mounted structure. In § 2.1, the filtered Navier–Stokes (N-S) and continuity equations in the large-eddy simulation are presented. In §§ 2.2 and 2.3, the details of VFIFE and IBM are introduced. In § 2.4, information on the coupling between the fluid and structure is provided.

2.1. Large-eddy simulation (LES)

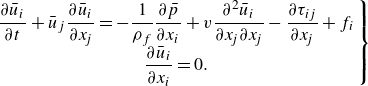

The governing equations for the incompressible flow are the filtered N-S and continuity equations expressed as follows:

\begin{equation} \left .\begin{array}{cc} & \displaystyle\frac {\partial \bar {u}_i}{\partial t}+\bar {u}_j \frac {\partial \bar {u}_i}{\partial x_{\!j}}=-\frac {1}{\rho _f} \frac {\partial \bar {p}}{\partial x_i}+v \frac {\partial ^2 \bar {u}_i}{\partial x_{\!j} \partial x_{\!j}}-\frac {\partial \tau _{i j}}{\partial x_{\!j}}+f_{i} \\ & \displaystyle\frac {\partial \bar {u}_i}{\partial x_i}=0 .\end{array}\right \} \end{equation}

\begin{equation} \left .\begin{array}{cc} & \displaystyle\frac {\partial \bar {u}_i}{\partial t}+\bar {u}_j \frac {\partial \bar {u}_i}{\partial x_{\!j}}=-\frac {1}{\rho _f} \frac {\partial \bar {p}}{\partial x_i}+v \frac {\partial ^2 \bar {u}_i}{\partial x_{\!j} \partial x_{\!j}}-\frac {\partial \tau _{i j}}{\partial x_{\!j}}+f_{i} \\ & \displaystyle\frac {\partial \bar {u}_i}{\partial x_i}=0 .\end{array}\right \} \end{equation}

Here,

![]() $u_i$

(

$u_i$

(

![]() $i=$

1, 2, 3) is the flow velocity of three directions in the Cartesian coordinate system, an overbar stands for the filtering procedure,

$i=$

1, 2, 3) is the flow velocity of three directions in the Cartesian coordinate system, an overbar stands for the filtering procedure,

![]() $p$

is the pressure,

$p$

is the pressure,

![]() $t$

is the time,

$t$

is the time,

![]() $\rho _f$

is the fluid density,

$\rho _f$

is the fluid density,

![]() $\nu$

is the kinematic viscosity of the fluid,

$\nu$

is the kinematic viscosity of the fluid,

![]() $f_i$

is the extra force that represents the action of immersed objects on the fluid and

$f_i$

is the extra force that represents the action of immersed objects on the fluid and

![]() $\tau _{i j}$

is the subgrid-scale stress, representing the influences of the filtered small-scale turbulent structures on the flow field (Smagorinsky Reference Smagorinsky1963). To ensure the closure of (2.1), the Smagorinsky eddy viscosity model is applied, which is given as

$\tau _{i j}$

is the subgrid-scale stress, representing the influences of the filtered small-scale turbulent structures on the flow field (Smagorinsky Reference Smagorinsky1963). To ensure the closure of (2.1), the Smagorinsky eddy viscosity model is applied, which is given as

where

![]() $C_s$

is the Smagorinsky constant. In the present study,

$C_s$

is the Smagorinsky constant. In the present study,

![]() $C_s=$

0.1 (Deardorff Reference Deardorff1970). The filter width

$C_s=$

0.1 (Deardorff Reference Deardorff1970). The filter width

![]() $\varDelta$

is adopted as

$\varDelta$

is adopted as

![]() $\varDelta =\sqrt [3]{\Delta x \Delta y \Delta z}$

with

$\varDelta =\sqrt [3]{\Delta x \Delta y \Delta z}$

with

![]() $\Delta x$

,

$\Delta x$

,

![]() $\Delta y$

, and

$\Delta y$

, and

![]() $\Delta z$

as the grid sizes in the three directions. Here,

$\Delta z$

as the grid sizes in the three directions. Here,

![]() $|\bar {S}|= (2 \bar {S}_{i j} \bar {S}_{i j} )^{1 / 2}$

is the magnitude of large-scale strain rate tensor, where

$|\bar {S}|= (2 \bar {S}_{i j} \bar {S}_{i j} )^{1 / 2}$

is the magnitude of large-scale strain rate tensor, where

![]() $\bar {S}_{i j}=({1}/{2}) (({\partial \bar {u}_i}/{\partial x_{\!j}})+({\partial \bar {u}_j}/{\partial x_i}) )$

.

$\bar {S}_{i j}=({1}/{2}) (({\partial \bar {u}_i}/{\partial x_{\!j}})+({\partial \bar {u}_j}/{\partial x_i}) )$

.

2.2. Vector form intrinsic finite element

The VFIFE method was first introduced by Ting, Shih & Wang (Reference Ting, Shih and Wang2004a ,Reference Ting, Shih and Wang b , Reference Ting, Duan and Wu2012), Ting & Wang (Reference Ting and Wang2008) and Shih, Wang & Ting (Reference Shih, Wang and Ting2004). It is an analytical and numerical method in structural mechanics based on point value description and vector form theory. The point value description in the VFIFE method relies on a lumped mass matrix, meaning that external force on one spatial point does not influence the motion dynamics of other spatial points. As a result, the method eliminates the need to construct complex rigidity matrix or solve large-scale nonlinear equations. Compared with conventional methods, the VFIFE method effectively avoids certain nonlinear issue that arise when structures undergo large deformations, dislocations, collisions or elastoplastic behaviours, such as iteration non-convergence and matrix singularity. Additionally, by appropriately discretising path elements, the characteristics between two path elements can be adjusted, allowing the method to handle structural discontinuities. Consequently, the VFIFE method has been widely applied to address challenging nonlinear and discontinuous scenarios (Duan et al. Reference Duan, He, Zhang, Ting, Wang, Chen and Wang2014; Xu et al. Reference Xu, Li, Jiang and Liu2015; Xu & Lin Reference Xu and Lin2017; Hou, Fang & Zhang Reference Hou, Fang and Zhang2018; Li, Wei & Bai Reference Li, Wei and Bai2020; Wu et al. Reference Wu, Zeng, Xiao, Yu, Dai and Yu2020).

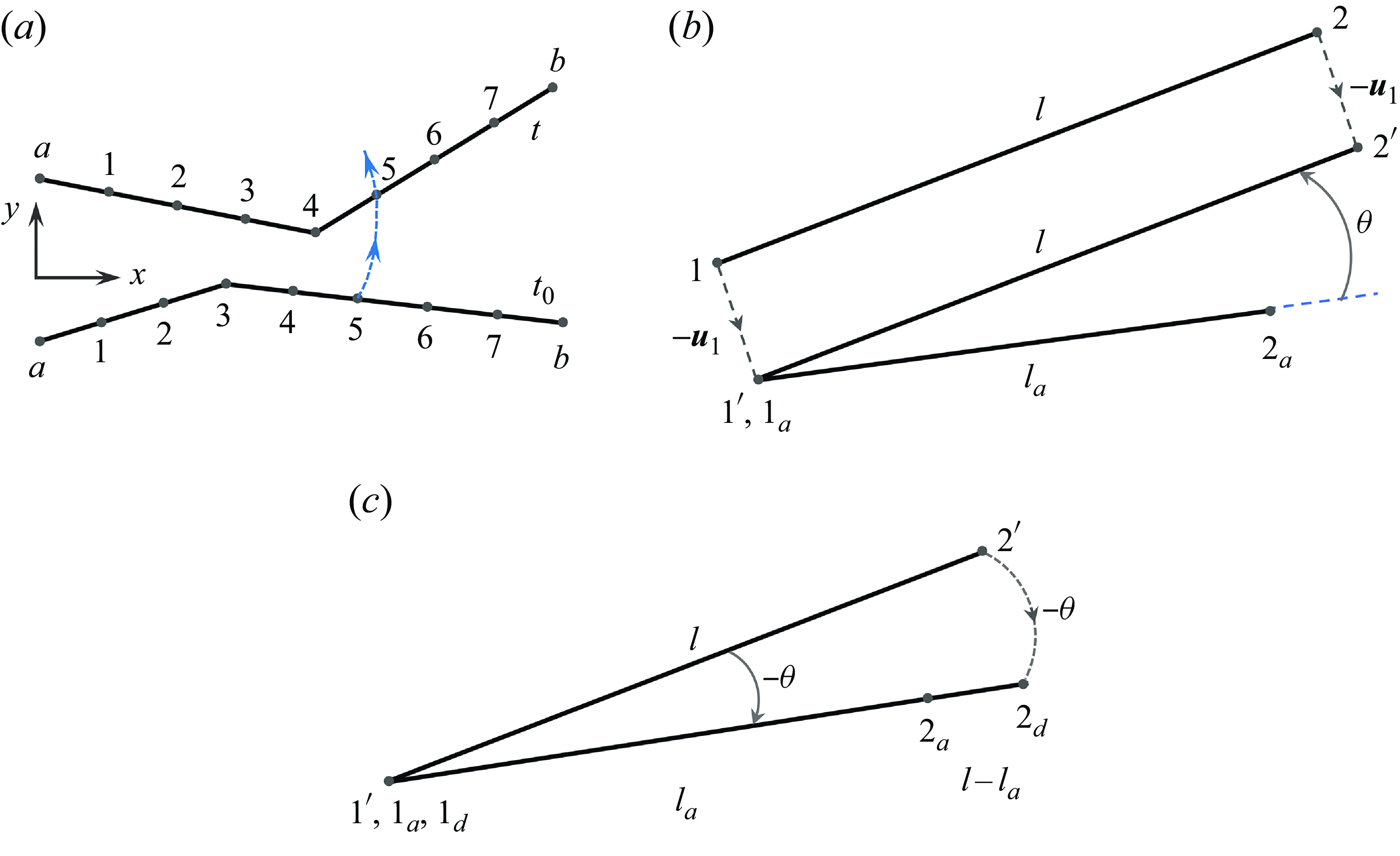

The foundation of the VFIFE lies in its spatial and temporal structural point value description. In the spatial point value description, the structural mass is concentrated at a series of discretised spatial points. The motion and deformation of structure can be determined through the positions of these spatial points, which are interconnected by linear beam elements, see figure 2(

![]() $a$

). It is assumed that the cross-sectional profiles of the elements remain identical and perpendicular to the principal axis at any position. Unlike conventional methods, the beam elements in the VFIFE are responsible solely for internal structural force and are independent of the governing equations. For cases involving multiple internal forces between two spatial points, multiple beam elements are used. These elements are positioned between the two spatial points to represent the internal force without needing to define it across the entire structural range (Ting, Duan & Wu Reference Ting, Duan and Wu2012).

$a$

). It is assumed that the cross-sectional profiles of the elements remain identical and perpendicular to the principal axis at any position. Unlike conventional methods, the beam elements in the VFIFE are responsible solely for internal structural force and are independent of the governing equations. For cases involving multiple internal forces between two spatial points, multiple beam elements are used. These elements are positioned between the two spatial points to represent the internal force without needing to define it across the entire structural range (Ting, Duan & Wu Reference Ting, Duan and Wu2012).

In the temporal point value description, the structure’s dynamics is represented by a series of path elements that follow the principle of ‘large dislocation and small deformation’. Within each path element, the shift of a spatial point comes from the two components: rigid body motion and pure deformation. The displacement due to rigid body motion is determined using Newton’s second law and the rotational equation, while the displacement caused by pure deformation is described by Hooke’s law through the introduction of a virtual reverse motion. Ensuring consistency of the structural properties and motion trajectories is crucial for accurately calculating pure deformation within each path unit via reverse motion. In the VFIFE, reverse motion is introduced to distinguish dislocations caused by rigid body movement from those caused by pure structural deformation, see figure 2(

![]() $b$

,

$b$

,

![]() $c$

). The processing steps are as follows. (i) The calculation of structural internal force is based on the state at the initial instant

$c$

). The processing steps are as follows. (i) The calculation of structural internal force is based on the state at the initial instant

![]() $t_a$

. (ii) Due to the consistency of structural properties and motion trajectories within each path element, a virtual structural state at any instant

$t_a$

. (ii) Due to the consistency of structural properties and motion trajectories within each path element, a virtual structural state at any instant

![]() $t$

is generated through a virtual reverse motion, which includes reverse translational and rotational motions for the spatial position at that instant. Subsequently, minor dislocations and deformations are identified by comparing the reference and virtual structural states. (iii) These small deformations and dislocations are then resolved using the structural deformation–internal force relationship. Finally, the structural state at

$t$

is generated through a virtual reverse motion, which includes reverse translational and rotational motions for the spatial position at that instant. Subsequently, minor dislocations and deformations are identified by comparing the reference and virtual structural states. (iii) These small deformations and dislocations are then resolved using the structural deformation–internal force relationship. Finally, the structural state at

![]() $t_b$

is obtained through a forward rigid body motion.

$t_b$

is obtained through a forward rigid body motion.

Figure 2. (

![]() $a$

) The beam elements, (

$a$

) The beam elements, (

![]() $b$

) reverse translation and (

$b$

) reverse translation and (

![]() $c$

) reverse rotation in the VFIFE.

$c$

) reverse rotation in the VFIFE.

