Refine search

Actions for selected content:

106102 results in Materials Science

Learning from failures

-

- Journal:

- MRS Bulletin / Volume 36 / Issue 6 / June 2011

- Published online by Cambridge University Press:

- 10 June 2011, pp. 416-417

- Print publication:

- June 2011

-

- Article

-

- You have access

- HTML

- Export citation

Energy Focus: Conjugated microporous polymer networks chemically tuned for CO2 adsorption

-

- Journal:

- MRS Bulletin / Volume 36 / Issue 6 / June 2011

- Published online by Cambridge University Press:

- 10 June 2011, pp. 408-410

- Print publication:

- June 2011

-

- Article

-

- You have access

- HTML

- Export citation

Converting light to electrons in oriented nanotube arrays used in sensitized solar cells

-

- Journal:

- MRS Bulletin / Volume 36 / Issue 6 / June 2011

- Published online by Cambridge University Press:

- 10 June 2011, pp. 446-452

- Print publication:

- June 2011

-

- Article

- Export citation

Meet Our Authors

-

- Journal:

- MRS Bulletin / Volume 36 / Issue 6 / June 2011

- Published online by Cambridge University Press:

- 10 June 2011, pp. 429-432

- Print publication:

- June 2011

-

- Article

-

- You have access

- HTML

- Export citation

Quantum phase transition revealed in ultrathin films

-

- Journal:

- MRS Bulletin / Volume 36 / Issue 6 / June 2011

- Published online by Cambridge University Press:

- 10 June 2011, pp. 406-408

- Print publication:

- June 2011

-

- Article

-

- You have access

- HTML

- Export citation

Pulsed-laser hyperdoping and surface texturing for photovoltaics

-

- Journal:

- MRS Bulletin / Volume 36 / Issue 6 / June 2011

- Published online by Cambridge University Press:

- 10 June 2011, pp. 439-445

- Print publication:

- June 2011

-

- Article

- Export citation

Estroff, Liu, Nielsch, and Wada to chair 2012 MRS Spring Meeting

-

- Journal:

- MRS Bulletin / Volume 36 / Issue 6 / June 2011

- Published online by Cambridge University Press:

- 10 June 2011, p. 468

- Print publication:

- June 2011

-

- Article

-

- You have access

- HTML

- Export citation

Nuclear Safety Convention Meeting commits to learn lessons from Fukushima nuclear accident

-

- Journal:

- MRS Bulletin / Volume 36 / Issue 6 / June 2011

- Published online by Cambridge University Press:

- 10 June 2011, p. 413

- Print publication:

- June 2011

-

- Article

-

- You have access

- HTML

- Export citation

MRS volume 36 issue 6 Cover and Front matter

-

- Journal:

- MRS Bulletin / Volume 36 / Issue 6 / June 2011

- Published online by Cambridge University Press:

- 10 June 2011, pp. f1-f6

- Print publication:

- June 2011

-

- Article

-

- You have access

- Export citation

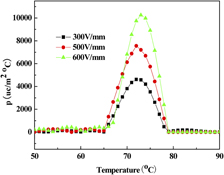

High pyroelectric properties of (Pb0.87La0.02Ba0.1)(Zr0.75Sn0.25–xTix)O3 ceramics near AFE/RFE phase boundary under DC bias field

-

- Journal:

- Journal of Materials Research / Volume 26 / Issue 11 / 14 June 2011

- Published online by Cambridge University Press:

- 31 May 2011, pp. 1441-1445

- Print publication:

- 14 June 2011

-

- Article

- Export citation

Modeling of exact viscoelastic stresses in bilayer systems due to thermal and/or lattice mismatch: Maxwell model

-

- Journal:

- Journal of Materials Research / Volume 26 / Issue 11 / 14 June 2011

- Published online by Cambridge University Press:

- 31 May 2011, pp. 1392-1398

- Print publication:

- 14 June 2011

-

- Article

- Export citation

JMR volume 26 issue 10 Cover and Back matter

-

- Journal:

- Journal of Materials Research / Volume 26 / Issue 10 / 28 May 2011

- Published online by Cambridge University Press:

- 24 May 2011, pp. b1-b5

- Print publication:

- 28 May 2011

-

- Article

-

- You have access

- Export citation

Atomistic study of the competitive relationship between edge dislocation motion and hydrogen diffusion in alpha iron

-

- Journal:

- Journal of Materials Research / Volume 26 / Issue 10 / 28 May 2011

- Published online by Cambridge University Press:

- 24 May 2011, pp. 1269-1278

- Print publication:

- 28 May 2011

-

- Article

- Export citation

JMR volume 26 issue 10 Cover and Front matter

-

- Journal:

- Journal of Materials Research / Volume 26 / Issue 10 / 28 May 2011

- Published online by Cambridge University Press:

- 24 May 2011, pp. f1-f5

- Print publication:

- 28 May 2011

-

- Article

-

- You have access

- Export citation

The energetics of La4LiAuO8

-

- Journal:

- Journal of Materials Research / Volume 26 / Issue 10 / 28 May 2011

- Published online by Cambridge University Press:

- 24 May 2011, pp. 1188-1192

- Print publication:

- 28 May 2011

-

- Article

- Export citation

Size-dependent strength in nanolaminate metallic systems

-

- Journal:

- Journal of Materials Research / Volume 26 / Issue 10 / 28 May 2011

- Published online by Cambridge University Press:

- 23 May 2011, pp. 1179-1187

- Print publication:

- 28 May 2011

-

- Article

- Export citation

Silica replication of the hierarchical structure of wood with nanometer precision

-

- Journal:

- Journal of Materials Research / Volume 26 / Issue 10 / 28 May 2011

- Published online by Cambridge University Press:

- 23 May 2011, pp. 1193-1202

- Print publication:

- 28 May 2011

-

- Article

- Export citation

A novel biomimetic material duplicating the structure and mechanics of natural nacre

-

- Journal:

- Journal of Materials Research / Volume 26 / Issue 10 / 28 May 2011

- Published online by Cambridge University Press:

- 19 May 2011, pp. 1203-1215

- Print publication:

- 28 May 2011

-

- Article

- Export citation

Thermal arrest analysis of thermoelastic martensitic transformations in shape memory alloys

-

- Journal:

- Journal of Materials Research / Volume 26 / Issue 10 / 28 May 2011

- Published online by Cambridge University Press:

- 19 May 2011, pp. 1243-1252

- Print publication:

- 28 May 2011

-

- Article

- Export citation

Measurements of residual stresses in Al film/silicon nitride substrate microcantilever beam systems

-

- Journal:

- Journal of Materials Research / Volume 26 / Issue 10 / 28 May 2011

- Published online by Cambridge University Press:

- 19 May 2011, pp. 1279-1284

- Print publication:

- 28 May 2011

-

- Article

- Export citation