Refine search

Actions for selected content:

106102 results in Materials Science

Mark E. Davis to give Kavli lecture on fighting cancer with nanoparticles

-

- Journal:

- MRS Bulletin / Volume 36 / Issue 11 / November 2011

- Published online by Cambridge University Press:

- 18 November 2011, p. 922

- Print publication:

- November 2011

-

- Article

-

- You have access

- HTML

- Export citation

Progress and future directions for atomic layer deposition and ALD-based chemistry

-

- Journal:

- MRS Bulletin / Volume 36 / Issue 11 / November 2011

- Published online by Cambridge University Press:

- 18 November 2011, pp. 865-871

- Print publication:

- November 2011

-

- Article

-

- You have access

- HTML

- Export citation

Energy Focus: Electronic bucket brigade could boost solar-cell voltages

-

- Journal:

- MRS Bulletin / Volume 36 / Issue 11 / November 2011

- Published online by Cambridge University Press:

- 18 November 2011, pp. 837-839

- Print publication:

- November 2011

-

- Article

-

- You have access

- HTML

- Export citation

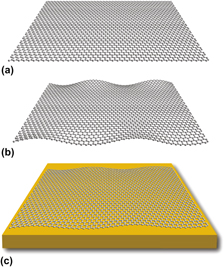

Nano Focus: Novel method developed to grow graphene on low reactivitymetals

-

- Journal:

- MRS Bulletin / Volume 36 / Issue 11 / November 2011

- Published online by Cambridge University Press:

- 18 November 2011, pp. 835-837

- Print publication:

- November 2011

-

- Article

-

- You have access

- HTML

- Export citation

Janglin Chen’s return to Taiwan brings display vision to fruition

-

- Journal:

- MRS Bulletin / Volume 36 / Issue 11 / November 2011

- Published online by Cambridge University Press:

- 18 November 2011, pp. 862-863

- Print publication:

- November 2011

-

- Article

-

- You have access

- HTML

- Export citation

Eric J. Amis to give MRS plenary address

-

- Journal:

- MRS Bulletin / Volume 36 / Issue 11 / November 2011

- Published online by Cambridge University Press:

- 18 November 2011, p. 921

- Print publication:

- November 2011

-

- Article

-

- You have access

- HTML

- Export citation

Creating the future of MRS meetings

-

- Journal:

- MRS Bulletin / Volume 36 / Issue 11 / November 2011

- Published online by Cambridge University Press:

- 18 November 2011, pp. 831-832

- Print publication:

- November 2011

-

- Article

-

- You have access

- HTML

- Export citation

MRC volume 1 issue 1 Cover and Front matter

-

- Journal:

- MRS Communications / Volume 1 / Issue 1 / November 2011

- Published online by Cambridge University Press:

- 21 November 2011, pp. f1-f4

- Print publication:

- November 2011

-

- Article

-

- You have access

- Export citation

MRS volume 36 issue 11 Cover and Front matter

-

- Journal:

- MRS Bulletin / Volume 36 / Issue 11 / November 2011

- Published online by Cambridge University Press:

- 18 November 2011, pp. f1-f8

- Print publication:

- November 2011

-

- Article

-

- You have access

- Export citation

Surface modification and fabrication of 3D nanostructures by atomic layer deposition

-

- Journal:

- MRS Bulletin / Volume 36 / Issue 11 / November 2011

- Published online by Cambridge University Press:

- 18 November 2011, pp. 887-897

- Print publication:

- November 2011

-

- Article

- Export citation

Quantum dot funnels increase solar-cell fill factor

-

- Journal:

- MRS Bulletin / Volume 36 / Issue 11 / November 2011

- Published online by Cambridge University Press:

- 18 November 2011, p. 841

- Print publication:

- November 2011

-

- Article

-

- You have access

- HTML

- Export citation

Ion motion and electrochemistry in nanostructures

-

- Journal:

- MRS Bulletin / Volume 36 / Issue 11 / November 2011

- Published online by Cambridge University Press:

- 18 November 2011, pp. 914-920

- Print publication:

- November 2011

-

- Article

- Export citation

CAREER CENTRAL

-

- Journal:

- MRS Bulletin / Volume 36 / Issue 11 / November 2011

- Published online by Cambridge University Press:

- 18 November 2011, pp. 935-942

- Print publication:

- November 2011

-

- Article

-

- You have access

- Export citation

2nd European Energy Conference to be held in April 2012: www.energy-conference.eu

-

- Journal:

- MRS Bulletin / Volume 36 / Issue 11 / November 2011

- Published online by Cambridge University Press:

- 18 November 2011, p. 934

- Print publication:

- November 2011

-

- Article

-

- You have access

- HTML

- Export citation

MRS collaborates with E-MRS on energy symposia within the 2011 E-MRS Spring Meeting/IUMRS-ICAM Meeting: www.emrs-strasbourg.com

-

- Journal:

- MRS Bulletin / Volume 36 / Issue 11 / November 2011

- Published online by Cambridge University Press:

- 18 November 2011, pp. 930-932

- Print publication:

- November 2011

-

- Article

-

- You have access

- HTML

- Export citation

GaN changes the game in power conversion

-

- Journal:

- MRS Bulletin / Volume 36 / Issue 11 / November 2011

- Published online by Cambridge University Press:

- 18 November 2011, pp. 853-854

- Print publication:

- November 2011

-

- Article

-

- You have access

- HTML

- Export citation

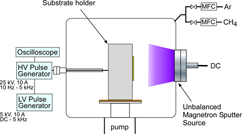

Properties of hydrogenated DLC films as prepared by a combined method of plasma source ion implantation and unbalanced magnetron sputtering

-

- Journal:

- Journal of Materials Research / Volume 27 / Issue 5 / 14 March 2012

- Published online by Cambridge University Press:

- 31 October 2011, pp. 845-849

- Print publication:

- 14 March 2012

-

- Article

- Export citation

Size effects in indentation of hydrated biological tissues

-

- Journal:

- Journal of Materials Research / Volume 27 / Issue 1 / 14 January 2012

- Published online by Cambridge University Press:

- 26 October 2011, pp. 245-255

- Print publication:

- 14 January 2012

-

- Article

- Export citation

Engineering materials properties in codimension > 0

-

- Journal:

- Journal of Materials Research / Volume 27 / Issue 3 / 14 February 2012

- Published online by Cambridge University Press:

- 26 October 2011, pp. 619-626

- Print publication:

- 14 February 2012

-

- Article

- Export citation

Effective Poisson’s ratio from combined normal and lateral contacts of single crystals

-

- Journal:

- Journal of Materials Research / Volume 27 / Issue 1 / 14 January 2012

- Published online by Cambridge University Press:

- 26 October 2011, pp. 182-191

- Print publication:

- 14 January 2012

-

- Article

- Export citation