The dynamics of a wall-mounted flexible stem is simulated using VFIFE method. Based on the point value description, the stem is discretised into a set of spatial nodes that connect to each other by beam elements. The motion of each node is applied to describe the movement and deformation of the stem and satisfies Newton’s second law

where

![]() $m$

and

$m$

and

![]() $I$

are the mass and momentum of inertia matrix of the node, respectively. Here,

$I$

are the mass and momentum of inertia matrix of the node, respectively. Here,

![]() $\dot {\boldsymbol{V}}$

,

$\dot {\boldsymbol{V}}$

,

![]() $\boldsymbol{V}$

,

$\boldsymbol{V}$

,

![]() $\dot {\boldsymbol{\omega }}$

and

$\dot {\boldsymbol{\omega }}$

and

![]() $\boldsymbol{\omega }$

are the acceleration, velocity, angular acceleration and angular velocity of the node, respectively,

$\boldsymbol{\omega }$

are the acceleration, velocity, angular acceleration and angular velocity of the node, respectively,

![]() $\boldsymbol{F}^{i n t}$

,

$\boldsymbol{F}^{i n t}$

,

![]() $\boldsymbol{F}^{e x t}$

,

$\boldsymbol{F}^{e x t}$

,

![]() $\boldsymbol{M}^{i n t}$

and

$\boldsymbol{M}^{i n t}$

and

![]() $\boldsymbol{M}^{e x t}$

are the internal force, external force, internal momentum and external momentum, respectively, and

$\boldsymbol{M}^{e x t}$

are the internal force, external force, internal momentum and external momentum, respectively, and

![]() $\zeta$

is the structural damping coefficient, which is zero in the present study. An explicit iterative scheme based on the central difference is adopted to solve equation (2.3) as follows:

$\zeta$

is the structural damping coefficient, which is zero in the present study. An explicit iterative scheme based on the central difference is adopted to solve equation (2.3) as follows:

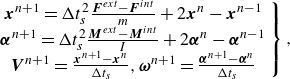

\begin{equation} \left .\begin{array}{cc} \boldsymbol{x}^{n+1}=\Delta t_s^2 \frac {\boldsymbol{F}^{e x t}-\boldsymbol{F}^{i n t}}{m}+2 \boldsymbol{x}^n-\boldsymbol{x}^{n-1} \\ \boldsymbol{\alpha }^{n+1}=\Delta t_s^2 \frac {\boldsymbol{M}^{e x t}-\boldsymbol{M}^{i n t}}{I}+2 \boldsymbol{\alpha }^n-\boldsymbol{\alpha }^{n-1} \\ \boldsymbol{V}^{n+1}=\frac {\boldsymbol{x}^{n+1}-\boldsymbol{x}^n}{\Delta t_s}, \boldsymbol{\omega }^{n+1}=\frac {\boldsymbol{\alpha }^{n+1}-\boldsymbol{\alpha }^n}{\Delta t_s} \end{array}\right \}, \end{equation}

\begin{equation} \left .\begin{array}{cc} \boldsymbol{x}^{n+1}=\Delta t_s^2 \frac {\boldsymbol{F}^{e x t}-\boldsymbol{F}^{i n t}}{m}+2 \boldsymbol{x}^n-\boldsymbol{x}^{n-1} \\ \boldsymbol{\alpha }^{n+1}=\Delta t_s^2 \frac {\boldsymbol{M}^{e x t}-\boldsymbol{M}^{i n t}}{I}+2 \boldsymbol{\alpha }^n-\boldsymbol{\alpha }^{n-1} \\ \boldsymbol{V}^{n+1}=\frac {\boldsymbol{x}^{n+1}-\boldsymbol{x}^n}{\Delta t_s}, \boldsymbol{\omega }^{n+1}=\frac {\boldsymbol{\alpha }^{n+1}-\boldsymbol{\alpha }^n}{\Delta t_s} \end{array}\right \}, \end{equation}

where

![]() $\boldsymbol{x}$

,

$\boldsymbol{x}$

,

![]() $\boldsymbol{\alpha }$

and

$\boldsymbol{\alpha }$

and

![]() $\Delta t_s$

represent the node position, rotation angle of the node and the structural time step, respectively. The temporal trajectory of any node on the stem is described by a set of spatial points, and the process between the spatial points is defined as the path element. Proper division of the path element allows the properties of each node to vary between two elements.

$\Delta t_s$

represent the node position, rotation angle of the node and the structural time step, respectively. The temporal trajectory of any node on the stem is described by a set of spatial points, and the process between the spatial points is defined as the path element. Proper division of the path element allows the properties of each node to vary between two elements.

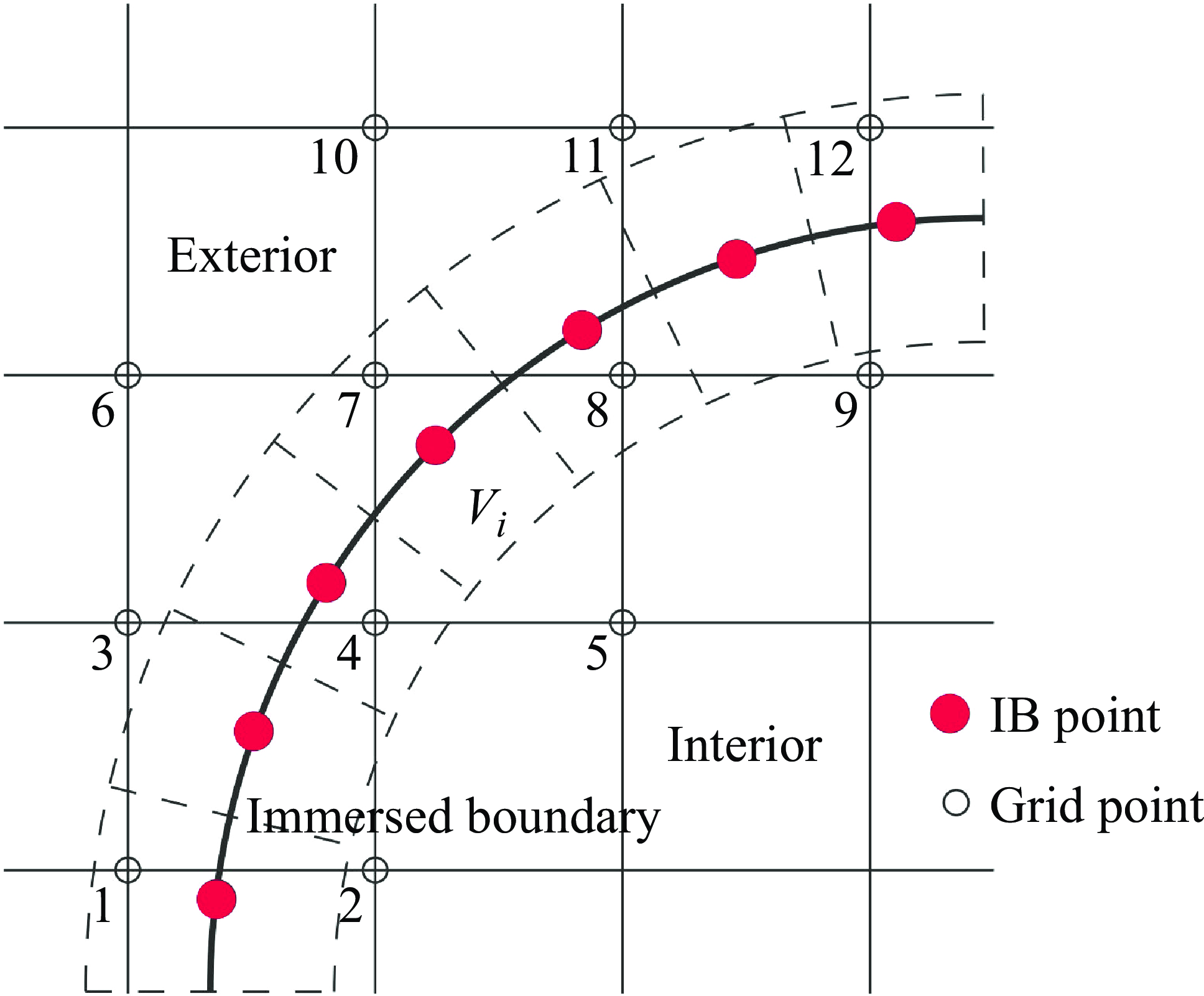

Figure 3. The layout of the immersed boundary method. The discrete volumes (

![]() $V_i$

) of the immersed boundary points (IBPs), marked by the dashed region, form a thin shell of thickness equal to one mesh width around each IBP.

$V_i$

) of the immersed boundary points (IBPs), marked by the dashed region, form a thin shell of thickness equal to one mesh width around each IBP.

2.3. Immersed boundary method

The IBM was first introduced by Peskin (Reference Peskin1972) for simulating blood flow around the flexible leaflet of a human heart. Compared with conventional numerical methods, IBM offers key advantages, particularly in FSI simulations involving topological changes. Another significant advantage is its parameterised and fast implementation, enabling the rapid simulation of numerous cases with different geometric configurations, unlike conventional methods that rely on body-conformal grids. In the IBM framework, the flow motion equations are discretised on a fixed Cartesian grid, while the structure is represented by a series of IBPs on a Lagrangian grid, which is curvilinear and free to move, see figure 3. The Cartesian grid does not conform to the geometry of a moving structure. As a result, the boundary conditions on the fluid–body interface cannot be imposed directly. Instead, an extra body force is incorporated into the fluid momentum equation to account for this interaction. This body force is updated during pressure iterations (Ji, Munjiza & Williams Reference Ji, Munjiza and Williams2012), ensuring that it is solved simultaneously with pressure and that the boundary condition on the immersed boundary is fully satisfied. In the current simulation, the stem is discretised into 160 elements along its height, resulting in 161 circular slices. Each slice is represented as a circle, further discretised into 256 IBPs uniformly distributed along its circumferences, as illustrated in figure 4(

![]() $c$

). This ensures that at least one IBP is present in each grid cell, maintaining accurate spatial resolution. Given an aspect ratio of AR

$c$

). This ensures that at least one IBP is present in each grid cell, maintaining accurate spatial resolution. Given an aspect ratio of AR

![]() $= 10$

, the resolution is 1/16 . Notably, when the stem deforms, the plane of each layer, composed of 256 IBPs, remains perpendicular to the tangent line at the corresponding node. As the structure’s surface is formed by these IBPs, the internal fluid remains entirely isolated from the external fluid, inherently satisfying the condition of a zero normal pressure gradient on the surface.

$= 10$

, the resolution is 1/16 . Notably, when the stem deforms, the plane of each layer, composed of 256 IBPs, remains perpendicular to the tangent line at the corresponding node. As the structure’s surface is formed by these IBPs, the internal fluid remains entirely isolated from the external fluid, inherently satisfying the condition of a zero normal pressure gradient on the surface.

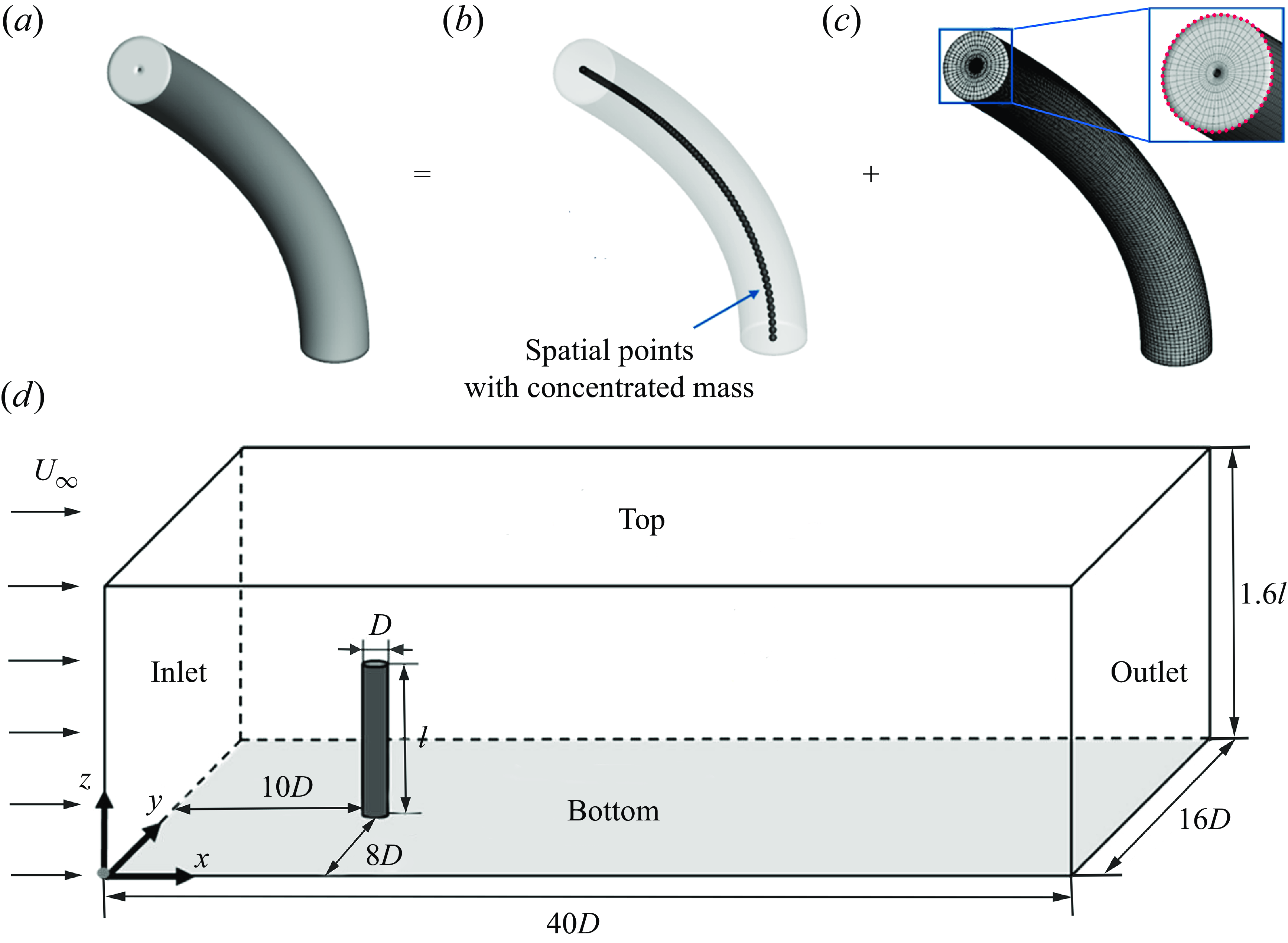

To discretise equation (2.1), the second-order Adams–Bashforth time scheme and the second-order central difference scheme are applied, which lead to the following conservation form:

\begin{equation} \left .\begin{array}{cc} \boldsymbol{u}^{n+1}=\boldsymbol{u}^n+\delta t\left (\frac {3}{2} \boldsymbol{h}^n-\frac {1}{2} \boldsymbol{h}^{n-1}-\frac {3}{2} \nabla p^n+\frac {1}{2} \nabla p^{n-1}\right )+\boldsymbol{f}^{n+\frac {1}{2}} \delta t \\ \nabla \cdot \boldsymbol{u}^{n+1}=0 ,\end{array}\right \} \end{equation}

\begin{equation} \left .\begin{array}{cc} \boldsymbol{u}^{n+1}=\boldsymbol{u}^n+\delta t\left (\frac {3}{2} \boldsymbol{h}^n-\frac {1}{2} \boldsymbol{h}^{n-1}-\frac {3}{2} \nabla p^n+\frac {1}{2} \nabla p^{n-1}\right )+\boldsymbol{f}^{n+\frac {1}{2}} \delta t \\ \nabla \cdot \boldsymbol{u}^{n+1}=0 ,\end{array}\right \} \end{equation}

where

![]() $\boldsymbol{h}=\nabla \cdot (-\boldsymbol{u} \boldsymbol{u}+ (v+v_t ) (\nabla \boldsymbol{u}+\nabla \boldsymbol{u}^T ) )$

