Refine search

Actions for selected content:

106100 results in Materials Science

Desert visions

-

- Journal:

- MRS Bulletin / Volume 36 / Issue 9 / September 2011

- Published online by Cambridge University Press:

- 16 September 2011, pp. 683-684

- Print publication:

- September 2011

-

- Article

-

- You have access

- HTML

- Export citation

Biorenewable nanocomposites

-

- Journal:

- MRS Bulletin / Volume 36 / Issue 9 / September 2011

- Published online by Cambridge University Press:

- 16 September 2011, pp. 703-710

- Print publication:

- September 2011

-

- Article

- Export citation

MRS volume 36 issue 9 Cover and Back matter

-

- Journal:

- MRS Bulletin / Volume 36 / Issue 9 / September 2011

- Published online by Cambridge University Press:

- 16 September 2011, pp. b1-b2

- Print publication:

- September 2011

-

- Article

-

- You have access

- Export citation

Natural fibers for biocomposites

-

- Journal:

- MRS Bulletin / Volume 36 / Issue 9 / September 2011

- Published online by Cambridge University Press:

- 16 September 2011, pp. 711-715

- Print publication:

- September 2011

-

- Article

- Export citation

Two-state dynamics achieved on amorphous silicon surface

-

- Journal:

- MRS Bulletin / Volume 36 / Issue 9 / September 2011

- Published online by Cambridge University Press:

- 16 September 2011, pp. 672-673

- Print publication:

- September 2011

-

- Article

-

- You have access

- HTML

- Export citation

Nano Focus: At small scales, tug-of-war between electrons may lead to magnetism

-

- Journal:

- MRS Bulletin / Volume 36 / Issue 9 / September 2011

- Published online by Cambridge University Press:

- 16 September 2011, p. 673

- Print publication:

- September 2011

-

- Article

-

- You have access

- HTML

- Export citation

Analysis of nanoindentation of soft materials with an atomic force microscope

-

- Journal:

- Journal of Materials Research / Volume 27 / Issue 1 / 14 January 2012

- Published online by Cambridge University Press:

- 31 August 2011, pp. 229-237

- Print publication:

- 14 January 2012

-

- Article

- Export citation

Dynamic response in Fe-doped La0.65Ca0.35Mn1−xFexO3: Rare-earth manganites

-

- Journal:

- Journal of Materials Research / Volume 26 / Issue 20 / 28 October 2011

- Published online by Cambridge University Press:

- 31 August 2011, pp. 2599-2603

- Print publication:

- 28 October 2011

-

- Article

- Export citation

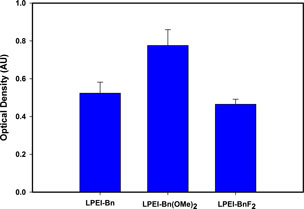

Bifunctional polyamines for the aqueous dispersion of carbon nanotubes and the formation of carbon nanotube-impregnated hydrogel composites

-

- Journal:

- MRS Communications / Volume 1 / Issue 1 / November 2011

- Published online by Cambridge University Press:

- 31 August 2011, pp. 37-40

- Print publication:

- November 2011

-

- Article

- Export citation

Experimental determination of the effective indenter shape and ε-factor for nanoindentation by continuously measuring the unloading stiffness

-

- Journal:

- Journal of Materials Research / Volume 27 / Issue 1 / 14 January 2012

- Published online by Cambridge University Press:

- 31 August 2011, pp. 214-221

- Print publication:

- 14 January 2012

-

- Article

- Export citation

The effects of low temperature and pressure on the fracture behaviors of organosilicate thin films

-

- Journal:

- Journal of Materials Research / Volume 26 / Issue 19 / 14 October 2011

- Published online by Cambridge University Press:

- 31 August 2011, pp. 2524-2532

- Print publication:

- 14 October 2011

-

- Article

- Export citation

Spatial control of the threshold voltage of low-voltage organic transistors by microcontact printing of alkyl- and fluoroalkyl-phosphonic acids

-

- Journal:

- MRS Communications / Volume 1 / Issue 1 / November 2011

- Published online by Cambridge University Press:

- 31 August 2011, pp. 33-36

- Print publication:

- November 2011

-

- Article

- Export citation

Implications of the idea of effective tip shape on nanoindentation unloading curves: AFM measurements and FE simulation

-

- Journal:

- Journal of Materials Research / Volume 27 / Issue 1 / 14 January 2012

- Published online by Cambridge University Press:

- 26 August 2011, pp. 126-131

- Print publication:

- 14 January 2012

-

- Article

- Export citation

Mechanochemical synthesis of ReB2 powder

-

- Journal:

- Journal of Materials Research / Volume 26 / Issue 21 / 14 November 2011

- Published online by Cambridge University Press:

- 26 August 2011, pp. 2772-2779

- Print publication:

- 14 November 2011

-

- Article

- Export citation

Microstructures and electrical properties of CaCu3Ti4O12 thin films on Pt/TiO2/SiO2/Si substrates by pulsed laser deposition

-

- Journal:

- Journal of Materials Research / Volume 26 / Issue 19 / 14 October 2011

- Published online by Cambridge University Press:

- 26 August 2011, pp. 2543-2551

- Print publication:

- 14 October 2011

-

- Article

- Export citation

Finite element analysis of blister formation in laser-induced forward transfer

-

- Journal:

- Journal of Materials Research / Volume 26 / Issue 18 / 28 September 2011

- Published online by Cambridge University Press:

- 26 August 2011, pp. 2438-2449

- Print publication:

- 28 September 2011

-

- Article

- Export citation

Catalytic influence of Ni-based additives on the dehydrogenation properties of ball milled MgH2

-

- Journal:

- Journal of Materials Research / Volume 26 / Issue 21 / 14 November 2011

- Published online by Cambridge University Press:

- 26 August 2011, pp. 2725-2734

- Print publication:

- 14 November 2011

-

- Article

- Export citation

Introduction

-

- Journal:

- Journal of Materials Research / Volume 26 / Issue 17 / 14 September 2011

- Published online by Cambridge University Press:

- 26 August 2011, pp. 2125-2126

- Print publication:

- 14 September 2011

-

- Article

- Export citation

Fabrication, structure, and performance of a microfabricated gallium electrical switch contact

-

- Journal:

- Journal of Materials Research / Volume 26 / Issue 18 / 28 September 2011

- Published online by Cambridge University Press:

- 26 August 2011, pp. 2428-2437

- Print publication:

- 28 September 2011

-

- Article

- Export citation

Thermally induced damages of PECVD SiNx thin films

-

- Journal:

- Journal of Materials Research / Volume 26 / Issue 19 / 14 October 2011

- Published online by Cambridge University Press:

- 25 August 2011, pp. 2552-2557

- Print publication:

- 14 October 2011

-

- Article

- Export citation