Refine search

Actions for selected content:

106102 results in Materials Science

Orientation informed nanoindentation of α-titanium: Indentation pileup in hexagonal metals deforming by prismatic slip

-

- Journal:

- Journal of Materials Research / Volume 27 / Issue 1 / 14 January 2012

- Published online by Cambridge University Press:

- 16 December 2011, pp. 356-367

- Print publication:

- 14 January 2012

-

- Article

- Export citation

Introduction

-

- Journal:

- Journal of Materials Research / Volume 27 / Issue 1 / 14 January 2012

- Published online by Cambridge University Press:

- 16 December 2011, p. 1

- Print publication:

- 14 January 2012

-

- Article

- Export citation

Nonlinear indentation of fibers

-

- Journal:

- Journal of Materials Research / Volume 27 / Issue 1 / 14 January 2012

- Published online by Cambridge University Press:

- 15 December 2011, pp. 197-213

- Print publication:

- 14 January 2012

-

- Article

- Export citation

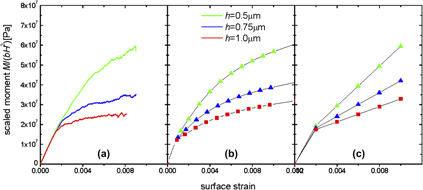

Modeling microbending of thin films through discrete dislocation dynamics, continuum dislocation theory, and gradient plasticity

-

- Journal:

- Journal of Materials Research / Volume 27 / Issue 3 / 14 February 2012

- Published online by Cambridge University Press:

- 14 December 2011, pp. 612-618

- Print publication:

- 14 February 2012

-

- Article

- Export citation

Original in situ observations of creep during indentation and recovery of the residual imprint on amorphous polymer

-

- Journal:

- Journal of Materials Research / Volume 27 / Issue 1 / 14 January 2012

- Published online by Cambridge University Press:

- 13 December 2011, pp. 12-19

- Print publication:

- 14 January 2012

-

- Article

- Export citation

Transforming large-scale industrially produced carbon nanotubes to high-performance electrode materials for lithium-ion batteries

-

- Journal:

- Journal of Materials Research / Volume 27 / Issue 2 / 28 January 2012

- Published online by Cambridge University Press:

- 13 December 2011, pp. 410-416

- Print publication:

- 28 January 2012

-

- Article

- Export citation

Electrochemical performance of TiO2/carbon nanotubes nanocomposite prepared by an in situ route for Li-ion batteries

-

- Journal:

- Journal of Materials Research / Volume 27 / Issue 2 / 28 January 2012

- Published online by Cambridge University Press:

- 13 December 2011, pp. 417-423

- Print publication:

- 28 January 2012

-

- Article

- Export citation

Dynamic tensile strength of polyurea

-

- Journal:

- Journal of Materials Research / Volume 27 / Issue 2 / 28 January 2012

- Published online by Cambridge University Press:

- 13 December 2011, pp. 494-499

- Print publication:

- 28 January 2012

-

- Article

- Export citation

Modulation of loop shift behavior by magnetic training for Co58Fe5Ni10Si11B16 amorphous ribbons

-

- Journal:

- Journal of Materials Research / Volume 27 / Issue 4 / 28 February 2012

- Published online by Cambridge University Press:

- 13 December 2011, pp. 720-724

- Print publication:

- 28 February 2012

-

- Article

- Export citation

Necessity of base fixation for helical growth of carbon nanocoils

-

- Journal:

- Journal of Materials Research / Volume 27 / Issue 2 / 28 January 2012

- Published online by Cambridge University Press:

- 12 December 2011, pp. 431-439

- Print publication:

- 28 January 2012

-

- Article

- Export citation

The long-term corrosion of mild steel in depassivated concrete: Localizing the oxygen reduction sites in corrosion products by isotopic tracer method

-

- Journal:

- Journal of Materials Research / Volume 26 / Issue 24 / 28 December 2011

- Published online by Cambridge University Press:

- 12 December 2011, pp. 3107-3115

- Print publication:

- 28 December 2011

-

- Article

- Export citation

Ultrafast self-catalytic growth of silicon carbide nanowires

-

- Journal:

- Journal of Materials Research / Volume 26 / Issue 24 / 28 December 2011

- Published online by Cambridge University Press:

- 12 December 2011, pp. 3065-3071

- Print publication:

- 28 December 2011

-

- Article

- Export citation

Electronic excitation induced controlled modifications of semiconductor-to-metal transition in epitaxial VO2 thin films

-

- Journal:

- Journal of Materials Research / Volume 26 / Issue 23 / 14 December 2011

- Published online by Cambridge University Press:

- 06 December 2011, pp. 2901-2906

- Print publication:

- 14 December 2011

-

- Article

- Export citation

JMR volume 26 issue 23 Cover and Front matter

-

- Journal:

- Journal of Materials Research / Volume 26 / Issue 23 / 14 December 2011

- Published online by Cambridge University Press:

- 06 December 2011, pp. f1-f6

- Print publication:

- 14 December 2011

-

- Article

-

- You have access

- Export citation

JMR volume 26 issue 23 Cover and Back matter

-

- Journal:

- Journal of Materials Research / Volume 26 / Issue 23 / 14 December 2011

- Published online by Cambridge University Press:

- 06 December 2011, pp. b1-b4

- Print publication:

- 14 December 2011

-

- Article

-

- You have access

- Export citation

Direct formation of nanostructured graphitic carbon from an acrylic ion-exchange resin at 600°C

-

- Journal:

- Journal of Materials Research / Volume 26 / Issue 24 / 28 December 2011

- Published online by Cambridge University Press:

- 02 December 2011, pp. 3083-3090

- Print publication:

- 28 December 2011

-

- Article

- Export citation

Shape control of highly crystallized titania nanorods based on formation mechanism

-

- Journal:

- Journal of Materials Research / Volume 27 / Issue 2 / 28 January 2012

- Published online by Cambridge University Press:

- 02 December 2011, pp. 440-447

- Print publication:

- 28 January 2012

-

- Article

- Export citation

Graphene allows ultrashort pulse generation in solid-state laser

-

- Journal:

- MRS Bulletin / Volume 36 / Issue 12 / December 2011

- Published online by Cambridge University Press:

- 14 December 2011, pp. 952-953

- Print publication:

- December 2011

-

- Article

-

- You have access

- HTML

- Export citation

Modeling evaporation, ion-beam assist, and magnetron sputtering of TiO2 thin films over realistic timescales

-

- Journal:

- Journal of Materials Research / Volume 27 / Issue 5 / 14 March 2012

- Published online by Cambridge University Press:

- 01 December 2011, pp. 799-805

- Print publication:

- 14 March 2012

-

- Article

- Export citation

John Cahn receives Kyoto Prize

-

- Journal:

- MRS Bulletin / Volume 36 / Issue 12 / December 2011

- Published online by Cambridge University Press:

- 14 December 2011, p. 954

- Print publication:

- December 2011

-

- Article

-

- You have access

- HTML

- Export citation