is composed of the convective and diffusive terms, in which the superscript

$\boldsymbol{h}=\nabla \cdot (-\boldsymbol{u} \boldsymbol{u}+ (v+v_t ) (\nabla \boldsymbol{u}+\nabla \boldsymbol{u}^T ) )$

is composed of the convective and diffusive terms, in which the superscript

![]() $T$

is the transpose of a matrix and

$T$

is the transpose of a matrix and

![]() $\nu _t$

is the turbulence eddy viscosity. Superscripts

$\nu _t$

is the turbulence eddy viscosity. Superscripts

![]() $n$

+1,

$n$

+1,

![]() $n$

+1/2,

$n$

+1/2,

![]() $n$

and

$n$

and

![]() $n$

–1 indicate the time steps. The extra force

$n$

–1 indicate the time steps. The extra force

![]() $\boldsymbol{f}$

is determined by setting the velocity consistent condition

$\boldsymbol{f}$

is determined by setting the velocity consistent condition

![]() $U^{n+1}=V^{n+1}$

on the fluid–structure interface, where

$U^{n+1}=V^{n+1}$

on the fluid–structure interface, where

![]() $U^{n+1}$

is the interpolated fluid velocity and

$U^{n+1}$

is the interpolated fluid velocity and

![]() $V^{n+1}$

is the update structure velocity. Extra force

$V^{n+1}$

is the update structure velocity. Extra force

![]() $\boldsymbol{f}$

is formally evaluated at the time step

$\boldsymbol{f}$

is formally evaluated at the time step

![]() $n + 1/2$

$n + 1/2$

where

![]() $\boldsymbol{F}$

is the extra body force on the structure and

$\boldsymbol{F}$

is the extra body force on the structure and

![]() $\boldsymbol{v}^{n+1}=\boldsymbol{V}^{n+1}+\boldsymbol{r} \times \boldsymbol{\omega }^{n+1}$

is the desired velocity on the IBPs obtained by solving equation (2.3), in which

$\boldsymbol{v}^{n+1}=\boldsymbol{V}^{n+1}+\boldsymbol{r} \times \boldsymbol{\omega }^{n+1}$

is the desired velocity on the IBPs obtained by solving equation (2.3), in which

![]() $\boldsymbol{r}$

is a vector from a node to an IBP. The interpolation and distribution functions,

$\boldsymbol{r}$

is a vector from a node to an IBP. The interpolation and distribution functions,

![]() $I$

and

$I$

and

![]() $D$

, suggested in Peskin (Reference Peskin1972) are applied, which are responsible for data transfer between the non-conforming Eulerian and Lagrangian grids.

$D$

, suggested in Peskin (Reference Peskin1972) are applied, which are responsible for data transfer between the non-conforming Eulerian and Lagrangian grids.

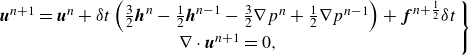

Figure 4. (

![]() $a$

,

$a$

,

![]() $b$

,

$b$

,

![]() $c$

) The wall-mounted flexible stem model in the present simulation and (

$c$

) The wall-mounted flexible stem model in the present simulation and (

![]() $d$

) the numerical set-up of the computational domain (not to scale). Part of the IBPs on the top surface are marked by the red dots in (

$d$

) the numerical set-up of the computational domain (not to scale). Part of the IBPs on the top surface are marked by the red dots in (

![]() $c$

).

$c$

).

2.4. Coupling between the fluid and structures

As mentioned earlier, in the present method, the wall-mounted flexible stem is materialised by the IBPs on the solid surface, see figure 4(a–c). However, as the stem’s motion is defined by spatial points with concentrated mass, an appropriate approach is needed to effectively transfer the fluid force from the surface IBPs to these spatial points. During each iteration of fluid-structure coupling, the solid surface surrounding these mass points is reconstructed using IBPs, see figure 4(

![]() $c$

). The fluid force on these reconstructed solid surface IBPs is then applied to the corresponding mass points as external forces. Consequently, the motion of each node is determined using (2.3). Simultaneously, the flow velocity and pressure are updated, and the velocity on the immersed boundary is corrected, thereby establishing the coupling between the fluid and the structure. It is important to note that the critical time step for solid motion is significantly smaller than that for the fluid. Therefore, within each fluid time step, the solid motion must be iterated multiple times under the assumption that the fluid forces remain unchanged.

$c$

). The fluid force on these reconstructed solid surface IBPs is then applied to the corresponding mass points as external forces. Consequently, the motion of each node is determined using (2.3). Simultaneously, the flow velocity and pressure are updated, and the velocity on the immersed boundary is corrected, thereby establishing the coupling between the fluid and the structure. It is important to note that the critical time step for solid motion is significantly smaller than that for the fluid. Therefore, within each fluid time step, the solid motion must be iterated multiple times under the assumption that the fluid forces remain unchanged.

Figure 5. Model for the deformation of a flexible stem under uniform loading.

3. Validation

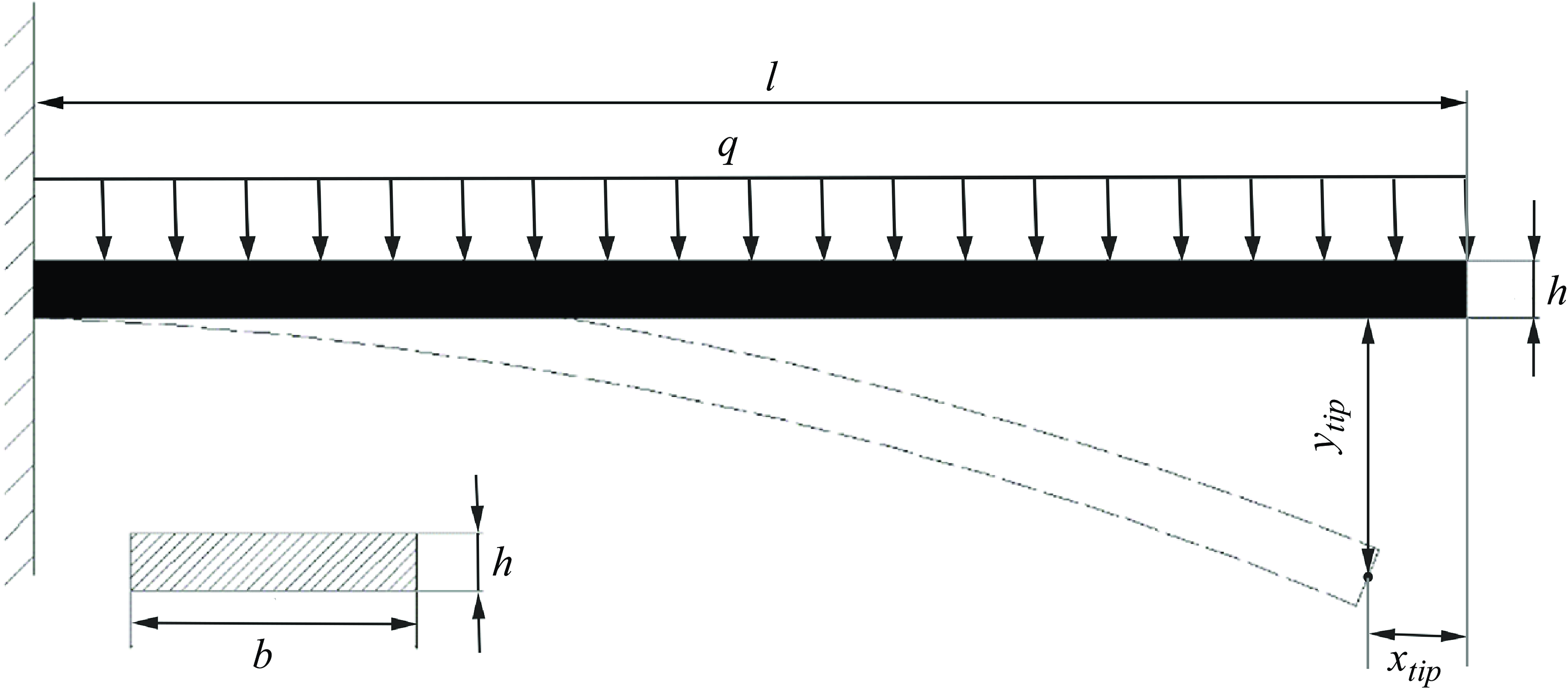

3.1. The deformation of a cantilever plate under uniform loading

First, we verify the codes for pure deformation of a wall-mounted flexible stem with a rectangular cross-section under uniform loading. As modelled in figure 5, the cantilever plate is wall mounted under uniform loading. The geometric parameters for the plate are the length (

![]() $l$

) of 5 cm, the width (

$l$

) of 5 cm, the width (

![]() $b$

) of 1 cm and the thickness (

$b$

) of 1 cm and the thickness (

![]() $h$

) of 0.2 cm. The plate density is 0.678 g cm–

$h$

) of 0.2 cm. The plate density is 0.678 g cm–

![]() $^3$

, the elastic modulus is 5

$^3$

, the elastic modulus is 5

![]() $\times$

$\times$

![]() $10^5$

Pa and Poisson’s ratio is 0.4. The uniform loading varies in the range of

$10^5$

Pa and Poisson’s ratio is 0.4. The uniform loading varies in the range of

![]() $q=$

0.0001–0.0008 N cm–1. The plate is divided into elements, i.e. 10, 25 and 50. The corresponding grid in the vertical direction (along the length) is

$q=$

0.0001–0.0008 N cm–1. The plate is divided into elements, i.e. 10, 25 and 50. The corresponding grid in the vertical direction (along the length) is

![]() ${\rm d}x_s$

. For different situations, the time step is controlled to be smaller than the critical time step

${\rm d}x_s$

. For different situations, the time step is controlled to be smaller than the critical time step

![]() ${\rm d}t_s^0$

calculated using the equation of

${\rm d}t_s^0$

calculated using the equation of

![]() ${\rm d}t_s^0 = {\rm d}x_s/\sqrt{E/\rho_s}$

, where E is Young’s modulus, and

${\rm d}t_s^0 = {\rm d}x_s/\sqrt{E/\rho_s}$

, where E is Young’s modulus, and

![]() $\rho_s$

is the plate density. The structural damping is set as

$\rho_s$

is the plate density. The structural damping is set as

![]() $\zeta=$

0.

$\zeta=$

0.

Based on the deformation theory of a plate under uniform loading (

![]() $q$

), the final deformation curve follows the equation

$q$

), the final deformation curve follows the equation

where

![]() $x$

is the distance of one point to the fixed end (positive in the

$x$

is the distance of one point to the fixed end (positive in the

![]() $x$

direction),

$x$

direction),

![]() $v(x)$

is the final deformation of the plate and

$v(x)$

is the final deformation of the plate and

![]() $I=bh^3/12$

is the cross-sectional inertial moment of the plate.

$I=bh^3/12$

is the cross-sectional inertial moment of the plate.

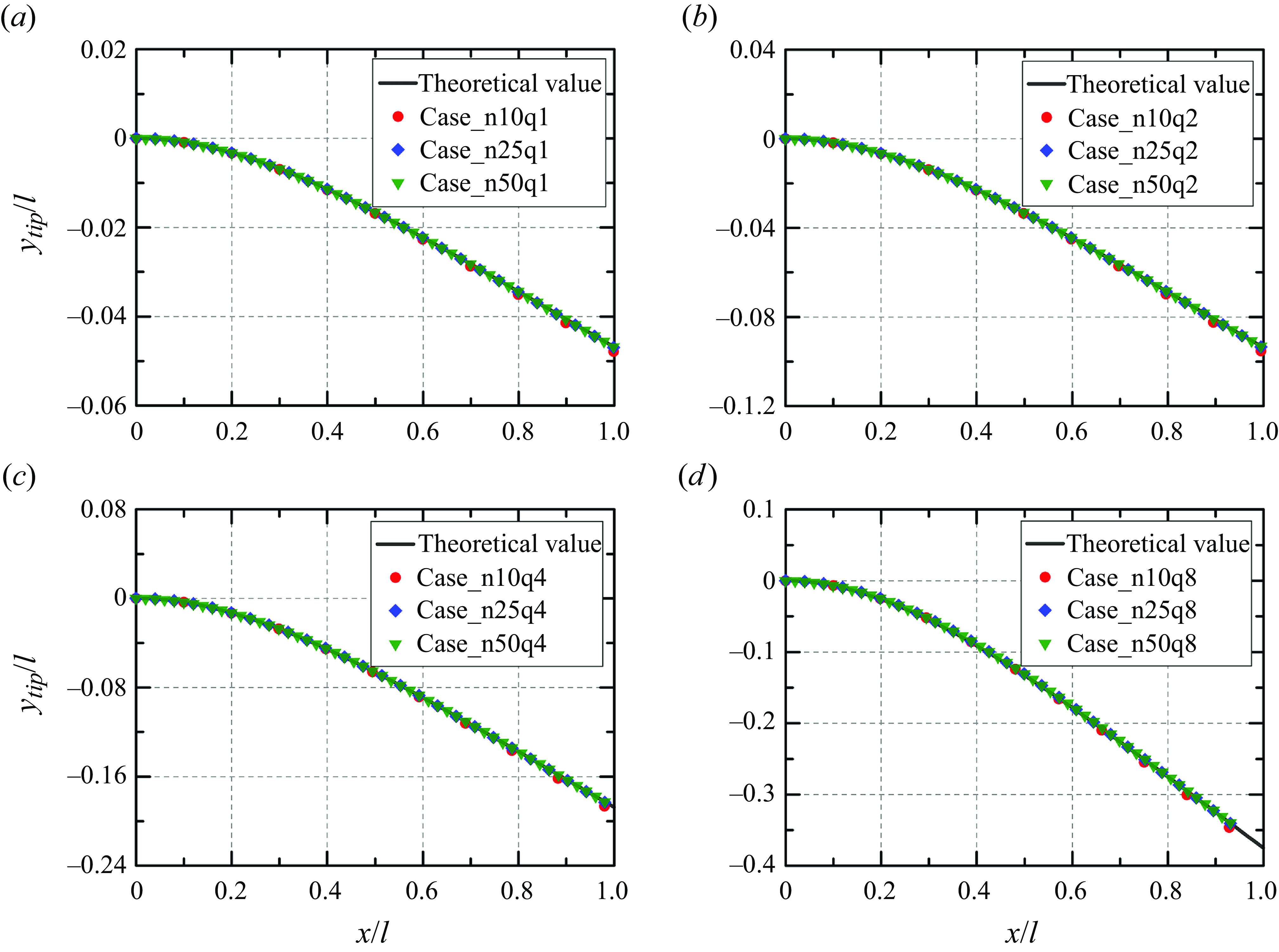

Figure 6. Comparison of the transverse shift of the tip with the theoretical value for a plate under uniform loading. Here, Case_n10q1 represents the case of the plate divided into 10 elements and under the loading of

![]() $q = 0.0001$

N cm–1. The naming scheme is applied for other cases. For example, Case_n25q8 denotes the case of the plate divided into 25 elements and under the loading of

$q = 0.0001$

N cm–1. The naming scheme is applied for other cases. For example, Case_n25q8 denotes the case of the plate divided into 25 elements and under the loading of

![]() $q = 0.0008$

N cm−1.

