Refine search

Actions for selected content:

8126 results in Fluid dynamics and solid mechanics

Index

-

- Book:

- Intermediate Dynamics for Engineers

- Published online:

- 08 February 2020

- Print publication:

- 30 January 2020, pp 522-526

-

- Chapter

- Export citation

4 - Lagrange’s Equations of Motion for a System of Particles

- from Part II - A System of Particles

-

- Book:

- Intermediate Dynamics for Engineers

- Published online:

- 08 February 2020

- Print publication:

- 30 January 2020, pp 137-169

-

- Chapter

- Export citation

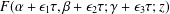

ASYMPTOTICS OF A GAUSS HYPERGEOMETRIC FUNCTION WITH TWO LARGE PARAMETERS: A NEW CASE

- Part of

-

- Journal:

- The ANZIAM Journal / Volume 62 / Issue 4 / October 2020

- Published online by Cambridge University Press:

- 10 December 2019, pp. 446-452

-

- Article

-

- You have access

- Export citation

NUMERICAL ENTROPY PRODUCTION AS SMOOTHNESS INDICATOR FOR SHALLOW WATER EQUATIONS

- Part of

-

- Journal:

- The ANZIAM Journal / Volume 61 / Issue 4 / October 2019

- Published online by Cambridge University Press:

- 28 November 2019, pp. 398-415

-

- Article

-

- You have access

- Export citation

PRICING HOLDER-EXTENDABLE CALL OPTIONS WITH MEAN-REVERTING STOCHASTIC VOLATILITY

- Part of

-

- Journal:

- The ANZIAM Journal / Volume 61 / Issue 4 / October 2019

- Published online by Cambridge University Press:

- 14 October 2019, pp. 382-397

-

- Article

-

- You have access

- Export citation

Multimedia Fluid Mechanics Online

- Site License

-

- Published online:

- 27 September 2019

A MULTIPHASE MULTISCALE MODEL FOR NUTRIENT-LIMITED TISSUE GROWTH, PART II: A SIMPLIFIED DESCRIPTION

- Part of

-

- Journal:

- The ANZIAM Journal / Volume 61 / Issue 4 / October 2019

- Published online by Cambridge University Press:

- 18 September 2019, pp. 368-381

-

- Article

-

- You have access

- Export citation

ANZ VOLUME 61 ISSUE 3 COVER AND BACK MATTER

-

- Journal:

- The ANZIAM Journal / Volume 61 / Issue 3 / July 2019

- Published online by Cambridge University Press:

- 02 September 2019, pp. b1-b6

-

- Article

-

- You have access

- Export citation

ANZ VOLUME 61 ISSUE 3 COVER AND FRONT MATTER

-

- Journal:

- The ANZIAM Journal / Volume 61 / Issue 3 / July 2019

- Published online by Cambridge University Press:

- 02 September 2019, pp. f1-f2

-

- Article

-

- You have access

- Export citation

The Seismic Wavefield

-

- Published online:

- 31 August 2019

- Print publication:

- 23 December 2002

Contents

-

- Book:

- Chemical Kinetics in Combustion and Reactive Flows

- Published online:

- 16 August 2019

- Print publication:

- 22 August 2019, pp ix-xii

-

- Chapter

- Export citation

3 - Software Tools for the Support of Calculation of Combustion and Reacting Flows

- from Part I - Basic Components of Chemical Nonequilibrium Models

-

- Book:

- Chemical Kinetics in Combustion and Reactive Flows

- Published online:

- 16 August 2019

- Print publication:

- 22 August 2019, pp 95-204

-

- Chapter

- Export citation

Part III - Simulation of Combustion and Nonequilibrium Flows in Propulsion and Power Generation Systems

-

- Book:

- Chemical Kinetics in Combustion and Reactive Flows

- Published online:

- 16 August 2019

- Print publication:

- 22 August 2019, pp 281-396

-

- Chapter

- Export citation

Part II - Mathematical Modeling of Selected Typical Modes of Combustion

-

- Book:

- Chemical Kinetics in Combustion and Reactive Flows

- Published online:

- 16 August 2019

- Print publication:

- 22 August 2019, pp 205-280

-

- Chapter

- Export citation

Acknowledgments

-

- Book:

- Chemical Kinetics in Combustion and Reactive Flows

- Published online:

- 16 August 2019

- Print publication:

- 22 August 2019, pp xix-xx

-

- Chapter

- Export citation

Index

-

- Book:

- Chemical Kinetics in Combustion and Reactive Flows

- Published online:

- 16 August 2019

- Print publication:

- 22 August 2019, pp 418-422

-

- Chapter

- Export citation

Preface

-

- Book:

- Chemical Kinetics in Combustion and Reactive Flows

- Published online:

- 16 August 2019

- Print publication:

- 22 August 2019, pp xiii-xviii

-

- Chapter

- Export citation

1 - Approaches to Combustion Simulation

- from Part I - Basic Components of Chemical Nonequilibrium Models

-

- Book:

- Chemical Kinetics in Combustion and Reactive Flows

- Published online:

- 16 August 2019

- Print publication:

- 22 August 2019, pp 3-40

-

- Chapter

- Export citation

4 - Laminar Premixed Flames: Simulation of Combustion in the Flame Front

- from Part II - Mathematical Modeling of Selected Typical Modes of Combustion

-

- Book:

- Chemical Kinetics in Combustion and Reactive Flows

- Published online:

- 16 August 2019

- Print publication:

- 22 August 2019, pp 207-227

-

- Chapter

- Export citation

5 - Droplets and Particles: Evaporation in High-Temperature Flow and Combustion in Boundary Layers

- from Part II - Mathematical Modeling of Selected Typical Modes of Combustion

-

- Book:

- Chemical Kinetics in Combustion and Reactive Flows

- Published online:

- 16 August 2019

- Print publication:

- 22 August 2019, pp 228-261

-

- Chapter

- Export citation