Refine search

Actions for selected content:

106102 results in Materials Science

Editorial

-

- Journal:

- MRS Communications / Volume 1 / Issue 1 / November 2011

- Published online by Cambridge University Press:

- 25 October 2011, pp. 1-2

- Print publication:

- November 2011

-

- Article

-

- You have access

- HTML

- Export citation

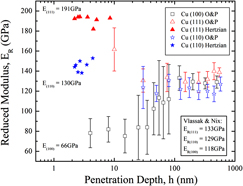

Elastic anisotropy of Cu and its impact on stress management for 3D IC: Nanoindentation and TCAD simulation study

-

- Journal:

- Journal of Materials Research / Volume 27 / Issue 1 / 14 January 2012

- Published online by Cambridge University Press:

- 21 October 2011, pp. 339-348

- Print publication:

- 14 January 2012

-

- Article

- Export citation

Quantifying plasticity-independent creep compliance and relaxation of viscoelastoplastic materials under contact loading

-

- Journal:

- Journal of Materials Research / Volume 27 / Issue 1 / 14 January 2012

- Published online by Cambridge University Press:

- 21 October 2011, pp. 302-312

- Print publication:

- 14 January 2012

-

- Article

- Export citation

Extended JKR theory on adhesive contact of a spherical tip onto a film on a substrate

-

- Journal:

- Journal of Materials Research / Volume 27 / Issue 1 / 14 January 2012

- Published online by Cambridge University Press:

- 21 October 2011, pp. 113-120

- Print publication:

- 14 January 2012

-

- Article

- Export citation

Synthesis and photoluminescence properties of perovskite KMgF3:Eu nanocubes

-

- Journal:

- Journal of Materials Research / Volume 26 / Issue 22 / 28 November 2011

- Published online by Cambridge University Press:

- 21 October 2011, pp. 2867-2870

- Print publication:

- 28 November 2011

-

- Article

- Export citation

6 - Elasticity

- from Part II - Mechanics

-

- Book:

- Mechanics of Biomaterials

- Published online:

- 05 June 2012

- Print publication:

- 20 October 2011, pp 167-207

-

- Chapter

- Export citation

3 - Ceramics

- from Part I - Materials

-

- Book:

- Mechanics of Biomaterials

- Published online:

- 05 June 2012

- Print publication:

- 20 October 2011, pp 70-91

-

- Chapter

- Export citation

Index

-

- Book:

- Mechanics of Biomaterials

- Published online:

- 05 June 2012

- Print publication:

- 20 October 2011, pp 645-681

-

- Chapter

- Export citation

16 - Soft tissue replacements

- from Part III - Case studies

-

- Book:

- Mechanics of Biomaterials

- Published online:

- 05 June 2012

- Print publication:

- 20 October 2011, pp 560-594

-

- Chapter

- Export citation

Prologue

-

- Book:

- Mechanics of Biomaterials

- Published online:

- 05 June 2012

- Print publication:

- 20 October 2011, pp xiv-xvi

-

- Chapter

- Export citation

7 - Viscoelasticity

- from Part II - Mechanics

-

-

- Book:

- Mechanics of Biomaterials

- Published online:

- 05 June 2012

- Print publication:

- 20 October 2011, pp 208-240

-

- Chapter

- Export citation

JMR volume 26 issue 20 Cover and Back matter

-

- Journal:

- Journal of Materials Research / Volume 26 / Issue 20 / 28 October 2011

- Published online by Cambridge University Press:

- 20 October 2011, pp. b1-b5

- Print publication:

- 28 October 2011

-

- Article

-

- You have access

- Export citation

Contents

-

- Book:

- Mechanics of Biomaterials

- Published online:

- 05 June 2012

- Print publication:

- 20 October 2011, pp v-x

-

- Chapter

- Export citation

11 - Friction, lubrication, and wear

- from Part II - Mechanics

-

- Book:

- Mechanics of Biomaterials

- Published online:

- 05 June 2012

- Print publication:

- 20 October 2011, pp 369-394

-

- Chapter

- Export citation

Glossary

-

- Book:

- Mechanics of Biomaterials

- Published online:

- 05 June 2012

- Print publication:

- 20 October 2011, pp 620-644

-

- Chapter

- Export citation

Frontmatter

-

- Book:

- Mechanics of Biomaterials

- Published online:

- 05 June 2012

- Print publication:

- 20 October 2011, pp i-iv

-

- Chapter

- Export citation

2 - Metals for medical implants

- from Part I - Materials

-

- Book:

- Mechanics of Biomaterials

- Published online:

- 05 June 2012

- Print publication:

- 20 October 2011, pp 26-69

-

- Chapter

- Export citation

Epilogue

-

- Book:

- Mechanics of Biomaterials

- Published online:

- 05 June 2012

- Print publication:

- 20 October 2011, pp 595-596

-

- Chapter

- Export citation

5 - Mechanical behavior of structural tissues

- from Part I - Materials

-

-

- Book:

- Mechanics of Biomaterials

- Published online:

- 05 June 2012

- Print publication:

- 20 October 2011, pp 129-164

-

- Chapter

- Export citation

Part I - Materials

-

- Book:

- Mechanics of Biomaterials

- Published online:

- 05 June 2012

- Print publication:

- 20 October 2011, pp 1-2

-

- Chapter

- Export citation

can be measured independently of any plastic deformation exhibited during loading through

can be measured independently of any plastic deformation exhibited during loading through  , where

, where