$q = 0.0008$

N cm−1.

Figure 7. (

![]() $a$

) The relative difference of the deformation at the free plate end versus the dimensions of the uniform loading, and (

$a$

) The relative difference of the deformation at the free plate end versus the dimensions of the uniform loading, and (

![]() $b$

) the relative difference of the vibration frequency of the plate with different elements versus the uniform loading.

$b$

) the relative difference of the vibration frequency of the plate with different elements versus the uniform loading.

Figure 6 shows the comparison of the simulated results and theoretical results. It is seen that the model for the plate motion can accurately predict the deformation of the plate. Further, the number of elements in the simulation is also essential. The difference (in percentage) between the simulation and the theoretical value becomes higher as it gets closer to the free end of the plate, which is related to the deformation growing smaller. Thus, it requires a higher number of elements. As shown in figure 7, after the element number exceeds 25, the simulated deformation and vibration frequency match very well the theoretical results. The relative difference generally gets smaller when the loading is higher. Here, the relative differences for the deformation and vibration frequency are defined as

![]() $\Delta v_{tip}=(v_{tip}-v_{tip}^0 )/v_{tip}^0$

and

$\Delta v_{tip}=(v_{tip}-v_{tip}^0 )/v_{tip}^0$

and

![]() $\Delta f_{1}=(f_{1}-f_{1}^0 )/f_{1}^0$

, respectively, where

$\Delta f_{1}=(f_{1}-f_{1}^0 )/f_{1}^0$

, respectively, where

![]() $v_{tip}$

is the simulated deformation,

$v_{tip}$

is the simulated deformation,

![]() $v_{tip}^0$

is the theoretical solution,

$v_{tip}^0$

is the theoretical solution,

![]() $f_{1}$

is the simulated vibration frequency and

$f_{1}$

is the simulated vibration frequency and

![]() $f_{1}^0$

is the theoretical value.

$f_{1}^0$

is the theoretical value.

3.2. Flexible plate in uniform channel flow

In this section, we validate the codes through a benchmark case of a wall-mounted flexible plate in uniform channel flow. Interactions between the fluid and plate are considered. Luhar & Nepf (Reference Luhar and Nepf2011) carried out a series of model experiments in the channel flow on a flexible plate, widely used to compare numerical or experimental results. To check the fidelity of our present numerical methodology, we compare our numerical results with those of Luhar & Nepf (Reference Luhar and Nepf2011).

In our present simulation, the setting of the computational domain is very similar to the water flume experiment in Luhar & Nepf (Reference Luhar and Nepf2011), see their figure 3. Based on this, the computational domain is 40 cm

![]() $\times$

16 cm

$\times$

16 cm

![]() $\times$

16 cm in length, width and height, respectively. The water depth in the channel is 16 cm. In the inlet, the incoming flow is a uniform velocity

$\times$

16 cm in length, width and height, respectively. The water depth in the channel is 16 cm. In the inlet, the incoming flow is a uniform velocity

![]() $U_\infty$

, while the velocity condition is applied in the outlet. For the top and lateral walls, free-slip boundaries are adopted. The bottom is a no-slip boundary and the wall function developed by Werner & Wengle (Reference Werner, Wengle, Durst, Friedrich, Launder, Schumann and Whitelaw1993) was used. The geometric parameters for the flexible plate are the length (

$U_\infty$

, while the velocity condition is applied in the outlet. For the top and lateral walls, free-slip boundaries are adopted. The bottom is a no-slip boundary and the wall function developed by Werner & Wengle (Reference Werner, Wengle, Durst, Friedrich, Launder, Schumann and Whitelaw1993) was used. The geometric parameters for the flexible plate are the length (

![]() $l$

) of 5 cm, width (

$l$

) of 5 cm, width (

![]() $b$

) of 1 cm and thickness (

$b$

) of 1 cm and thickness (

![]() $h$

) of 0.2 cm, respectively. The density of the flexible plate is 0.678 g cm–

$h$

) of 0.2 cm, respectively. The density of the flexible plate is 0.678 g cm–

![]() $^3$

, the elastic modulus is

$^3$

, the elastic modulus is

![]() $5 \times 10^5$

Pa and the Poisson ratio is 0.4.

$5 \times 10^5$

Pa and the Poisson ratio is 0.4.

Before the validation, we first carry out a convergence test. A uniform mesh is applied around the flexible plate, and a large region is adopted to cover the possible motion of the plate. Outside this region, the stretched mesh with the constant ratio (not larger than 1.02) is adopted. Therefore, the total meshes is affordable in the present simulations. Four uniform meshes are selected, i.e.

![]() $\Delta h/b=$

0.2, 0.1, 0.0625 and 0.05. Here,

$\Delta h/b=$

0.2, 0.1, 0.0625 and 0.05. Here,

![]() $h$

is the minimum mesh. The dimension (

$h$

is the minimum mesh. The dimension (

![]() ${\rm d}x_s$

) of the solid element is the same as the minimum mesh adopted. The fluid time step (

${\rm d}x_s$

) of the solid element is the same as the minimum mesh adopted. The fluid time step (

![]() ${\rm d}t_f$

) for each situation is smaller than the critical time step (

${\rm d}t_f$

) for each situation is smaller than the critical time step (

![]() ${\rm d}t_f^0$

) calculated through the equation below

${\rm d}t_f^0$

) calculated through the equation below

where

![]() ${\rm d}x_f$

is the fluid mesh,

${\rm d}x_f$

is the fluid mesh,

![]() ${\rm d}x_s$

is the dimension of the solid element,

${\rm d}x_s$

is the dimension of the solid element,

![]() $E$

is Young’s modulus,

$E$

is Young’s modulus,

![]() $\rho _s$

is the solid (or structure) density and

$\rho _s$

is the solid (or structure) density and

![]() $U_\infty$

is the incoming flow velocity. The Reynolds number is

$U_\infty$

is the incoming flow velocity. The Reynolds number is

![]() $Re_b=$

1600 when the width (

$Re_b=$

1600 when the width (

![]() $b$

) of the plate is used as the characteristic length.

$b$

) of the plate is used as the characteristic length.

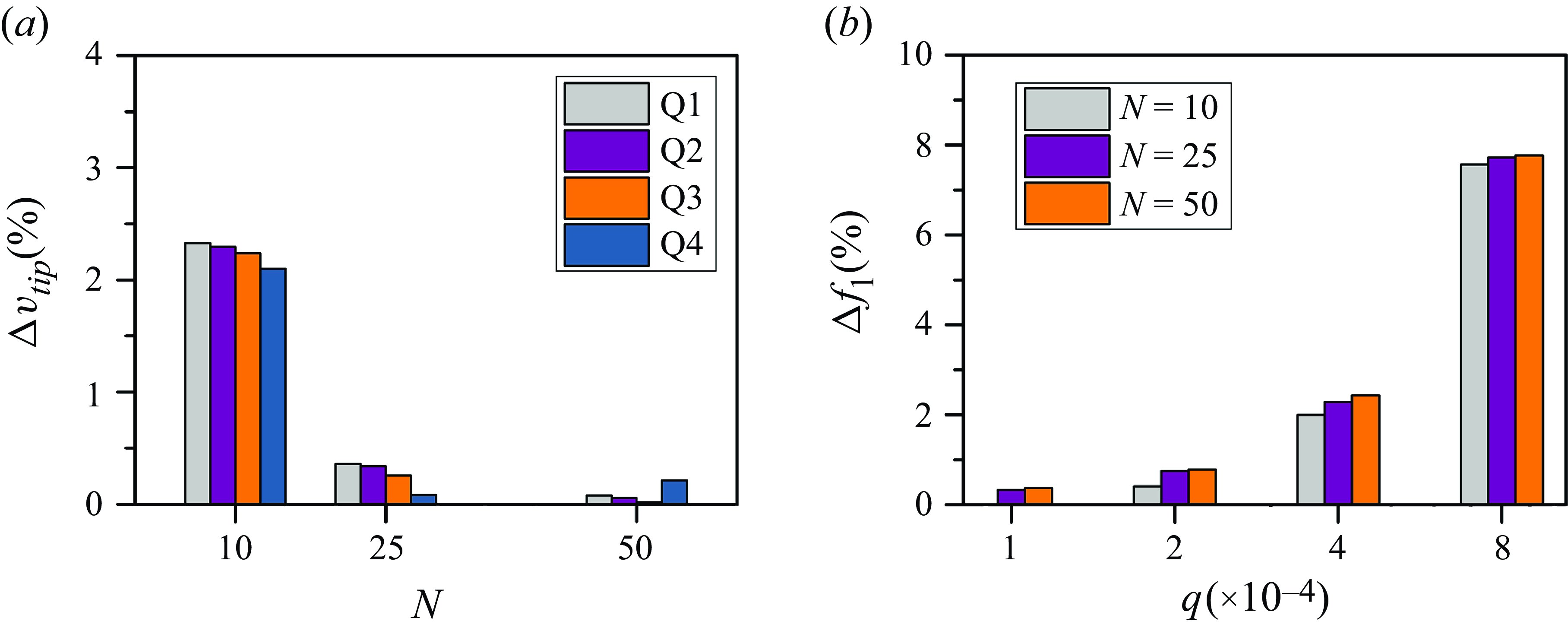

Figure 8(

![]() $a$

) compares the simulation results and those (

$a$

) compares the simulation results and those (

![]() $D_x/b=$

2.14,

$D_x/b=$

2.14,

![]() $D_z/b=$

0.59 and

$D_z/b=$

0.59 and

![]() $C_d=$

1.03) of model experiments in Luhar & Nepf (Reference Luhar and Nepf2011) under different mesh spacings. Here,

$C_d=$

1.03) of model experiments in Luhar & Nepf (Reference Luhar and Nepf2011) under different mesh spacings. Here,

![]() $D_x$

is the deflection of the plate at the free end in the streamwise direction,

$D_x$

is the deflection of the plate at the free end in the streamwise direction,

![]() $D_z$

is the height reduction of the plate at the free end and

$D_z$

is the height reduction of the plate at the free end and

![]() $C_d$

is the drag force because of the flow around the vegetation. It is seen that the relative difference between the present simulation and the experiments of Luhar & Nepf (Reference Luhar and Nepf2011) becomes lower as the mesh is finer. When the mesh is no larger than

$C_d$

is the drag force because of the flow around the vegetation. It is seen that the relative difference between the present simulation and the experiments of Luhar & Nepf (Reference Luhar and Nepf2011) becomes lower as the mesh is finer. When the mesh is no larger than

![]() $\Delta h/b=$

0.0625, the relative errors for

$\Delta h/b=$

0.0625, the relative errors for

![]() $D_x/b$

and

$D_x/b$

and

![]() $C_d$

are lower than 1

$C_d$

are lower than 1

![]() $\, \%$

and smaller than 6

$\, \%$

and smaller than 6

![]() $\, \%$

for

$\, \%$

for

![]() $D_z/b$

. Thus, our numerical results agree well with the experiments of Luhar & Nepf (Reference Luhar and Nepf2011), suggesting a high fidelity of the present numerical methodology. Further, the mesh with

$D_z/b$

. Thus, our numerical results agree well with the experiments of Luhar & Nepf (Reference Luhar and Nepf2011), suggesting a high fidelity of the present numerical methodology. Further, the mesh with

![]() $h/b$

smaller than 0.0625 is an appropriate choice for our following simulations.

$h/b$

smaller than 0.0625 is an appropriate choice for our following simulations.

The incoming flow velocities, including

![]() $U_\infty=$

3.6, 11.0, 16.0 and 27.0 cm s–1, are simulated and compared with the experiments in Luhar & Nepf (Reference Luhar and Nepf2011) for further validation. The mesh with

$U_\infty=$

3.6, 11.0, 16.0 and 27.0 cm s–1, are simulated and compared with the experiments in Luhar & Nepf (Reference Luhar and Nepf2011) for further validation. The mesh with

![]() $\Delta h/b=$

0.0625 is adopted. Figure 8(

$\Delta h/b=$

0.0625 is adopted. Figure 8(

![]() $b$

) compares the drag force (

$b$

) compares the drag force (

![]() $F_d$

) acting on the plate of the present simulation with both model predictions and experiment results. It is seen that the present simulation results are well matched with those in the experiments. This again indicates that our present methodology has high fidelity in simulating flexible plates in uniform channel flow.

$F_d$

) acting on the plate of the present simulation with both model predictions and experiment results. It is seen that the present simulation results are well matched with those in the experiments. This again indicates that our present methodology has high fidelity in simulating flexible plates in uniform channel flow.

Figure 8. (

![]() $a$

) The relative errors in hydrodynamic forces with different

$a$

) The relative errors in hydrodynamic forces with different

![]() $b/h$

values and (

$b/h$

values and (

![]() $b$

) comparison of the drag force with prediction values and experimental results in Luhar & Nepf (Reference Luhar and Nepf2011).

$b$

) comparison of the drag force with prediction values and experimental results in Luhar & Nepf (Reference Luhar and Nepf2011).

3.3. Flexible stem under uniform loading

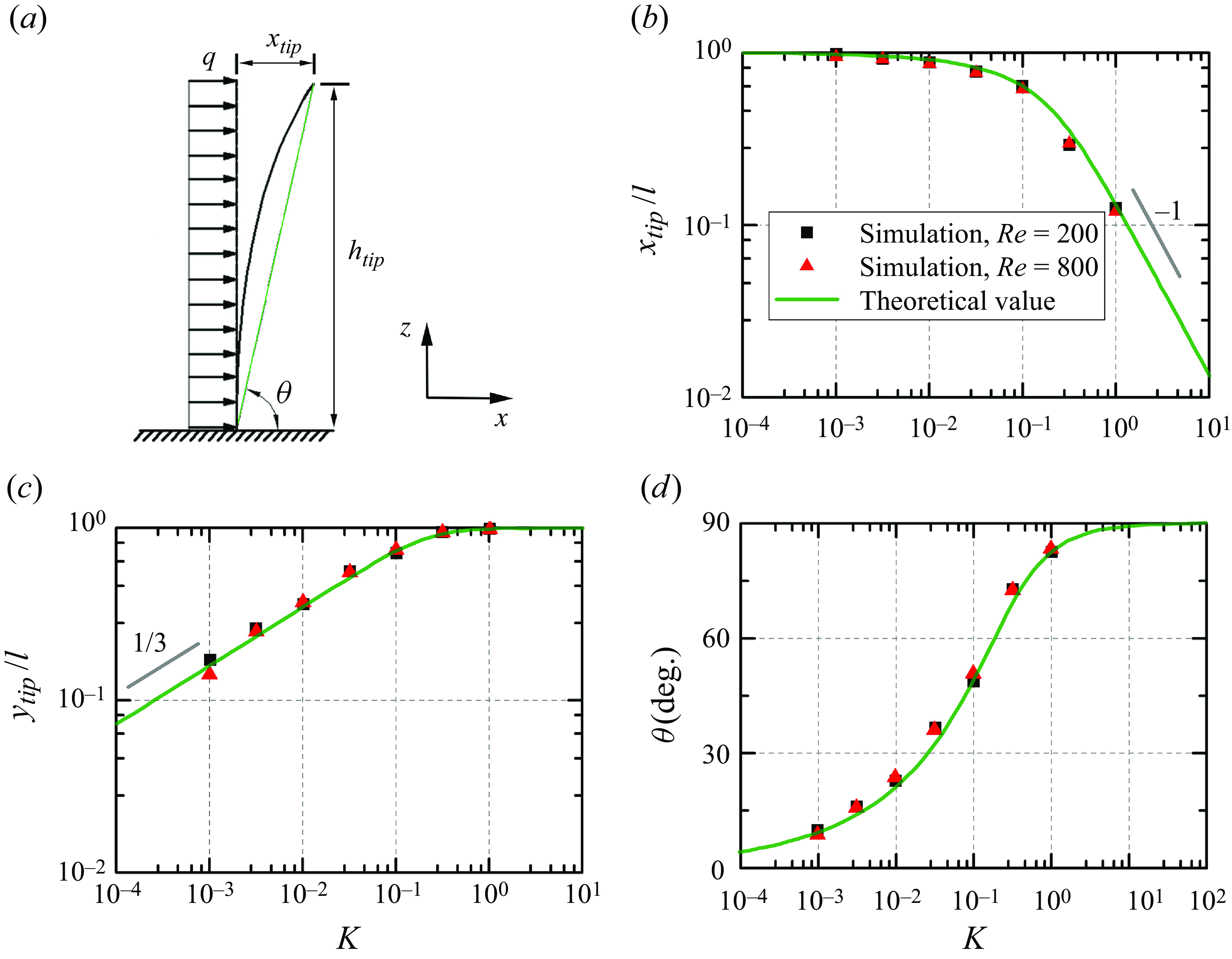

In this section, the deformation, including the tip position in the

![]() $x$

and

$x$

and

![]() $z$

directions and inclination angle of the chord line (i.e. between the tip and root) and horizontal line of a wall-mounted stem under uniform loading, is investigated and verified against the theoretical value, see figure 9(

$z$

directions and inclination angle of the chord line (i.e. between the tip and root) and horizontal line of a wall-mounted stem under uniform loading, is investigated and verified against the theoretical value, see figure 9(

![]() $a$

). The aspect ratio is AR

$a$

). The aspect ratio is AR

![]() $= 10$

and the uniform loading

$= 10$

and the uniform loading

![]() $q$

is given according to the drag coefficient on the rigid stem. Figure 9(b–d) compares our simulation results with the theoretical value. It shows a good agreement for all three deformation quantities, thus suggesting a high fidelity.

$q$

is given according to the drag coefficient on the rigid stem. Figure 9(b–d) compares our simulation results with the theoretical value. It shows a good agreement for all three deformation quantities, thus suggesting a high fidelity.

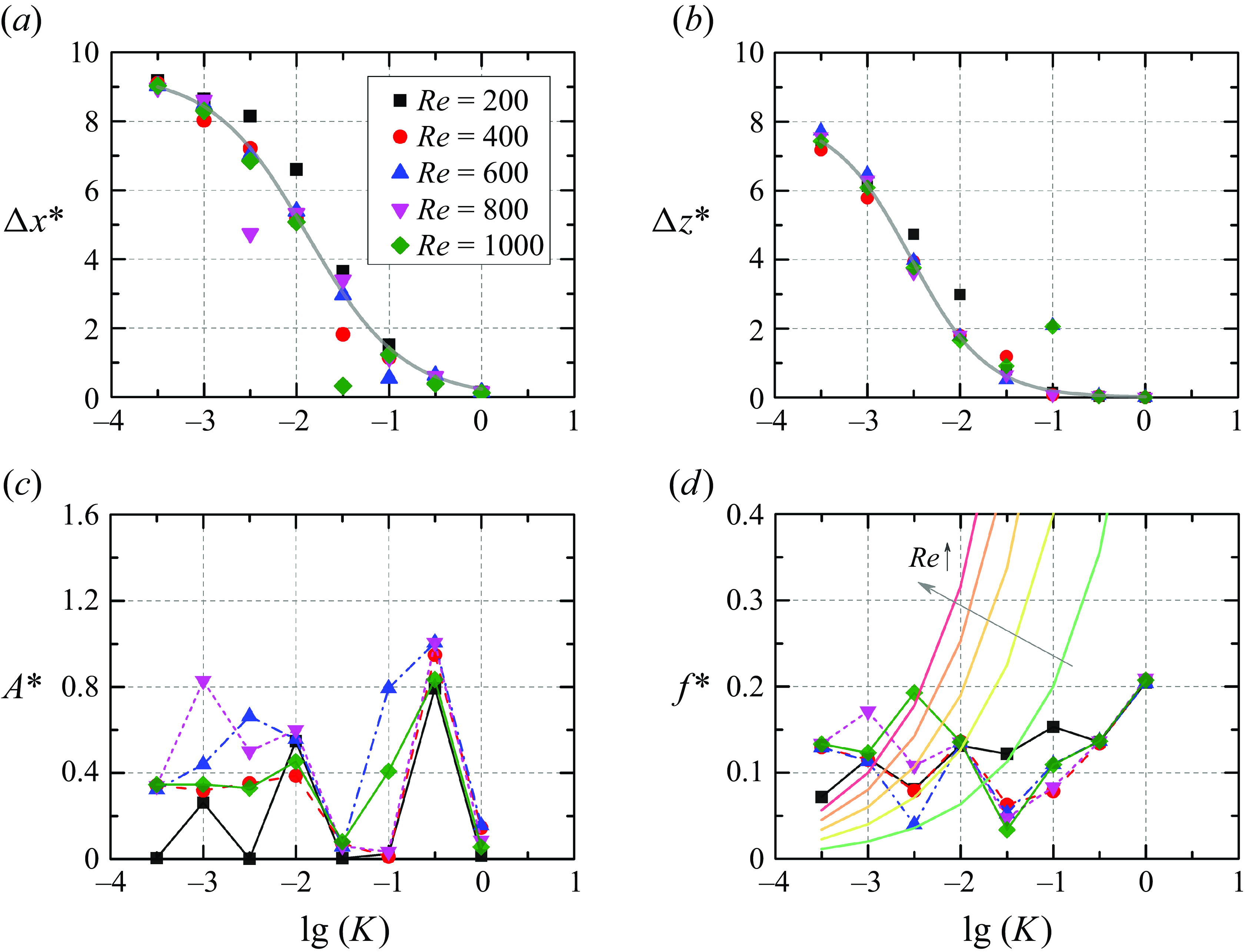

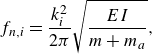

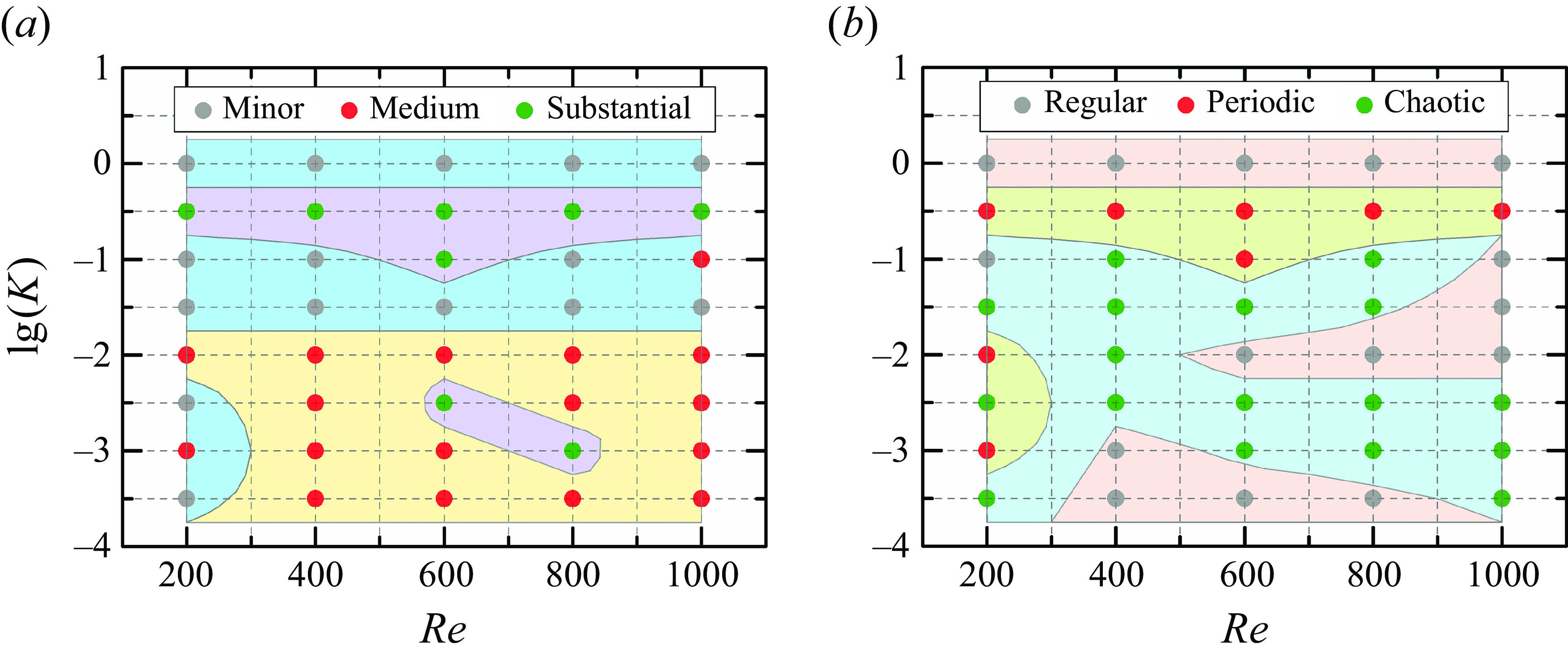

As shown in figure 9(

![]() $b$

,

$b$

,

![]() $c$

), the tip position in either direction is dominated by stem stiffness while it is independent of

$c$

), the tip position in either direction is dominated by stem stiffness while it is independent of

![]() $Re$

. With increasing

$Re$

. With increasing

![]() $K$

,

$K$

,

![]() $x_{tip}/l$

decreases while

$x_{tip}/l$

decreases while

![]() $h_{tip}/l$

increases gradually, corresponding to the state changing from upright to lodging. However, when lg(

$h_{tip}/l$

increases gradually, corresponding to the state changing from upright to lodging. However, when lg(

![]() $K$

)

$K$

)

![]() $\gt$

0,

$\gt$

0,

![]() $h_{tip}/l$

remains almost constant while

$h_{tip}/l$

remains almost constant while

![]() $x_{tip}/l$

decreases approximately linearly when the log–log coordinate is used. When lg(

$x_{tip}/l$

decreases approximately linearly when the log–log coordinate is used. When lg(

![]() $K$

)

$K$

)

![]() $\lt$

–3,

$\lt$

–3,

![]() $h_{tip}/l$

follows the relationship

$h_{tip}/l$

follows the relationship

![]() $h_{tip}/l$

$h_{tip}/l$

![]() $\sim$

$\sim$

![]() $K^{1/3}$

. This relationship was reported in Luhar & Nepf (Reference Luhar and Nepf2011).

$K^{1/3}$

. This relationship was reported in Luhar & Nepf (Reference Luhar and Nepf2011).

As shown in figure 9(

![]() $d$

), the inclination angle

$d$

), the inclination angle

![]() $\theta$

grows with

$\theta$

grows with

![]() $K$

, following the theoretical line. When

$K$

, following the theoretical line. When

![]() $K$

is large, the stem maintains upright, thus

$K$

is large, the stem maintains upright, thus

![]() $\theta$

$\theta$

![]() $\approx$

90

$\approx$

90

![]() $^\circ$

; while

$^\circ$

; while

![]() $K$

is extremely small, the stem maintains nearly parallel to the wall,

$K$

is extremely small, the stem maintains nearly parallel to the wall,

![]() $\theta$

approaches 0

$\theta$

approaches 0

![]() $^\circ$

, indicating a lodging state.

$^\circ$

, indicating a lodging state.

Figure 9. (

![]() $a$

) Schematic of a wall-mounted flexible stem and deformation quantities, (

$a$

) Schematic of a wall-mounted flexible stem and deformation quantities, (

![]() $b$

,

$b$

,

![]() $c$

) the tip position in the

$c$

) the tip position in the

![]() $x$

and

$x$

and

![]() $z$

directions with

$z$

directions with

![]() $K$

, and (

$K$

, and (

![]() $d$

) the inclination angle

$d$

) the inclination angle

![]() $\theta$

with

$\theta$

with

![]() $K$

. The theoretical value is superimposed for comparison.

$K$

. The theoretical value is superimposed for comparison.

Figure 10. (

![]() $a$

,

$a$

,

![]() $c$

) Comparison of the time history of the inclination angle (

$c$

) Comparison of the time history of the inclination angle (

![]() $\theta$

) of the present study with Zhang et al. (Reference Zhang, He and Zhang2020), and (

$\theta$

) of the present study with Zhang et al. (Reference Zhang, He and Zhang2020), and (

![]() $b$

,

$b$

,

![]() $d$

) time history of the inclination angle (

$d$

) time history of the inclination angle (

![]() $\theta$

) at different grid spacings. (

$\theta$

) at different grid spacings. (

![]() $a$

,

$a$

,

![]() $b$

) Are for the case of

$b$

) Are for the case of

![]() $Re = 400$

and

$Re = 400$

and

![]() $\gamma = 0.008$

, and (

$\gamma = 0.008$

, and (

![]() $c$

,

$c$

,

![]() $d$

) are for the case of

$d$

) are for the case of

![]() $Re = 400$

and

$Re = 400$

and

![]() $\gamma = 0.004$

.

$\gamma = 0.004$

.

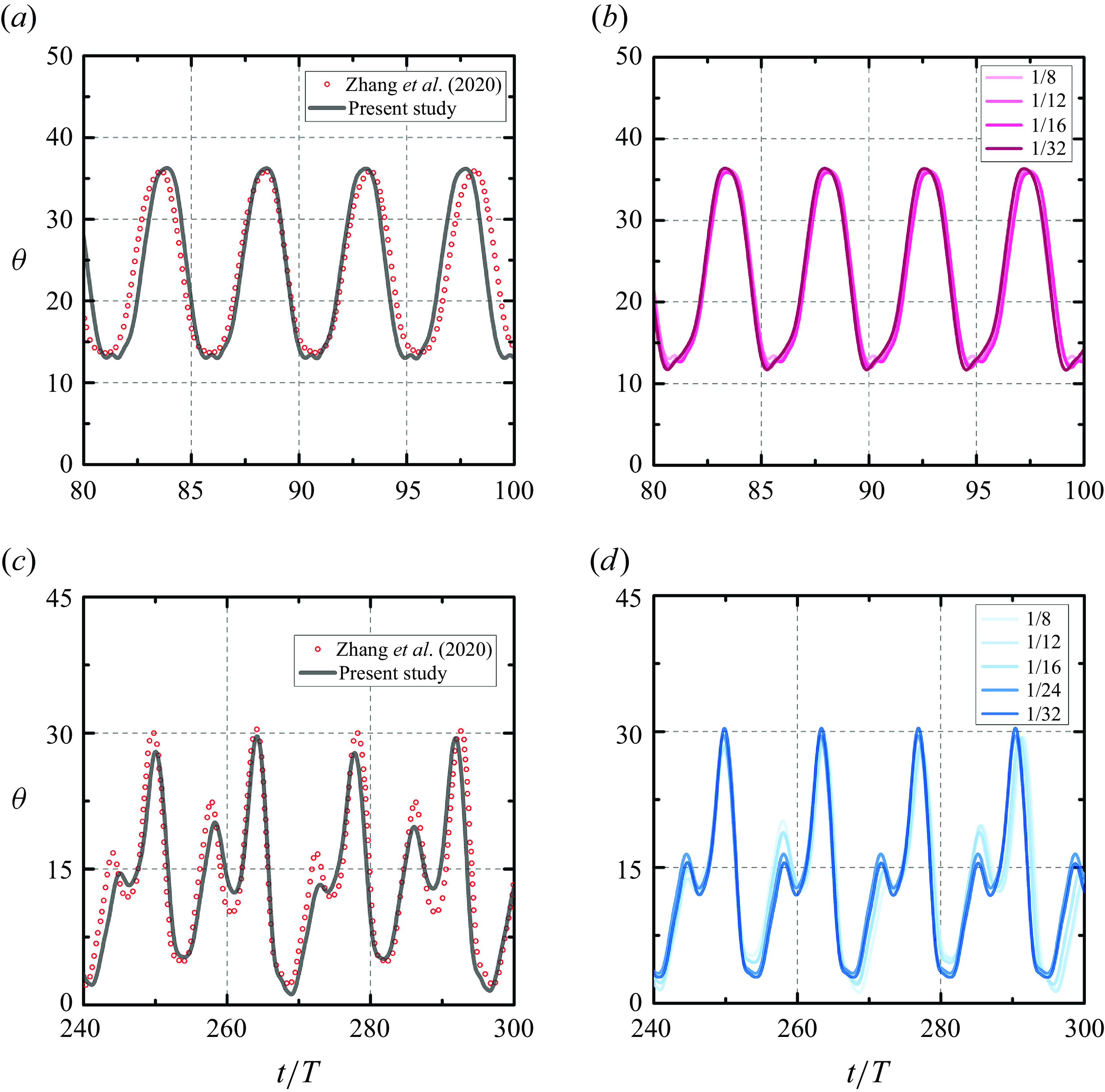

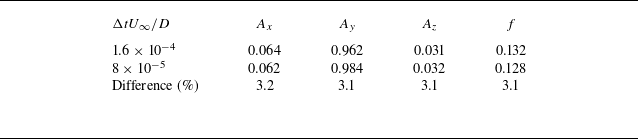

3.4. Dynamics of a flexible filament in uniform flow

In this section, we validate the dynamics of a flexible filament by comparing our simulation results with those in Zhang et al. (Reference Zhang, He and Zhang2020). The computation domain and parameter settings are the same as those in Zhang et al. (Reference Zhang, He and Zhang2020). Two cases are selected: one is at

![]() $\gamma = 0.008$

and the other is at

$\gamma = 0.008$

and the other is at

![]() $\gamma = 0.004$

, with

$\gamma = 0.004$

, with

![]() $\beta$

and

$\beta$

and

![]() $Re$

being constant at 1.0 and 400, respectively. Here,

$Re$

being constant at 1.0 and 400, respectively. Here,

![]() $ Re = {U_{\infty } L}/{v}$

,

$ Re = {U_{\infty } L}/{v}$

,

![]() $\beta = {\rho _s \delta_1 }/{\rho _f L}$

and

$\beta = {\rho _s \delta_1 }/{\rho _f L}$

and

![]() $ \gamma ={B}/{\rho _f U_{\infty }^2 L^3}$

, where

$ \gamma ={B}/{\rho _f U_{\infty }^2 L^3}$

, where

![]() $B$

is the bending rigidity,

$B$

is the bending rigidity,

![]() $L$

is the length of the filament,

$L$

is the length of the filament,

![]() $\rho _s$

is the filament density and

$\rho _s$

is the filament density and

![]() $\delta_1$

is the thickness of the filament.

$\delta_1$

is the thickness of the filament.

The time history of the inclination angle (

![]() $\theta$

) is plotted to check the consistency of the filament dynamics. Figure 10(

$\theta$

) is plotted to check the consistency of the filament dynamics. Figure 10(

![]() $a$

,

$a$

,

![]() $c$

) shows the comparison of our simulation results with those in Zhang et al. (Reference Zhang, He and Zhang2020). Note that the results in figure 10(

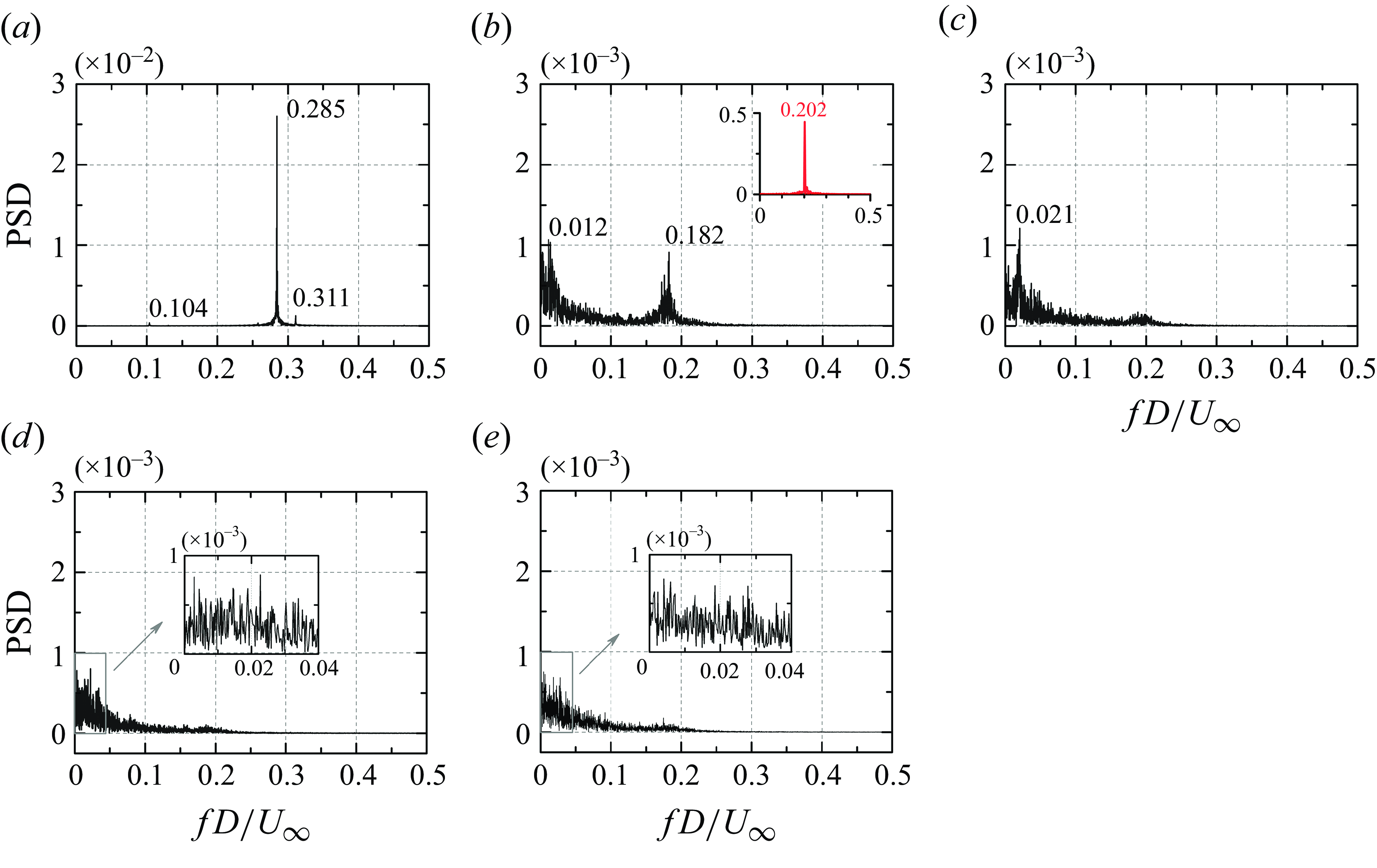

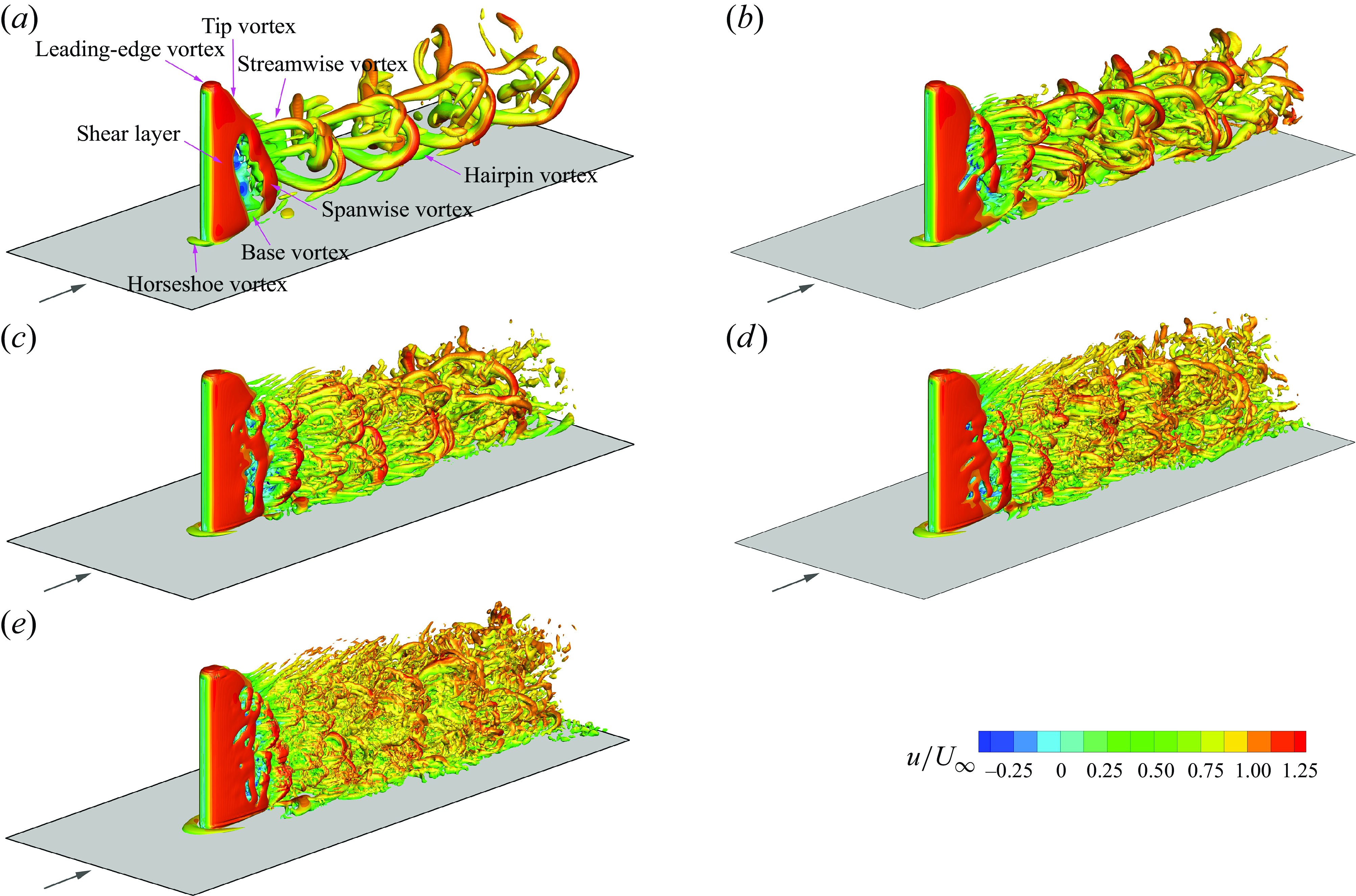

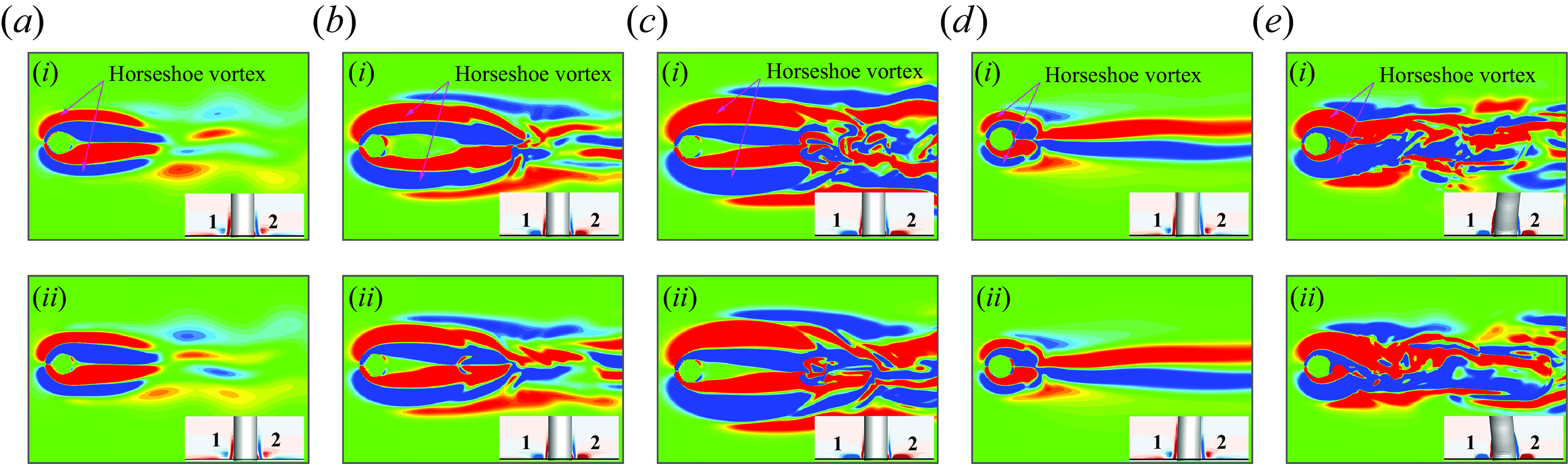

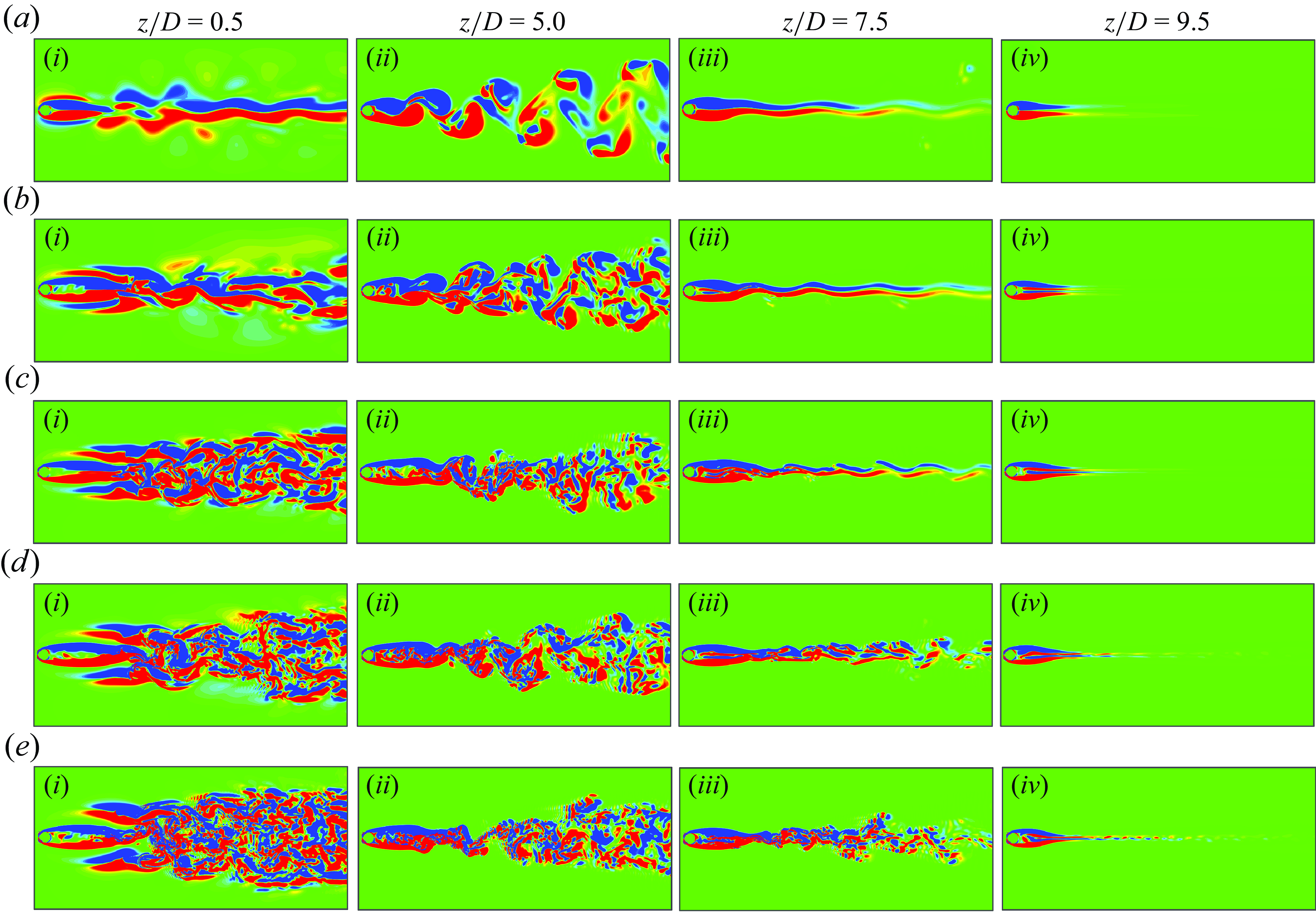

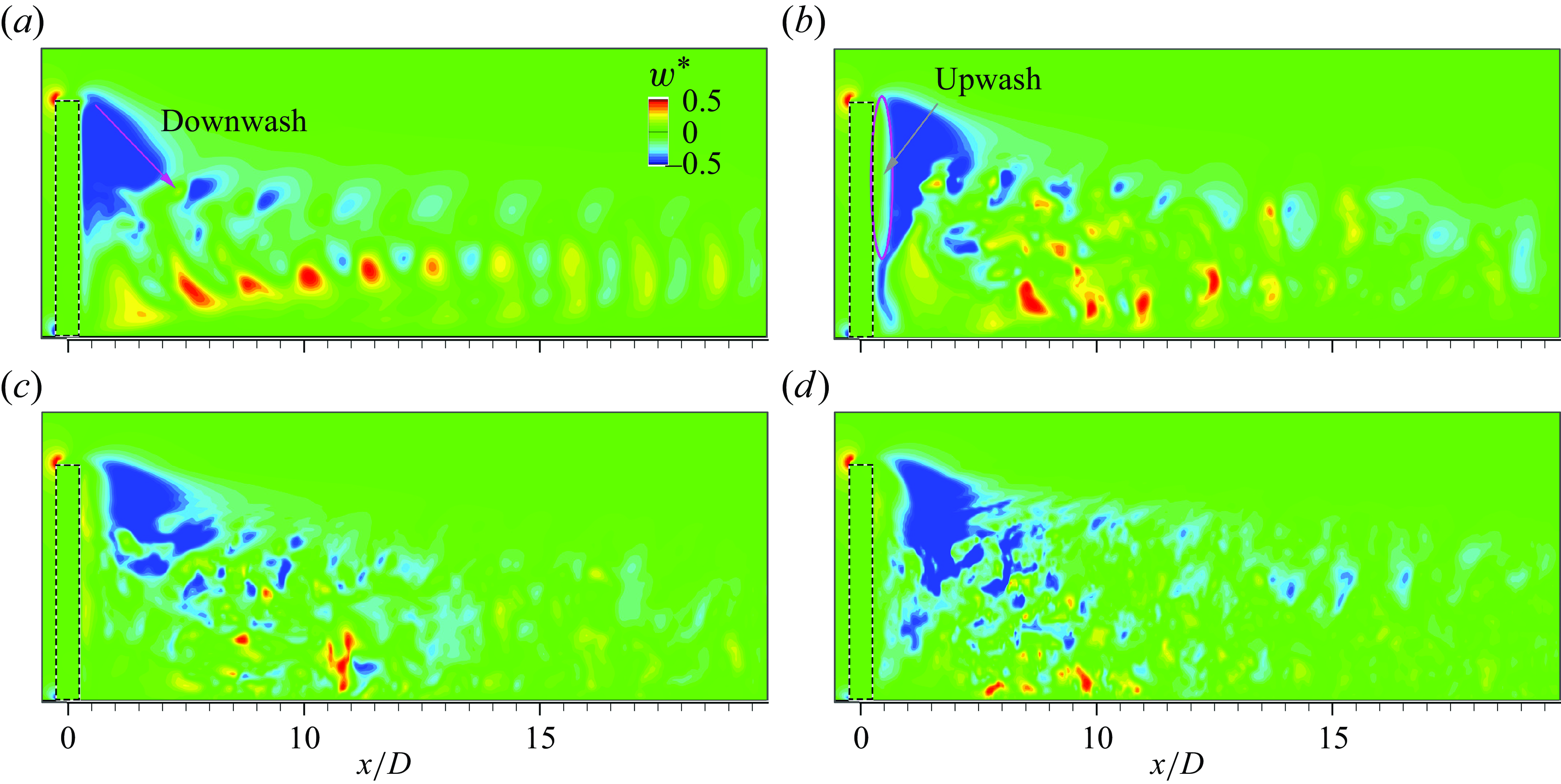

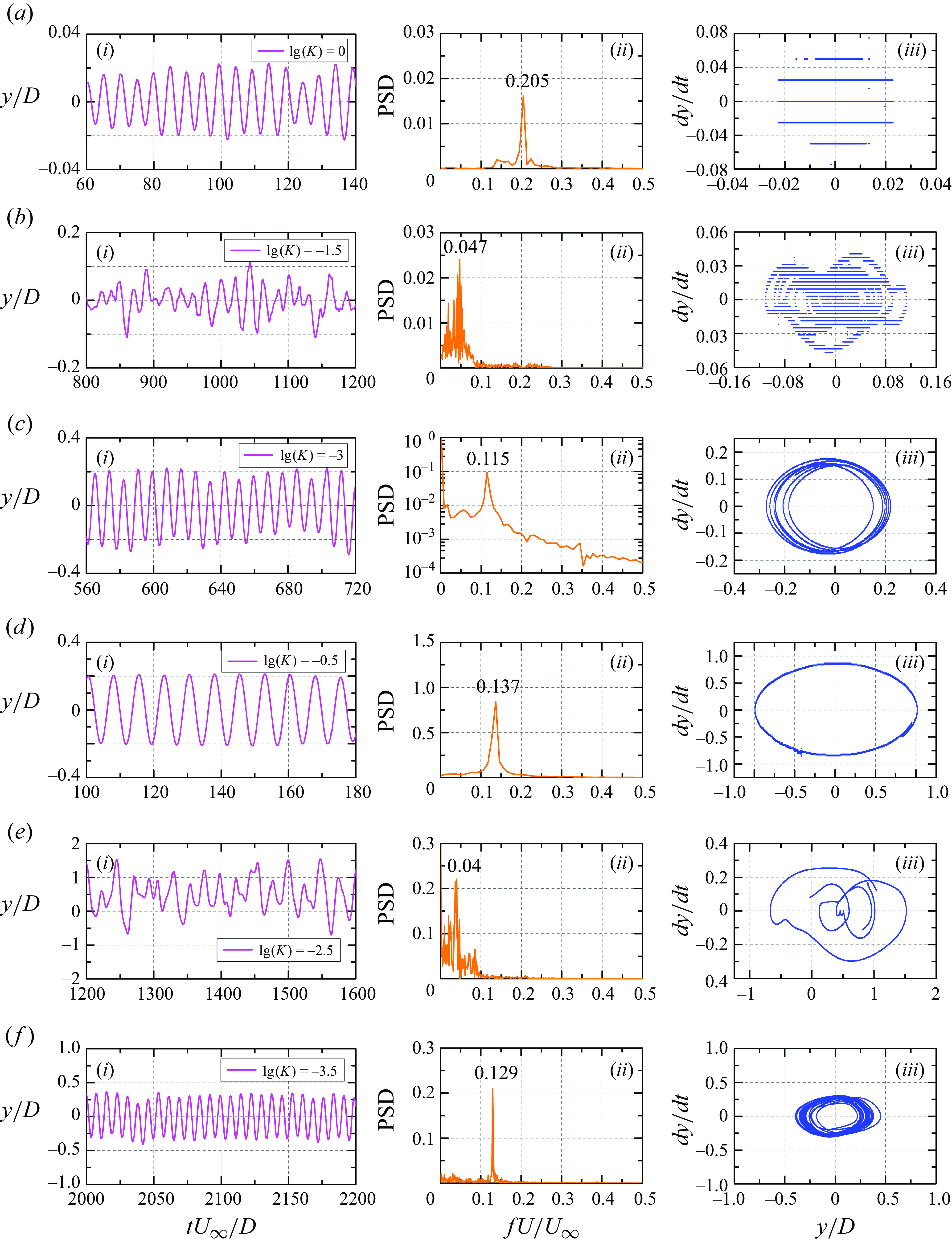

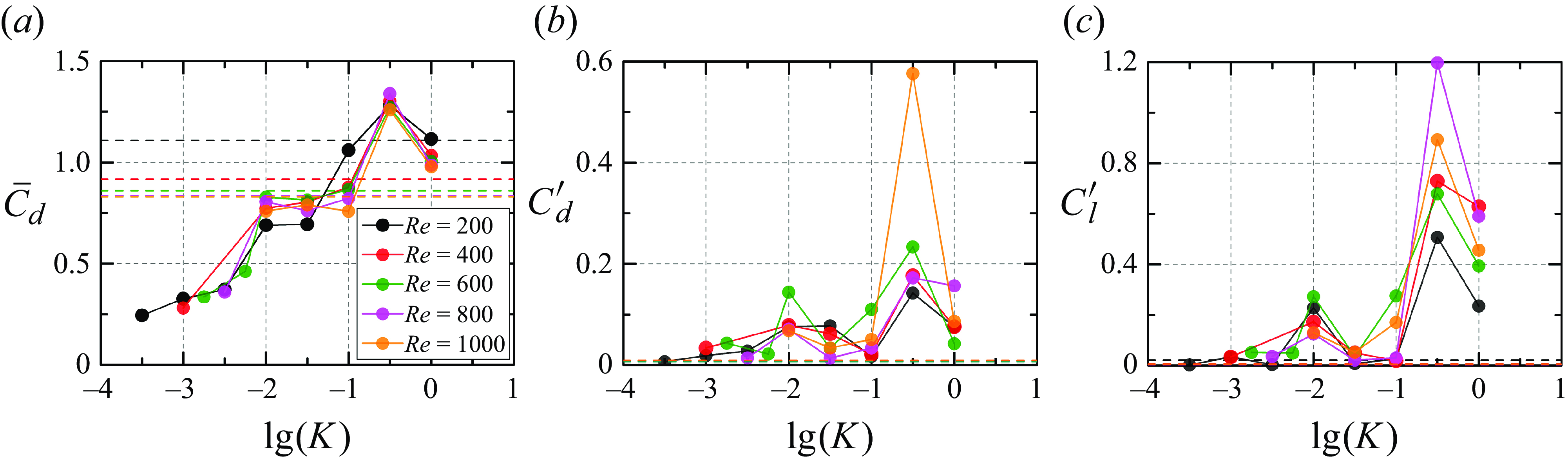

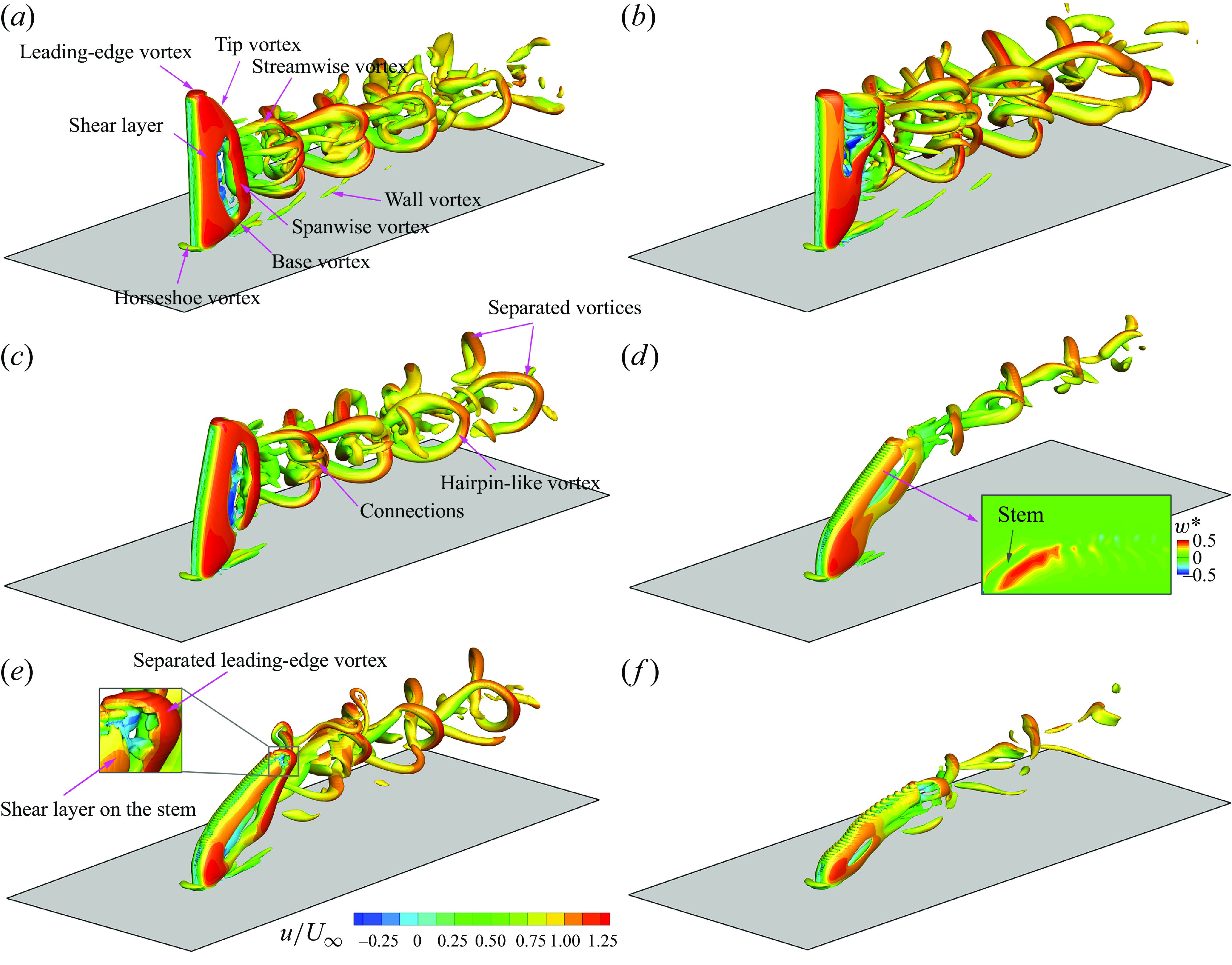

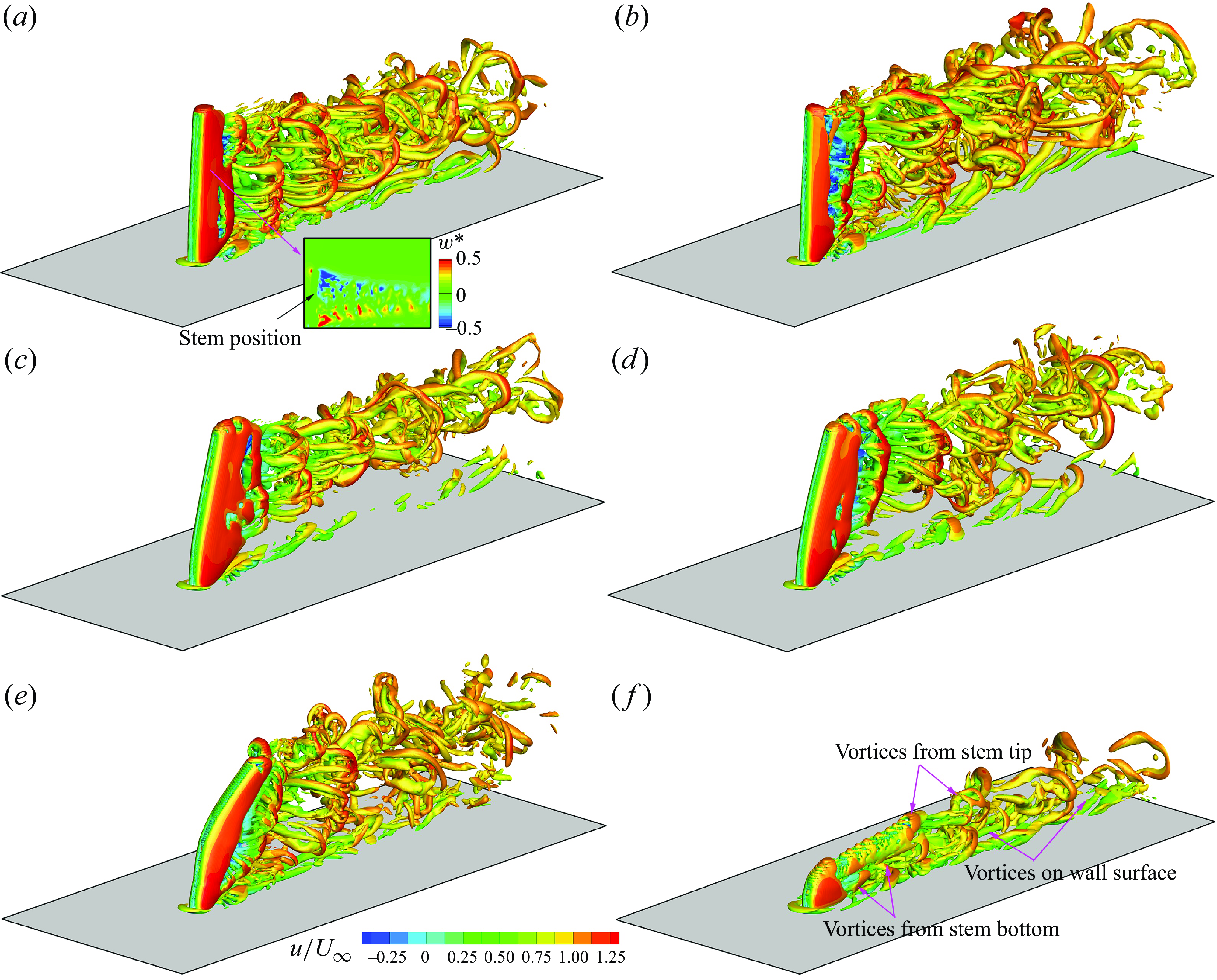

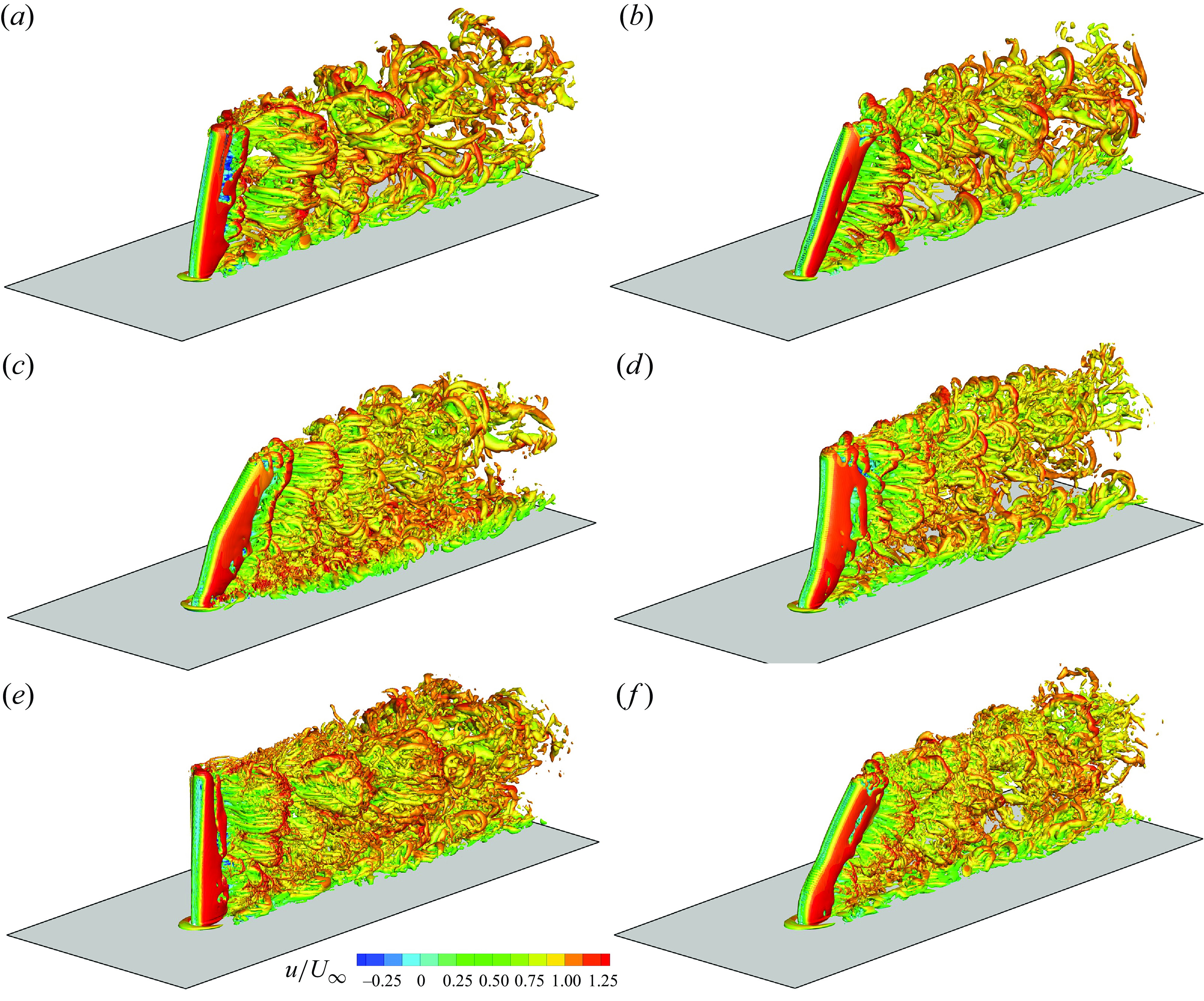

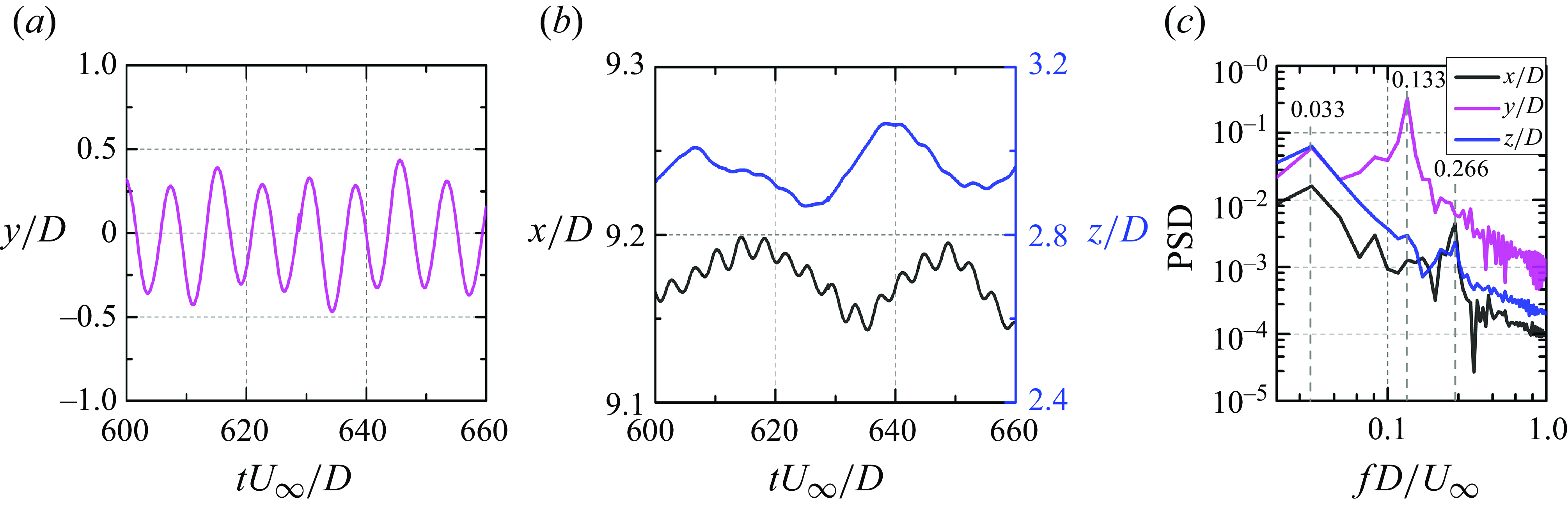

$c$